Carpenter Technology Introduces New Alloy That Combines High Strength and Toughness Properties at a Reasonable Cost

March 24 2011 - 10:33AM

Business Wire

Carpenter Technology Corporation (NYSE:CRS) has developed a new

ultra high-strength steel (UHSS) alloy that is a lower cost

alternative to many cobalt-containing precipitation hardenable

alloys. TEMPER TOUGH™ alloy is an air-melted, cobalt-free quench

and tempered alloy that has a unique combination of high strength

and high toughness attributes that may allow designers and

engineers to achieve an extended cycle life where components are

under high loads with constant stress of intense, repetitive

motion.

This alloy is a readily available, lower cost alternative to

cobalt-containing precipitation hardenable alloys for a variety of

general purpose tooling, industrial and automotive applications,

especially those in which designers may be seeking to lighten the

weight and increase the longevity of their products.

TEMPER TOUGH alloy is able to attain both a typical strength of

290 ksi ultimate tensile strength (UTS) and a typical range of

toughness between 60 and 65 ksi√in. TEMPER TOUGH alloy has also

demonstrated superior fatigue resistance properties (axial-axial)

of 120 ksi (827 MPa) compared to traditional quench-and-temper

alloy steels averaging 79-85 ksi (545-586 MPa).

The attributes of TEMPER TOUGH alloy make it a candidate for

applications in high-demand crank cases, drive trains, power

trains, structural members, suspensions, and industrial tooling,

especially when designers are looking for affordable solutions to

reduce the weight of parts and/or components without sacrificing

performance.

Carpenter Technology’s development of TEMPER TOUGH alloy is an

example of the company’s commitment to technical leadership in

specialty metals. Carpenter has experienced technical service

engineers and technicians, metallurgists and market specialists who

are available to assist its customers with material development

selection, specifications, properties and fabrication

characteristics.

Carpenter Technology currently offers TEMPER TOUGH alloy in bar

product forms.

For more information about TEMPER TOUGH alloy or other alloys

visit Carpenter’s website at www.cartech.com or send an e-mail to

service@cartech.com or telephone (610) 208-2000 or (800)

654-6543.

About Carpenter Technology

Carpenter Technology produces and distributes conventional and

powder metal specialty alloys, including stainless steels, titanium

alloys, tool steels and superalloys. Information about Carpenter

can be found at www.cartech.com.

Forward-Looking Statements

Except for historical information, all other information in this

news release consists of forward-looking statements within the

meaning of the Private Securities Litigation Act of 1995. These

forward-looking statements are subject to risks and uncertainties

that could cause actual results to differ from those projected,

anticipated or implied. The most significant of these uncertainties

are described in Carpenter's filings with the Securities and

Exchange Commission including its annual report on Form 10-K for

the year ended June 30, 2010 and the quarterly reports on Form 10-Q

for the quarters ended September 30, 2010 and December 31, 2010 and

the exhibits attached to those filings. They include but are not

limited to: the cyclical nature of the specialty materials business

and certain end-use markets, including aerospace, industrial,

automotive, consumer, medical, and energy, or other influences on

Carpenter's business such as new competitors, the consolidation of

competitors, customers, and suppliers or the transfer of

manufacturing capacity from the United States to foreign countries;

the ability of Carpenter to achieve cost savings, productivity

improvements or process changes; the ability to recoup increases in

the cost of energy, raw materials, freight or other factors;

domestic and foreign excess manufacturing capacity for certain

metals; fluctuations in currency exchange rates; the degree of

success of government trade actions; the valuation of the assets

and liabilities in Carpenter's pension trusts and the accounting

for pension plans; possible labor disputes or work stoppages; the

potential that our customers may substitute alternate materials or

adopt different manufacturing practices that replace or limit the

suitability of our products; the availability of credit facilities

to Carpenter, its customers or other members of the supply chain;

the ability to obtain energy or raw materials; our manufacturing

processes are dependent upon highly specialized equipment located

primarily in one facility in Reading, Pennsylvania for which there

may be limited alternatives if there are significant equipment

failures or catastrophic event; our future success depends on the

continued service and availability of key personnel, including

members of our executive management team, management, metallurgists

and other skilled personnel and the loss of these key personnel

could affect our ability to perform until suitable replacements are

found; the ability to successfully integrate the Amega West

Services, LLC acquisition; the ability to achieve additional

opportunities for selling specialty alloys into the oil & gas

market; and the ability to expand Amega West’s manufacturing

capacity, rental fleet and service centers. Any of these factors

could have an adverse and/or fluctuating effect on Carpenter's

results of operations. The forward-looking statements in this

document are intended to be subject to the safe harbor protection

provided by Section 27A of the Securities Act of 1933, as amended,

and Section 21E of the Securities Exchange Act of 1934, as amended.

Carpenter undertakes no obligation to update or revise any

forward-looking statements.

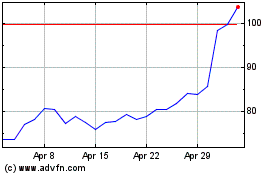

Carpenter Technology (NYSE:CRS)

Historical Stock Chart

From Jun 2024 to Jul 2024

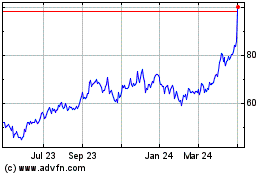

Carpenter Technology (NYSE:CRS)

Historical Stock Chart

From Jul 2023 to Jul 2024