MAG Silver Corp. (TSX / NYSE American: MAG) (“MAG”

or “MAG Silver”) reports results from six completed holes (10,972 m

total) in surface-based Phase 2 drilling on its Deer Trail

Carbonate Replacement Deposit (“CRD”) Project in central Utah, USA

(Figure 1, Tables 1 & 2).

The highlight is the

discovery of the “Carissa” zone found in aggressive step-outs

drilled 1 km to the southwest of the “Deer Trail Mine Corridor”.

Discovery Hole DT22-09 cut the

longest intercept of continuous mineralisation with

273.8 m of sulfide “lacing” (Figure 2) averaging

12 g/t Silver, 0.2% Copper and 0.3% Lead plus Zinc with

individual sulfide bands grading from 59-266 g/t Silver

0.2-5.5% Copper, 0.1-1.5% Lead, 0.1-5.2% Zinc (Table

1)

.

Phase 2 drilling also included drilling within

the Deer Trail Mine Corridor (Table 2). Differing characteristics

suggest Carissa and the Deer Trail Mine Corridor were both fed

along separate mineralization channel-ways leading from the

interpreted Deer Trail Mountain Porphyry to the west. Assays are

pending for two additional holes and drilling continues 1.7 km

southeast of the Carissa zone on a strong geophysical anomaly at

the intersection of two major structures. Follow-up drill permits

for Carissa are expected soon.

Carissa Zone Discovery:

DT22-09 & 10 contain, by far, the most

widespread mineralization and strongest alteration drilled on the

property. Both holes cut several hundred meters of progressively

increasing Argentiferous (Silver-bearing) Manganese-Oxide

Mineralization (“AMOM”), marble and skarn before entering

distinctive zones of Silver-Copper-Zinc bearing sulfide

“lacing”, in turn cut by zones of pervasive mineralized skarn

(Figure 2). DT22-10 was lost above target

depth in a mineralized structure after cutting 115.7 m of very

similar alteration and lacing mineralization (Table 1, Figure 1).

The sulfide lacing and skarn zones in both Carissa holes become

progressively stronger with depth and show significant increases in

pathfinder elements (W, Sn, Bi, Mo), suggesting increasing

proximity to the suspected porphyry-related mineralization

source.

“Stepping out aggressively into the previously

untouched Carissa zone led to the strongest and most extensive

mineralization and alteration seen at Deer Trail. This tells us we

are on the right track, and that track appears to lead towards the

copper-moly porphyry we believe is the source of the system. Most

importantly, this tells us that there is more to Deer Trail than

meets the eye, which confirms our belief that this is a major

mineralized system with much left to discover,” said George

Paspalas, MAG’s President and CEO. “With the Juanicipio processing

plant in Mexico now connected to power and ramp-up underway, these

encouraging results combined with prospective indications at the

Larder Project in Ontario, position us to make 2023 a meaningful

year for MAG shareholders.”

Key Takeaways:

-

DT22-09 intercepted 273.8m of distinctive sulfide

lacing (mineralization) averaging 12 g/t Silver, 0.2% Copper, 0.1%

Lead and 0.2% Zinc, with individual sulphide bands grading 59-266

g/t Silver, 0.2-5.5% Copper, 0.1-1.5% Lead, 0.1-5.2% Zinc and

Trace-1.5 g/t Gold (Table 1).

- The lacing zone

in Hole DT22-09 is preceded by hundreds of metres of progressively

zoned AMOM, marble and mineralized garnet-pyroxene-magnetite

skarn.

-

DT22-10 cut the same progression of alteration as

DT22-09 over 115.6 m before being lost in sulphide lacing

mineralization.

-

High grade mineralization intercepted in holes DT22-05 through 08

within the “Deer Trail Mine Corridor” (Table 2, Figures 1 & 2)

has differing compositional and geological characteristics from

those observed at Carissa, indicating they were likely fed along

separate mineralization pathways from those responsible for

Carissa.

-

The overall results continue to reinforce MAG’s CRD exploration

model and suggest multiple mineralization channel-ways extending

from the inferred Deer Trail Mountain porphyry center. Multiple

fluid channel-ways are a characteristic of many major CRD

system.

