TIDMCTL

RNS Number : 0712O

CleanTech Lithium PLC

29 September 2023

29 September 2023

CleanTech Lithium PLC ("CleanTech Lithium", "CTL" or the

"Company")

Update on Exploration Stage Projects

CleanTech Lithium PLC (AIM:CTL, Frankfurt:T2N, OTCQX:CTLHF), an

exploration and development company, advancing sustainable lithium

projects in Chile for the clean energy transition, announces an

update on activities at two exploration stage projects - sampling

results from the Llamara Project and commencement of initial

geophysics at a new exploration project in the Salar de Atacama

basin.

Llamara Highlights:

-- Llamara is a greenfield exploration project with a licence

area of 605km(2) located within a large basin in Northern Chile

-- The maiden drill programme aimed to test the lithium

prospectivity of two targets, firstly a subsurface brine aquifer

and secondly a surface evaporite mineral

-- Brine samples collected from the first well were depleted in

lithium while the first batch of surface samples recorded minor

lithium enrichment along with high grades of boron

-- A second batch of surface sample results are pending, and the

Company will then consider the next stage of exploration at the

project

Salar de Atacama Highlights:

-- Applications lodged and now registered for new licences

covering a total area of 377 km(2) in the Salar de Atacama basin,

the leading lithium production base in the world

-- A geophysics programme has commenced with the first completed

section identifying a subsurface brine aquifer target

-- Salar de Atacama is designated as a strategic salar by the

Chilean government - any commercial development will require a

joint venture with a state entity holding a majority (51%) stake,

which the Company views as suitable for such a strategically

important basin

-- Community engagement will also be crucial. CTL's focus on

Direct Lithium Extraction (DLE), which removes the need for

evaporation ponds, provides a compelling case for a new low impact

approach to lithium production in the Salar de Atacama basin

-- Whilst CTL's exploration stage projects provide upside, the

Company remains fully focused on the advanced Laguna Verde (PFS

underway) and Francisco Basin (Scoping Study completed)

projects

Commenting, Aldo Boitano, Chief Executive Officer, of CleanTech

Lithium PLC, said:

"While we continue to progress our key projects Laguna Verde and

Francisco Basin, exploration at additional prospects in Chile is

also advancing. At our Llamara project we are in the process of

receiving and evaluating the results, while initial geophysics

results from new licences applied for recently at the Salar de

Atacama basin are very positive. We will continue to update the

market on how we move forward with these projects ."

Further Information

Llamara Project Exploration Update

The Llamara Project is a greenfield exploration project where a

geophysics programme identified an interpreted subsurface brine

aquifer that has not previously been drilled for lithium. A

secondary target is a surface evaporite mineral that has been

mapped in the licence area and has been sampled in other areas of

the large Llamara basin and where sampling results indicated

lithium enrichment of interest. As a result, the Company undertook

an exploration programme at the project in recent months with two

objectives:

(i) Complete an exploration drill hole to intersect and sample

the interpreted brine aquifer

(ii) Complete a sediment sampling programme on the surface evaporite mineral

An initial exploration drill hole (LL01) intersected a gas

bearing interval requiring the hole to be shut-in, as reported to

the market on June 6, 2023. A second drill hole (LL02) was

completed to a depth of 550m. Brine was intersected at 395m and a

total of eight brine samples were collected from the start of the

aquifer to the bottom of the well. The samples were submitted for

analysis to ALS Chile with results showing low grades of

lithium.

Sediment samples collected from the LL02 drill core were also

analysed for lithium and showed a rising trend with depth, with the

final sample taken at approximately 545m depth recording the

highest value of 120ppm Lithium, indicating that there is an

increasing trend of lithium with depth and that the brine aquifer

below the 550m end of hole may have higher prospectivity.

Figure 1: Lithium Grade of Sediments Collected from LL02 Core

Samples

The sampling programme on the surface evaporite deposit was

completed with a total of 23 samples collected. There were two

geologically distinct types of samples collected, the first

characterised as loose sediment samples and the second being the

hard evaporite mineral. Laboratory analysis has been completed on

the loose sediment samples which showed minor lithium enrichment of

up to 106ppm Lithium, while high boron grades were notable with

three of the samples exceeding 20,000ppm Boron. Laboratory results

are pending for the hard evaporite mineral samples which in the

view of the Company's geology team, will be more prospective for

lithium. On receiving the final evaporite mineral sample results,

the Company will evaluate and consider the next steps.

Salar de Atacama Project - New Licence Applications and

Geophysics Update

From June to August 2023 the Company submitted applications over

areas in the Salar de Atacama basin as shown in Figure 2. The

applications, covering a total area of 377 km(2) , have now been

registered on the Chilean Mining Register and it is expected these

licences will be granted in the next few months. Salar de Atacama

is the largest lithium production base in the world where the two

leading producers of battery grade lithium, SQM and Albemarle, have

extensive licence positions. Several of CTL's application blocks

are adjacent to SQM's licences. Information derived from publicly

available Environmental Studies, conducted by SQM and other

organizations suggests that the lithium-rich brine deposits extend

beyond the core salar region inside the basin. This underscores the

promising potential for CTL's applications in these areas of

significant prospective lithium reserves. A geophysics programme

comprising both Transient Electro Magnetic (TEM) and

Magnetotellurics (MT) lines has commenced with the planned lines

shown in Figure 3. MT allows for the depth profile to extend to

1000m.

Figure 2: CTL Licence Applications Figure 3: Planned Geophysics

Lines

The geophysics contractor recently completed a section of seven

stations spaced 200m apart on the first west-east transect located

on the southern licence block. The resistivity profile based on the

completed section extends to 1,200m in depth, as shown in Figure 4.

