false

0001334933

0001334933

2024-11-07

2024-11-07

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 8-K

CURRENT REPORT

Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

November 7, 2024

Date of Report (Date of earliest event reported)

URANIUM ENERGY CORP.

(Exact name of registrant as specified in its charter)

|

Nevada

|

001-33706

|

98-0399476

|

|

(State or other jurisdiction of incorporation)

|

(Commission File Number)

|

(IRS Employer Identification No.)

|

|

500 North Shoreline, Ste. 800

Corpus Christi, Texas

|

78401

|

|

(U.S. headquarters)

|

(Zip Code)

|

|

1830 – 1188 West Georgia Street

Vancouver, British Columbia, Canada

|

V6E 4A2

|

|

(Canadian headquarters)

|

(Zip Code)

|

(Address of principal executive offices)

(361) 888-8235

Registrant’s telephone number, including area code

Not applicable.

(Former name or former address, if changed since last report)

Check the appropriate box below if the Form 8-K is intended to simultaneously satisfy the filing obligation of the registrant under any of the following provisions:

|

☐

|

Written communications pursuant to Rule 425 under the Securities Act (17 CFR 230.425)

|

| ☐ |

Soliciting material pursuant to Rule 14a-12 under the Exchange Act (17 CFR 240.14a-12)

|

| ☐ |

Pre-commencement communications pursuant to Rule 14d-2(b) under the Exchange Act (17 CFR 240.14d-2(b))

|

| ☐ |

Pre-commencement communications pursuant to Rule 13e-4(c) under the Exchange Act (17 CFR 240.13e-4(c))

|

Securities registered pursuant to Section 12(b) of the Act:

|

Title of each class

|

Trading Symbol (s)

|

Name of each exchange on which registered

|

|

Common Stock

|

UEC

|

NYSE American

|

Indicate by check mark whether the registrant is an emerging growth company as defined in as defined in Rule 405 of the Securities Act of 1933 (Section 230.405 of this chapter) or Rule 12b-2 of the Securities Exchange Act of 1934 (Section 240.12b-2 of this chapter).

Emerging growth company ☐

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. ☐

__________

Uranium Energy Corp. has completed a S-K 1300 Technical Report Summary entitled “S-K 1300 Initial Assessment Report – Roughrider Uranium Project, Saskatchewan, Canada”, dated November 5, 2024, for its Roughrider Project.

A copy of such Technical Report Summary is attached as Exhibit 96.1 hereto.

|

Item 9.01

|

Financial Statements and Exhibits

|

|

(a)

|

Financial Statements of Business Acquired

|

Not applicable.

|

(b)

|

Pro forma Financial Information

|

Not applicable.

|

(c)

|

Shell Company Transaction

|

Not applicable.

|

Exhibit

|

|

Description

|

|

23.1

|

|

|

|

23.2

|

|

|

|

23.3

|

|

|

|

23.4

|

|

|

|

23.5

|

|

|

|

96.1

|

|

|

|

104

|

|

Cover Page Interactive Data File (the cover page XBRL tags are embedded within the inline XBRL document).

|

__________

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned hereunto duly authorized.

|

|

URANIUM ENERGY CORP.

|

|

|

|

|

|

|

|

DATE: November 7, 2024.

|

By:

|

/s/ Josephine Man |

|

|

|

|

Josephine Man, Chief Financial

Officer, Treasurer and Secretary

|

|

__________

Exhibit 23.1

CONSENT OF TETRA TECH CANADA INC.

We consent to the use of our name, or any quotation from, or summarization of the technical report summary entitled “S-K 1300 Initial Assessment Report – Roughrider Uranium Project, Saskatchewan, Canada” dated November 5, 2024 (the “TRS”), that we prepared, included or incorporated by reference in:

| |

(i)

|

the Current Report on Form 8-K dated November 7, 2024 (the “8-K”) of Uranium Energy Corp. (the “Company”) being filed with the United States Securities and Exchange Commission;

|

| |

(ii)

|

the Company’s Form S-3 Registration Statements (File Nos. 333-220404, 333-267992 and 333-268417), and any amendments or supplements thereto; and

|

| |

(iii)

|

the Company’s Form S-8 Registration Statements (File Nos. 333-147626, 333-162264, 333-172092, 333-192462, 333-201423, 333-213500, 333-227023, 333-233736, 333-249679, 333-262197, 333-273321 and 333-280795); and any amendments or supplements thereto.

|

We further consent to the filing of the TRS as exhibit 96.1 to the 8-K.

Tetra Tech Canada Inc.

/s/ Hassan Ghaffari

Hassan Ghaffari, M.A.Sc., P.Eng.

Director of Metallurgy

Date: November 7, 2024.

Exhibit 23.2

CONSENT OF UNDERSTOOD MINERAL RESOURCES LTD.

We consent to the use of our name, or any quotation from, or summarization of the technical report summary entitled “S-K 1300 Initial Assessment Report – Roughrider Uranium Project, Saskatchewan, Canada” dated November 5, 2024 (the “TRS”), that we prepared, included or incorporated by reference in:

| |

(i)

|

the Current Report on Form 8-K dated November 7, 2024 (the “8-K”) of Uranium Energy Corp. (the “Company”) being filed with the United States Securities and Exchange Commission;

|

| |

(ii)

|

the Company’s Form S-3 Registration Statements (File Nos. 333-220404, 333-267992 and 333-268417), and any amendments or supplements thereto; and

|

| |

(iii)

|

the Company’s Form S-8 Registration Statements (File Nos. 333-147626, 333-162264, 333-172092, 333-192462, 333-201423, 333-213500, 333-227023, 333-233736, 333-249679, 333-262197, 333-273321 and 333-280795); and any amendments or supplements thereto.

|

We further consent to the filing of the TRS as exhibit 96.1 to the 8-K.

Understood Mineral Resources Ltd.

/s/ Matt Batty

Matt Batty, Geostatistican and Owner

Date: November 7, 2024.

Exhibit 23.3

CONSENT OF TERRACON GEOTECHNIQUE LTD.

We consent to the use of our name, or any quotation from, or summarization of the technical report summary entitled “S-K 1300 Initial Assessment Report – Roughrider Uranium Project, Saskatchewan, Canada” dated November 5, 2024 (the “TRS”), that we prepared, included or incorporated by reference in:

| |

(i)

|

the Current Report on Form 8-K dated November 7, 2024 (the “8-K”) of Uranium Energy Corp. (the “Company”) being filed with the United States Securities and Exchange Commission;

|

| |

(ii)

|

the Company’s Form S-3 Registration Statements (File Nos. 333-220404, 333-267992 and 333-268417), and any amendments or supplements thereto; and

|

| |

(iii)

|

the Company’s Form S-8 Registration Statements (File Nos. 333-147626, 333-162264, 333-172092, 333-192462, 333-201423, 333-213500, 333-227023, 333-233736, 333-249679, 333-262197, 333-273321 and 333-280795); and any amendments or supplements thereto.

|

We further consent to the filing of the TRS as exhibit 96.1 to the 8-K.

Terracon Geotechnique Ltd.

/s/ J. Roland Tosney

J. Roland Tosney, P.Eng.

Principal Mining Geotechnical Engineer

Date: November 7, 2024.

Exhibit 23.4

CONSENT OF SNOWDEN OPTIRO

We consent to the use of our name, or any quotation from, or summarization of the technical report summary entitled “S-K 1300 Initial Assessment Report – Roughrider Uranium Project, Saskatchewan, Canada” dated November 5, 2024 (the “TRS”), that we prepared, included or incorporated by reference in:

| |

(i)

|

the Current Report on Form 8-K dated November 7, 2024 (the “8-K”) of Uranium Energy Corp. (the “Company”) being filed with the United States Securities and Exchange Commission;

|

| |

(ii)

|

the Company’s Form S-3 Registration Statements (File Nos. 333-220404, 333-267992 and 333-268417), and any amendments or supplements thereto; and

|

| |

(iii)

|

the Company’s Form S-8 Registration Statements (File Nos. 333-147626, 333-162264, 333-172092, 333-192462, 333-201423, 333-213500, 333-227023, 333-233736, 333-249679, 333-262197, 333-273321 and 333-280795); and any amendments or supplements thereto.

|

We further consent to the filing of the TRS as exhibit 96.1 to the 8-K.

Snowden Optiro

/s/ Damian Gregory

Damian Gregory, P.Eng., Principal Consultant

Date: November 7, 2024.

Exhibit 23.5

CONSENT OF CLIFTON ENGINEERING GROUP LTD.

