By Andrew Tangel and Alison Sider

When a Boeing 777's engine cover broke apart and rained parts on

a Denver suburb on Feb. 20, the news rang familiar to Christopher

Behnam. In February 2018, the 777 he was piloting as captain

suffered a similar emergency with the same engine type.

His plane, United Airlines Flight 1175 to Honolulu, was over the

ocean 120 miles from the runway carrying more than 370 passengers

and crew when a violent blast rocked it.

The jet shook uncontrollably, rolled sharply, and the noise was

deafening, said Capt. Behnam. An engine had suffered severe damage.

Years of training kicked in, the pilots regained control and shut

the engine down. Even so, the plane was hard to handle. A third

pilot went into the cabin and looked out the window: The engine

hadn't just failed; its cover had ripped away.

"After the explosion, it felt like she was going to fall apart,"

Capt. Behnam said. "I knew I could fly the airplane. The issue was,

can I fly it long enough to land it?" The pilots brought the plane

to a safe landing in Hawaii.

The National Transportation Safety Board, which investigates

U.S. aviation failures, concluded that a roughly 35-pound fan blade

broke in the plane's Pratt & Whitney PW4000 engine due to

fatigue, spiraling forward and causing parts of the engine cover to

drop into the sea.

Until last month's Colorado incident involving United Flight

328, the aviation industry and the Federal Aviation Administration

had acted only haltingly to address such breakups. That's despite a

series of such failures starting at least five years ago.

Engine "fan blade-outs" are an old problem in aviation. But in

recent cases involving Boeing airliners, fast-spinning blade

fragments have shot forward into the engine's inlet, rather than

into a protective casing that acts like a bulletproof vest around

the sides.

That has resulted in another problem. Engine covers sometimes

aren't surviving those blade fractures, creating bigger hazards for

planes, passengers and people on the ground.

A similar engine-cover emergency had hit a Southwest Airlines

Co. Boeing 737 flight in 2016. At least three more happened after

Capt. Behnam's flight. Two months after his scare, a Southwest

engine cover broke and blasted out a window; a passenger was

partially sucked out and died. On Dec. 4, 2020, an engine broke up

on a 777 flight near Japan.

Regulators, engine makers and airlines have confronted the

problem with a short-term remedy. With varying degrees of urgency

in recent years, they have stepped up fan-blade inspections to find

pre-fracture cracks that could lead to engine covers ripping

off.

Despite working on modifications and replacements for more than

two years, plane maker Boeing Co., which is responsible for engine

coverings on its aircraft, and the FAA have yet to finalize plans

to redesign the types of engine covers that have ripped off. "We've

already seen extreme cases," said NTSB Chairman Robert Sumwalt. "It

is something that the industry needs to get on top of and get

corrected immediately."

Complicating the industry's response to the safety hazard is

that it requires coordination among several segments -- airplane

manufacturers, engine makers, airlines -- and among different

engineers and regulators focused on avoiding fan-blade fractures

and still others focused on preventing engine covers from detaching

midair.

In the U.S., that puts the FAA in the best position to tackle

the hazard. Its handling of the engine breakups is the regulator's

first big test since its fumbled responses to fatal Boeing 737 MAX

crashes in 2018 and 2019.

The FAA declined to make senior agency officials available for

interviews. A spokesman said a priority has been reducing the risk

of fan-blade failures that can lead to engine covers detaching

midair. The FAA spokesman said design changes to a "critical piece

of structure must be carefully evaluated and tested" to ensure they

provide the same level of safety or better without introducing

unintended risks.

Boeing spokesman Bradley Akubuiro said the company "has taken

steps to move forward" with the FAA to improve engine covers and is

giving its technical teams time they need to ensure any of the

manufacturer's design changes provide their expected performance

and maintain overall safety. While designing changes is "exacting

and time-consuming," he said, "this work has been, and remains, a

high priority."

Southwest spokeswoman Brandy King said the airline's leaders,

including Chief Executive Gary Kelly, were focused on understanding

and learning from the carrier's fatal accident while working with

manufacturers to prevent similar tragedies in the future. Pratt

& Whitney and United Airlines Holdings Inc. declined to

comment.