Table 1: Phase 2 Drilling Highlights “Carissa

Zone”

|

HOLE ID |

From (m) |

To (m) |

Length (m)3 |

Ag (g/t) |

Au (g/t) |

Cu (%) |

Pb (%) |

Zn (%) |

|

DT22-09 |

480.39 |

480.69 |

0.30 |

96 |

0.65 |

0.08 |

0.21 |

0.20 |

|

and |

830.50 |

830.75 |

0.25 |

81 |

0.09 |

0.03 |

0.40 |

0.02 |

|

and |

914.50 |

915.40 |

0.90 |

2 |

1.49 |

0.00 |

0.00 |

0.01 |

|

and |

1262.25 |

1262.70 |

0.45 |

68 |

0.03 |

0.01 |

0.39 |

0.47 |

|

and |

1295.47 |

1569.28 |

273.81 |

12 |

0.04 |

0.21 |

0.07 |

0.20 |

|

incl |

1303.46 |

1350.83 |

47.37 |

17 |

0.02 |

0.30 |

0.12 |

0.35 |

|

incl |

1372.60 |

1375.53 |

2.93 |

171 |

0.19 |

0.68 |

1.08 |

0.82 |

|

incl |

1511.03 |

1569.28 |

58.25 |

22 |

0.10 |

0.44 |

0.11 |

0.26 |

|

incl |

1511.03 |

1521.17 |

10.14 |

43 |

0.15 |

0.85 |

0.14 |

0.21 |

|

incl |

1518.87 |

1521.17 |

2.30 |

108 |

0.26 |

2.65 |

0.29 |

0.65 |

|

incl |

1542.66 |

1569.28 |

26.62 |

30 |

0.16 |

0.62 |

0.17 |

0.46 |

|

incl |

1543.25 |

1545.11 |

1.86 |

93 |

0.16 |

0.07 |

1.46 |

5.24 |

|

incl |

1565.30 |

1569.00 |

3.70 |

53 |

0.49 |

1.98 |

0.08 |

0.07 |

|

incl |

1566.42 |

1566.62 |

0.20 |

142 |

0.82 |

5.47 |

0.29 |

0.15 |

|

DT22-102 |

833.80 |

834.90 |

1.10 |

32 |

0.07 |

0.01 |

0.23 |

0.20 |

|

and |

1285.35 |

1286.25 |

0.90 |

39 |

0.02 |

0.62 |

0.45 |

0.99 |

|

and |

1240.00 |

1355.68 |

115.68 |

11 |

0.01 |

0.20 |

0.12 |

0.32 |

|

incl |

1294.90 |

1319.85 |

24.95 |

24 |

0.01 |

0.44 |

0.26 |

0.68 |

|

incl |

1309.45 |

1317.55 |

8.10 |

34 |

0.02 |

0.61 |

0.36 |

1.02 |

|

incl |

1314.75 |

1317.55 |

2.80 |

45 |

0.03 |

0.87 |

0.46 |

1.17 |

|

and |

1354.55 |

1355.15 |

0.60 |

31 |

0.14 |

0.97 |

0.04 |

7.47 |

|

incl |

1354.75 |

1354.95 |

0.20 |

35 |

0.20 |

1.92 |

0.01 |

14.90 |

1 grammes per tonne 2 hole

lost within mineralization at 1355.68m 3

core length

Deer Trail Mine Corridor:

Narrow high-grade mineralization was also intercepted in three

holes within the “Deer Trail Mine Corridor" (Figure 1, Table 2)

with intercept grades of 17-151 g/t Silver, Trace (Tr)-6.5 g/t

Gold, Tr-0.9% Copper and Tr-29.5% Lead plus Zinc, all of which

appear related to bleeder structures.

Table 2: Phase 2 Drilling Highlights

“Deer Trail Mine Corridor”

|

HOLE ID |

From(m) |

To (m) |

Length (m)2 |

Ag (g/t) |

Au (g/t) |

Cu (%) |

Pb (%) |

Zn (%) |

|

DT21-04 |

|

|

|

Lost |

|

|

|

|

|

DT21-05 |

645.95 |

646.40 |

0.45 |

5 |

2.74 |

0.00 |

0.00 |

0.01 |

|

and |

700.36 |

700.85 |

0.49 |

137 |

0.60 |

0.18 |

15.30 |

14.24 |

|

and |

906.38 |

906.62 |

0.24 |

41 |

1.85 |

0.43 |

5.66 |

5.16 |

|

and |

912.35 |

913.10 |

0.75 |

75 |

1.11 |

0.34 |

0.28 |

0.32 |

|

DT21-06 |

1466.38 |

1469.70 |

3.32 |

17 |

0.12 |

0.92 |

0.26 |

0.53 |

|

DT22-07 |

690.72 |

691.88 |

1.16 |

151 |

0.53 |

0.06 |

0.03 |

0.11 |

|

and |

939.67 |

940.07 |

0.40 |

1 |

6.53 |

0.01 |

0.00 |

0.00 |

|

and |

1082.80 |

1085.70 |

2.90 |

24 |

0.03 |

0.67 |

6.69 |

7.37 |

|

DT22-08 |

1112.37 |

1113.40 |

1.03 |

2 |

0.11 |

0.50 |

0.00 |

0.01 |

1 grammes per tonne 2 core

length

Phase 2 Drilling Program

The Phase 2 drilling program was designed to

follow up on 2021’s limited Phase 1 drilling, which successfully

proved three vital features for project viability:

- Adequate

thickness of favorable host rocks: All holes cut between

250 and 300 meters of the Redwall Limestone, a regionally pure

limestone and excellent potential host for CRD mineralization;

-

Traceable Plumbing: All holes succeeded in cutting

projections of identified mineralized “feeder” structures to depth;

and

-

Mineralization: All holes cut high-grade

Silver-Gold-Copper-Lead-Zinc mineralization in the targets.

The Phase 2 drilling program built on

those results and is focused on:

- Follow-up

testing of Phase 1 mineralized intercepts;

- Testing newly

developed targets (including Carissa); and

- Identifying

vectors leading towards the Porphyry Copper-Molybdenum source

intrusion inferred to underlie Deer Trail Mountain 3 km to the

west.

Eight holes were completed in the Phase 2

drilling program with results for six reported here. Two holes,

DT22-04 and 10 were lost before reaching target depth. Assays are

pending for completed holes DT22-11 & 12 and a large step out

hole (DT22-13) is currently in progress 1.7 km southeast of the

Carissa zone testing a strong geophysical anomaly coincident with

the intersection of 2 major structures. Like Phase 1, all completed

Phase 2 holes have cut 210 m – 320 m of intensely marbled +/-

skarned Redwall Limestone and all but the abandoned DT22-10 ended

in a felsic porphyritic intrusive rock interpreted to post-date

mineralization.

As with Phase 1, all core is:

- oriented,

allowing collection of structural data down hole;

- photographed in

natural and UV light; and

- systematically

analysed with a pXRF and Terraspec Halo providing inexpensive

detailed downhole geochemical and alteration profiles.

Deer Trail Mine Corridor Holes: DT21-04 to

DT22-08

DT22-04 to 08 were designed to test:

- the down dip

extension of well-mineralized feeder structures intercepted in

Phase 1 within the mixed lithologies of the Callville Limestone

(see Press Release dated September 7, 2021) projected into the

Redwall Limestone; and

- highly

prospective additional targets within the Deer Trail Mine

Corridor.

Narrow (0.2 m to 3.3 m) mineralization was

intercepted in these holes. DT22-05 (a redo of the lost DD22-04)

was aimed at the intersection of the mineralized Wet and Monster

Faults and intercepted 0.5 m grading 137 g/t Silver, 0.6

g/t Gold, and 30% Lead plus Zinc in bedding controlled

manto-style mineralization. Hole DT22-06 a

follow-up of DT21-02 from Phase 1, targeted the mineralized Red

Fissure Fault, the principal feeder of the historic Deer Trail

Manto, deeper within the Redwall Limestone.

DT21-06 cut 3.3 m grading 17 g/t Silver,

0.12 g/t Gold, and 0.8% Lead plus Zinc and 0.9% Copper.

DT22-07, a splay off of Hole 05, cut 2.9 m grading 24 g/t

Silver, 0.03 g/t Gold, and 14.0% Lead plus Zinc.

DT22-08, a follow-up splay off of

DT21-03 from Phase 1, targeted

the Wet Fault deeper within the Redwall Limestone and intersected

1.03 m grading 2 g/t Silver, 0.11 g/t Gold, and 0.01% Lead

plus Zinc and 0.5% Copper.

The mineralization and alteration intercepted in

these holes include manto-style sulphides, skarn and marble

alteration features indicating the targeted feeder structures are

nearby. These feeders appear to be offset across the Callville

Limestone/Redwall Limestone contact. The high grades encountered in

Phase 1 drilling, the extensive alteration in both phases and the

indications of feeder proximity in Phase 2 indicates additional

drilling is justified to continue seeking stronger mineralization

along the feeders in these areas.

DT21-09 to DT22-10 - Carissa Zone

Discovery

The discovery of the Carissa Zone, in

DT22-09 & 10, 1 km to the southwest of the

historic Deer Trail Mine, includes pervasive AMOM a distinctive

alteration style found in CRD systems, as well as poly-directional

interlaced sulfide veining, manto style massive sulfide,

mineralized garnet-pyroxene skarn and mineralized magnetite-skarn.

