Intervals include 210m grading 0.50% Cu Eq.

including 68m grading 0.86% Cu Eq. and 154m grading 0.53% Cu

Eq.

Highlights:

- Results from GS24-07 through GS24-10 have now been released and

each includes wide intercepts of copper-gold porphyry related

mineralization

- Holes show increasing grade and intensity of stockwork veining

going to the northwest within the West Goodspeed mineralized

zone

- The West Goodspeed intercepts are near surface and cover a

lateral extent of at least 800 meters and the target remains open

both along strike and down dip with additional potential for

fault-offset mineralization

- Drilling is scheduled to return to this area in the coming days

with the goal of further expanding the limits of mineralization

using helicopter-assisted drilling

Northisle Copper and Gold Inc. (TSX-V: NCX)

(“Northisle” or the “Company”) is pleased to announce that

additional diamond drill holes and assays from its West Goodspeed

exploration program confirm the existence of near-surface

porphyry-style mineralization over wide intervals.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20240819045342/en/

Figure 1: Aerial View Looking East to

West Goodspeed (Photo: Business Wire)

Assays released today for GS24-07 through GS24-10, combined with

previously released drill holes at West Goodspeed have all

intercepted copper and gold mineralization within a large,

structurally controlled zone stretching over at least 800m of

strike length which remains open along strike and at depth.

Significant intervals from 2024 drilling at West Goodspeed are

shown in Table 1. GS24-10 stands out as containing the longest

intercept to date from West Goodspeed of 210m grading 0.50% Cu Eq.

starting at overburden with a sub-interval of 68m grading 0.86% Cu

Eq.

Table 1: West Goodspeed Significant

Intercepts

Hole ID

From (m)

To (m)

Interval (m)

Cu Grade (%)

Au Grade (g/t)

Mo Grade (%)

Ag Grade (g/t)

Re Grade (g/t)

Cu Eq. Grade (%)

Au Eq.

Grade (g/t)

GS24-06

9.4

93.0

83.6

0.20

0.184

0.005

1.18

0.271

0.38%

0.511

including

9.4

69.2

59.8

0.22

0.201

0.005

1.24

0.291

0.42%

0.556

and

125.0

237.0

112.0

0.20

0.270

0.009

0.21

0.700

0.47%

0.623

Including

133.0

201.0

68.0

0.28

0.384

0.009

0.28

0.743

0.63%

0.846

GS24-07

13.2

168.0

154.8

0.23

0.313

0.008

1.19

0.533

0.53%

0.709

GS24-08

105.0

174.0

69.0

0.19

0.217

0.006

0.56

0.433

0.40%

0.533

and

186.0

302.0

116.0

0.15

0.134

0.006

0.19

0.385

0.29%

0.391

GS24-09

151.0

274.0

123.0

0.21

0.165

0.010

0.21

0.808

0.41%

0.542

GS24-10

46.0

256.0

210.0

0.23

0.285

0.007

1.19

0.447

0.50%

0.671

including

110.0

178.0

68.0

0.37

0.580

0.005

1.83

0.260

0.86%

1.142

Copper and gold equivalent calculations

based on the following metal prices which were used in the

Company’s 2024 Resource Estimate for Northwest Expo:

Cu = US$3.50/lb, Au = US$1,800/oz, as well

as Mo = US$20/lb, Ag = US$25/oz and Re = US$1,256/kg. Calculations

assume 100% recovery; totals may not add due to rounding. Intervals

were selected based on continuous intercepts with a copper grade

above 0.1% Cu or a gold grade above 0.1g/t Au.

Intercepts for GS24-06 have been revised

to incorporate larger intervals following a review of assay data in

context of other results.

Note on equivalent calculation:

Copper equivalent is determined by

calculating total contained metal value per tonne, dividing by the

copper price, and then dividing the resultant number of pounds of

copper by 2204.6. Gold equivalent is determined by calculating

total contained metal value/tonne, dividing by the gold price, and

then multiplying the resultant number of troy ounces of gold by

31.103. Analyzed metal equivalent calculations are reported for

illustrative purposes only and assume 100% recoveries as

metallurgical testing has not yet been completed on material from

the West Goodspeed target.

Sam Lee, President and CEO stated, “Our exploration team

continues to deliver at West Goodspeed following its discovery in

late 2023. Our 2024 Phase 1 program has been very successful to

date as all holes assayed have intercepted grades and widths

anticipated to have a positive impact on our overall resource

portfolio. The mineralization is near surface, open along strike

and down dip, and is adjacent to the footprint of the North Island

Project as defined in our 2021 PEA as well as the ongoing updated

PEA work. The results to date support prioritizing further

exploration at this compelling target as part of future

programs.”