The profile shows a low resistivity anomaly starting from a depth

of 400m with an approximate thickness of 200m which deepens to the

south-east. This is interpreted to be a sub-surface hypersaline

aquifer which provides a target for further exploration

evaluation.

Figure 4: MT-TEM Resistivity Profile Salar de Atacama South

Block

The Salar de Atacama is by far the largest lithium production

base in the world producing approximately 25% of the world's

battery grade lithium. Unlike CleanTech Lithium's Laguna Verde and

Francisco Basin projects, under Chile's National Lithium strategy,

Salar de Atacama has been designated a strategic asset which means

any commercial development will require a joint venture with a

state entity holding a majority (51%) stake. The Company welcomes

this framework for any potential development in such a

strategically important site.

In addition, indigenous and local communities live within the

Salar de Atacama basin and have a strong voice on lithium

developments. The Company will follow its established policy of

early community engagement before undertaking any ground

disturbance exploration activities. Furthermore, CTL's focus on

Direct Lithium Extraction (DLE) provides a compelling case for a

new low impact approach to lithium production in the Salar de

Atacama basin.

Existing producers pump brine from the upper 50m of the salar

sub-surface and use evaporation ponds to concentrate the brine,

resulting in a large volume of water being lost to the atmosphere

which depletes the shallow aquifers that are also used by local

communities. Exploration and any potential development activities

by CleanTech Lithium will focus on the deeper aquifer outside the

salar margin and on introducing a new model for sustainable lithium

extraction in the basin, utilising DLE technology where the spent

brine is reinjected into the basin aquifers minimising aquifer

depletion.

Competent Person

The information in this release relates to drilling results,

geology, brine assays reports and sediment sampling are based on

information compiled by Christian Gert Feddersen Welkner, who is an

independent Qualified Person to the Company and is a Member of

Comision Calificadora de Competencias en Recursos y Reservas

Mineras Chile that is a 'Recognised Professional Organisation'

(RPO). Mr Feddersen has sufficient experience that is relevant to

the style of mineralization and type of deposit under consideration

and to the activity being undertaken to qualify as a Competent

Person as defined in the 2012 Edition of the 'Australasian Code for

Reporting of Exploration Results, Mineral Resources and Ore

Reserves'. Mr Feddersen consents to the inclusion in the press

release of the matters based on his information in the form and

context in which it appears.

Llamara - JORC Code, 2012 Edition - Table 1 report template

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

Criteria JORC Code explanation Commentary

Sampling

techniques * Nature and quality of sampling (eg cut channels, * Subsurface brine samples were collected using a

random chips, or specific specialised industry specialized packer sampling technique. A packer bit

standard measurement tools appropriate to the tool supplied by the drilling company Big Bear was

minerals under investigation, such as down hole gamma utilized. Following the sealing of the sampling

sondes, or handheld XRF instruments, etc). These support, a thorough purging procedure was executed

examples should not be taken as limiting the broad until no traces of drilling mud were discernible.

meaning of sampling. Subsequently, a thirty-minute waiting period was

observed to facilitate the ingress of brine into the

drilling rods through the slots in the packer tool,

* Include reference to measures taken to ensure sample enabling to proceed with the sampling process using a

representivity and the appropriate calibration of any double valve bailer.

measurement tools or systems used.

* Aspects of the determination of mineralisation that * Successive one-liter samples were collected, with a

are Material to the Public Report. half-hour interval between each, using a double valve

bailer made of steel. For each sample, Total

Dissolved Solids (TDS) using a Hanna Multiparameter

* In cases where 'industry standard' work has been done model HI98192 based on conductivity were measured.

this would be relatively simple (eg 'reverse The final two samples that exhibited consistent and

circulation drilling was used to obtain 1 m samples stable TDS values were designated as the Original and

from which 3 kg was pulverised to produce a 30 g Reject samples, signifying their non-contaminated

charge for fire assay'). In other cases more status.

explanation may be required, such as where there is

coarse gold that has inherent sampling problems.

Unusual commodities or mineralisation types (eg * Packer samples were obtained every 27 m support in

submarine nodules) may warrant disclosure of detailed general due the tools movement involved to take every

information. sample.

* For all samples, the materials and sampling bottles

were first flushed with 100 cc of brine water before

receiving the final sample

* Two Packer samples were obtained in well LL01 and

eight, in well LL02.

* Ten selected 500 grams entire core pieces were

selected from LL02 drillhole for laboratory analysis.

* 1 km X 1 km surface soil samples between 2 to 3

kilograms were obtained from Llamara south tenements

for analysis

Drilling

techniques * Drill type (eg core, reverse circulation, open-hole * On both wells LL01 and LL02, diamond drilling with

hammer, rotary air blast, auger, Bangka, sonic, etc) PQ3 diameter down to 197.7 m and 149 m respectively.

and details (eg core diameter, triple or standard Below that depth the drilling diameter was reduced to

tube, depth of diamond tails, face-sampling bit or HQ3 to the end of hole.

other type, whether core is oriented and if so, by

what method, etc).

* In both diameters, a triple tube was used for the

core recovery.

* Packer bit provided by Big Bear was used to obtain

brine samples.

Drill sample

recovery * Method of recording and assessing core and chip * Diamond Core recovery were assured by direct

sample recoveries and results assessed. supervision and continuous geotechnical logging done

by ROKO geological consultants

* Measures taken to maximise sample recovery and ensure

representative nature of the samples.

* Whether a relationship exists between sample recovery

and grade and whether sample bias may have occurred

due to preferential loss/gain of fine/coarse

material.

Logging

* Whether core and chip samples have been geologically * Continue geological and geotechnical logging took

and geotechnically logged to a level of detail to place during drilling done by ROKO geological

support appropriate Mineral Resource estimation, consultants

mining studies and metallurgical studies.