We consent to the use of our name, or any quotation from, or summarization of the technical report summary entitled “S-K 1300 Initial Assessment Report – Roughrider Uranium Project, Saskatchewan, Canada” dated November 5, 2024 (the “TRS”), that we prepared, included or incorporated by reference in:

| |

(i)

|

the Current Report on Form 8-K dated November 7, 2024 (the “8-K”) of Uranium Energy Corp. (the “Company”) being filed with the United States Securities and Exchange Commission;

|

| |

(ii)

|

the Company’s Form S-3 Registration Statements (File Nos. 333-220404, 333-267992 and 333-268417), and any amendments or supplements thereto; and

|

| |

(iii)

|

the Company’s Form S-8 Registration Statements (File Nos. 333-147626, 333-162264, 333-172092, 333-192462, 333-201423, 333-213500, 333-227023, 333-233736, 333-249679, 333-262197, 333-273321 and 333-280795); and any amendments or supplements thereto.

|

We further consent to the filing of the TRS as exhibit 96.1 to the 8-K.

Clifton Engineering Group Ltd.

/s/ Mark Wittrup

Mark Wittrup

Vice-President Environmental and Regulatory Affairs

Date: November 7, 2024.

Exhibit 96.1

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

TABLE OF CONTENTS

|

1.0 Executive Summary

|

1-1 |

|

1.1 Property Description

|

1-1 |

|

1.2 Geology and Mineralization

|

1-1 |

|

1.3 Status of Exploration and Development

|

1-1 |

|

1.4 Mineral Processing and Metallurgical Testing

|

1-2 |

|

1.5 Mineral Resource Estimate

|

1-2 |

|

1.6 Mining Methods

|

1-3 |

|

1.7 Processing and Recovery Methods

|

1-3 |

|

1.8 Project Infrastructure

|

1-4 |

|

1.9 Environmental, Permitting and Social License

|

1-4 |

|

1.10 Capital and Operating Costs

|

1-4 |

|

1.11 Economic Analysis

|

1-5 |

|

1.12 Conclusions and Recommendations

|

1-6 |

| |

|

|

2.0 Introduction

|

2-1 |

|

2.1 Background

|

2-1 |

|

2.2 Registrant for Whom the Technical Report Summary was Prepared

|

2-1 |

|

2.3 Terms of Reference and Purpose of the Report

|

2-1 |

|

2.4 Source of Information and Data

|

2-1 |

|

2.5 Qualified Persons

|

2-2 |

|

2.6 Details of Personal Inspection

|

2-3 |

| |

|

|

3.0 Property Description

|

3-1 |

|

3.1 Coordinate System

|

3-1 |

|

3.2 Project Location

|

3-1 |

|

3.3 Mineral Lease

|

3-3 |

|

3.4 Mineral Rights

|

3-4 |

|

3.4.1 Mineral Claim and Mineral Lease

|

3-5 |

|

3.4.2 Surface Lease

|

3-5 |

|

3.5 Violations and Fines

|

3-6 |

|

3.6 Royalties or Similar Interest

|

3-6 |

|

3.6.1 Uranium Crown Royalty

|

3-6 |

|

3.6.2 Roughrider Royalty

|

3-7 |

|

3.6.3 Corporation Capital Tax

|

3-7 |

| |

|

|

4.0 Accessibility, Climate, Local Resources, Infrastructure, and Physiography

|

4-1 |

|

4.1 Topography and Elevation

|

4-1 |

|

4.2 Vegetation (and Habitats/Species of Conservation Importance)

|

4-1 |

|

4.3 Property Access

|

4-3 |

|

4.4 Climate and Length of Operating Season

|

4-3 |

|

4.5 Catchments and Water Resources

|

4-4 |

|

4.6 Availability of Infrastructure

|

4-4 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

5.0 History

|

5-1 |

|

5.1 Pre-Discovery

|

5-1 |

|

5.2 Discovery to Present

|

5-2 |

|

5.3 Historical Production

|

5-3 |

| |

|

|

6.0 Geological Setting, Mineralization, and Deposit

|

6-1 |

|

6.1 Regional Geology

|

6-1 |

|

6.2 Local Geology

|

6-2 |

|

6.2.1 Hearne Subprovince

|

6-2 |

|

6.2.2 Athabasca Group

|

6-3 |

|

6.2.3 Surficial Geology

|

6-3 |

|

6.3 Property Geology

|

6-3 |

|

6.3.1 Structural Geology

|

6-6 |

|

6.3.2 Mineralization

|

6-7 |

|

6.3.3 Alteration

|

6-11 |

|

6.4 Deposit Type

|

6-12 |

| |

|

|

7.0 Exploration

|

7-1 |

|

7.1 Exploration

|

7-1 |

|

7.1.1 2005 GEOTEM and Aeromagnetic Survey

|

7-1 |

|

7.1.2 2006 Logging of Historic Drill Core

|

7-1 |

|

7.1.3 2007 Aeromagnetic Survey

|

7-1 |

|

7.1.4 2007 Tempest and Magnetic Gradiometer Survey

|

7-1 |

|

7.1.5 Ambient Noise Tomography

|

7-1 |

|

7.1.6 Photo-Relogging

|

7-2 |

|

7.2 Exploration Drilling

|

7-2 |

|

7.2.1 Drilling Methodology and Procedures

|

7-5 |

|

7.2.2 Drillhole Surveys

|

7-6 |

|

7.2.3 Geophysical Surveys

|

7-7 |

|

7.2.4 Drill Core Logging

|

7-7 |

|

7.2.5 Drill Core Sampling

|

7-8 |

|

7.2.6 Core Recovery

|

7-9 |

|

7.2.7 Hydrogeologic Characterization

|

7-12 |

|

7.2.8 Geotechnical Characterization

|

7-15 |

| |

|

|

8.0 Sample Preparation, Analyses, and Security

|

8-1 |

|

8.1 Drill Core Preparation and Analysis

|

8-1 |

|

8.2 Specific Gravity Sample Preparation and Analysis

|

8-3 |

|

8.3 PIMA Sample Preparation and Analysis

|

8-3 |

|

8.4 Quality Assurance and Quality Control

|

8-3 |

|

8.4.1 Blanks

|

8-3 |

|

8.4.2 Duplicates

|

8-4 |

|

8.4.3 Certified Reference Materials (CRM)

|

8-7 |

|

8.4.4 SRC Internal QAQC Report

|

8-12 |

|

8.4.5 External Duplicates (Umpires)

|

8-13 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

8.4.6 Density Samples

|

8-16 |

|

8.4.7 Umpire Density Samples

|

8-18 |

|

8.5 Sample Security

|

8-19 |

|

8.6 QP Opinion of the Adequacy of Sample Preparation, Security and Analytical Procedures

|

8-19 |

| |

|

|

9.0 Data Verification

|

9-1 |

|

9.1 Site Visit

|

9-1 |

|

9.2 Core and Collar Review

|

9-1 |

|

9.3 Database Validation

|

9-4 |

|

9.4 Review of UEC QA/QC

|

9-5 |

|

9.5 Limitations

|

9-5 |

|

9.6 Qualified Person’s Opinion

|

9-5 |

| |

|

|

10.0 Mineral Processing and Metallurgical Testing

|

10-1 |

|

10.1 Metallurgical Test Work Program

|

10-1 |

|

10.2 SGS Canada Phase 1 Test Work (2008 – 2009)

|

10-1 |

|

10.2.1 Test Program

|

10-1 |

|

10.2.2 Phase 1 Test Results

|

10-3 |

|

10.3 SGS Canada Phase 2 Test Work (2009 – 2010)

|

10-5 |

|

10.3.1 Test Program

|

10-5 |

|

10.3.2 Phase 2 Test Results

|

10-5 |

|

10.4 SGS Canada Phase 3 Test Work (2010 – 2011)

|

10-8 |

|

10.4.1 Test Program

|

10-8 |

|

10.4.2 Phase 3 Test Results

|

10-8 |

|

10.5 SGS Canada Phase 4 Test Work (2011 – 2012)

|

10-12 |

|

10.5.1 Test Program

|

10-12 |

|

10.5.2 Phase 4 Test Results

|

10-12 |

|

10.6 SRC Phase 5 Test Work (2013)

|

10-14 |

|

10.6.1 Phase 5 Test Results

|

10-14 |

|

10.7 Summary

|

10-16 |

|

10.8 QP Opinion

|

10-16 |

| |

|

|

11.0 Mineral Resource Estimates

|

11-1 |

|

11.1 Introduction

|

11-1 |

|

11.2 Source Database

|

11-1 |

|

11.2.1 Drillholes

|

11-2 |

|

11.3 Geologic Domaining

|

11-3 |

|

11.3.1 Lithology Model

|

11-3 |

|

11.3.2 Structural Model

|

11-4 |

|

11.3.3 Mineralization Model

|

11-4 |

|

11.3.4 Boundary Analysis

|

11-7 |

|

11.4 Density and Missing Values

|

11-11 |

|

11.5 Probe Grade Conversion

|

11-12 |

|

11.6 Compositing and Statistical Analysis

|

11-13 |

|

11.6.1 Compositing

|

11-13 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

11.6.2 Declustering

|

11-13 |

|

11.6.3 Outlier Capping and Restrictions

|

11-13 |

|

11.6.4 Representative Distributions

|

11-16 |

|

11.7 Variography

|

11-17 |

|

11.8 Block Model Estimation

|

11-23 |

|

11.8.1 Estimation Overview