Planes made by Airbus SE haven't experienced any such

engine-cover breakups due to fan-blade fractures in recent years,

according to the European Union Aviation Safety Agency, the primary

regulator for Boeing's rival across the Atlantic.

Over the past five years, the problem of engine covers detaching

due to fan-blade failures that spew parts forward appears to have

primarily surfaced on two Boeing aircraft types, the 777 and 737,

which use engines made by different manufacturers, according to

current and former FAA officials.

To keep fan blades from breaking in the first place, regulators

have focused first on stepping up inspections. Within days of the

Dec. 4 engine breakup near Japan, Tokyo's air-safety regulators

ordered new engine inspections -- visual checks and

ultraviolet-light tests, a Japanese aviation official said.

The FAA opted against immediate action and was still considering

its next step when the United 777's engine broke apart near Denver

last month. Before that incident, Pratt & Whitney, a unit of

Raytheon Technologies Corp., was considering issuing a service

bulletin telling airlines to conduct specialized inspections of

certain 777 engines every 1,000 flights, said the NTSB's Mr.

Sumwalt. The FAA had required the deep inspections every 6,500

flights after the 2018 incident in Hawaii.

The FAA declined to comment about its response to the December

breakup. The agency said it makes safety-oversight decisions in a

rigorous, well-established analytical process aimed at quickly

identifying and mitigating risk, adding: "To suggest that there is

commonality among different events ignores the fact that data for

different events is unique to each specific event."

Early warning

An early warning about the risk that engine covers could crumble

when broken blades fly far enough forward came in August 2016. A

Southwest flight from New Orleans to Orlando made an emergency

landing after an engine failed -- a fan blade broke, causing

significant damage and leading the cabin to depressurize. One of

the engine's 24 fan blades had broken due to fatigue, NTSB

investigators found.

The spinning blade had careened into the front inlet where air

flows into the engine. Most of the inlet broke off, spitting debris

into the Boeing 737 jet's fuselage, wing and horizontal

stabilizer.

Regulators and industry experts, including at the NTSB,

generally viewed that event as a one-off, the NTSB's Mr. Sumwalt

said.

The engine's manufacturer, CFM International -- a joint venture

of General Electric Co. and France's Safran SA -- developed a new,

more high-tech inspection protocol using ultrasound technology. A

GE spokesman speaking on behalf of the joint venture said the

engine maker worked with regulators and customers to enhance and

implement inspection procedures and remained committed to working

on changes stemming from the NTSB's recommendations.

The FAA in 2017 considered mandating additional fan-blade

testing, though it didn't require additional checks until the

following year when it ordered emergency inspections in the

aftermath of the fatal engine-cover breakup on another Southwest

flight.

"We determined early that we would require some corrective

action and that it was an unsafe condition," Christopher Spinney,

an FAA engine specialist, said during an NTSB hearing in 2018. "But

we also determined that we had some time." Mr. Spinney, through an

FAA spokesman, declined to comment.

On Capt. Behnam's flight that year, after the fan blade

scattered parts of the 777's engine cover, the plane's aerodynamics

were out of whack. It felt, he said, like "having an open barn

door" on the right side of the plane.

Two months later on a Southwest 737, debris from an engine

covering -- again loosened by a broken fan blade -- smashed into

the plane's body, blasting out the window through which the

passenger was partially sucked.

She was the first U.S. airline-passenger fatality in nearly a

decade and Southwest's first passenger fatality. After the death,

Mr. Kelly, Southwest's CEO, pushed Boeing for an engine-cover fix

to avoid a repeat of such a tragedy, according to a person familiar

with the plane maker's work on the 737 engine cover.

After those incidents, the industry began to grapple with

vulnerable engine covers. Not only were fan blades failing, they

were doing damage to engine coverings that had been expected to

withstand such events.

Boeing engineers were particularly concerned about a potential

loss of control should engine covers break off and damage a plane's

horizontal stabilizer, said the person familiar with the plane

maker's work.

Engine makers put their engines through a battery of tests to

make sure they will hold together if a fan blade breaks. They are

largely focused on making sure debris doesn't go through the side

of the engine casing, where it could penetrate the body of the

plane. Broken fan blades can still cause damage by flying

forward.

Coverings go through their own certification process on a

separate track.

