Eurotin Inc.: Drilling Reconfirms the Presence of High Grade Tin Mineralization in All Parts of the 1200m Long Oropesa Deposit

June 04 2012 - 8:17AM

Marketwired Canada

Eurotin Inc. ("Eurotin" or the "Company") (TSX VENTURE:TIN), is pleased to

provide the following drill results and update on its Oropesa tin project,

located in SW Spain.

Drilling Highlights:

ORPD 128: 16.8m @ 1.09% Sn from 97.0m

ORPD 123: 13.5m @ 0.75% Sn from 191.0m

ORPD 129: 6.5m @ 0.86% Sn from 111.0m

ORPD 142: 25.2m @ 0.85% Sn from 85.7m

ORPD 142: 6.3m @ 1.85% Sn from 200.2m

Other Highlights:

-- The second of the four planned large diameter (PQ) drill holes has now

been completed. These drill cores will shortly be shipped to the

laboratories of SGS Mineral Services UK Ltd in Cornwall, UK for detailed

metallurgical testwork.

-- Sufficient holes have now been drilled to demonstrate good continuity of

the mineralized structures over 1200 metres of the known approx. 2000

metres of tin mineralization at Oropesa.

-- A modest, deep hole, drilling campaign will begin shortly to test for

the presence of additional high grade Primary Structures at depths of

between 250 and 750 metres.

The most recent drill results are shown below:

----------------------------------------------------------------------------

Est.

True

From To Length Width Tin -

Hole No. Dip & Azimuth (m) (m) (m) (m) Sn (%) Comment

----------------------------------------------------------------------------

ORPD-113 60 degrees @

200 degrees 14.3 16.7 2.4 0.45%

----------------------------------------------------------------------------

26.3 33.9 7.6 0.23%

----------------------------------------------------------------------------

38.6 48.6 8.0 0.21%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-116 60 degrees @

200 degrees NSV

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-118 60 degrees @

200 degrees 32.3 48.3 16.0 0.42%

----------------------------------------------------------------------------

195.3 201.0 5.7 0.43%

----------------------------------------------------------------------------

214.0 219.2 5.2 0.29%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-119 60 degrees @

200 degrees 87.0 91.4 4.4 0.40%

----------------------------------------------------------------------------

114.1 116.1 2.0 0.38%

----------------------------------------------------------------------------

approx. Primary

222.4 230.1 7.7 6.9 0.67% Structure

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-120 60 degrees @

200 degrees 19.5 33.1 13.6 0.29%

----------------------------------------------------------------------------

100.9 116.0 15.1 0.50%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-122 60 degrees @

200 degrees 11.3 17.3 6.0 0.24%

----------------------------------------------------------------------------

56.3 58.3 4.0 0.20%

----------------------------------------------------------------------------

166.3 175.4 9.1 0.36%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-123 60 degrees @

200 degrees 89.5 97.6 8.1 0.27%

----------------------------------------------------------------------------

approx. Primary

191.0 204.5 13.5 12.2 0.75% Structure

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-124 60 degrees @

200 degrees 74.2 86.4 12.2 0.35%

----------------------------------------------------------------------------

117.6 123.6 6.0 0.24%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-125 60 degrees @

200 degrees 9.3 16.1 6.8 0.24%

----------------------------------------------------------------------------

21.3 29.3 8.0 0.27%

----------------------------------------------------------------------------

61.4 72.7 11.3 0.22%

----------------------------------------------------------------------------

82.4 92.6 10.2 0.30%

----------------------------------------------------------------------------

Top of

approx. Primary

120.6 122.6 2.0 1.8 0.82% Structure

----------------------------------------------------------------------------

132.4 135.3 2.9 0.33%

----------------------------------------------------------------------------

138.4 147.0 8.6 0.47%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-126 60 degrees @

200 degrees 8.3 17.3 9.0 0.39%

----------------------------------------------------------------------------

71.3 82.0 10.7 0.21%

----------------------------------------------------------------------------

225.3 274.4 22.1 0.23%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-128 60 degrees @ approx. Primary

200 degrees 97.0 113.8 16.8 15.1 1.09% Structure

----------------------------------------------------------------------------

approx. Primary

Inc. 98.0 106.1 8.1 7.3 1.82% Structure

----------------------------------------------------------------------------

171.3 189.1 17.8 0.40%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-129 60 degrees @ approx. Primary

200 degrees 111.0 119.5 6.5 5.9 0.86% Structure

----------------------------------------------------------------------------

129.0 140.0 11.0 0.31%

----------------------------------------------------------------------------

144.0 148.1 4.1 0.39%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-131 Top of

60 degrees @ approx. Primary

200 degrees 172.8 175.8 3.0 2.7 0.61% Structure

----------------------------------------------------------------------------

181.8 188.6 6.8 0.34%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-133 60 degrees @

200 degrees 86.8 89.8 3.0 0.44%

----------------------------------------------------------------------------

119.6 137.6 18.0 0.30%

----------------------------------------------------------------------------

----------------------------------------------------------------------------

ORPD-142 60 degrees @ approx. Primary

200 degrees 85.7 110.9 25.2 22.7 0.85% Structure

----------------------------------------------------------------------------

approx. Primary

Inc. 101.9 110.9 9.8 8.8 1.19% Structure

----------------------------------------------------------------------------

approx. Primary

200.2 206.5 6.3 5.7 1.85% Structure

----------------------------------------------------------------------------

Note 1: A cut off grade of 0.20% tin has been used.