* For the sub surface brine packer samples

* Whether logging is qualitative or quantitative in conductivity-based TDS, Temperature degC and pH

nature. Core (or costean, channel, etc) photography. parameters were measured during the sampling

* The total length and percentage of the relevant

intersections logged.

Sub-sampling

techniques * If core, whether cut or sawn and whether quarter, * During LL02 brine samples batch preparation process,

and sample half or all core taken. the samples were transferred to new sampling bottles.

preparation Standard (internal standard composed by known stable

brine), Duplicates and Blank samples (distilled

* If non-core, whether riffled, tube sampled, rotary water) were randomly included in the batch in the

split, etc and whether sampled wet or dry. rate of one every ten original samples. After check

samples insertion, all samples were re-numbered

before submitted to laboratory. Before transferring

* For all sample types, the nature, quality and each sample, the materials used for the transfer were

appropriateness of the sample preparation technique. flushed with distilled water and then shacked to

remove water excess avoiding contamination.

* Quality control procedures adopted for all

sub-sampling stages to maximise representivity of

samples.

* Measures taken to ensure that the sampling is

representative of the in situ material collected,

including for instance results for field

duplicate/second-half sampling.

* Whether sample sizes are appropriate to the grain

size of the material being sampled.

Quality

of assay * The nature, quality and appropriateness of the * Brine samples were assayed on ALS Life Science Chile

data and assaying and laboratory procedures used and whether laboratory by the following analysis:

laboratory the technique is considered partial or total.

tests

* Total Metals Full Elemental Swift analysis method

* For geophysical tools, spectrometers, handheld XRF using ICP-OES, described on QWI-IO-ICP-OES- 01

instruments, etc, the parameters used in determining Edisión A, Modification 0 EPA 3005A; EPA 200.2

the analysis including instrument make and model,

reading times, calibrations factors applied and their

derivation, etc. * Alkalinity by method described in QWI-IO-ALC-01

Emisión B mod. 4

* Nature of quality control procedures adopted (eg

standards, blanks, duplicates, external laboratory * Anions by crotomography by method described in

checks) and whether acceptable levels of accuracy (ie QWI-IO-ANA-01 Emisión B, mod. 7 QWI-IO-EXT-01

lack of bias) and precision have been established. Emisión B, mod. 3 Density by method described on

QWI-IO-Density-02 (Issue A Modification 1).

* Total Dissolved Solids (TDS) with method described in

QWI-IO-SDT-01 Emisión B mod. 5

* Sulfate according method described on 4500-SO42-.

* Duplicates were obtained randomly during the brine

sampling. Also, Blanks (distilled water) and

Standards were randomly inserted during the

laboratory batch preparation on LL02 well samples.

* Standards were internally prepared on the

Copiapó warehouse installations, using 200

liters of brine obtained from well LV02 during the

development process. Standard nominal Lithium grade

was calculated in a round robin process that include

04 laboratories (Ch. Feddersen Standards preparation,

statistical analysis, nominal valuation &

laboratories analysis, February 2023)

* Core samples were assayed on AGS laboratory in

Coquimbo by Fusion ICP-OES method

* Soil samples were assayed on ALS laboratory by Soil

ICP-MS method

Verification

of sampling * The verification of significant intersections by * Brine, core and soil samples batches were prepared by

and assaying either independent or alternative company personnel. ROKO consultant personnel according the Competent

Person instructions.

* The use of twinned holes.

* Documentation of primary data, data entry procedures,

data verification, data storage (physical and

electronic) protocols.

* Discuss any adjustment to assay data.

Location

of data * Accuracy and quality of surveys used to locate drill * Surface samples coordinates were captured with

points holes (collar and down-hole surveys), trenches, mine non-differential hand held GPS

workings and other locations used in Mineral Resource

estimation.

* Drillhole collars were captured with non-differential

hand held GPS. Position was verified by the mining

* Specification of the grid system used. concessions field markings. Total station topographic

capture of the drillhole collars is pending

* Quality and adequacy of topographic control.

* The coordinate system is UTM, Datum WGS84 Zone 19K

Data spacing

and * Data spacing for reporting of Exploration Results. * Packer brine samples were taken in general every 27 m

distribution

* Whether the data spacing and distribution is * Surface soil samples were obtained in a 1 km X 1 km

sufficient to establish the degree of geological and grid

grade continuity appropriate for the Mineral Resource

and Ore Reserve estimation procedure(s) and

classifications applied. * The author believes that the data spacing and

distribution is sufficient to establish the degree of

geological and grade continuity appropriate to report

* Whether sample compositing has been applied. Exploration Results

Orientation

of data * Whether the orientation of sampling achieves unbiased * The drilling orientation and surface sampling is

in relation sampling of possible structures and the extent to direct

to which this is known, considering the deposit type.

geological

structure

* If the relationship between the drilling orientation

and the orientation of key mineralised structures is

considered to have introduced a sampling bias, this

should be assessed and reported if material.

Sample

security * The measures taken to ensure sample security. * All brine samples were marked and keep on site before

transporting them to Copiapó city warehouse

* The brine water samples were transported without any

perturbation directly to a warehouse in Copiapó

city, were laboratory samples batch was prepared and

stored in sealed plastic boxes, then sent via currier

to ALS laboratory in Santiago. All the process was

made under the Competent Person instructions.

* ALS personnel report that the samples were received

without any problem or disturbance

Audits

or reviews * The results of any audits or reviews of sampling * The assay data was verified by the Competent Person

techniques and data. against the assay certificate.

* No audits has been done in Llamara

============= ============================================================ ================================================================

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this

section.)

