Highlights:

- Terminated Stockpile oxide columns in 90-day cycle indicates

90% recoveries after 60 days, pending final residue analysis

- Preliminary results from Parks/Salyer enriched columns after

160 days demonstrate recoveries of approximately 80%

- Current metallurgical programs will feed into both the pending

PFS (1Q24), and FS (2H24)

- Hydrodynamic testing supports multi-lift leach pads

- Post-refurbishment, TruStone Facility now hosts a sample prep

lab, 12 metallurgical columns and a core storage facility

Arizona Sonoran Copper Company Inc. (TSX:ASCU |

OTCQX:ASCUF) (“ASCU” or the “Company”) an emerging US-based

copper developer and near-term producer, provides an update on

metallurgy and improvements to the TruStone Facility (“TruStone”).

ASCU continues to improve metallurgical recoveries through ongoing

Pre-Feasibility (“PFS”) and Feasibility Study (“FS”)-level columns

located onsite and in TruStone. The 90-day Stockpile oxide cycle is

now complete with 90% recoveries of each column’s head grade.

Preliminary results from the Parks/Salyer enriched columns after

160 days are tracking to approximately 80% recovery. Samples for

each of the TruStone columns were sent to HydroGeoSense Inc.

(“HGS”) and Skyline Lab for sequential copper and total copper

analysis. The metallurgical programs are overseen by Dan Johnson,

ASCU Projects Director and QP’d by Samuel Engineering.

Dan Johnson, ASCU Projects Director commented, “The

completed Stockpile oxides recoveries and highly encouraging

preliminary Park/Salyer enriched recoveries continue to build on

and improve our metallurgical understanding of the Cactus and

Parks/Salyer deposits. With the Stockpile oxides performing at ~90%

recoveries and Parks/Salyer enriched at ~80%, we see an improvement

over the PEA programs after only 60 and 160 days, respectively, in

comparison to the Cactus deposit. We note the metallurgy from the

two deposits respond quite similarly to the raffinate which should

support future economies of scale while conducting mine sequencing

and planning for the PFS.”

TruStone Building Improvements:

Refurbishment of the TruStone Facility (see IMAGE 1) is

near completion. TruStone, a former factory located between the

Parks/Salyer and Cactus deposits and accessed by the paved access

road will also serve as an auxiliary building to support the future

Solvent Extraction/Electrowinning (“SX/EW”) plant, as outlined in

the PEA. It now accommodates 12, 20 ft (6 m) columns for PFS and

FS-level metallurgical programs with the potential to install an

additional three columns and for conversion to 30 ft (9 m) columns,

as required (IMAGE 2), an onsite full-scale sample

preparation lab with five crusher stations (IMAGE 3) and

also serves as a main core storage facility (IMAGE 4).

The electrical upgrades are nearly complete, and connection is

expected in May, post-Arizona Public Service inspection. Outside,

the surrounding areas have been cleared, doors have been repaired

or replaced and all openings in the building exterior have been

repaired. Inside, new and used core shelving units have been

assembled and core boxes are being relocated and stacked in the

west side of TruStone.

Metallurgy and Hydrodynamic Testing Program – Oxide,

Enriched, Stockpile Material

Samples from Cactus, Parks/Salyer and the Stockpile were prepped

and composited for both the Prefeasibility and Feasibility Study

metallurgical testwork program within TruStone. Samples for each of

the TruStone columns were sent to HydroGeoSense Inc. (“HGS”) and

Skyline Lab for sequential copper and total copper analysis. TABLE

1 below illustrates results from initial head grade assaying from

recently loaded columns. Results from Skyline Lab are still

pending.

PARKS/SALYER – ENRICHED (SECONDARY SULPHIDE) COLUMNS

Three 6-inch (15 cm) enriched columns loaded with crushed minus

1-inch (25 mm) p80 non-agglomerated multiple copper grade material

from Parks/Salyer enriched material, with preliminary recoveries

tracking to approximately 80% after 160 days. Particle size

distribution analysis showed favorable results with a low fines

content. These columns continue to be ran with 4 g/L raffinate feed

solution at 3 to 4 L/hm2, with no forced aeration into the 20 ft (6

m), 6-inch (15 cm) column. Solution temperatures have been

continuously monitored and range between 15°C to 20°C. Columns have

been equipped with evaporation reduction measures. Preliminary

results are shown in FIGURE 1.

Material was gathered from Park/Salyer core holes SE-16, SE-17

and SE-18 and subsequently separated into three different grades

(low, medium, and high). Mineralogical and bacteria samples were

collected and have been submitted to qualified laboratories for

analysis. Initially, low net sulphuric acid (“H2SO4”) consumption

is experienced and within a few weeks, the columns begin generating

H2SO4. The generation of H2SO4 in the enriched materials benefits

future project sequencing.