|

11-23 |

|

11.8.2 Block Model Definition

|

11-23 |

|

11.8.3 Interpolation Methods

|

11-24 |

|

11.9 Model Validation

|

11-29 |

|

11.9.1 Global Bias

|

11-29 |

|

11.9.2 Histogram

|

11-30 |

|

11.9.3 Visual Inspection

|

11-31 |

|

11.9.4 Swath Plots

|

11-33 |

|

11.10 Mineral Resource Classification

|

11-35 |

|

11.11 Cut-off Grade and Reasonable Prospects of Economic Extraction

|

11-40 |

|

11.12 Mineral Resource Statement

|

11-40 |

|

11.13 Mineral Resource Uncertainty

|

11-41 |

|

11.13.1 Specific Identified Risks

|

11-41 |

|

11.13.2 Generic Mineral Resource Uncertainty

|

11-42 |

|

11.14 Mineral Resource Sensitivity

|

11-42 |

|

11.15 Audit Findings

|

11-44 |

|

11.16 Recommendations

|

11-45 |

|

11.17 QP Opinion

|

11-46 |

| |

|

|

12.0 Mineral Reserve Estimates

|

12-1 |

| |

|

|

13.0 Mining Methods

|

13-1 |

|

13.1 Geotechnical and Hydrological Information

|

13-1 |

|

13.1.1 Geotechnical

|

13-1 |

|

13.1.2 Hydrogeological

|

13-3 |

|

13.2 Mining Methods

|

13-3 |

|

13.2.1 Mining Blocks

|

13-3 |

|

13.2.2 Mine Access

|

13-4 |

|

13.2.3 Lateral Development

|

13-5 |

|

13.2.4 Cross-Cuts

|

13-5 |

|

13.2.5 Ventilation Shaft

|

13-5 |

|

13.2.6 Backfill

|

13-6 |

|

13.2.7 Stoping

|

13-6 |

|

13.2.8 Ground Support

|

13-6 |

|

13.2.9 Ground Freezing

|

13-7 |

|

13.3 Cut-off

|

13-8 |

|

13.4 Mine Layout

|

13-10 |

|

13.4.1 Stope Shape Design

|

13-10 |

|

13.4.2 Dilution

|

13-11 |

|

13.4.3 Mining Recovery

|

13-11 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

13.5 Mining Equipment

|

13-11 |

|

13.6 Fixed Mining Equipment

|

13-12 |

|

13.6.1 Fans

|

13-12 |

|

13.6.2 Heating

|

13-12 |

|

13.6.3 Electrical Distribution

|

13-13 |

|

13.6.4 Grade Control

|

13-13 |

|

13.6.5 Refuge System

|

13-13 |

|

13.7 Mining Labour

|

13-13 |

|

13.8 Ventilation

|

13-13 |

|

13.8.1 Airflow Assumptions

|

13-13 |

|

13.8.2 Airflow Velocities

|

13-14 |

|

13.9 Secondary Egress

|

13-14 |

|

13.10 Mine Schedule

|

13-14 |

|

13.10.1 Production Cycle

|

13-14 |

|

13.10.2 Production Rates

|

13-15 |

|

13.10.3 Mining Sequence

|

13-17 |

|

13.10.4 Development Schedule

|

13-17 |

|

13.10.5 Production Schedule

|

13-19 |

|

13.11 Indicated Category Only

|

13-22 |

|

13.12 Potential Mill Feed

|

13-22 |

| |

|

|

14.0 Processing and Recovery Methods

|

14-1 |

|

14.1 Flowsheet Development

|

14-1 |

|

14.2 Process Description

|

14-3 |

|

14.3 Reagents and Consumables

|

14-5 |

|

14.4 Plant Services

|

14-7 |

|

14.4.1 Water Supply and Distribution

|

14-7 |

|

14.4.2 Air Supply and Distribution

|

14-7 |

|

14.4.3 Instrumentation and Process Control

|

14-7 |

|

14.4.4 Quality Control

|

14-7 |

|

14.5 Annual Production Estimate

|

14-7 |

|

14.6 Staffing

|

14-8 |

|

14.7 QP Opinion

|

14-8 |

| |

|

|

15.0 Project Infrastructure

|

15-1 |

|

15.1 External and Internal Site Access Roads

|

15-1 |

|

15.2 Underground Mine and Surface Support Infrastructure

|

15-1 |

|

15.3 Processing Plant Infrastructure

|

15-3 |

|

15.4 Water Treatment Plant

|

15-5 |

|

15.5 Site Ancillary Infrastructure

|

15-5 |

|

15.5.1 Truck Shop Complex

|

15-5 |

|

15.5.2 Permanent Accommodation Camp

|

15-5 |

|

15.5.3 Administration Building and Mill Dry

|

15-5 |

|

15.5.4 Assay and Metallurgical Laboratory

|

15-5 |

|

15.5.5 Warehouse & Cold Storage

|

15-6 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

15.5.6 Power Supply and Distribution

|

15-6 |

|

15.5.7 Fuel Storage and Dispensing

|

15-6 |

|

15.5.8 Communication System

|

15-6 |

|

15.5.9 Fresh and Fire Water

|

15-7 |

|

15.5.10 Waste Disposal

|

15-7 |

|

15.6 Waste Rock Management Facility

|

15-7 |

|

15.7 Tailings Management Facility

|

15-7 |

|

15.7.1 Design Criteria

|

15-7 |

|

15.7.2 Design and Construction Concept

|

15-8 |

|

15.7.3 Operation and Closure

|

15-8 |

| |

|

|

16.0 Market Studies

|

16-1 |

|

16.1 Markets

|

16-1 |

|

16.1.1 Uranium Market Demand

|

16-1 |

|

16.1.2 Uranium Market Supply

|

16-1 |

|

16.1.3 Market Prices

|

16-2 |

|

16.1.4 Contracts

|

16-2 |

| |

|

|

17.0 Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups

|

17-1 |

|

17.1 Environmental Considerations

|

17-1 |

|

17.1.1 Baseline Studies

|

17-2 |

|

17.1.2 Environmental Risks and Opportunities

|

17-3 |

|

17.2 Social (Including Labour) Considerations

|

17-5 |

|

17.3 Governance Considerations

|

17-7 |

|

17.4 Current and Future Permitting Requirements

|

17-8 |

|

17.4.1 Provincial EIA and Permitting

|

17-8 |

|

17.4.2 Federal Impact Assessment and Licensing

|

17-9 |

|

17.4.3 Decommissioning

|

17-10 |

|

17.4.4 Indigenous Engagement

|

17-11 |

|

17.4.5 Summary

|

17-12 |

|

17.5 Other Significant Factors or Risks

|

17-13 |

|

17.6 QP Opinion

|

17-14 |

| |

|

|

18.0 Capital and Operating Costs

|

18-1 |

|

18.1 Capital Costs

|

18-1 |

|

18.1.1 Initial Capital Costs

|

18-2 |

|

18.1.2 Sustaining Capital Cost

|

18-3 |

|

18.1.3 Capital Cost Exclusions

|

18-4 |

|

18.2 Operating Costs

|

18-5 |

|

18.2.1 Mining Operating Cost

|

18-5 |

|

18.2.2 Processing Operating Cost

|

18-6 |

|

18.2.3 G&A and Site Services Cost

|

18-7 |

| |

|

|

19.0 Economic Analysis

|

19-1 |

|

19.1 Forward-looking Statements

|

19-1 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

19.2 Assumptions and Inputs

|

19-2 |

|

19.2.1 General

|

19-2 |

|

19.2.2 Metal Pricing

|

19-2 |

|

19.2.3 Production

|

19-2 |

|

19.2.4 Working Capital

|

19-2 |

|

19.2.5 Taxes, Provincial Royalties, and Depreciation

|

19-3 |

|

19.3 Economic Analysis Results

|

19-3 |

|

19.3.1 Sensitivity Analysis

|

19-8 |

| |

|

|

20.0 Adjacent Properties

|

20-1 |

| |

|

|

21.0 Other Relevant Data and Information

|

21-1 |

| |

|

|

22.0 Interpretation and Conclusions

|

22-1 |

|

22.1 Geology and Mineral Resources

|

22-1 |

|

22.2 Metallurgy and Process

|

22-1 |

|

22.3 Mining Methods

|

22-2 |

|

22.4 Infrastructure

|

22-2 |

|

22.5 Environmental

|

22-2 |

|

22.6 Capital and Operating Costs

|

22-2 |

|

22.7 Economic Analysis

|

22-3 |

|

22.8 Risks and Uncertainties

|

22-3 |

| |

|

|

23.0 Recommendations

|

23-1 |

|

23.1 Introduction

|

23-1 |

|

23.1.1 Mineral Resource Estimate

|

23-1 |

|

23.1.2 Mining

|

23-2 |

|

23.1.3 Metallurgy and Processing

|

23-3 |

|

23.1.4 Infrastructure

|

23-4 |

|

23.1.5 Environmental

|

23-4 |

|

23.1.6 Tailings Management Facility

|

23-4 |

|

23.2 Cost Estimate for Recommendations

|

23-5 |

| |

|

|

24.0 References

|

24-1 |

| |

|

|

25.0 Reliance on Information Provided by the Registrant

|

25-1 |

| |

|

|

26.0 Date and Signature Pages

|

26-1 |

| |

|

|

27.0 Glossary

|

27-1 |

| |

|

|

Appendix A

|

1 |

|

List of Potential, Permits, Approvals, and Authorizations

|

2 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

LIST OF FIGURES

|

Figure 3‑1: Project Location in Saskatchewan (SRK, 2023)