West Goodspeed Drill Result Details

Assay results have now been received for five of the eight drill

holes completed during 2024 on the West Goodspeed target. These

include GS24-06 (previously reported) to GS24-10. All holes were

drilled from existing reactivated forest service roads.

Table 2 shows the collar data for the holes drilled at West

Goodspeed during 2023 and 2024.

Table 2: West Goodspeed 2023 and 2024 Drill

Hole Collar Locations

Hole ID

Length (m)

UTM East

UTM North

UTM Elevation

Azimuth

Dip

GS23-04

384

573657

5617478

341

225

-80

GS23-05

294

573387

5617444

312

90

-55

GS24-06

531

573668

5617298

337

60

-85

GS24-07

365.6

573668

5617298

337

270

-60

GS24-08

387

573901

5617365

379

170

-80

GS24-09

471

573901

5617365

379

125

-60

GS24-10

396

573461

5617615

324

250

-45

GS24-11

378

573661

5617800

341

180

-60

GS24-12

GS24-13

549

467

572890

574477

5617695

5617428

412

467

180

220

-65

-55

GS24-07 was drilled from the same drill pad as GS24-06 but

directed in the opposite direction targeting an area to the west,

180 metres south of discovery hole GS23-04. GS24-08 and GS24-09

were collared on the same pad 240 metres east-north-east of

GS24-06/07 and were targeted to step out to the east and down dip

of previous drill holes. GS24-10 was collared 200 metres northwest

of GS24-04 directed in a southwesterly direction with the goal of

testing the northwest extension of the target. Despite the paucity

of outcrop here, field mapping has confirmed the existence of late

fault sets parallel to the major mineralization bounding faults

observed in core and interpreted as shown by the red dashed lines

in Figure 1, which also shows the location of the drill collars for

completed Phase 1 holes in a birds-eye view looking northeast

towards West Goodspeed.

Figure 2 shows the drilling at West Goodspeed in a plan view, as

well as additional targets in the Red Dog / Goodspeed area.

The two post mineralization faults shown in figures 1, 2 and 3

appear to control the location of porphyry style copper-gold

mineralization consisting of potassic alteration of

biotite-magnetite (retrograded to chlorite-magnetite) and

overprinted by quartz-sericite-pyrite alteration, as well as

porphyry related banded magnetite or stockwork quartz magnetite and

quartz-sulphide veining as shown in Figures 4, 5 and 6. The

intensity of this porphyry related veining and copper

mineralization appears to increase to the northwest as seen in

GS24-10.

Additional drilling is now planned at West Goodspeed to step out

along strike to the northwest and southeast as well as searching

for additional mineralization on the hanging wall and footwall of

the two structurally bounding faults, and to better define the

mineralized zone.

Figure 3 shows the Company’s working 3D model of the West

Goodspeed target, looking down the dip between the interpreted

bounding faults with the calculated Cu Eq. assays using the same

basis as the highlighted intervals above.

Mineralization at West Goodspeed exhibits multiple generations

of Cu and Au +/- Ag/Re/Mo mineralization. Magmatic hydrothermal

breccias shown in Figure 4 host multiple phases of porphyry clasts,

as well as refractory quartz-chalcopyrite-pyrite vein fragments.

Mineralization occurs as disseminated, remobilized chalcopyrite

grains, as well as late magnetite-chalcopyrite veins and clots.

Figure 5 shows multiple phases of overprinting stockwork veining.

Vein related mineralization occurs as early banded quartz-magnetite

+/- chalcopyrite veins, early quartz-chalcopyrite centreline veins

(off-set and undulating), late magnetite-chalcopyrite +/- chlorite

(after biotite) veinlets as well as the latest stage

pyrite-chalcopyrite-sericite-quartz veinlets commonly with

muscovite-illite halos as shown in Figure 6, which locally appears

to supply a late Cu additive overprint on the early Cu-Au

endowment. Cu Eq. grades appear to correlate best with increased

stockwork vein abundance as seen in GS24-10.