DT22-09 intersected 273.8m of continuous

mineralization including sulfide lacing with individual bands

grading 59-266 g/t Silver, 0.2-5.5% Copper, 0.1-1.5% Lead, 0.1-5.2%

Zinc and Tr-1.5 g/t Gold and mineralized skarn including 2.3m

grading 108g/t Silver, 0.26 g/t Gold, 2.7% Copper, 0.94% Lead plus

Zinc. Overall, the full 273.8m averages 12 g/t Silver,0.2% Copper,

0.07% Lead and 0.2% Zinc. Follow-up hole,

DT22-10 was lost in mineralization after cutting

115m of intense skarn alteration and sulfide lacing averaging 11

g/t Silver, 0.1 g/t Gold, and 0.4 % Lead plus Zinc and 0.2 %

Copper, with sub-intervals of higher grade like those in

DT22-09 (Table 1).

The Carissa Zone shows features not seen before

at Deer Trail including the distinctive, widespread sulfide lacing

and the mineralized garnet and magnetite skarns. Additionally,

pervasive AMOM is developed over hundreds of meters, two orders of

magnitude more than those intercepted in the Deer Trail Mine

Corridor. These features suggest that Carissa lies close to a major

mineralization source and its orientation and distance from the

Deer Trail Mine Corridor suggests a separate mineralization

corridor is present. Similar features are seen in large, well-known

CRD-skarn-porphyry systems in Utah and elsewhere. Follow-up targets

with better drilling geometry have been developed for Carissa and

will be tested once permits are in hand.

Property Wide Exploration

Since MAG consolidated the Deer Trail

properties, regional mapping, sampling, hyperspectral surveys and

geophysics have been run to locate the porphyry intrusive inferred

to lie at the system’s center. These programs, using modern

techniques and equipment, build on decades of historic exploration

resulting in a comprehensive integrated district-scale geological,

geochemical and geophysical dataset. Regional drill target planning

and permitting is well underway for more expansive property-wide

exploration.

About Deer Trail

The silver-rich Deer Trail Carbonate Replacement

Deposit “CRD” project in Piute County, Utah (the “Deer Trail

Project” or “Project”) includes both patented and unpatented claims

(approximately 7,250 Ha) in the historic Deer Trail Mine and the

adjoining Alunite Ridge area. The property lies directly on the

Tushar strand of the Wasatch-Tushar Fault, the major 100 km wide

structural zone separating the Great Basin from the Colorado

Plateau. Farther north, this same fault system hosts the Tintic and

Bingham Canyon Carbonate Replacement Deposit (CRD) -Skarn-Porphyry

districts. Age dates from all three systems fall around 28-35Ma,

suggesting metallogenic affinity.

MAG has consolidated the Deer Trail properties

for the first time since the early 1980s, allowing us to apply an

integrated district-scale exploration approach based on the

continuum of mineralization styles from CRD through Skarn to

Porphyry Copper-Molybdenum shown by many related systems worldwide.

This model suggests that the high-grade silver, gold, lead, zinc

and copper CRD sulphides of the Deer Trail mine are linked by

kilometers of continuous mineralization to a Porphyry

Copper-Molybdenum centre lying to the west under Deer Trail

Mountain or Alunite Ridge. The system’s plumbing framework was

outlined through detailed core relogging and underground mapping,

which were combined into a detailed 3D model of potential “bleeder”

structures connected to potentially larger deposit to the southeast

of the historic Deer Trail Mine. The Deer Trail Project team is led

by Dr. Lex Lambeck an A.I.P.G. Certified Professional

Geologist with over 15 years of relevant experience in CRD

exploration.

Quality Assurance and Control:

The samples (half core) are shipped directly in security-sealed

bags to ALS- Laboratories preparation facilities in Elko, Nevada,

USA (Certification ISO/IEC 17025:2017). Samples shipped also

include intermittent standards and blanks. Pulp samples are

subsequently shipped to ALS-Chemex Laboratories in North Vancouver,

Canada for analysis. The remaining half core is placed back into

the core boxes and is stored on site with the rest of the drill

hole core in a secured core storage facility.

Qualified Persons: Dr. Peter

Megaw, Ph.D., C.P.G. and Lyle Hansen, M.Sc., P.Geo have acted as

the qualified persons as defined in National Instrument 43-101 for

this disclosure and supervised the preparation of the technical

information in this release. Dr. Megaw has a Ph.D. in geology and

more than 37 years of relevant experience focussed on silver and

gold exploration in Mexico. He is a Certified Professional

Geologist (CPG 10227) by the American Institute of Professional

Geologists and an Arizona Registered Geologist (ARG 21613). Dr.