|

3-2 |

|

Figure 3‑2: Project Location (SRK, 2023)

|

3-3 |

|

Figure 4‑1: Plan View of the Project Topography (SRK, 2023)

|

4-1 |

|

Figure 4‑2: Habitat Areas as defined in ADEX (BARR, 2013)

|

4-3 |

|

Figure 6‑1: Geological Sketch Map of Athabasca Basin

|

6-2 |

|

Figure 6‑2: Stratigraphic Column of the Property Geology (UEC, 2024)

|

6-5 |

|

Figure 6‑3: Long Section of the Geological Model (SRK, 2023)

|

6-6 |

|

Figure 6‑4: Macro-scale Lineaments on First Vertical Derivative Ground Magnetics Image (SRK, 2023)

|

6-7 |

|

Figure 6‑5: Uranium Mineralized Drill Core from MWNE-085 from 252.2 m to 258.1 m (SRK, 2023)

|

6-8 |

|

Figure 6‑6: Plan View of the Project Uranium Deposits (SRK, 2023)

|

6-9 |

|

Figure 6‑7: Cross Section W-W’ through the RRW Deposit (SRK, 2023)

|

6-9 |

|

Figure 6‑8: Cross Section E-E’ through the RRE Deposit (SRK, 2023)

|

6-10 |

|

Figure 6‑9: Cross Section FE-FE’ through the RRFE Deposit (SRK, 2023)

|

6-11 |

|

Figure 7‑1: Plan View of the Project Drillhole Collars by Company (UEC, 2024)

|

7-4 |

|

Figure 7‑2: Drilling operations at the Project (SRK, 2023)

|

7-6 |

|

Figure 7‑3: Recovery vs. U3O8% Grade within Modelled Mineralization (SRK, 2023)

|

7-10 |

|

Figure 7‑4: Cross Section of RRW Modelled Mineralization (SRK, 2023)

|

7-11 |

|

Figure 7‑5: Contact Analysis Plot of Recovery vs. Distance from the Unconformity (SRK, 2023)

|

7-12 |

|

Figure 7‑6: Plan View and Long Section Looking North of Hydrogeological Holes (SRK, 2023)

|

7-13 |

|

Figure 7‑7: Interval Logging Data Availability in Each Deposit Area Below the Unconformity (SRK, 2023)

|

7-19 |

|

Figure 7‑8: Distribution of Logged Structures (SRK, 2023)

|

7-20 |

|

Figure 7‑9: Distribution of Mineral Infill in Logged Structures (SRK, 2023)

|

7-21 |

|

Figure 7‑10: Distribution of Logging IRS Strength Estimate and Locations of PLT Tests (SRK, 2023)

|

7-22 |

|

Figure 8‑1: Blank Sample Results for Fluorimetry (AQRFLR) and ICP-OES (SCUIOS) at SRC (SRK, 2023)

|

8-4 |

|

Figure 8‑2: Field Duplicate Sample Results for Fluorimetry (AQRFLR - U3O8%) (SRK, 2023)

|

8-5 |

|

Figure 8‑3: Coarse Reject Duplicate Sample Results for Fluorimetry (AQRFLR -U3O8 %) (SRK, 2023)

|

8-6 |

|

Figure 8‑4: Pulp Duplicate Sample Results for ICP-OES (SRUIOS - U3O8%) (SRK, 2023)

|

8-7 |

|

Figure 8‑5: CRM Plot for STD-BL5 Analyzed at SRC (SRK, 2023)

|

8-9 |

|

Figure 8‑6: CRM Plot for STD-SRCU02 Analyzed at SRC (SRK, 2023)

|

8-10 |

|

Figure 8‑7: CRM Plot for STD-BL4A Analyzed at SRC (SRK, 2023)

|

8-11 |

|

Figure 8‑8: SRC Internal BL5 CRM Performance (Hathor samples 2007 to 2011) (SRK, 2023)

|

8-13 |

|

Figure 8‑9: External Duplicate Sample Results for U3O8% (SRC vs SGS) (SRK, 2023)

|

8-14 |

|

Figure 8‑10: External Duplicate Sample Results for DNC vs U3O8% (SRC vs SGS) (SRK, 2023)

|

8-15 |

|

Figure 8‑11: Standard 01 Density CRM plot (SRK, 2023)

|

8-17 |

|

Figure 8‑12: External Duplicate Density Sample Results (Hathor vs SRC) (SRK, 2023)

|

8-18 |

|

Figure 9‑1: Core Review at Roughrider (UMR, 2024)

|

9-2 |

|

Figure 9‑2: Confirmation of Mineralization via a SPP2 Scintillometer (UMR, 2024)

|

9-3 |

|

Figure 9‑3: Drill Collar MWNE-11-682 (UMR, 2024)

|

9-4 |

|

Figure 10‑1: Extraction Isotherm for Aqueous and Organic using Strong Acid and Ammonia Strip

|

10-11 |

|

Figure 11‑1: Cross Section looking North at the Project Lithological Model and Drillholes Coloured by Logged Lithology (UMR, 2024)

|

11-3 |

| Figure 11‑2: Long Section looking North of the Modelled RRW, RRE, and RRFE Zones (SRK, 2023) |

11-5 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

Figure 11‑3: Oblique View of RRW Mineralization Model Underlain by Drill Hole Traces Looking at Plunge of 50° Along an Azimuth of 354°

|

11-5 |

|

Figure 11‑4: Oblique View of RRE Mineralization Model Underlain by Drill Hole Traces Looking at Plunge of 40° along an Azimuth of 355°

|

11-6 |

|

Figure 11‑5: Oblique View of the RRFE Mineralization Model Underlain by Drill Hole Traces Looking at Plunge of +45° along an Azimuth of 000°

|

11-6 |

|

Figure 11‑6: Contact Analysis between Layer-Parallel Veins and Northeast Striking Veins of RRW Zone

|

11-8 |

|

Figure 11‑7: Contact Analysis between the Combined Vein Domains and Surrounding Low-Grade Domain of RRW Zone

|

11-9 |

|

Figure 11‑8: Oblique View (Azimuth of 336°, Plunge of +47°) of Intersecting Domains High-Grade Layering 7 and High-Grade NE Overlain by Primary Search Ellipse of the High-Grade Layering 7 Domain and the Associated Restricted Soft Boundary Search (SRK, 2023)

|

11-10 |

|

Figure 11‑9: Measured Density versus U3O8 % Grade; Samples colored by Clay Alteration Intensity

|

11-11 |

|

Figure 11‑10: Measured Specific Gravity versus U3O8 % grade, with samples colored by Low and High Clay Alteration Groupings.