Criteria JORC Code explanation Commentary

Mineral

tenement * Type, reference name/number, location and ownership * CleanTech Lithium holds in Llamara 60,500 hectares of

and land including agreements or material issues with third Exploration Mining Concessions were the company have

tenure status parties such as joint ventures, partnerships, preferential rights over 58,335 hectares.

overriding royalties, native title interests,

historical sites, wilderness or national park and

environmental settings. * All prohibition certificates in favour of CLS Chile

SpA The Competent Person relies in the Mining Expert

Surveyor Mr, Juan Bedmar.

* The security of the tenure held at the time of

reporting along with any known impediments to

obtaining a licence to operate in the area. * All concession acquisition costs and taxes have been

fully paid and that there are no claims or liens

against them

* There are no known impediments to obtain the licence

to operate in the area

Exploration

done by * Acknowledgment and appraisal of exploration by other * Exploration works has been done by several parties on

other parties parties. clay lithium potential.

Geology

* Deposit type, geological setting and style of * Llamara corresponds a salar and paleo salar with

mineralisation. Lithium in brine potential and Lithium potential in

clay beds and surface saline deposits

Drill hole

Information * A summary of all information material to the * The following drillhole coordinates are in WGS84 zone

understanding of the exploration results including a 19 K Datum

tabulation of the following information for all

Material drill holes:

* LL01 E467,000 N7,617,000 ELEV 1,134 m a.s.l. Azimuth

0deg, dip -90deg, Length 293 m

o easting and northing

of the drill hole collar

o elevation or RL (Reduced * LL02 E461,000 N7,617,000 ELEV 1,065 m a.s.l. Azimuth

Level - elevation above 0deg, dip -90deg, Length 550 m

sea level in metres)

of the drill hole collar

o dip and azimuth of

the hole

o down hole length and

interception depth

o hole length.

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

Data

aggregation * In reporting Exploration Results, weighting averaging * Not applied at this exploration level

methods techniques, maximum and/or minimum grade truncations

(eg cutting of high grades) and cut-off grades are

usually Material and should be stated.

* Where aggregate intercepts incorporate short lengths

of high grade results and longer lengths of low grade

results, the procedure used for such aggregation

should be stated and some typical examples of such

aggregations should be shown in detail.

* The assumptions used for any reporting of metal

equivalent values should be clearly stated.

Relationship

between * These relationships are particularly important in the * The relationship between aquifer widths and intercept

mineralisation reporting of Exploration Results. lengths are direct

widths and

intercept

lengths * If the geometry of the mineralisation with respect to

the drill hole angle is known, its nature should be

reported.

* If it is not known and only the down hole lengths are

reported, there should be a clear statement to this

effect (eg 'down hole length, true width not known').

Diagrams * Addressed in the report

* Appropriate maps and sections (with scales) and

tabulations of intercepts should be included for any

significant discovery being reported These should

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

Balanced * All results have been included.

reporting * Where comprehensive reporting of all Exploration

Results is not practicable, representative reporting

of both low and high grades and/or widths should be

practiced to avoid misleading reporting of

Exploration Results.

Other

substantive * Other exploration data, if meaningful and material, * Natural gas reservoir was intercepted with LL01

exploration should be reported including (but not limited to): drillhole at 293 m. This situation doesn't permit the

data geological observations; geophysical survey results; further drilling on this position due safety

geochemical survey results; bulk samples - size and considerations. Natural gas potential should be

method of treatment; metallurgical test results; bulk studied in the future.

density, groundwater, geotechnical and rock

characteristics; potential deleterious or

contaminating substances.

Further

work * The nature and scale of planned further work (eg * Make a Magneto Telluric geophysical survey to study

tests for lateral extensions or depth extensions or the brine potential in high depth in the tenements

large-scale step-out drilling). area. Depending on the results consider to drill a

deep exploration drillhole.

* Diagrams clearly highlighting the areas of possible

extensions, including the main geological

interpretations and future drilling areas, provided

this information is not commercially sensitive.

=============== =============================================================== ======================================================================

Section 3 Estimation and Reporting of Mineral Resources

(Criteria listed in section 1, and where relevant in section 2,

also apply to this section.)

Criteria JORC Code explanation Commentary

Database

integrity * Measures taken to ensure that data has not been * Cross-check of laboratory assay reports and Database

corrupted by, for example, transcription or keying

errors, between its initial collection and its use

for Mineral Resource estimation purposes. * All databases were built from original data by the

Competent Person

* Data validation procedures used.

Site visits

* Comment on any site visits undertaken by the * A site visit was undertaken by the Competent

Competent Person and the outcome of those visits.

Person in several times on January,

* If no site visits have been undertaken indicate why April and May, 2023. The outcome

this is the case. of the visits were the drillholes

organization and installation, Roko

geological personnel Packer sampling

protocol training and drilling &

sampling supervision.

Geological

interpretation * Confidence in (or conversely, the uncertainty of ) * For the Sub-Surface Resource, the geological

the geological interpretation of the mineral deposit. interpretation was made based on the public DGA

seismic geophysics and ENAMI Hylarico01 drillhole.

* Nature of the data used and of any assumptions made.

* Drillholes confirm the geological interpretations

* The effect, if any, of alternative interpretations on

Mineral Resource estimation.

* The use of geology in guiding and controlling Mineral

Resource estimation.

* The factors affecting continuity both of grade and

geology.

Dimensions * Not applied for Exploration Results

* The extent and variability of the Mineral Resource

expressed as length (along strike or otherwise), plan

width, and depth below surface to the upper and lower

limits of the Mineral Resource.

Estimation * The nature and appropriateness of the estimation * Not applied for Exploration Results

and modelling technique(s) applied and key assumptions, including

techniques treatment of extreme grade values, domaining,

interpolation parameters and maximum distance of

extrapolation from data points. If a computer

assisted estimation method was chosen include a

description of computer software and parameters used.

