LithiumBank Resources Corp. (

TSX-V:

LBNK) (

OTCQX: LBNKF) (FSE: HT9)

(“

LithiumBank” or the “

Company”)

is pleased to announce results from the Direct Lithium Extraction

(DLE) test work on brine from the 100% owned Boardwalk Lithium

Brine Project in Alberta. Test work results indicate the selected

DLE technology to be a highly effective and scalable method of

extracting lithium chloride from the Boardwalk brine.

Highlights

- 93% Lithium Chloride recovery

achieved in under 60 minutes of extraction processing.

- Testing produced a lithium

concentrate with a range between 35-60 times grade increase over

the initial raw lithium brine concentration level.

- High purity lithium concentrates

between 2,500 - 4,000 mg/L (4 g/L) achieved at the end of the DLE

process.

- Boardwalk raw brine characteristics

prove to be well-suited in terms of temperature, pH, grade,

impurities with the DLE Ion Exchange method.

- Results are expected to be

incorporated in the upcoming Preliminary Economic Assessment

(“PEA”) that details and estimates the costs of the engineering and

design of a commercial-scale lithium processing facility at

Boardwalk.

LithiumBank engaged Conductive Energy Inc.

(“Conductive”) from Alberta, Canada to test their proprietary

Direct Lithium Extraction (“DLE”) technology using brine collected

from the Leduc Formation at the Boardwalk project. Conductive has

proprietary Ion Exchange (“IX”) material (also known as a bead or

resin) that LithiumBank has tested to selectively recover lithium

from the Company’s Boardwalk brine. Conductive’s IX materials are

safer than other commonly known materials, such as manganese-based

sieves, and is produced in Conductive’s own manufacturing facility

in North America. Their IX material is currently being piloted on

two other Lithium DLE projects in North America.

The purpose of the DLE test work was to

determine the ideal parameters whereby the highest level of lithium

recovery is achieved in the shortest amount of time while using the

least amount of IX material. This test work was successful in

achieving 93% recovery of high-purity, high concentrate lithium

chloride (LiCl) within 60 minutes. The success of this test work

provides the technical support required to progress the Preliminary

Economic Assessment (“PEA”) in designing an on-site commercial

scale lithium production facility.

Kevin Piepgrass, LithiumBank COO states, “We put

Conductive’s DLE technology through a very comprehensive test

program and their proprietary ion-exchange material has proven to

be very effective in extracting lithium from our Boardwalk brine.

The collaboration of Hatch and Conductive Energy Inc. has resulted

in high-quality data set that can confidently be used in the

processing design and engineering of a commercial scale lithium

processing facility. This will be instrumental for delivering a

robust PEA of the Boardwalk Lithium Brine Project. As part of

LithiumBank’s long-term strategy, the Company continues to build a

strong technical foundation in lithium brine development that is

expected to benefit Boardwalk as well as the Company’s 100 percent

owned Park Place and Kindersley Projects.”

DLE testing was conducted over a four-month

period at Conductive’s Calgary laboratory, to examine the IX

material’s spectrum of capabilities and limitations. These tests

examine the brine characteristics such as temperature, grade,

interactions with impurities, and pH, and test it with several

different conditions that can be controlled such as;

- Loading capacity at temperatures

ranging from 60-80 degrees Celsius;

- Loading capacity with specified

amounts of IX material;

- Loading capacity over specified

time intervals;

- Lithium recovery after elution

(washing of the IX material);

- Elution testing at specified pH

levels; and

- Elution testing at specified

temperatures.

LithiumBank, Hatch Ltd.

(“Hatch”), and Conductive are expected to continue

to work together to optimize their DLE process through additional

tests. Further testing and pre-concentration may improve the

reported recovery and residence time that is expected to be used in

the PEA.

The Conductive IX material lithium extraction process has two

stages, loading and elution.

The loading cycle is the front end of the DLE

process where brine interacts directly with the IX material and

undergoes a simple reaction in which lithium ions are

preferentially attracted to the IX material. After a specific

amount of time, as determined by the test work, the IX material is

‘loaded’ and cannot attract additional lithium ions. This is the

end of the loading stage, and the IX material is ready for the

elution stage.

The elution stage takes the IX material out of

the brine to separate the lithium from the IX material in a washing

cycle. The residual lithium-depleted brine is then sent to existing

oil wells for reinjection into the subsurface. The elution stage of

the DLE achieved concentrations up to 4,000 mg/L (4 g/L) LiCl. The

optimization of the elution stage is ongoing and is expected to be

between the range of 2,500 – 4,000 mg/L.