|

11-12 |

|

Figure 11‑11: Probability and Histogram Plots of U3O8 % in RRW High-Grade Layering Group (UMR, 2024)

|

11-14 |

|

Figure 11‑12: Probability and Histogram Plots of U3O8 % in RRW High-Grade NE Group (UMR, 2024)

|

11-14 |

|

Figure 11‑13: Probability and Histogram Plots of U3O8 % in RRW Low-Grade Group (UMR, 2024)

|

11-15 |

|

Figure 11‑14: Experimental and Modelled Variograms for High-Grade Layering in RRW (1100)

|

11-18 |

|

Figure 11‑15: Experimental and Modelled Variograms for High-Grade NE in RRW (1200)

|

11-19 |

|

Figure 11‑16: Experimental and Modelled Variograms for Low-Grade in RRW (1400)

|

11-20 |

|

Figure 11‑17: Diagram Demonstrating the Change of Support Principle

|

11-30 |

|

Figure 11‑18: Quantile-Quantile Plot of DGM Comparison to Blocks (UMR, 2024)

|

11-31 |

|

Figure 11‑19: Cross-Section of RRW Estimated Block Grades Underlain by Composite Grades Looking Northeast (UMR, 2024)

|

11-32 |

|

Figure 11‑20: Cross-Section of RRFE Estimated Block Grades Underlain by Composite Grades Looking Northeast (UMR, 2024)

|

11-33 |

|

Figure 11‑21: Swath Plot of % U3O8 Composites and Block Model for RRW High-Grade Layering (1100) Domain in the X, Y, Z Directions (UMR, 2024)

|

11-34 |

|

Figure 11‑22: Swath Plot of % U3O8 Composites and Block Model for RRW High-Grade NE (1200) Domain in the X, Y, Z Directions (UMR, 2024)

|

11-34 |

|

Figure 11‑23: Swath Plot of % U3O8 Composites and Block Model for RRW Low-Grade (1400) Domain in the X, Y, Z Directions (UMR, 2024)

|

11-35 |

|

Figure 11‑24: Long Section Looking North of In-Situ Classification of RRW, RRE, and RRFE Zones (UMR, 2024)

|

11-36 |

|

Figure 11‑25: Cross Section Looking East of the Classification of the RRW Zone, Underlain by Drillhole Traces (UMR, 2024)

|

11-37 |

|

Figure 11‑26: Cross Section Looking East of the Classification of the RRFE Zone, Underlain by Drillhole Traces (UMR, 2024)

|

11-38 |

|

Figure 11‑27: Cross Section Looking East-northeast of the In-situ Classification of the RRW Zone Transferred to the Stope Classification (UMR, 2024)

|

11-39 |

|

Figure 11‑28: Long Section Looking North of Classified Stopes for RRW, RRE, and RRFE (UMR, 2024)

|

11-39 |

|

Figure 11‑29: Diluted Block Model Grade Tonnage Curves for Indicated Mineral Resources (UMR, 2024)

|

11-43 |

| Figure 11‑30: Diluted Block Model Grade Tonnage Curves for Inferred Mineral Resources (UMR, 2024) |

11-44 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

Figure 13‑1: Section showing Shaft Geotechnical Data (Golder, 2014)

|

13-1 |

|

Figure 13‑2: Exploration Level Geotechnical Data

|

13-2 |

|

Figure 13‑3: Plan view of Roughrider Uranium Deposits (Snowden, 2024)

|

13-4 |

|

Figure 13‑4: Cross Section of Main Decline (Snowden, 2024)

|

13-5 |

|

Figure 13‑5: NGI Empirical Rock Mass Support Chart (Norwegian Geotechnical Institute, 2022)

|

13-7 |

|

Figure 13‑6: Conceptual Isometric View of Freeze Wells Surrounding Mineralized Material Zones (Snowden, 2024)

|

13-8 |

|

Figure 13‑7: Grade-tonnage Curve of Indicated and Inferred Material within Block Model (Snowden, 2024)

|

13-10 |

|

Figure 13‑8: Mining Order (Snowden, 2024)

|

13-15 |

|

Figure 13‑9: Mining Sequence (Isometric View) (Snowden, 2024)

|

13-17 |

|

Figure 13‑10: Lateral Development by Period (COG 0.3% U3O8) (Snowden, 2024)

|

13-18 |

|

Figure 13‑11: Vertical Development by Period (COG 0.3% U3O8) (Snowden, 2024)

|

13-18 |

|

Figure 13‑12: Stope Production (COG 0.3% U3O8) (Snowden, 2024)

|

13-19 |

|

Figure 13‑13: Overall Production Schedule (COG 0.30% U3O8) (Snowden, 2024)

|

13-20 |

|

Figure 13‑14: Overall Production Schedule (COG 0.40% U3O8) (Snowden, 2024)

|

13-20 |

|

Figure 13‑15: Overall Production Schedule (COG 0.45% U3O8) (Snowden, 2024)

|

13-21 |

|

Figure 13‑16: Overall Production Schedule (COG 0.50% U3O8) (Snowden, 2024)

|

13-21 |

|

Figure 13‑17: Production Schedule excluding Inferred Category (COG 0.40% U3O8) (Snowden, 2024)

|

13-22 |

|

Figure 14‑1: Simplified Process Flowsheet (Tetra Tech, 2024)

|

14-2 |

|

Figure 15‑1: Overall Site General Arrangement (Tetra Tech, 2024)

|

15-2 |

|

Figure 15‑2: Preliminary Process Plant General Arrangement (Tetra Tech, 2024)

|

15-4 |

|

Figure 17‑1: Known Heritage Sites near the Project site (BARR, 2013)

|

17-14 |

|

Figure 19‑1: Post-Tax Annual and Cumulative Cash Flow (with Inferred Resources) (Tetra Tech, 2024)

|

19-4 |

|

Figure 19‑2: Post-Tax Annual and Cumulative Cash Flow (without Inferred Resources) (Tetra Tech, 2024)

|

19-5 |

|

Figure 19‑3: Sensitivity Analysis of Post-Tax NPV (with Inferred Resources) (Tetra Tech, 2024)

|

19-8 |

|

Figure 19‑4: Sensitivity Analysis of Post-Tax IRR (with Inferred Resources) (Tetra Tech, 2024)

|

19-8 |

|

Figure 19‑5: Sensitivity Analysis of Post-Tax NPV (without Inferred Resources) (Tetra Tech, 2024)

|

19-9 |

|

Figure 19‑6: Sensitivity Analysis of Post-Tax IRR (without Inferred Resources) (Tetra Tech, 2024)

|

19-9 |

|

Figure 20‑1: Plan View of the Roughrider Deposit Area of the Eastern Athabasca (SRK, 2023)

|

20-1 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

LIST OF TABLES

|

Table 1‑1: Mineral Resource Statement for the Project (as of November 5, 2024)

|

1-3 |

|

Table 1‑2: Capital Cost Summary

|

1-5 |

|

Table 1‑3: Operating Cost Summary

|

1-5 |

|

Table 1‑4: Summary of Economic Analysis Results

|

1-6 |

|

Table 2‑1: Technical Report Sections and Third-Party Firms

|

2-2 |

|

Table 2‑2: Site Visit

|

2-3 |

|

Table 3‑1: ML-5547 Boundary Points

|

3-4 |

|

Table 3‑2: List of Permits (UEC, 2024)

|

3-5 |

|

Table 7‑1: Project Drilling Summary by Year, Company, and Deposit (UEC, 2024)

|

7-3 |

|

Table 7‑2: Key Geotechnical Data Categories Relevant for Rock Quality Classification Rating Systems

|

7-17 |

|

Table 7‑3: Project Geotechnical Data Collection Sources (SRK, 2023)

|

7-18 |

|

Table 8‑1: Project U3O8% and U ppm CRMS (SRK, 2023)

|

8-8 |

|

Table 8‑2: Project Density CRMs (SRK, 2023)

|

8-16 |

|

Table 9‑1: Reviewed Drill Core by Zone

|

9-1 |

|

Table 10‑1: Simplified Test Procedures used in Phase 1 of the Test Program (SGS, 2011)

|

10-2 |

|

Table 10‑2: Multi-Element Analysis Results for the Three Composite Samples

|

10-3 |

|

Table 10‑3: Leaching Test Results for the Three Composite Samples

|

10-4 |

|

Table 10‑4: Multi-Element Analysis Results for the Phase 2 Composite Samples

|

10-5 |

|

Table 10‑5: Comminution Characterization Test Results for the Phase 2 Composite Samples

|

10-6 |

|

Table 10‑6: Leaching Test Results for the Three Composite Samples

|

10-7 |

|

Table 10‑7: Multi-Element Analysis Results for the Phase 3 Composite Samples

|

10-9 |

|

Table 10‑8: Bond Ball Mill Work Index for the Phase 3 Composite Samples

|

10-9 |

|

Table 10‑9: Leaching Test Results for the Phase 3 Composite Samples

|

10-10 |

|

Table 10‑10: Multi-Element Analysis Results for the Phase 4 Composite Samples

|

10-12 |

|

Table 10‑11: Comminution Test Results for the Phase 4 Mineralized Composite Samples

|

10-13 |

|

Table 10‑12: Comminution Test Results for the Phase 4 Non-Mineralized Composite Samples

|

10-13 |

|

Table 10‑13: Leaching Test Results for the Phase 5 Composite Samples

|

10-14 |

|

Table 10‑14: Multi-Element Analysis Results for the Phase 5 Composite Samples

|

10-15 |

|

Table 10‑15: Comminution Characterization Test Results for the Phase 5 Composite Samples

|

10-15 |

|

Table 10‑16: Leaching Test Results for the Phase 5 Composite Samples

|

10-16 |

|

Table 11‑1: Excluded Drillholes

|

11-2 |

|

Table 11‑2: Final Estimation Domains and Coding by Zone and Mineralization Group

|

11-7 |

|

Table 11‑3: Boundary Conditions for the RRW Domains

|

11-7 |

|

Table 11‑4: Boundary Conditions for the RRE Domains

|

11-8 |

|

Table 11‑5: Boundary Conditions for the RRFE Domains

|

11-8 |

|

Table 11‑6: Soft Boundary Search Parameters (Recreated from SRK, 2023)