STOCKPILE – OXIDE COLUMNS

Three multiple calcium content materials were crushed to minus

3-inch (7.6 cm) and cured with 2.2 lbs-g/ton acid and subsequently

loaded into 8-inch (20 cm) 20 ft (6m) columns. An application rate

of 6 L/hm2 of 6 g/L acid was applied to each column. After only 60

days, results indicated average preliminary calculated recoveries

of approximately 90% and average gross H2SO4 consumption of 22

lb/t.

An initial concentration of 6 g/L of acidified raffinate was

applied at start up and then adjusted down to 4 g/L after 30 days

to the three above columns. These columns continue to be ran with 4

g/L raffinate feed solution at 6L/day. Solution temperatures have

been continuously monitored and range typically from 15°C to 20°C.

Solution samples are being collected initially on a daily and now

weekly basis for analyses. Results are shown in FIGURE

2.

Copper recoveries were derived from laboratory head grades from

the entire length core material selected for each column. Composite

head grade pulps were sent to Skyline Lab and HGS for analysis. All

three columns were terminated in mid-March, due to depleted copper

concentrations. Final metallurgical performance estimates will

require analysis of the column residues to confirm the head grade

based recovery estimates.

Hydrodynamic Testing

ASCU retained HydroGeoSense, Inc. (HGS) to conduct a preliminary

hydrodynamic characterization of samples from their Cactus and

Parks/Salyer deposits to determine the feasibility of a multi-lift

heap operation. The results of this study illustrate a competent

multi-lift operation with sufficient percolation capacity from the

Cactus and Park/Salyer deposits when crushed to a top size of minus

1.25-inch (30 mm).

Specifically, the porosity graphs as a function of heap height

(profile) presented in FIGURE 3 indicate that the Cactus and

Parks/Salyer material samples, prepared to an intermediate level of

agglomeration (L2), would maintain a total porosity larger than 30%

(horizontal red line) for heap heights larger than 184 ft (56 m)

(seven, 26 ft (8 m) lifts). Additionally, the percolation capacity

(saturated hydraulic conductivity) of these samples illustrated in

FIGURE 4 is more than adequate to support irrigation rates

of 6 L/h/m2 (horizontal red line) or larger for heap heights taller

than 210 ft (64 m).

Ongoing Column Leach Testing

In addition to the three ongoing Parks/Salyer columns, nine new

PFS and FS columns have been prepared in 6-inch (15 cm) columns

with material from both the Cactus (enriched and oxide) and

Parks/Salyer (enriched) deposits. The particle size distribution

and head sample assays (TABLE 1 below) have been completed

for two oxide and seven different secondary mixed rock-type sulfide

(enriched) copper grade materials. Based on the particle size

distribution analyses, materials have been crushed at minus 1 inch

(25 mm) (3 columns) or minus 1.25 inch (30 mm) (4 columns), p80

size for the column testing.

Table 1 – New PFS/FS Column Head Assay

Results (HGS)

Sequential Copper Assays

Total Copper

Assay #

Sample Description

AS

Cu %

CNS

Cu %

Residue

Cu %

Calculated CuT

Head CuT

7378

Column 5 Head Composite (Oxide/Enriched

Blend)

0.32

0.21

0.02

0.56

0.53

7379

Column 6 Granite Head Composite

(Oxide)

1.68

0.04

0.03

1.75

1.82

7380

Column 6 Monzonite Head Composite

(Oxide)

1.05

0.25

0.01

1.32

1.31

7549

Column 7 Granite Head Composite

(Enriched)

0.13

1.22

0.01

1.36

1.31

7549D

Column 7 Granite Head Composite

(Duplicate)

0.13

1.16

0.01

1.31

1.26

7381

Column 8 & 9 Monzonite Head Composite

(Enriched)

0.15

0.24

0.08

0.46

0.48

7550

Column 9 Granite Head Composite

(Enriched)

0.12

0.75

0.01

0.88

0.88

7547

Column 10 Granite Head Composite

(Enriched)

0.23

2.13

0.02

2.38

2.40

7548

Column 10 Monzonite Head Composite

(Enriched)

0.22

0.64

0.02

0.88

0.83

7373

Park Salyer Low Grade Head Composite

(Enriched)

0.10

0.57

0.01

0.68

0.67

7374

Park Salyer Mod Grade Head Composite

(Enriched)

0.14

1.61

0.01

1.76

1.71

7551

Park Salyer High Grade Head Composite

(Enriched)

0.16

2.41

0.01

2.58

2.52

The 4-30 mm columns have been agglomerated with either 5 or 7.5

g/L of sulfuric acid. Low-pressure (near ambient) aeration systems

have been installed to optimize bacteria growth during the leaching

period. Additionally, the columns continue to be equipped with

measures to minimize potential losses from evaporation and control

solution temperatures. ASCU ran particle size distribution and

sequential assays on the remaining specified collected materials

and continues to review and select materials from both Cactus and

Parks/Salyer metallurgical core holes. The selected materials

loaded in the initial Parks/Salyer materials were crushed to the

initial minus 1.25-inch (30 mm) p80 based on low, moderate and

high-grade ranges. The higher grades include a moderate to high

presence of chalcocite, covellite, chalcopyrite and other less

abundant copper bearing mineralogical species. Mature solutions

from the previous PFS columns that have been or are nearly

completed were obtained to begin the leaching process (presence

residual acid and bacteria), which shall accelerate the dissolution

of copper. The current raffinate application rates are slightly

below 3L/day of 6 g/L mature raffinate for these smaller 6-inch (15

cm) columns and 6L/day of 6 g/L mature raffinate for the 8-inch (20

cm) columns.

