TIDMALBA

RNS Number : 3884O

Alba Mineral Resources PLC

09 February 2021

Alba Mineral Resources plc

("Alba" or the "Company")

Testwork Results on Amitsoq Graphite

Indicate Suitability for Lithium-Ion Batteries

Alba Mineral Resources plc (AIM: ALBA) is pleased to announce

the results of the independent testwork programme undertaken on

graphite material from the Company's high-grade Amitsoq graphite

project in southern Greenland.

The testwork has confirmed that the graphite content of Amitsoq

ore is very high, amongst the highest found in flake graphite

deposits globally. It has also demonstrated that a >96% graphite

concentrate can be produced and that many of the inherent

characteristics exhibited by Amitsoq graphite are positive.

Accordingly, subject to certain follow-up testwork which is

recommended, the testwork indicates the suitability of Amitsoq

graphite as feed material for Lithium-Ion Batteries ("LIBs"), the

fastest growing market for flake graphite globally.

Key Points

-- Latest testwork by ProGraphite confirms Amitsoq graphite's

very high carbon content - one of the highest grades for flake

graphite deposits globally

-- Carbon content of 97% achieved by flotation

o Considered probable that for some fractions 98% carbon will be achievable by flotation

-- Testwork shows Amitsoq graphite probably usable in most applications

-- Based on the results obtained so far, recommendation for

final treatment of concentrate would be to:

o screen and sell the <=150 micron material separately;

and

o use remaining -150 micron material (approx. 85% of total

concentrate mass) for spherical graphite production (LIBs require

spherical graphite)

-- Amitsoq graphite concentrate's potential suitability for LIBs is a significant finding

o Market for LIBs is fastest growing market for flake graphite

o Massive growth rates forecast for demand for LIBs in electric vehicles

George Frangeskides, Alba's Executive Chairman, commented:

"The successful completion of this testwork phase is a timely

affirmation of the potential of the Amitsoq Project and reinforces

our aim to drill the deposit later this year."

"The testwork has confirmed that a high-grade saleable

concentrate can be produced from Amitsoq graphite. With the input

of recognised graphite experts ProGraphite, we now see a path

opening up for Amitsoq graphite to be used in the dynamic and

ever-expanding global electric vehicle sector."

Introduction

Graphite ore from the Amitsoq deposit was supplied to the

ProGraphite GmbH ("ProGraphite") laboratory in Germany.

Approximately 10 kg was used by ProGraphite in the processing. The

material was screened at 710 micron and the oversized material was

ground in a rod mill until all material was below 710 microns. This

material was the feed for the flotation testwork. It had Fixed

Carbon grading 25.97%.

Flotation was conducted with a standard flotation cell. In order

to protect the flakes, multiple milling and attritioning was

applied. After the stage 7 flotation step, the carbon content of

the concentrate reached 96.2% LOI. Most of the analytical testwork

was carried out on this concentrate. However, a further 300 g of

the concentrate was subjected to a further round of attritioning

and flotation and, as a result, the carbon content reached 97.2%

LOI.

NB: As graphite mineralogy and processing is a highly technical

and specialised area of work, a general overview follows first,

followed by a section containing greater technical detail. Please

also note that a glossary of terms is set out at the end of this

release.

Overview

This testwork programme has confirmed that Amitsoq graphite has

a very high carbon content, one of the highest for flake graphite

deposits globally.

The testwork has also confirmed the following:

(a) The ore crushes easily and comminution and flotation can also be easily achieved.

(b) Carbon content of 97% was reached by flotation, and it is

considered quite probable that for at least some fractions 98%

Carbon will be achievable by flotation. This is very high and would

offer a significant advantage, as no purification would be needed

to achieve that level.

(c) While the concentrate is quite fine, with 16.5% of the mass

being larger than 150 microns, the carbon content in the different

sieve fractions is evenly distributed and the content of volatiles

is low in all fractions.

(d) The bulk density is in a normal range, whereas the specific

surface area shows an increased value which might lead to an

increased oxidation behaviour. The elemental distribution is quite

normal for this type of ore, showing increased values for silica,

iron and sulphur.

(e) Via XRD it was determined that the crystals forming the

graphite flakes are quite small. The crystal lattice has a certain

level of defects, however this is still in the normal range for

flake graphite.

The conclusion from this round of testwork is that Amitsoq

graphite can probably be used for most applications, perhaps

excepting those where high oxidation-resistance is mandatory.

Based on the results obtained so far, ProGraphite's

recommendation for the final treatment of the concentrate would be

to screen the concentrate at 150 microns, with the flakes thereby

obtained being sold separately at higher prices, and with the

remaining product (approximately 85% of the concentrate mass) being

used for spherical graphite production.