|

11-10 |

|

Table 11‑7: High-Grade Threshold Restrictions by Domain

|

11-16 |

|

Table 11‑8: Summary Composite Statistics of U3O8 by Domain (Recreated from SRK, 2023)

|

11-17 |

|

Table 11‑9: Summary of Variogram Models for RRW

|

11-21 |

|

Table 11‑10: Summary of Variogram Models for RRE

|

11-22 |

|

Table 11‑11: Summary of Variogram Models for RRFE

|

11-23 |

| Table 11‑12: Block Model Definition |

11-24 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

Table 11‑13: Estimation Parameter Summary

|

11-25 |

|

Table 11‑14: Declustered Composite Mean versus Block Mean

|

11-29 |

|

Table 11‑15: Mineral Resource Statement for the Project (as of November 5, 2024)

|

11-41 |

|

Table 13‑1: Longhole Stope Parameters

|

13-6 |

|

Table 13‑2: MSO Inventories

|

13-6 |

|

Table 13‑3: Cut-off Grade Parameters

|

13-9 |

|

Table 13‑4: MSO Parameters

|

13-10 |

|

Table 13‑5: Mobile Equipment List

|

13-12 |

|

Table 13‑6: Mining Labour Requirements

|

13-13 |

|

Table 13‑7: Airflow Assumptions

|

13-14 |

|

Table 13‑8: Development Rates

|

13-16 |

|

Table 13‑9: Production Rates

|

13-16 |

|

Table 13‑10: Equipment Rates

|

13-16 |

|

Table 13‑11: MSO Inventory Excluding Inferred Category

|

13-22 |

|

Table 13‑12: Potential Mill Feed (COG 0.30% U3O8)

|

13-23 |

|

Table 13‑13: Potential Mill Feed (COG 0.40% U3O8)

|

13-23 |

|

Table 13‑14: Potential Mill Feed (COG 0.45% U3O8)

|

13-23 |

|

Table 13‑15: Potential Mill Feed (COG 0.50% U3O8)

|

13-23 |

|

Table 14‑1: Major Plant Design Criteria

|

14-1 |

|

Table 14‑2: Reagents and Major Consumables Consumption

|

14-6 |

|

Table 14‑3: Projected Yellowcake Production

|

14-8 |

|

Table 14‑4: Plant Staffing Requirements

|

14-8 |

|

Table 18‑1: Capital Cost Summary

|

18-1 |

|

Table 18‑2: Initial Mining Capital Cost Summary

|

18-2 |

|

Table 18‑3: Process Plant Capital Cost Summary

|

18-3 |

|

Table 18‑4: LOM Sustaining Capital Cost Summary

|

18-4 |

|

Table 18‑5: Average LOM Operating Cost Summary

|

18-5 |

|

Table 18‑6: Average Mining Operating Cost Summary

|

18-6 |

|

Table 18‑7: Average Process Operating Cost Summary

|

18-6 |

|

Table 19‑1: LOM Average Production Statistics

|

19-2 |

|

Table 19‑2: Cash Flow Summary

|

19-4 |

|

Table 19‑3: Summary of Pre-Tax Economic Analysis (with Inferred Resources)

|

19-5 |

|

Table 19‑4: Summary of Pre-Tax Economic Analysis (without Inferred Resources)

|

19-5 |

|

Table 19‑5: Summary of LOM Annual Cash Flow (with Inferred Resources)

|

19-6 |

|

Table 19‑6: Summary of LOM Annual Cash Flow (without Inferred Resources)

|

19-7 |

|

Table 23‑1: Cost Estimate for Drilling Recommendations

|

23-2 |

|

Table 23‑2: Cost Estimate for Mining Recommendations

|

23-3 |

|

Table 23‑3: Cost Estimate for Recommendations

|

23-5 |

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

This Technical Report Summary (“TRS”) was prepared in accordance with the U.S. Securities and Exchange Commission (“SEC”) Regulation S-K Subpart 1300 (“S-K 1300”) and specifically Item 17 Code for Federal Regulations Parts 229, 230, 239 and 249) for Uranium Energy Corporation (“UEC”) by Tetra Tech Canada Inc. (“Tetra Tech”), Understood Mineral Resources Ltd. (“UMR”), Terracon Geotechnique Ltd. (“Terracon”), Snowden Optiro (“Snowden”) and Clifton Engineering Group Inc. (“Clifton”) on the Roughrider Project (the “Project”).

The Project is located 7 km north, via gravel road, of Points North Landing, a regional service center on Provincial Highway 905, in the eastern Athabasca basin of northern Saskatchewan, Canada. The Project is an Exploration Stage Property within the 597-hectare mineral lease ML-5547, which is 100% held by UEC. The Project site comprises core logging, office, and storage facilities. The uranium deposits at the Project were discovered in 2008 by Hathor Exploration Limited (“Hathor”) and were subsequently explored and studied in increasing detail until 2016.

|

1.2

|

Geology and Mineralization

|

The Project is located in the Athabasca Basin, a prolific uranium producing district, and comprises the Roughrider West Zone (“RRW”), the Roughrider East Zone (“RRE”) and Roughrider Far East Zone (“RRFE”) unconformity-related uranium deposits. The deposits occur at, and below, the unconformity between the overlying Athabasca group sandstones and conglomerates, and the Wollaston group orthogneisses. Uranium mineralization is localized by structures, adjacent to, and within graphitic meta-pelites. The mineralization is characterized by uraninite and lesser amounts of uranophane, and red to orange coloured oxy-hydroxillized iron oxides.

Uranium mineralization in the Athabasca basin, and the Project, is interpreted to form where oxidized uranium bearing fluids, presumably sourced from the Athabasca group, mix, at or near the unconformity with reduced fluids, or rock masses of the basement, Wollaston group. Uranium is reduced at the redox front where these conditions exist.

|

1.3

|

Status of Exploration and Development

|

Prospecting, airborne radiometric surveys, and lake sediment sampling for uranium in the Project area began in 1969. As a result of regional exploration work and targeting by various operators, significant uranium mineralization was discovered in 1978 at the Dawn Lake Project (east of the Project) and Midwest Lake (south of the Project). Exploration and drilling efforts around the property concentrated on an east-west trending conductor (indicative of graphitic gneisses of the Wollaston group), although no anomalous mineralization was intersected.

In 2006, Hathor acquired mineral lease, ML-5544 (now part of ML-5547). Drilling in 2008 intersected high-grade uranium mineralization, of the RRW deposit. In 2009 and 2011, the RRE and RRFE were discovered respectively. Based on the RRW and RRE deposits only, Hathor completed a Preliminary Economic Assessment (“PEA”) in 2011.

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

Hathor was acquired by Rio Tinto Canada Uranium Corp. (“RTCU”) in 2011. RTCU continued to advance the Project through to 2016, completing substantial pre-development and environmental baseline work including dedicated geotechnical drilling, shaft versus decline modelling, the establishment of hydrogeological monitoring wells, terrestrial and aquatic environmental assessments, heritage assessments, species at risk, and a conceptual reclamation plan. In 2013, RTCU submitted an Advanced Exploration Program (“ADEX”) proposal to the Saskatchewan Ministry of Environment that was intended to initiate an Environmental Impact Study (“EIS”) review of the Project. Ministerial approval for RTCU to proceed with the ADEX Program was received on August 20, 2014, from the Saskatchewan Minister of Environment pursuant to Section 15(1)(a) of the Environmental Assessment Act. Although ADEX development by RTCU did not start due to low uranium prices in the subsequent years, the original approval remains in effect.

The Project comprises data from 665 drillholes, for a total of 228,185 m, drilled on the property by Hathor and RTCU from 2007 to 2016. On October 17, 2022, UEC completed the acquisition of 100% of the Project from RTCU. On November 1, 2023, UEC commenced an exploration drill program, and as of July 31, 2024, UEC has drilled an additional 29,840 m in 94 holes to further explore on the Property.

|

1.4

|

Mineral Processing and Metallurgical Testing

|

From 2008 to 2013, SGS Canada carried out four phases of test work on uranium recovery at the Roughrider deposits. The work included extensive metallurgical testing, covering preliminary leaching tests and variability tests. After acquiring the Roughrider prospect, Rio Tinto continued with a fifth phase of tests in 2013. Since UEC acquired the project in 2022, no additional tests have been conducted.