While engine coverings are expected to contain broken fan

blades, they aren't designed to shield more-serious failures of

hubs the blades are attached to -- as happened on an Airbus A380

jet over Greenland in 2017. Parts fell off at 37,000 feet, damaging

buildings but causing no injuries.

Within about two weeks of that incident, the FAA issued an

emergency order requiring inspections on roughly 120 of the jets

equipped with certain engines produced by Engine Alliance, a joint

venture between GE and Pratt & Whitney. GE referred inquiries

to Pratt & Whitney, which declined to comment on Engine

Alliance's behalf. An Airbus spokesman said the plane maker takes

into account past incidents and accidents, including those on other

manufacturers' aircraft, to enhance safety.

Boeing engineers have been working on a plan to strengthen 737

engine covers, essentially to soften the shock of a fan-blade

failure and keep parts attached to the plane even when the blades

fly forward, people familiar with the work said.

In March 2020, FAA Administrator Steve Dickson told the NTSB the

agency was working with the plane maker to strengthen the 737

engine covers, according to written responses to the NTSB's

recommendations. He said the agency would eventually mandate a new

design change. The FAA declined to make Mr. Dickson available for

an interview.

In August 2020, Boeing provided an update to the FAA on its work

to also strengthen 777 engine covers. The manufacturer told

regulators it had decided to redesign and make replacement covers

with which airlines could retrofit their fleets, according to the

FAA document.

Boeing's 777 engine-cover fix didn't come in time for the Dec. 4

incident near Japan, on a Japan Airlines Co. 777 with Pratt &

Whitney PW4000 engines. Two of an engine's fan blades broke shortly

after takeoff from Okinawa, according to a preliminary report by

Japanese investigators. Part of the engine's cover detached, and

the jet's body and horizontal stabilizer sustained damage, the

report said. A JAL spokesman declined to comment on the cause of

the incident.

The FAA held off ordering immediate action. After the December

incident, the agency said it reviewed the JAL engine's maintenance

and inspection history, conducted a metallurgical exam and was

evaluating whether to adjust blade inspections.

It wasn't immediately clear to investigators and regulators

whether the fan-blade cracks at the root of both 777 engine

breakups roughly two years apart shared the same underlying cause,

according to a person familiar with the FAA's response. Age,

manufacturing defects or maintenance slip-ups can cause metal to

crack and eventually fracture. The FAA declined to comment about

its work with Boeing on 777 engine covers.

Since the Colorado 777 incident, Boeing has shared some of the

changes it is considering to shore up 737 engine covers with

carriers including Southwest and American Airlines Group Inc., said

people briefed on the matter. It has also been in talks with United

about potential changes to 777 engine covers, according to a person

familiar with those discussions. Boeing and the FAA declined to

comment on when 777 or 737 engine-cover fixes would be

completed.

Japanese regulators grounded the aircraft the day after the

Colorado incident. Soon thereafter, Mr. Dickson ordered immediate

specialized inspections even while some FAA officials didn't

believe such drastic action was necessary, said people familiar

with the agency's response.

The move, which the FAA described as "decisive action,"

effectively took more than 50 Boeing 777s with certain Pratt &

Whitney engines -- all operated by United -- out of service for

months, until inspections have been completed.

Tom Haueter, a former NTSB director of aviation safety who now

consults on safety and accident investigations, said: "They

grounded the fleet -- that's about as aggressive as you can

get."

--Chieko Tsuneoka, Benjamin Katz and Doug Cameron contributed to

this article.

Write to Andrew Tangel at Andrew.Tangel@wsj.com and Alison Sider

at alison.sider@wsj.com

(END) Dow Jones Newswires

March 19, 2021 10:19 ET (14:19 GMT)

Copyright (c) 2021 Dow Jones & Company, Inc.

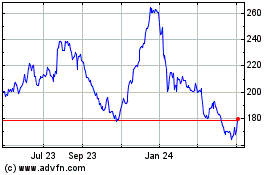

Boeing (NYSE:BA)

Historical Stock Chart

From Jun 2024 to Jul 2024

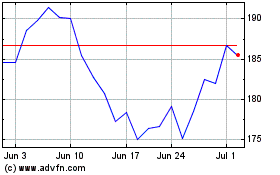

Boeing (NYSE:BA)

Historical Stock Chart

From Jul 2023 to Jul 2024