Further Technical Details

In respect of the analytical testwork carried out on the

produced concentrate:

(a) Particle size distribution

The particle size distribution shows that the portion of flakes

in the >150 micron size categories is 16.5%, which is quite low

albeit in line with some Chinese or African deposits which are

mined. It is expected that the process of repeated grinding and

attritioning in order to attain a 96% concentrate has the effect of

reducing the overall particle size.

However, it should be noted that the recovery of larger flake

graphite was not an objective for this round of testwork. The flake

size of the graphite used to produce LIB anode material is far less

important, as the graphite is micronised to less than 30 microns

prior to shaping and purification, this being the process for

producing spherical graphite for LIBs.

The latest round of testwork has shown, however, that the carbon

content of the concentrate is very homogenous for all fractions,

which is a significant advantage, as all fractions are saleable

with a high carbon content, allowing for higher prices.

(b) Volatiles

Volatiles are an important factor in graphite quality, as flake

graphite is often used in hot environments, where a high portion of

volatiles can be disturbing. The volatiles in the Amitsoq graphite

concentrate vary between 0.38% and 0.71%, which are low values and

thus a positive property of this graphite.

(c) Bulk density

The concentrate returned a bulk density of 480 g/l, which is a

medium value for flake graphite with the given particle size

distribution. It is comparable with most graphite from China.

(d) Specific Surface Analysis (SSA)

SSA is analysed with the BET method (Brunauer-Emett-Teller). The

result obtained was a SSA of 7.5 m(2)/g. Generally, the higher the

BET value, the higher the porosity or surface inhomogeneity of the

material. A high BET value (and high surface inhomogeneity) leads

to high absorptivity of the material. The test result shows quite a

high BET value for the flake graphite tested.

(e) Thermogravimetric Analysis (TGA)

TGA analyses the oxidation behaviour of graphite. Due to its

heat-resistant properties, a major application for graphite is

refractories, where high oxidation resistance is important. The TGA

analysis shows that Amitsoq graphite has low volatiles and is very

stable at temperatures up to over 400degC, which is very positive.

When the temperature is further increased, the oxidation rate is

quite high, which might be a result of the increased specific

surface area.

(f) XRF analysis

XRF trace element analysis was conducted. The main elemental

impurity in the concentrate was found to be silicon (Si), which is

typical for flake graphite. The iron (Fe) and Sulphur (S) content

are relatively high in the Amitsoq graphite concentrate. Other

elements with an increased level are zinc (Zn) and potassium (K).

The other elements are in a normal range for flake graphite of 96%

carbon level.

(g) X-Ray Diffraction (XRD)

Full XRD analysis was conducted on a combined +100 mesh

concentrate sample.

The graphitisation level shows the degree of lattice perfection

of a sample in comparison with ideal graphite (value 1). Flake

graphite is usually close to 1. The value returned for Amitsoq

graphite was 0.98, which constitutes a good result and is

comparable to graphite which is mined in northern China.

The graphite from Amitsoq consists of quite small crystals,

which have quite a high degree of lattice deformation.

Recommendations and Next Steps

The standard feed material for LIBs is termed "-195" grade,

comprising a minimum of 80% below -100 mesh (or -150 microns) with

a minimum 95% Fixed Carbon. Based on the results obtained so far,

ProGraphite's recommendation for the final treatment of the

concentrate would be as follows:

(1) the concentrate should be screened at 150 microns, with the

flakes thereby obtained being sold separately at higher prices.

(2) The remaining material (-150 micron, approx. 85% of the

concentrate mass) appears to be a typical -195 grade product, which

could be used for spherical graphite production.

This finding that the concentrate from Amitsoq graphite appears

to be suitable for LIBs is significant, as the market for LIBs is

the fastest growing market for flake graphite, with massive growth

rates forecast for the next decade due to the expected demand for

LIBs in electric vehicles.

Alba will now commission ProGraphite to undertake the next phase

of testwork, which is to assess the purification behaviour of the

material. Given that the particle size distribution should be

suitable for usage in LIBs, it should also be confirmed that it is

possible to lower the impurities in the concentrate to typical

values for LIBs.

About Graphite

Graphite is a non-toxic, chemically inert material. Additional

characteristics of graphite are its high electric and thermic

conductivity, excellent lubricity and exceptional thermal shock

resistance. These characteristics mean that graphite is widely used

in a variety of industrial applications. However, graphite is also

an essential component in certain critical technological advances

that are at the forefront of the drive to reduce global CO (2)

emissions. In particular, graphite is the anode material in

lithium-ion batteries which are used to power electric vehicles and

domestic electricity storage systems.