The washed IX material can then be reused to

recover lithium from the further brine multiple times. The IX

material, based on Conductive’s previous experience, is expected to

be reused over 1000 times before it reaches its life-cycle

(Conductive has not yet conducted tests with Boardwalk brine to

measures longevity of the IX material).

After the DLE process, the concentrated brine is

then required to undergo additional steps before it is upgraded to

a battery grade lithium product such as lithium carbonate (LC) or

lithium hydroxide monohydrate (LHM). The processes following the

DLE are being evaluated by Hatch and is expected to be incorporated

in the PEA.

Figure 1. Boardwalk Lithium Brine Project mineral

title map highlighting the "Production Zone"

Brine used in the DLE test work was collected in

August 2021 from Well 100/09-26-068-22WS/OO located in the South

Sturgeon Lake oilfield (see figure 1), within the “Production

Zone”, and has a reported average grade of 73.8 mg/L Lithium (as

previously reported in LithiumBank news release dated June 28,

2022).

LithiumBank first engaged Hatch in August 2021

to conduct a comparative study of a number of North American based

DLE technologies that could deliver a high purity Lithium Chloride

(LiCI) concentrate to be used in commercial, battery grade lithium

chemical production from the Boardwalk brine. After an iterative

process by Hatch, LithiumBank has narrowed the potential technology

providers, with Conductive technology providing the most optimal

results.

Table 1. Boardwalk (formally Sturgeon Lake) Leduc Formation

Li-brine NI 43-101 inferred resource estimate presented as a global

(total) resource.

|

Reporting parameter |

Leduc Formation Reef Domain |

|

Aquifer volume |

321.99 (km3) |

|

Brine volume |

16.72 (km3) |

|

Average lithium concentration |

67.1 (mg/L) |

|

Average porosity |

5.3 (%) |

|

Average brine in pore space |

98.0 (%) |

|

Total elemental lithium resource |

1,122,000 (tonnes) |

|

Total lithium carbonate equivalent |

5,973,000 tonnes (LCE) |

Note 1: Mineral resources are not mineral

reserves and do not have demonstrated economic viability. There is

no guarantee that all or any part of the mineral resource will be

converted into a mineral reserve. The estimate of mineral resources

may be materially affected by geology, environment, permitting,

legal, title, taxation, socio-political, marketing, or other

relevant issues.Note 2: The weights are reported in metric tonnes

(1,000 kg or 2,204.6 lbs).Note 3: Tonnage numbers are rounded to

the nearest 1,000 unit.Note 4: In a ‘confined' aquifer (as reported

herein), porosity is a proxy for specific yield.Note 5: The

resource estimation was completed and reported using a cut-off of

50 mg/L Li.Note 6: In order to describe the resource in terms of

industry standard, a conversion factor of 5.323 is used to convert

elemental Li to Li2CO3, or Lithium Carbonate Equivalent

The Boardwalk (formally Sturgeon Lake) Leduc

Formation Li-brine inferred resource, with an effective date of May

18th, 2021, is globally estimated at 1,122,000 tonnes of elemental

Li at an average lithium concentration of 67.1 mg/L Li in 16.7 km3

of formation brine volume (Table 2). The global (total) lithium

carbonate equivalent (LCE) for the inferred mineral resource is

5,973,000 tonnes LCE at an average grade of 67.1 mg/L Li (as

reported May 31, 2022).

Mineral resources are not mineral reserves and

do not have demonstrated economic viability. There is no guarantee

that all or any part of the mineral resource will be converted into

a mineral reserve. While bench-scale, and demonstration pilot

plants operated by companies other than LithiumBank are reportedly

having success in the recovery of high purity battery-grade lithium

from subsurface confined aquifers, DLE technology is in the

development stage and has not yet been proven at commercial

scale.

The scientific and technical disclosure in this

news release has been reviewed and approved by Mr. Kevin Piepgrass

(Chief Operations Officer, LithiumBank Resources Corp.), who is a

Member of the Association of Professional Engineers and

Geoscientists of the province of BC (APEGBC) and is a Qualified

Person (QP) for the purposes of National Instrument 43-101. Mr.

Piepgrass consents to the inclusion of the data in the form and

context in which it appears.

About LithiumBank Resources

Corp.