Megaw is not independent as he is Chief Exploration Officer and a

Shareholder of MAG. Dr. Megaw is satisfied that the results are

verified based on an inspection of the core and underground

exposures, a review of the sampling procedures, the credentials of

the professionals completing the work and the visual nature of the

silver and base metal sulphides within a district where he is

familiar with the style and continuity of mineralization. Mr.

Hansen is a registered Professional Geologist with Engineers and

Geoscientists BC (149624) and has more than 12 years experience in

epithermal veins. Mr. Hansen is not independent as he is

Geotechnical Director of MAG.

About MAG Silver Corp.

(www.magsilver.com)

MAG Silver Corp. is a growth-oriented Canadian

development and exploration company focused on becoming a top-tier

primary silver mining company by exploring and advancing

high-grade, district scale, precious metals projects in the

Americas. Its principal focus and asset is the Juanicipio Project

(44%), being developed with Fresnillo Plc (56%), the operator. The

project is located in the Fresnillo Silver Trend in Mexico, the

world's premier silver mining camp, where the operator is currently

advancing underground mine development and commissioning a 4,000

tonnes per day processing plant. Underground mine production of

mineralized development material commenced in Q3 2020, and an

expanded exploration program is in place targeting multiple highly

prospective targets at Juanicipio. MAG is also executing

multi-phase exploration programs at the Deer Trail 100% earn-in

Project in Utah and the recently acquired Larder Project, located

in the historically prolific Abitibi region of Canada.

Neither the Toronto Stock Exchange nor the NYSE

American has reviewed or accepted responsibility for the accuracy

or adequacy of this press release, which has been prepared by

management.

This release includes certain statements that

may be deemed to be “forward-looking statements” within the meaning

of the US Private Securities Litigation Reform Act of 1995. All

statements in this release, other than statements of historical

facts are forward looking statements, including statements that

address future mineral production, reserve potential,

exploration drilling, exploitation activities and events or

developments. Forward-looking statements are often, but not always,

identified by the use of words such as "seek", "anticipate",

"plan", "continue", "estimate", "expect", "may", "will", "project",

"predict", "potential", "targeting", "intend", "could", "might",

"should", "believe" and similar expressions. These statements

involve known and unknown risks, uncertainties and other factors

that may cause actual results or events to differ materially from

those anticipated in such forward-looking statements.

Although MAG believes the expectations expressed in such

forward-looking statements are based on reasonable assumptions,

such statements are not guarantees of future performance and actual

results or developments may differ materially from those in the

forward-looking statements. Factors that could cause actual results

to differ materially from those in forward-looking statements

include, but are not limited to, changes in

commodities prices, changes in mineral

production performance, exploitation and exploration

successes, continued availability of capital and financing, and

general economic, market or business conditions, political risk,

currency risk and capital cost inflation. In addition,

forward-looking statements are subject to various risks, including

that data is incomplete and considerable additional work will be

required to complete further evaluation, including but not limited

to drilling, engineering and socio-economic studies and

investment. The reader is referred to the Company’s filings

with the SEC and Canadian securities regulators for disclosure

regarding these and other risk factors. There is no certainty that

any forward-looking statement will come to pass and investors

should not place undue reliance upon forward-looking statements.

Please Note: Investors are urged to consider closely the

disclosures in MAG's annual and quarterly reports and

other public filings, accessible through the Internet at

www.sedar.com and www.sec.govLEI: 254900LGL904N7F3EL14

Figure 1 accompanying this

announcement is available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/643f498b-dc63-45cf-93fd-99fc47d38910

Figure 2 accompanying this

announcement is available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/b981d61f-6c5a-40f6-8000-4ba3d8446fd2

For further information on behalf of MAG Silver Corp.

Contact Michael J. Curlook, VP Investor Relations and Communications

Phone: (604) 630-1399

Website: www.magsilver.com

Toll Free: (866) 630-1399

Email: info@magsilver.com

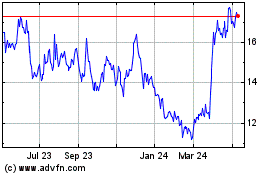

MAG Silver (TSX:MAG)

Historical Stock Chart

From Nov 2024 to Dec 2024

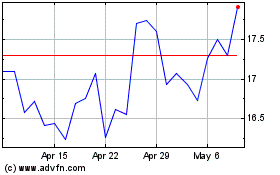

MAG Silver (TSX:MAG)

Historical Stock Chart

From Dec 2023 to Dec 2024