Graphite and the Battery Metals Sector

To meet battery cell manufacturers' specifications for use as

the anode in lithium-ion batteries, natural flake graphite must be

purified and shaped into small spheres, at which point the material

is referred to a High Purity Spherical Graphite ("HPSG"). After

shaping, the natural flake graphite is purified by chemical

leaching to remove impurities and raise the carbon content to above

99.95% C. HPSG is further processed by coating a single layer of

carbon onto the spheres to produce spherical coated graphite.

Spherical graphite commands much a higher price than selling a

flake graphite concentrate.

Demand for graphite from the lithium-ion market alone is

forecast to rise from nearly 200,000 tonnes per year currently in a

700,000 to 800,000 tonne overall graphite market to nearly 3

million tonnes a year in a 4 million tonne graphite market by 2030

(Benchmark Mineral Intelligence, December 2020, as quoted in

www.investingnews.com , 11 January 2021) .

About ProGraphite

Headquartered in Germany, ProGraphite GmbH offers professional

expertise in natural graphite and other carbon products, acquired

during several decades of working in the graphite industry

worldwide. ProGraphite's business activities include consulting,

laboratory and mineralogical services. Additionally, due to its

extensive experience in the graphite sector, ProGraphite supports

customers and end users to evaluate the optimal graphite type and

grade for their specific projects.

This announcement contains inside information for the purposes

of Article 7 of EU Regulation 596/2014.

Forward Looking Statements

This announcement contains forward-looking statements relating

to expected or anticipated future events and anticipated results

that are forward-looking in nature and, as a result, are subject to

certain risks and uncertainties, such as general economic, market

and business conditions, competition for qualified staff, the

regulatory process and actions, technical issues, new legislation,

uncertainties resulting from potential delays or changes in plans,

uncertainties resulting from working in a new political

jurisdiction, uncertainties regarding the results of exploration,

uncertainties regarding the timing and granting of prospecting

rights, uncertainties regarding the timing and granting of

regulatory and other third party consents and approvals,

uncertainties regarding the Company's or any third party's ability

to execute and implement future plans, and the occurrence of

unexpected events.

Without prejudice to the generality of the foregoing,

uncertainties also exist in connection with the ongoing Coronavirus

(COVID-19) pandemic which may result in further lockdown measures

and restrictions being imposed by Governments and other competent

regulatory bodies and agencies from time to time in response to the

pandemic, which measures and restrictions may prevent or inhibit

the Company from executing its work activities according to the

timelines set out in this announcement or indeed from executing its

work activities at all. The Coronavirus (COVID-19) pandemic may

also affect the Company's ability to execute its work activities

due to personnel and contractors testing positive for COVID-19 or

otherwise being required to self-isolate from time to time.

Actual results achieved may vary from the information provided

herein as a result of numerous known and unknown risks and

uncertainties and other factors.

Competent Person Declaration

The information in this release that relates to Exploration

Results has been reviewed by Mr Mark Austin. Mr Austin is a member

of SACNASP (Reg. No. 400235/06), Fellow of The Geological Society

and Fellow of the Geological Society of South Africa. He has a

B.Sc. Honours in Geology with 38 years' experience.

Mark Austin has sufficient experience that is relevant to the

style of mineralisation and type of deposit under consideration and

to the activity being undertaken to qualify as a Competent Person

as defined in the 2012 Edition of the 'Australasian Code for

Reporting of Exploration targets, Exploration Results, Mineral

Resources and Ore Reserves', also known as the JORC Code. The JORC

code is a national reporting organisation that is aligned with

CRIRSCO. Mr Austin consents to the inclusion in the announcement of

the matters based on his information in the form and context in

which they appear.

Glossary

Attrition or Attritioning : the process of grinding ore in

mineral processing.

Comminution : reduction of the particle size of materials.

Crushing and grinding are the two primary comminution

processes.

Fixed Carbon (or Total Carbon) : Carbon may be present in rocks

in various forms including organic carbon, carbonates or graphitic

carbon. Carbon in rocks may be reported as fixed or total carbon

(organic carbon + carbon in carbonate minerals + carbon as

graphite) or as total graphitic carbon (or TGC) (total carbon -

(organic + carbonate carbon).

Flotation : in mineral processing, the method used to separate

and concentrate ores by altering their surfaces to a hydrophobic

condition-that is, so that the surfaces are repelled by water. A

stream of air bubbles is then passed through the pulp. The bubbles

attach to and levitate the hydrophobic particles, which collect in

a froth layer which flows over the weir of the flotation cell.

LOI : Loss on ignition (LOI) is a test used in inorganic

analytical chemistry and soil science, particularly in the analysis

of minerals and the chemical makeup of soil. It consists of

strongly heating ("igniting") a sample of the material at a

specified temperature, allowing volatile substances to escape,

until its mass ceases to change.