LithiumBank Resources Corp. is an exploration

and development company focused on lithium-enriched brine projects

in Western Canada where low-carbon-impact, rapid DLE technology can

be deployed. LithiumBank currently holds over four million acres of

mineral titles, 3.68M acres in Alberta and 326K acres in

Saskatchewan. LithiumBank’s mineral titles are strategically

positioned over known reservoirs that provide a unique combination

of scale, grade and exceptional flow rates that are necessary for a

large-scale direct brine lithium production. LithiumBank is

advancing and de-risking several projects in parallel of the

Boardwalk Lithium Brine Project.

About Hatch Ltd.

Hatch is an engineering firm that has expertise

in engineering, procurement, and construction management (EPCM) of

lithium processing plants. LithiumBank's management team is working

with senior members of Hatch's lithium group, with recent DLE

project experience, to assess DLE technology options for the

Boardwalk project. The results of the technology assessment

performed by Hatch will be used in preparing a NI 43-101

Preliminary Economic Assessment (PEA) in respect of the Boardwalk

Project. This PEA is a key steppingstone towards the design of a

commercial facility that the Company anticipates will produce

battery grade lithium chemical product.

Contact:

Rob ShewchukCEO &

Directorrob@lithiumbank.ca(778) 987-9767

Neither the TSX Venture Exchange nor its

Regulation Services Provider (as that term is defined in the

policies of the TSX Venture Exchange) accepts responsibility for

the adequacy or accuracy of this release.

Cautionary Statement Regarding Forward Looking

Statements

This release includes certain statements and

information that may constitute forward-looking information within

the meaning of applicable Canadian securities laws. All statements

in this news release, other than statements of historical facts,

including statements regarding future estimates, plans, objectives,

timing, assumptions or expectations of future performance,

including without limitation, statements regarding: the DLE test

work results, the inclusion of DLE test work results and the

processes following the DLE in the PEA of the Boardwalk Lithium

Brine Project, the effects of the DLE test work results on the

Boardwalk, Park Place and Kindersley Projects, the Company, Hatch

and Conductive’s ability to optimize their DLE process and the

Company’s ability to produce battery grade lithium chemical

products. Such statements are forward-looking statements and

contains forward-looking information.

Generally, forward-looking statements and

information can be identified by the use of forward-looking

terminology such as “intends" or “anticipates", or variations of

such words and phrases or statements that certain actions, events

or results “may", “could", “should", “would" or “occur".

Forward-looking statements are based on certain material

assumptions and analysis made by the Company and the opinions and

estimates of management as of the date of this press release,

including: the DLE test work results and the processes following

the DLE are expected to be included in the PEA of the Boardwalk

Lithium Brine Project, the expected effects of the DLE test work

results on the Boardwalk, Park Place and Kindersley Projects and

the Company’s anticipated production of battery grade lithium

chemical products. Such statements are forward-looking statements

and contains forward-looking information.

These forward-looking

statements are subject to known and unknown risks, uncertainties

and other factors that may cause the actual results, level of

activity, performance or achievements of the Company to be

materially different from those expressed or implied by such

forward-looking statements or forward-looking information.

Important factors that may cause actual results to vary, include,

without limitation: that the DLE test work results will differ from

the anticipated results, that the DLE test work results and the

processes following the DLE will not be included in the PEA of the

Boardwalk Lithium Brine Project, that the effects of the DLE test

work results on the Boardwalk, Park Place and Kindersley Projects

will not be as anticipated and that the Company, Hatch and

Conductive’s will not produce battery grade lithium chemical

products.

Although management of

the Company has attempted to identify important factors that could

cause actual results to differ materially from those contained in

forward-looking statements or forward-looking information, there

may be other factors that cause results not to be as anticipated,

estimated or intended. There can be no assurance that such

statements will prove to be accurate, as actual results and future

events could differ materially from those anticipated in such

statements. Accordingly, readers should not place undue reliance on

forward-looking statements and forward-looking information. Readers

are cautioned that reliance on such information may not be

appropriate for other purposes. The Company does not undertake to

update any forward-looking statement, forward-looking information

or financial out-look that are incorporated by reference herein,

except in accordance with applicable securities laws.

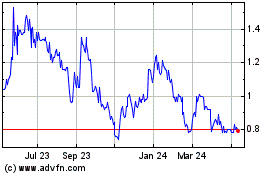

LithiumBank Resources (TSXV:LBNK)

Historical Stock Chart

From Nov 2024 to Dec 2024

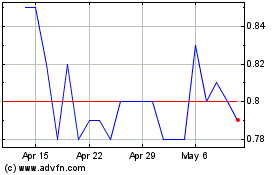

LithiumBank Resources (TSXV:LBNK)

Historical Stock Chart

From Dec 2023 to Dec 2024