Note 2: True widths for Replacement Structures not ascertained due to irregular

shaped mineralized envelopes.

Note 3: Figures shown in bold represent significant tin results of Width (m) x

Grade (%), exceeding a value of 6 and having a grade exceeding 0.65% tin.

Please see below link for Oropesa drill hole locations reported in and prior to

this press release:

http://media3.marketwire.com/docs/604TINfig1.pdf

Latest Developments at Oropesa

1. The Company will shortly commence an approx. 10km2 soil geochemistry

survey at Oropesa. The lines will be 250 metres apart and samples will

be taken on 50 metre spacings. Wherever tin anomalies are found, the

area will then be tested on spacings of 25 metres.

2. The Oropesa property is host to several regional geological structures.

Testwork, including drilling, has now commenced to determine which

structures were the conduits for tin mineralization from a deep granite

source.

Conclusion

Peter Miller, President & CEO, comments: "Geological interpretation of our

recent drill results has added further evidence to our belief that the Oropesa

deposit is part of a major new Tin District, probably the first to be discovered

in over 40 years. So while the development of an open pit mine here obviously

remains our first priority in providing value to our shareholders, we are also

keen to determine the district's tin potential."

Assay and QA/QC Methodology for Oropesa Drill Core

All core produced is taken daily from each drill site to the Company's secure

facility in Fuente Obejuna, where it is logged by the Company's geologists. This

process takes place under the supervision of Qualified Person Victor Guerrero

Merino, Euro.Geol.

The core, usually of around one metre length, which is chosen by the Company's

geologists for assaying, is then cut in half either at the Company's own

facilities at Fuente Obejuna or at ALS Chemex's sample preparation facility in

Seville in southern Spain.

At the ALS Chemex facility, the cut core is logged into the in house LIMS

tracking system, after which each sample is prepared using procedure code 'Prep

31'. This procedure involves the drying, weighing and fine crushing to 70%

passing -2mm. A 250g split of the crushed material is then pulverised to greater

than 85% passing 75 microns. Samples are then shipped by bonded courier to

Vancouver for analysis.

In Vancouver, ALS Chemex procedure ME-XRF10 is used for tin analysis and

ME-ICP61 for multi-element (33) analysis. The ME-XRF10 procedure uses 0.9g of

calcined sample pulp, which is mixed with 4.5g of lithium tetraborate and 4.5g

of lithium metaborate. This mixture is then fused at 1,100 degrees C to produce

a flat molten disc, which is subsequently analysed by XRF spectrometry. ALS

Chemex analyses its own standard samples and blanks, plus duplicates, within

each set of samples provided by the Company. The Company has recently introduced

its own blanks and standards as a further means of checking the accuracy of the

assay results. One in every 15 samples analysed by ALS Chemex is then sent to

SGS's laboratories in Cornwall, UK, for check assaying for tin. The Company

keeps all its sample pulps and rejects in locked steel containers at its secure

storage facility in Fuente Obejuna.

The Company recently completed a new check assay program using five certified

laboratories. The pulp sample composites used had varying tin grades; the

accuracy of the results obtained was within acceptable parameters.

Mr. Victor Guerrero Merino, an independent geological consultant and a Qualified

Person pursuant to NI 43-101, has reviewed and approved the technical

information in this news release on behalf of the Company.

Forward-Looking Statements

Results presented in this press release are exploratory in nature. Historical

data, if mentioned, should not be relied upon, as they are not admissible under

NI 43-101 rules and the Company has not conducted sufficient testing to verify

this type of information. In addition, this press release includes certain

forward-looking statements within the meaning of Canadian securities laws that

are based on expectations, estimates and projections as of the date of this

press release. There can be no assurance that such statements will prove

accurate, and actual results and developments are likely to differ, in some case

materially, from those expressed or implied by the forward-looking statements

contained in this press release. Readers of this press release are cautioned not

to place undue reliance on any such forward-looking statements.

Forward-looking statements contained in this press release are based on a number

of assumptions that may prove to be incorrect, including, but not limited to:

timely implementation of anticipated drilling and exploration programs; the

successful completion of new development projects, planned expansions or other

projects within the timelines anticipated and at anticipated production levels;

the accuracy of reserve and resource estimates, grades, mine life and cash cost

estimates; whether mineral resources can be developed; title to mineral

properties; financing requirements, general market conditions, and the

uncertainty of access to additional capital; changes in the world-wide price of

mineral commodities; general economic conditions; and changes in laws, rules and

regulations applicable to the Company. In addition to being subject to a number

of assumptions, forward-looking statements in this press release involve known

and unknown risks, uncertainties and other factors that may cause actual results

and developments to be materially different from those expressed or implied by

such forward-looking statements. The Company has no intention or obligation to

update the forward-looking statements contained in this press release.

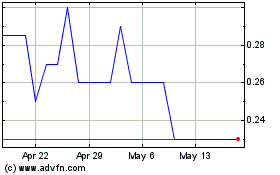

Tincorp Metals (TSXV:TIN)

Historical Stock Chart

From Dec 2024 to Jan 2025

Tincorp Metals (TSXV:TIN)

Historical Stock Chart

From Jan 2024 to Jan 2025