Mesh : mesh or mesh size refers to the mesh number (a US

measurement standard) and its relationship to the size of the

openings in a mesh and thus the size of particles that can pass

through these openings. The mesh number is equal to the number of

openings in one linear inch of screen. A 4-mesh screen means there

are four square openings across one inch of screen. A 100-mesh

screen has 100 openings per inch, and so on. As the number

indicating the mesh size increases, the size of the openings and

thus the size of particles captured by the screen decreases.

Micronising : micronisation is the process of reducing the

average diameter of a solid material's particles. Traditional

techniques for micronisation focus on mechanical means, such as

milling and grinding. Modern techniques make use of the properties

of supercritical fluids and manipulate the principles of

solubility.

Micron : a micron is the measure of length most frequently used

to describe tiny particle sizes. The term micron is shorthand for

micrometre. The official symbol for the micron or micrometer is

<MU>m, sometimes simplified as um. A micron is defined as

one-millionth of a metre, a little more than one twenty-five

thousandth of an inch.

Milling : a mill is a device that breaks solid materials into

smaller pieces by grinding, crushing or cutting.

Spherical graphite : used as the anode in lithium-ion batteries.

Natural flake graphite is first purified and shaped into small

spheres, at which point the material is referred to a High Purity

Spherical Graphite ("HPSG"). After shaping, the natural flake

graphite is purified by chemical leaching to remove impurities and

raise the carbon content to above 99.95% C. HPSG is further

processed by coating a single layer of carbon onto the spheres to

produce spherical coated graphite. The spheronisation process

decreases the surface area to allow more graphite into a smaller

volume. This creates a smaller, denser, more efficient anode

product for the battery. It also increases the rate at which the

cell can be charged and discharged.

TGA (Thermogravimetric analysis or thermal gravimetric analysis)

: a method of thermal analysis in which the mass of a sample is

measured over time as the temperature changes.

XRD (X-ray diffraction) : a rapid analytical technique primarily

used for phase identification of a crystalline material and can

provide information on unit cell dimensions. The analysed material

is finely ground, homogenized, and average bulk composition is

determined. XRD determines the mineralogy.

XRF (x-ray fluorescence) : an x-ray optical analysis technique

which is based on spectroscopic detection of fluorescence of atoms

which are excited by x-rays. It is an elemental analysis technique

which is able to confirm the concentration of different elements in

a sample. XRF analyses for chemistry.

For further information, please contact:

Alba Mineral Resources plc

George Frangeskides, Executive Chairman +44 20 3950 0725

Cairn Financial Advisers LLP (Nomad)

James Caithie / Liam Murray +44 20 7213 0880

ETX Capital (Broker)

Thomas Smith +44 20 7392 1494

Alba's Project and Investment Portfolio

Project (commodity) Location Ownership

Mining Projects

Amitsoq (graphite) Greenland 90%

----------- ----------

Clogau (gold) Wales 90%

----------- ----------

Gwynfynydd (gold) Wales 100%

----------- ----------

Inglefield (copper, cobalt,

gold) Greenland 100%

----------- ----------

Limerick (zinc-lead) Ireland 100%

----------- ----------

Melville Bay (iron ore) Greenland 51%

----------- ----------

TBS (ilmenite) Greenland 100%

----------- ----------

Oil & Gas Investments

Brockham (oil) England 5%

----------- ----------

Horse Hill (oil) England 11.765%

----------- ----------

This information is provided by RNS, the news service of the

London Stock Exchange. RNS is approved by the Financial Conduct

Authority to act as a Primary Information Provider in the United

Kingdom. Terms and conditions relating to the use and distribution

of this information may apply. For further information, please

contact rns@lseg.com or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms

and conditions, to analyse how you engage with the information

contained in this communication, and to share such analysis on an

anonymised basis with others as part of our commercial services.

For further information about how RNS and the London Stock Exchange

use the personal data you provide us, please see our Privacy

Policy.

END

MSCDKFBNNBKBQBK

(END) Dow Jones Newswires

February 09, 2021 02:00 ET (07:00 GMT)

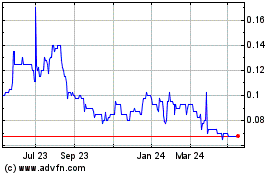

Alba Mineral Resources (LSE:ALBA)

Historical Stock Chart

From Oct 2024 to Nov 2024

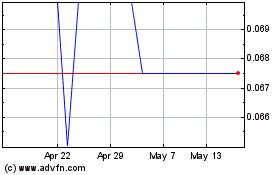

Alba Mineral Resources (LSE:ALBA)

Historical Stock Chart

From Nov 2023 to Nov 2024