* The availability of check estimates, previous

estimates and/or mine production records and whether

the Mineral Resource estimate takes appropriate

account of such data.

* The assumptions made regarding recovery of

by-products.

* Estimation of deleterious elements or other non-grade

variables of economic significance (eg sulphur for

acid mine drainage characterisation).

* In the case of block model interpolation, the block

size in relation to the average sample spacing and

the search employed.

* Any assumptions behind modelling of selective mining

units.

* Any assumptions about correlation between variables.

* Description of how the geological interpretation was

used to control the resource estimates.

* Discussion of basis for using or not using grade

cutting or capping.

* The process of validation, the checking process used,

the comparison of model data to drill hole data, and

use of reconciliation data if available.

Moisture * Not applicable for brine resources

* Whether the tonnages are estimated on a dry basis or

with natural moisture, and the method of

determination of the moisture content.

Cut-off * No cut-off grade was applied

parameters * The basis of the adopted cut-off grade(s) or quality

parameters applied.

Mining * Not applied for Exploration Results

factors * Assumptions made regarding possible mining methods,

or assumptions minimum mining dimensions and internal (or, if

applicable, external) mining dilution. It is always

necessary as part of the process of determining

reasonable prospects for eventual economic extraction

to consider potential mining methods, but the

assumptions made regarding mining methods and

parameters when estimating Mineral Resources may not

always be rigorous. Where this is the case, this

should be reported with an explanation of the basis

of the mining assumptions made.

Metallurgical

factors * The basis for assumptions or predictions regarding * Not applied for Exploration Results

or assumptions metallurgical amenability. It is always necessary as

part of the process of determining reasonable

prospects for eventual economic extraction to

consider potential metallurgical methods, but the

assumptions regarding metallurgical treatment

processes and parameters made when reporting Mineral

Resources may not always be rigorous. Where this is

the case, this should be reported with an explanation

of the basis of the metallurgical assumptions made.

Environmen-tal

factors * Assumptions made regarding possible waste and process * The main environmental impacts expected is the main

or assumptions residue disposal options. It is always necessary as plant installations, the surface disturbance

part of the process of determining reasonable associated with production wells and brine mixing

prospects for eventual economic extraction to ponds. These impacts are not expected to prevent

consider the potential environmental impacts of the project development

mining and processing operation. While at this stage

the determination of potential environmental impacts,

particularly for a greenfields project, may not

always be well advanced, the status of early

consideration of these potential environmental

impacts should be reported. Where these aspects have

not been considered this should be reported with an

explanation of the environmental assumptions made.

Bulk density

* Whether assumed or determined. If assumed, the basis * Not applied for Exploration Results.

for the assumptions. If determined, the method used,

whether wet or dry, the frequency of the measurements,

the nature, size and representativeness of the

samples.

* The bulk density for bulk material must have been

measured by methods that adequately account for void

spaces (vugs, porosity, etc), moisture and

differences between rock and alteration zones within

the deposit.

* Discuss assumptions for bulk density estimates used

in the evaluation process of the different materials.

Classification * Not applied for Exploration Results

* The basis for the classification of the Mineral

Resources into varying confidence categories.

* Whether appropriate account has been taken of all

relevant factors (ie relative confidence in

tonnage/grade estimations, reliability of input data,

confidence in continuity of geology and metal values,

quality, quantity and distribution of the data).

* Whether the result appropriately reflects the

Competent Person's view of the deposit.

Audits

or reviews * The results of any audits or reviews of Mineral * No audits or reviews has been taken

Resource estimates.

Discussion * Not applied for Exploration Results

of relative * Where appropriate a statement of the relative

accuracy/ accuracy and confidence level in the Mineral Resource

confidence estimate using an approach or procedure deemed

appropriate by the Competent Person. For example, the

application of statistical or geostatistical

procedures to quantify the relative accuracy of the

resource within stated confidence limits, or, if such

an approach is not deemed appropriate, a qualitative

discussion of the factors that could affect the

relative accuracy and confidence of the estimate.

* The statement should specify whether it relates to

global or local estimates, and, if local, state the

relevant tonnages, which should be relevant to

technical and economic evaluation. Documentation

should include assumptions made and the procedures

used.

* These statements of relative accuracy and confidence

of the estimate should be compared with production

data, where available.

=============== ================================================================ ============================================================

Salar de Atacama - JORC Code, 2012 Edition - Table 1 report

template

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

Criteria JORC Code explanation Commentary

Sampling

techniques * Nature and quality of sampling (eg cut channels, * No sampling has been executed in the tenements

random chips, or specific specialised industry

standard measurement tools appropriate to the

minerals under investigation, such as down hole gamma

sondes, or handheld XRF instruments, etc). These

examples should not be taken as limiting the broad

meaning of sampling.

* Include reference to measures taken to ensure sample

representivity and the appropriate calibration of any

measurement tools or systems used.

* Aspects of the determination of mineralisation that

are Material to the Public Report.

* In cases where 'industry standard' work has been done

this would be relatively simple (eg 'reverse

circulation drilling was used to obtain 1 m samples

from which 3 kg was pulverised to produce a 30 g

charge for fire assay'). In other cases more

explanation may be required, such as where there is

coarse gold that has inherent sampling problems.

Unusual commodities or mineralisation types (eg

submarine nodules) may warrant disclosure of detailed

information.

Drilling

techniques * Drill type (eg core, reverse circulation, open-hole * No drilling has been executed in the tenements

hammer, rotary air blast, auger, Bangka, sonic, etc)

and details (eg core diameter, triple or standard

tube, depth of diamond tails, face-sampling bit or

other type, whether core is oriented and if so, by

what method, etc).

