Visteon Helps Raise Fuel Economy and Reduce Emissions With First-to-Market Products

June 15 2004 - 11:05AM

PR Newswire (US)

Visteon Helps Raise Fuel Economy and Reduce Emissions With

First-to-Market Products DEARBORN, Mich., June 15

/PRNewswire-FirstCall/ -- Visteon Corporation (NYSE:VC) is helping

customers improve fuel economy and reduce emissions through the

innovation of six first-to-market products. (Logo:

http://www.newscom.com/cgi-bin/prnh/20001201/DEF008LOGO )

Slip-in-Tube Propshaft reduces weight Visteon's patented

Slip-in-Tube Propshaft is a weight-reducing, quieting and

safety-enhancing solution that will be introduced later this year

on a high-volume, mid-size sport-utility vehicle. First introduced

in 2002 on the Chevrolet Express and GMC Savana rear- drive vans,

Slip-in-Tube is manufactured through a Computer Numerically

Controlled (CNC) cold-rolling spline process. No material --

neither the inner nor the outer tube -- is machined away. The

process allows the tubes to slide, or telescope, in and out of each

other easily, even under heavy torque. During some durability tests

the Slip-in-Tube Propshaft lasted more than four times longer than

traditional propshafts. As the two pieces of the propshaft

telescope into each other a distance of up to eight inches, it

improves the ability to absorb energy in the event of sudden

impact. This eliminates the need for the heavier slip and stud

yokes typically required with conventional propshafts. Slip-in-Tube

comes in either steel or aluminum. The aluminum version reduces

weight by as much as 30 percent over conventional propshaft

designs. Air Induction Systems Help Reduce Emissions and Wear on

Battery Visteon's Air Induction System with Emissions Control

reduces the evaporative emissions of vehicles when the engine isn't

running. When the engine is running Visteon's AIS sends filtered

air to the engine while providing noise control with minimal power

loss. Engineered to prevent the escape of engine fuel and oil

vapors, the system uses a patent-pending hydrocarbon trapping

technology. Through the chemical process of adsorption, the trap

attracts and holds the fuel vapors during engine-off conditions.

When energy is added to the trap (by ambient air flow during engine

operation) the stored vapors are released back into the engine for

consumption through combustion. Visteon's Air Induction System is

manufactured from 25 to 30 percent Post- Consumer Recycled (PCR)

resins for plastic components. Another product, Visteon's

Integrated Air Induction System features a unique design that

extends the functionality beyond conventional air induction to

include support, insulation and cooling of the battery, thereby

reducing the incidence of battery warranty and replacement. The

system was designed, developed and launched in less than 13 months.

Other benefits include the ability to tune Noise, Vibration and

Harshness (NVH) characteristics to match specific vehicle sound

signatures. Integrated AIS can be incorporated into 4-, 6-, 8- or

10-cylinder engines. Long Life Filtration System Visteon's Long

Life Filtration System is an innovative, patented system and the

only zero-maintenance long-life filter produced by a Tier 1

automotive supplier. This air induction system contains a

reticulated foam filter that traps over 300 grams of dust, salt,

moisture and other corrosives. It delivers a 150,000- to

200,000-mile filter life, virtually eliminating the need for

replacement filters. When packaged with Visteon's Integrated Air

Induction System, this product helps reduce evaporative emissions.

Long Life Filtration won a PACE Award in March from Automotive

News. Negative Thermoforming Makes Cockpits Easier to Recycle,

Allows Higher Level of Craftsmanship Negative Thermoforming is a

process through which Visteon delivers improved quality and

craftsmanship to cockpits, and makes them easier to recycle at the

end of the vehicle's life. The first step of the Negative

Thermoforming process involves heating the thermoplastic olefin

skin, which takes less than one minute. The heated skin is then

drawn into a nickel tool, which shapes the skin to fit the

instrument panel and imprints the grain and lettering through

vacuum pressure. Because more of the cockpit is recyclable when

this process is used, it will enable customers to meet the European

Union's End-of-Life-Vehicle Directive. Visteon Corporation is a

leading full-service supplier that delivers consumer-driven

technology solutions to automotive manufacturers worldwide and

through multiple channels within the global automotive aftermarket.

Visteon has about 72,000 employees and a global delivery system of

more than 200 technical, manufacturing, sales and service

facilities located in 25 countries.

http://www.newscom.com/cgi-bin/prnh/20001201/DEF008LOGO DATASOURCE:

Visteon Corporation CONTACT: Robin Pannecouk, +1-313-755-9121, , or

Greg Gardner, +1-313-755-0927, , both of Visteon Corporation Web

site: http://www.visteon.com/

Copyright

Visteon (NASDAQ:VC)

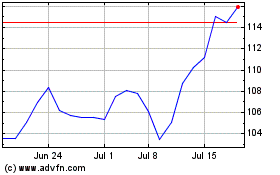

Historical Stock Chart

From Jun 2024 to Jul 2024

Visteon (NASDAQ:VC)

Historical Stock Chart

From Jul 2023 to Jul 2024