Ongoing testing to optimize the crushing size is expected to

improve the samples' mechanical and hydrodynamic performance and

enhance the metallurgical performance of the leaching process.

Overall, ASCU and HGS are pleased with these findings of this

preliminary study and continue to work in the development of an

even more efficient and effective leaching process.

Initial 2022 metallurgical studies involving the Stockpile and

Cactus deposit materials were completed at McClelland Laboratories

within the last few months and final reports are being prepared.

Final reports for the columns at TruStone will be prepared by

Samuel Engineering, who will also draft final reports for the

recent terminated stockpile oxide and the initial Parks/Salyer

enriched columns when completed at the end of June.

Links from the Press Release:

Figures and Images:

https://arizonasonoran.com/projects/cactus-mine-project/press-release-images

Qualified Persons Statement

Technical aspects related to the metallurgical program of this

news release have been reviewed and verified by James L. Sorensen –

FAusIMM Reg. No. 221286 with Samuel Engineering, who is a qualified

person as defined by National Instrument 43-101– Standards of

Disclosure for Mineral Projects. The indicative metallurgical

information presented describes preliminary results from testing

that is currently in progress and subject to confirmation.

Final metallurgical performance estimates will require

decommissioning of the columns and analysis of the column

residues.

Neither the Toronto Stock Exchange nor the regulating authority

has approved or disproved the information contained in this press

release.

About Arizona Sonoran Copper Company (www.arizonasonoran.com |

www.cactusmine.com)

ASCU’s objective is to become a mid-tier copper producer with

low operating costs and to develop the Cactus and Parks/Salyer

Projects that could generate robust returns for investors and

provide a long term sustainable and responsible operation for the

community and all stakeholders. The Company’s principal asset is a

100% interest in the Cactus Project (former ASARCO, Sacaton mine)

which is situated on private land in an infrastructure-rich area of

Arizona. Contiguous to the Cactus Project is the Company’s

100%-owned Parks/Salyer deposit that could allow for a phased

expansion of the Cactus Mine once it becomes a producing asset. The

Company is led by an executive management team and Board which have

a long-standing track record of successful project delivery in

North America complemented by global capital markets expertise.

Forward-Looking Statements

Forward-looking statements involve known and unknown risks,

uncertainties and other factors which may cause the actual results,

performance or achievements of ASCU to be materially different from

any future results, performance or achievements expressed or

implied by the forward-looking statements. Factors that could

affect the outcome include, among others: future prices and the

supply of metals; the results of drilling; inability to raise the

money necessary to incur the expenditures required to retain and

advance the properties; environmental liabilities (known and

unknown); general business, economic, competitive, political and

social uncertainties; results of exploration programs; accidents,

labour disputes and other risks of the mining industry; political

instability, terrorism, insurrection or war; or delays in obtaining

governmental approvals, projected cash operating costs, failure to

obtain regulatory or shareholder approvals.

Although ASCU has attempted to identify important factors that

could cause actual actions, events or results to differ materially

from those described in forward-looking statements, there may be

other factors that cause actions, events or results to differ from

those anticipated, estimated or intended. Forward-looking

statements contained herein are made as of the date of this news

release and ASCU disclaims any obligation to update any

forward-looking statements, whether as a result of new information,

future events or results or otherwise, except as required by

applicable securities laws.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20230502005450/en/

For more information Alison Dwoskin, Director, Investor

Relations 647-233-4348 adwoskin@arizonasonoran.com

George Ogilvie, President, CEO and Director 416-723-0458

gogilvie@arizonasonoran.com

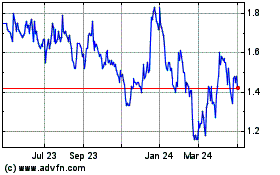

Arizona Sonoran Copper (TSX:ASCU)

Historical Stock Chart

From Dec 2024 to Jan 2025

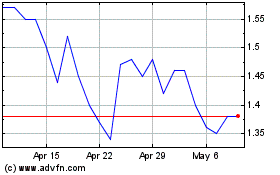

Arizona Sonoran Copper (TSX:ASCU)

Historical Stock Chart

From Jan 2024 to Jan 2025