Drill sample

recovery * Method of recording and assessing core and chip * No drilling has been executed in the tenements

sample recoveries and results assessed.

* Measures taken to maximise sample recovery and ensure

representative nature of the samples.

* Whether a relationship exists between sample recovery

and grade and whether sample bias may have occurred

due to preferential loss/gain of fine/coarse

material.

Logging

* Whether core and chip samples have been geologically * No drilling or sampling has been executed in the

and geotechnically logged to a level of detail to tenements

support appropriate Mineral Resource estimation,

mining studies and metallurgical studies.

* Whether logging is qualitative or quantitative in

nature. Core (or costean, channel, etc) photography.

* The total length and percentage of the relevant

intersections logged.

Sub-sampling

techniques * If core, whether cut or sawn and whether quarter, * No sampling has been executed in the tenements

and sample half or all core taken.

preparation

* If non-core, whether riffled, tube sampled, rotary

split, etc and whether sampled wet or dry.

* For all sample types, the nature, quality and

appropriateness of the sample preparation technique.

* Quality control procedures adopted for all

sub-sampling stages to maximise representivity of

samples.

* Measures taken to ensure that the sampling is

representative of the in situ material collected,

including for instance results for field

duplicate/second-half sampling.

* Whether sample sizes are appropriate to the grain

size of the material being sampled.

Quality

of assay * The nature, quality and appropriateness of the * No sampling has been executed in the tenements

data and assaying and laboratory procedures used and whether

laboratory the technique is considered partial or total.

tests * For the TEM Geophysical survey a Zonge Engineering

and Research Organization, USA equipment was used,

* For geophysical tools, spectrometers, handheld XRF composed by a multipurpose digital receiver model

instruments, etc, the parameters used in determining GDP-32 and a transmitter TEM model ZT-30, with

the analysis including instrument make and model, batteries as power source.

reading times, calibrations factors applied and their

derivation, etc.

* For the Magneto Telluric geophysical survey a Zonge

Engineering and Research Organization, USA equipment

* Nature of quality control procedures adopted (eg was used, composed by a eight channel receptor model

standards, blanks, duplicates, external laboratory GDP-32 II, a magnetic sensor model MT ANT/4 and a

checks) and whether acceptable levels of accuracy (ie second magnetic sensor model MT ANT/6.

lack of bias) and precision have been established.

* Stations coordinates are been captured with

non-differential hand held GPS

Verification

of sampling * The verification of significant intersections by * No sampling has been executed in the tenements

and assaying either independent or alternative company personnel.

* The use of twinned holes.

* Documentation of primary data, data entry procedures,

data verification, data storage (physical and

electronic) protocols.

* Discuss any adjustment to assay data.

Location

of data * Accuracy and quality of surveys used to locate drill * No drilling or sampling has been executed in the

points holes (collar and down-hole surveys), trenches, mine tenements

workings and other locations used in Mineral Resource

estimation.

* For the TEM geophysical survey 20 stations with a 1

km to 1.5 km separation are planned as complement of

* Specification of the grid system used. the Magneto Telluric survey. This work is actually

ongoing on the south-west and the eastern tenements

near the Peine locality

* Quality and adequacy of topographic control.

* For the Magneto Telluric geophysical survey, 131

stations with a 200 m separation are planned with the

purpose to reach 800 m depth. This work is actually

ongoing on the south-west and the eastern tenements

near the Peine locality

* Stations coordinates are been captured with

non-differential hand held GPS

* The coordinate system is UTM, Datum WGS84 Zone 19K

Data spacing

and * Data spacing for reporting of Exploration Results. * No sampling has been executed in the tenements

distribution

* Whether the data spacing and distribution is

sufficient to establish the degree of geological and

grade continuity appropriate for the Mineral Resource

and Ore Reserve estimation procedure(s) and

classifications applied.

* Whether sample compositing has been applied.

Orientation

of data * Whether the orientation of sampling achieves unbiased * No drilling or sampling has been executed in the

in relation sampling of possible structures and the extent to tenements

to which this is known, considering the deposit type.

geological

structure

* If the relationship between the drilling orientation

and the orientation of key mineralised structures is

considered to have introduced a sampling bias, this

should be assessed and reported if material.

Sample

security * The measures taken to ensure sample security. * No sampling has been executed in the tenements

Audits

or reviews * The results of any audits or reviews of sampling * No sampling has been executed in the tenements

techniques and data.

============= ============================================================ ============================================================

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this

section.)

Criteria JORC Code explanation Commentary

Mineral

tenement * Type, reference name/number, location and ownership * CleanTech Lithium holds in Salar de Atacama 26,600

and land including agreements or material issues with third hectares of Exploration Mining applications in favour

tenure status parties such as joint ventures, partnerships, of CLS Chile SpA.

overriding royalties, native title interests,

historical sites, wilderness or national park and

environmental settings. * All concession acquisition costs and taxes have been

fully paid and that there are no claims or liens

against them

* The security of the tenure held at the time of

reporting along with any known impediments to

obtaining a licence to operate in the area. * There are no known impediments to obtain the licence

to operate in the area

* The Competent Person relies in the Mining Expert

Surveyor Mr, Juan Bedmar.

Exploration

done by * Acknowledgment and appraisal of exploration by other * Extensive Lithium exploration and exploitation

other parties parties. activities has been executed, mainly by Sociedad

Química y Minera Chile S.A. (SQM) and Albemarle

Geology

* Deposit type, geological setting and style of * CLS's tenements in Salar de Atacama corresponds to

mineralisation. marginal facies of a Mature Halite Salar (Huston et.

al., 2011)

Drill hole

Information * A summary of all information material to the * No drilling or has been executed in the tenements

understanding of the exploration results including a

tabulation of the following information for all

Material drill holes:

o easting and northing

of the drill hole collar

o elevation or RL (Reduced

Level - elevation above

sea level in metres)

of the drill hole collar

o dip and azimuth of

the hole

o down hole length and

interception depth

o hole length.