A summary of the metallurgical testing results is listed below:

|

■

|

The comminution test work showed that Roughrider samples are soft in nature with the average Bond Ball Mill Work Index of 10.6 kWh/t.

|

|

■

|

Agitated tank leach test results showed that Roughrider mineralization is amenable for uranium extraction via atmospheric acid leaching. On average 98.5% of extraction can be achieved within 12-h of leach retention time at 50°C with a grind size of 250 µm. Further, it was found that no significant difference in dissolution and extraction of uranium from the different deposits (RRW, RRE and RRFE).

|

|

■

|

Two different approaches (strong acid strip with uranyl peroxide precipitation and ammonia strip with ammonium diuranate precipitation) were examined for production of final yellowcake product. It was found that organic extraction followed by strong acid strip produced higher quality yellowcake meeting the refinery specifications compared to the ammonium sulfate strip method.

|

|

■

|

Tailings neutralization and effluent treatment test work based on the standard approaches used in the Athabasca region indicated that effluent quality meeting the Metal and Diamond Mining Effluent Regulations (MDMER) guidelines can be achieved.

|

|

1.5

|

Mineral Resource Estimate

|

The 2024 Mineral Resource Statement for the Roughrider Project adheres to SEC’s property disclosure regulations, S-K 1300. To meet the requirement of Reasonable Prospects of Eventual Economic Extraction, the Mineral Resource estimate is reported within a constrained mineable shape optimizer (MSO) as informed by a breakeven cut-off grade of 0.30% U3O8. The Mineral Resources are reported diluted, including waste and mineralization below cut-off. The reporting date of this Mineral Resource Statement is November 5, 2024.

The Mineral Resource is composed of Indicated and Inferred Mineral Resources (Table 1‑1). No Mineral Reserves have been estimated at the Property.

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

Table 1‑1: Mineral Resource Statement for the Project (as of November 5, 2024)

|

Zone

|

Classification

|

Tonnage (kt)

|

Grade U3O8 (%)

|

Contained U3O8 Metal (M lb U3O8)

|

|

RRW

|

Indicated

|

431

|

1.89

|

17.97

|

|

Inferred

|

152

|

2.80

|

9.39

|

|

RRE

|

Indicated

|

-

|

-

|

-

|

|

Inferred

|

390

|

2.57

|

22.05

|

|

RRFE

|

Indicated

|

268

|

1.67

|

9.89

|

|

Inferred

|

78

|

1.13

|

1.94

|

|

Total

|

Indicated

|

699

|

1.81

|

27.86

|

|

Inferred

|

620

|

2.45

|

33.38

|

*Notes

| |

1.

|

There are no Mineral Reserves estimated for this Project.

|

| |

2.

|

Mineral Resource estimate is reported on a 100% ownership basis.

|

| |

3.

|

Mineral Resource estimate is reported diluted within the underground MSO shapes based on a U3O8 price of US$85/lb and metallurgical recovery of 97.5%. A longhole mining method was assumed with an approximate cut-off of 0.30% U3O8. The MSO shapes were estimated by Snowden, a third-party firm comprising mining experts the definition defined by S-K 1300.

|

| |

4.

|

The Mineral Resource estimate was prepared by UMR, a third-party comprising mining experts under the definitions defined by S-K 1300.

|

| |

5.

|

The tonnage is presented in metric tonnes and contained metal is in reported in both metric tonnes and imperial pounds. Estimates have been rounded and may not add up due to significant figure rounding.

|

This TRS was completed assuming a decline would be suitable to access the deposits. A longhole transverse retreat mining method was assumed for the three mining areas. The mining rate was assumed at 400 t/d with mill feed being hauled to surface stockpiles. Various cut-off grades were assessed from a breakeven of 0.3% U3O8 to 0.5% U3O8. For the Initial economic analysis, a cut-off grade of 0.4% U3O8 was assumed. The initial economic analysis includes Inferred Mineral Resources which by definition of SEC is speculative. Other potential risks might be contributed to the limited ventilation, geotechnical, backfill, and hydrogeological studies on the Project.

|

1.7

|

Processing and Recovery Methods

|

The processing facility is designed using established methods from other Athabasca basin region operations like Rabbit Lake, Key Lake, and McClean Lake. It will operate at an average throughput of 400 t/d with a life of mine (“LOM”) average mill feed grade of 2.36% U3O8 and a recovery rate of 97.5%. Mineralized material feed from the underground mine will be trucked to the run of mine (“ROM”) pad, ground to 250 µm in a single-stage semi-autogenous grinding (“SAG”) circuit, and leached with sulphuric acid and hydrogen peroxide at 50°C. The pregnant leach solution (“PLS”) will be produced using counter-current decantation (“CCD”) and clarification. Solvent extraction (“SX”) will be used to remove impurities enriching uranium concentration in the PLS. Yellowcake will be precipitated from the enriched solution using hydrogen peroxide and magnesium oxide. The precipitated yellowcake will undergo solid-liquid separation, drying at 450°C and finally packaged in barrels for shipment. Tailings and waste process solutions will be neutralized and stored in the Tailings Management Facility (“TMF”). Reclaimed water will be treated in a water treatment plant (“WTP”) and monitored for environmental compliance before discharge.

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

1.8

|

Project Infrastructure

|

The Roughrider project site is located 7 km north of Points North Landing, via an existing pioneering access road that connects to Provincial Highway 905 in the eastern Athabasca basin of northern Saskatchewan, Canada. While there are existing roads for exploration, all-weather access upgrades are necessary for better connectivity. The nearby Points North Landing Airstrip can support aerial personnel and cargo transportation, with Rise Air providing flights to various regional airports. Currently, the site lacks a permanent power supply, but a connection to the provincial grid via a new 138 kV transmission line is envisioned, along with backup diesel generators for emergencies.

Key mining infrastructure will include an underground mine with ventilation shafts, a decline for material transport, a backfill plant, and a waste rock management facility (WRMF) for storing different types of waste materials. The process plant area will feature surface stockpiles, processing facilities, water treatment plant, a laboratory, and various support structures like fuel storage and maintenance shops. Additionally, the TMF, including tailings transport system, deposition system and a reclaim water system, will be established to safely handle the tailings.

|

1.9

|

Environmental, Permitting and Social License

|

The ADEX Environmental Impact Assessment (“EIA”) from 2012 to 2014 included extensive baseline studies, but further environmental studies have been requested by federal and provincial regulators to confirm previous findings. A new baseline program initiated in 2023, largely completed in 2024, supports the Project's assessment and licensing. Water quality impacts are crucial and treated effluent discharge is expected. Air quality and radiation monitoring is planned. Species identified in terrestrial and aquatic programs align with previous surveys. Radiological and environmental safety controls will be implemented, along with a Radiation Protection Program.

Indigenous engagement is crucial under the United Nations Declaration on the Rights of Indigenous Peoples Act, ensuring free, prior, and informed consent (“FPIC”). UEC has re-engaged with neighboring communities to gain social licence to operate. Governance risks include establishing Environmental, Social, and Governance (ESG) frameworks and compliance with Canadian Nuclear Safety Commission (“CNSC”) regulations, focusing on health, safety, and environmental protection. Sensitive habitats and water bodies require a risk-informed approach. The power supply may be hydroelectric, but greenhouse gas emissions from diesel and propane use must be managed. Decarbonization strategies will align with federal climate commitments.

Uranium's role in reducing carbon emissions offers positive corporate marketing opportunities. Future environmental assessments will consider cumulative impacts and social enhancement opportunities with nearby projects, particularly in water resources, traffic, and local employment.

|

1.10

|

Capital and Operating Costs

|

The total estimated initial capital cost for the design, construction, installation and commissioning of the Project is $545.5 million for a 400 t/d operation. This includes all direct costs, indirect costs, owner’s costs and contingency. The capital cost estimate is consistent with an Association for the Advancement of Cost Engineering (“AACE”) Class 5 estimate with the expected accuracy within ±50%. The project contingency is estimated to be 18.3% of the total capital cost. A breakdown of the initial capital cost is provided in Table 1‑2. The LOM sustaining capital cost is estimated at $115.2 million. All currencies are expressed in US dollars, unless otherwise stated.

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

Table 1‑2: Capital Cost Summary

|

Capital Cost Area

|

Value (US$ million)

|

|

Mining

|

96.8

|

|

Processing Plant

|

89.5

|

|

Infrastructure

|

80.1

|

|

Tailings and Waste Rock Management

|

19.0

|

|

Direct Cost

|

285.4

|

|

Indirect Cost*

|

99.9

|

|

Owner's Cost

|

60.2

|

|

Contingency

|

99.9

|

|

Total Initial Capital Cost

|

545.5

|

|

Pre-production Cost

|

35.6

|

|

Total Initial Cost (inc. pre-production)

|

581.1

|

|

Sustaining Cost

|

115.2

|

Note: Total may not add due to rounding.

*Includes Engineering, Procurement, Construction Management (“EPCM”) cost of $34.0 million

The operating cost estimate for the Project consists of mining, processing, General and Administrative (“G&A”) and site services costs. The LOM operating costs are summarized in Table 1‑3. The average LOM operating cost is estimated at $493.5/t processed, or $9.72/lb yellowcake recovered in the concentrate. The expected accuracy of the operating cost estimate is within ±50%. Operating costs include contingency which does not exceed 25%.

Table 1‑3: Operating Cost Summary

|

Description

|

LOM Cost

(US$ million)

|

Unit Cost

(US$/t processed)

|

Unit Cost (US$/lb

U3O8 Recovered)

|

|

Mining

|

198.5

|

164.8

|

3.25

|

|

Processing

|

262.9

|

218.2

|

4.30

|

|

G&A

|

133.1

|

110.5

|

2.18

|

|

Total Operating Costs

|

594.5

|

493.5

|

9.72

|

Note: Total may not add due to rounding.

The Project has been evaluated using a long-term U3O8 market price of $85/lb. The LOM base case Project net cash flows before and after tax are presented in Table 1‑4.

The base case post-tax cash flow for mineral resources including inferred resource is evaluated to be a Net Present Value (“NPV”) of US$946 million and an Internal Rate of Return (“IRR”) of 40% and payback period of 1.4 years when discounted at 8% per year. All-in sustaining cost (“AISC”) is estimated to be $20.48/lb of U3O8 recovered.

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

The base case post-tax cash flow for mineral resources excluding inferred resource is evaluated to be a NPV of US$162 million and an IRR of 19.8% and payback period of 2.0 years when discounted at 8% per year. The AISC is estimated to be $24.81/lb of U3O8 recovered.

Table 1‑4: Summary of Economic Analysis Results

|

Description

|

Unit

|

With Inferred Resources

|

Without Inferred Resources

|

|

Pre-tax

|

Post-tax

|

Pre-tax

|

Post-tax

|

|

NPV @ 8% Discount Rate

|

US$ million

|

1,628.8

|

946.2

|

342.1

|

161.7

|

|

IRR

|

%

|

52.7

|

40.0

|

29.7

|

19.8

|

|

Payback Period

|

years

|

1.2

|

1.4

|

1.7

|

2.0

|

|

1.12

|

Conclusions and Recommendations

|

The economic assessment result shows robust economics for the Project at 400 t/d of mill feed with a nine-year mine life producing yellowcake concentrate. Overall, the Project is considered to be technically and economically viable based on assessment parameters and results.

The QPs recommend UEC focus on advancing development of the Roughrider Project as described in the TRS by completing the data collection required to conduct a Pre-Feasibility Study (“PFS”) and update the inferred resources to indicated resource to the extent possible. Furthermore, it is recommended to continue with the Project permitting process, planning and scheduling and sourcing financing. A list of recommendations and a summary of estimated costs for various areas to complete the recommended work is presented in Section 23.0. A budget of US$18.5 million is proposed for work carrying through to the completion of PFS level design.

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

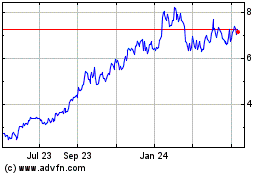

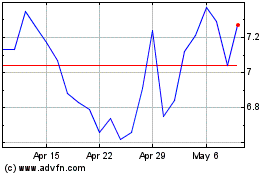

Tetra Tech, UMR, Terracon, Snowden and Clifton have been requested by UEC (hereinafter also referred to as the “Company” or the “Client”) to prepare an S-K 1300 TRS on the Initial Assessment of the Roughrider Project located in Saskatchewan, Canada. UEC is a public company listed on the New York Stock Exchange (NYSE American: UEC).

The Project is a uranium project located in the eastern Athabasca Basin of northern Saskatchewan, Canada, one of the world’s premier uranium mining jurisdictions. The Project occurs entirely within the 597-hectare Mineral Lease ML-5547, which is registered to Roughrider Mineral Assets Inc. (“RMA”), a wholly owned subsidiary of UEC. The Project is located approximately 13 km west of Orano’s McClean Lake Mill, near UEC’s existing Athabasca Basin properties. The Project was the flagship asset of Hathor (“Hathor”), which Rio Tinto Canada Uranium Corp. (“RTCU”) acquired on December 1, 2011, for $550 million (“M”). On October 17, 2022, UEC completed the acquisition of 100% of the Project from RTCU for a total acquisition cost of $150M in cash and shares.

|

2.2

|

Registrant for Whom the Technical Report Summary was Prepared

|

This report was prepared as an initial assessment level Technical Report Summary in accordance with the SEC S-K regulations (Title 17, Part 229, Items 601 and 1300 through 1305) for UEC.

|

2.3

|

Terms of Reference and Purpose of the Report

|

The quality of information, conclusions, and estimates contained herein are based upon the following: i.) information available at the time of preparation and ii.) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by UEC subject to the terms and conditions of its contract with Tetra Tech and relevant securities legislation. The contract permits UEC to file this report as a Technical Report Summary with United States securities regulatory authorities pursuant to the SEC S-K regulations, more specifically Title 17, Subpart 229.600, item 601(b)(96) - Technical Report Summary and Title 17, Subpart 229.1300 - Disclosure by Registrants Engaged in Mining Operations.

The Initial Assessment is preliminary in nature. It includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that the economic assessment will be realized.

|

2.4

|

Source of Information and Data

|

The information and data used to prepare the TRS have been provided by UEC, its consultants, or are available in the public domain. This TRS is based in part on internal Company technical reports, previous studies, maps, published government reports, Company letters and memoranda, and public information, as cited throughout this TRS and listed in the References Section (Section 24). Reliance upon information provided by the registrant Company is listed in Section 25, when applicable.

This TRS supersedes the previous report, SK-1300 Technical Report Summary: Roughrider Uranium Project, Saskatchewan, Canada, dated 25th April 2023, prepared by SRK Consulting which had previously been filed accordance with the U.S. SEC (Regulation S-K Subpart 1300 (“S-K 1300”) and specifically Item 17 CFR § 229, 230, 239 and 249)).

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

This report was compiled by Tetra Tech, with sub-sections authored by UMR, Terracon, Snowden and Clifton. All four firms are third-party firms comprising mining experts in accordance with 17 CFR § 229.1302(b)(1). UEC has determined that all four firms meet the qualifications specified under the definition of qualified person in 17 CFR § 229.1300. The list of firms responsible for each report section is presented in Table 2‑1.

Table 2‑1: Technical Report Sections and Third-Party Firms

|

No.

|

Section

|

Company

|

|

1.0

|

Executive Summary

|

All

|

|

2.0

|

Introduction

|

Tetra Tech

|

|

3.0

|

Property Description and Location

|

Tetra Tech

|

|

4.0

|

Accessibility, Climate, Local Resources, Infrastructure and Physiography

|

Tetra Tech

|

|

5.0

|

History

|

|

6.0

|

Geological Setting, Mineralization and Deposit

|

UMR

|

|

7.0

|

Exploration

|

UMR & Terracon

|

|

8.0

|

Sample Preparation, Analyses and Security

|

UMR

|

|

9.0

|

Data Verification

|

UMR

|

|

10.0

|

Mineral Processing and Metallurgical Testing

|

Tetra Tech

|

|

11.0

|

Mineral Resource Estimates

|

UMR & Snowden

|

|

12.0

|

Mineral Reserve Estimates

|

Snowden

|

|

13.0

|

Mining Methods

|

Snowden

|

|

14.0

|

Recovery Methods

|

Tetra Tech

|

|

15.0

|

Project Infrastructure

|

Tetra Tech

|

|

16.0

|

Market Studies and Contracts

|

Tetra Tech

|

|

17.0

|

Environmental Studies, Permitting and Social or Community Impact

|

Clifton

|

|

18.0

|

Capital and Operating Costs

|

Tetra Tech & Snowden

|

|

19.0

|

Economic Analysis

|

Tetra Tech

|

|

20.0

|

Adjacent Properties

|

Tetra Tech

|

|

21.0

|

Other Relevant Data and Information

|

Tetra Tech

|

|

22.0

|

Interpretation and Conclusions

|

All

|

|

23.0

|

Recommendations

|

All

|

|

24.0

|

References

|

All

|

|

25.0

|

Reliance on Information provided by the Registrant

|

Tetra Tech

|

|

26.0

|

Date & Signature Pages

|

All

|

|

|

S-K 1300 INITIAL ASSESSMENT REPORT – ROUGHRIDER URANIUM PROJECT

REPORT DATE: NOVEMBER 5, 2024

|

|

2.6

|

Details of Personal Inspection

|

A site visit to the Project was most recently completed on August 1, 2024. Table 2‑2 summarizes the details of the personal inspections on the property by each qualified person or, if applicable:

Table 2‑2: Site Visit

|

Expertise

|

Company

|

Date of Visit

|

Details of Inspection

|

|

Geology/Mineral Resources

|

UMR

|

August 1, 2024

|