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

Data

aggregation * In reporting Exploration Results, weighting averaging * Not applied at this exploration level

methods techniques, maximum and/or minimum grade truncations

(eg cutting of high grades) and cut-off grades are

usually Material and should be stated.

* Where aggregate intercepts incorporate short lengths

of high grade results and longer lengths of low grade

results, the procedure used for such aggregation

should be stated and some typical examples of such

aggregations should be shown in detail.

* The assumptions used for any reporting of metal

equivalent values should be clearly stated.

Relationship

between * These relationships are particularly important in the * No drilling or sampling has been executed in the

mineralisation reporting of Exploration Results. tenements

widths and

intercept

lengths * If the geometry of the mineralisation with respect to

the drill hole angle is known, its nature should be

reported.

* If it is not known and only the down hole lengths are

reported, there should be a clear statement to this

effect (eg 'down hole length, true width not known').

Diagrams * Addressed in the report

* Appropriate maps and sections (with scales) and

tabulations of intercepts should be included for any

significant discovery being reported These should

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

Balanced * All results have been included.

reporting * Where comprehensive reporting of all Exploration

Results is not practicable, representative reporting

of both low and high grades and/or widths should be

practiced to avoid misleading reporting of

Exploration Results.

Other Other exploration data, * None

substantive if meaningful and material,

exploration should be reported including

data (but not limited to):

geological observations;

geophysical survey results;

geochemical survey results;

bulk samples - size

and method of treatment;

metallurgical test results;

bulk density, groundwater,

geotechnical and rock

characteristics; potential

deleterious or contaminating

substances.

Further

work * The nature and scale of planned further work (eg * Complete the TEM and Magneto Telluric geophysical

tests for lateral extensions or depth extensions or survey in the tenements. Depending on the results

large-scale step-out drilling). consider to drill exploration drillholes.

* Diagrams clearly highlighting the areas of possible

extensions, including the main geological

interpretations and future drilling areas, provided

this information is not commercially sensitive.

=============== =============================================================== ===================================================================

Section 3 Estimation and Reporting of Mineral Resources

(Criteria listed in section 1, and where relevant in section 2,

also apply to this section.)

Criteria JORC Code explanation Commentary

Database

integrity * Measures taken to ensure that data has not been * No drilling or sampling has been executed in the

corrupted by, for example, transcription or keying tenements

errors, between its initial collection and its use

for Mineral Resource estimation purposes.

* Data validation procedures used.

Site visits

* Comment on any site visits undertaken by the * No visits have been done recently by the Competent

Competent Person and the outcome of those visits. Person under CTL's consultancy

* If no site visits have been undertaken indicate why * The Competent Person has visited and knows very well

this is the case. the area under consulting for other parties

Geological

interpretation * Confidence in (or conversely, the uncertainty of) the * No geological interpretation further the general

geological interpretation of the mineral deposit. mineralization type classification has been done in

the tenements

* Nature of the data used and of any assumptions made.

* The effect, if any, of alternative interpretations on

Mineral Resource estimation.

* The use of geology in guiding and controlling Mineral

Resource estimation.

* The factors affecting continuity both of grade and

geology.

Dimensions * Not applied for Exploration Results

* The extent and variability of the Mineral Resource

expressed as length (along strike or otherwise), plan

width, and depth below surface to the upper and lower

limits of the Mineral Resource.

Estimation * The nature and appropriateness of the estimation * Not applied for Exploration Results

and modelling technique(s) applied and key assumptions, including

techniques treatment of extreme grade values, domaining,

interpolation parameters and maximum distance of

extrapolation from data points. If a computer

assisted estimation method was chosen include a

description of computer software and parameters used.

* The availability of check estimates, previous

estimates and/or mine production records and whether

the Mineral Resource estimate takes appropriate

account of such data.

* The assumptions made regarding recovery of

by-products.

* Estimation of deleterious elements or other non-grade

variables of economic significance (eg sulphur for

acid mine drainage characterisation).

* In the case of block model interpolation, the block

size in relation to the average sample spacing and

the search employed.

* Any assumptions behind modelling of selective mining

units.

* Any assumptions about correlation between variables.

* Description of how the geological interpretation was

used to control the resource estimates.

* Discussion of basis for using or not using grade

cutting or capping.

* The process of validation, the checking process used,

the comparison of model data to drill hole data, and

use of reconciliation data if available.

Moisture * Not applicable for brine resources

* Whether the tonnages are estimated on a dry basis or

with natural moisture, and the method of

determination of the moisture content.

Cut-off

parameters * The basis of the adopted cut-off grade(s) or quality * No drilling or sampling has been executed in the

parameters applied. tenements

Mining * Not applied for Exploration Results

factors * Assumptions made regarding possible mining methods,

or assumptions minimum mining dimensions and internal (or, if

applicable, external) mining dilution. It is always

necessary as part of the process of determining

reasonable prospects for eventual economic extraction

to consider potential mining methods, but the

assumptions made regarding mining methods and

parameters when estimating Mineral Resources may not

always be rigorous. Where this is the case, this

should be reported with an explanation of the basis

of the mining assumptions made.

Metallurgical

factors * The basis for assumptions or predictions regarding * Not applied for Exploration Results

or assumptions metallurgical amenability. It is always necessary as

part of the process of determining reasonable

prospects for eventual economic extraction to

consider potential metallurgical methods, but the

assumptions regarding metallurgical treatment

processes and parameters made when reporting Mineral

Resources may not always be rigorous. Where this is

the case, this should be reported with an explanation

of the basis of the metallurgical assumptions made.

Environmen-tal

factors * Assumptions made regarding possible waste and process * The main environmental impacts expected is the main

or assumptions residue disposal options. It is always necessary as plant installations, the surface disturbance

part of the process of determining reasonable associated with production wells and brine mixing

prospects for eventual economic extraction to ponds. These impacts are not expected to prevent

consider the potential environmental impacts of the project development

mining and processing operation. While at this stage

the determination of potential environmental impacts,

particularly for a greenfields project, may not

always be well advanced, the status of early

consideration of these potential environmental

impacts should be reported. Where these aspects have

not been considered this should be reported with an

explanation of the environmental assumptions made.

Bulk density

* Whether assumed or determined. If assumed, the basis * Not applied for Exploration Results.

for the assumptions. If determined, the method used,

whether wet or dry, the frequency of the measurements,

the nature, size and representativeness of the

samples.

* The bulk density for bulk material must have been

measured by methods that adequately account for void

spaces (vugs, porosity, etc), moisture and

differences between rock and alteration zones within

the deposit.

* Discuss assumptions for bulk density estimates used

in the evaluation process of the different materials.

Classification * Not applied for Exploration Results

* The basis for the classification of the Mineral

Resources into varying confidence categories.

* Whether appropriate account has been taken of all

relevant factors (ie relative confidence in

tonnage/grade estimations, reliability of input data,

confidence in continuity of geology and metal values,

quality, quantity and distribution of the data).

* Whether the result appropriately reflects the

Competent Person's view of the deposit.

Audits

or reviews * The results of any audits or reviews of Mineral * No audits or reviews has been taken

Resource estimates.

Discussion * Not applied for Exploration Results

of relative * Where appropriate a statement of the relative

accuracy/ accuracy and confidence level in the Mineral Resource

confidence estimate using an approach or procedure deemed

appropriate by the Competent Person. For example, the

application of statistical or geostatistical

procedures to quantify the relative accuracy of the

resource within stated confidence limits, or, if such

an approach is not deemed appropriate, a qualitative

discussion of the factors that could affect the

relative accuracy and confidence of the estimate.

* The statement should specify whether it relates to

global or local estimates, and, if local, state the

relevant tonnages, which should be relevant to

technical and economic evaluation. Documentation

should include assumptions made and the procedures

used.

* These statements of relative accuracy and confidence

of the estimate should be compared with production

data, where available.

=============== ================================================================ ==============================================================

For further information contact:

CleanTech Lithium PLC

Aldo Boitano/Gordon Stein Jersey office: +44 (0)

1534 668 321

Chile office: +562-32239222

Or via Celicourt

Celicourt Communications +44 (0) 20 7770 6424

Felicity Winkles/Philip Dennis/Ali cleantech@celicourt.uk

AlQahtani

Dr. Reuter Investor Relations +49 69 1532 5857

Dr. Eva Reuter

Porter Novelli - Chile +569 95348744

Ernesto Escobar Ernesto @publicoporternovelli.cl

Harbor Access - North America +1 475 477 9401

Jonathan Paterson/Lisa Micali

Beaumont Cornish Limited +44 (0) 207 628 3396

(Nominated Adviser)

Roland Cornish/Asia Szusciak

Fox-Davies Capital Limited

(Joint Broker) +44 20 3884 8450

Daniel Fox-Davies daniel@fox-davies.com

Canaccord Genuity Limited +44 (0) 207 523 4680

(Joint Broker)

James Asensio

Gordon Hamilton

Notes

About CleanTech Lithium

CleanTech Lithium (AIM:CTL, Frankfurt:T2N, OTCQX:CTLHF) is an

exploration and development company advancing sustainable lithium

projects in Chile for the clean energy transition. Committed to

net-zero, CleanTech Lithium's mission is to produce material

quantities of battery grade using sustainable Direct Lithium

Extraction technology, powered by renewable energy, the Company

plan to be the leading supplier of 'green' lithium to the EV and

battery manufacturing market.

CleanTech Lithium has four lithium projects - Laguna Verde,

Francisco Basin, Llamara and Salar de Atacama - located in the

lithium triangle, the world's centre for battery grade lithium

production. The two major projects: Laguna Verde and Francisco

Basin are situated within basins controlled by the Company, which

affords significant potential development and operational

advantages. All four projects have direct access to existing

infrastructure and renewable power.

CleanTech Lithium is committed to using renewable power for

processing and reducing the environmental impact of its lithium

production by utilising Direct Lithium Extraction. Direct Lithium

Extraction is a transformative technology which removes lithium

from brine, with higher recoveries and purities. The method offers

short development lead times, low upfront capex, with no extensive

site construction and no evaporation pond development so there is

no water depletion from the aquifer. www.ctlithium.com

This information is provided by RNS, the news service of the

London Stock Exchange. RNS is approved by the Financial Conduct

Authority to act as a Primary Information Provider in the United

Kingdom. Terms and conditions relating to the use and distribution

of this information may apply. For further information, please

contact rns@lseg.com or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms

and conditions, to analyse how you engage with the information

contained in this communication, and to share such analysis on an

anonymised basis with others as part of our commercial services.

For further information about how RNS and the London Stock Exchange

use the personal data you provide us, please see our Privacy

Policy.

END

UPDFLFIDASITFIV

(END) Dow Jones Newswires

September 29, 2023 02:00 ET (06:00 GMT)

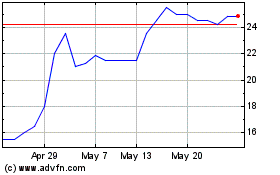

Cleantech Lithium (LSE:CTL)

Historical Stock Chart

From Apr 2024 to May 2024

Cleantech Lithium (LSE:CTL)

Historical Stock Chart

From May 2023 to May 2024