Upcoming Catalysts

In 2024, the Company will continue advancing the North Island

Project, with development and exploration catalysts throughout the

year leading to measurable impacts for shareholders, including the

following:

- COMPLETED - Geophysics results from Northwest Expo and

West Goodspeed

- COMPLETED - Northwest Expo metallurgical testing and

initial resource estimate

- COMPLETED - Final 2023 Pemberton Hills Drill

Results

- COMPLETED - Commencement of 2024 drilling program

- COMPLETED - Preliminary Project Trade-offs

- COMPLETED - Commencement of advanced economic and

technical studies

- COMPLETED - Initial drill results from West

Goodspeed

- Q3 2024 - Continued Exploration Results from 2024 Phase

1 drilling program

- Q3 2024 - Integrated North Island Project Mineral

Resource Estimate Update

- Q4 2024 - North Island Project 2024 PEA

- H2 2024 - Full Results from 2024 Phase 1 drilling

program

- Ongoing - Continued positive engagement with indigenous

rightsholders and local stakeholders

Upcoming Investor Events

During 2024, the Company will continue to be active in investor

outreach. Northisle will be attending several external investor

events including the following events during Q3/Q4 2024:

- Summer 2024: Broker and Institutional Site Visits

- September 10 – 13, 2024: Precious Metals Summit, Beaver

Creek, CO

- September 15 – 18, 2024: Gold Forum Americas, Colorado

Springs, CO

- November 20 – 21, 2024: Swiss Mining Institute, Zurich,

Switzerland

Additional Technical Details

Logging, Sampling and Assaying Procedures and QA/QC

The diamond drill core logging and sampling program was carried

out under a rigorous quality assurance / quality control (QA/QC)

program. Drill intersections in this release are typically HQ to

100 m and NQ thereafter to the end of holes. After drilling, core

was logged for geology, structure, and geotechnical characteristics

utilizing Geospark© core logging software, then marked for sampling

and photographed on site. The cores for analyses were marked for

sampling based on geological intervals with individual samples 3 m

or less in length. Drill core was cut lengthwise in half with a

core saw. Half-core was sent for assays reported in this news

release. Prior to cutting core for assay bulk density was also

determined on site by taking 15 to 20 centimetres (cm) lengths of

whole core of each lithology at 10 m intervals. The ends of these

were then cut at right angle to the core axis, retaining all pieces

to be returned to the core box for later sample cutting and

analysis. The diameter of each core sampled for bulk density was

measured at each end with digital calipers to 3 decimal places and

recorded. The length of the core was measured on four sides at 90

degrees to each other, to 2 decimal places and recorded. The

software averaged the lengths and diameters. The mass of the dry

core was measured twice on an Ohaus© balance to 2 decimal places.

If no discrepancy occurred the measurement was recorded. If there

was a discrepancy the measuring was repeated until no discrepancy

between 2 measurements occurred. The density was calculated using

the formula Bulk Density = π times r² times h (where r is radius of

core and h is length of core). Certified standard masses are used

to calibrate the scale balance used for bulk density

determinations. The balance in the core logging area was levelled

on a large concrete block to avoid vibration, was leveled, and

surrounded by a wooden partition to avoid wind affecting the

balance. The measurements were recorded in Geospark© logging

software and Bulk Density calculated to 2 decimal places.

A total of 5% assay standards or blanks and 5% core duplicates

are included in the sample stream as a quality control measure and

are reviewed after analyses are received. Standards were obtained

from WCM Minerals, Vancouver, CDN Minerals, Langley and OREAS,

Canada. Blanks were obtained from unmineralized course bagged

limestone landscaping rock. Standards and blanks in 2023 drill

results to date have been approved as acceptable. Duplicate data

add to the long-term estimates of precision for assay data on the

project and precision for drill results reported is deemed to be

within acceptable levels. Samples were sent to the MSALABS in

Langley, BC where the samples were dried, then crushed, split and a

250 gram (g) split was pulverized to 85% passing -200 mesh (-75

micrometres (µm)) size pulps. Clean crush material was passed

through the crusher and clean silica was pulverized between each

sample. The pulps were analyzed for gold by fire assay fusion of 50

g of the 250 g split. Total gold content was determined by

digesting the silver doré bead from the fusion and then analysing

by AA (MSA Code FAS-121). All samples were also analyzed for

multiple elements by taking a 0.25 g of the 250g split which was

heated in HNO3, HClO4 and HF to fuming and taken to dryness. The

residue was dissolved in HCl and then analyzed utilizing ICP-MS

(MSA Code IMS-230). Any sulphur analysis from this latter analysis

with a value greater than 10% was reanalyzed utilizing a Leco

sulfur analyzer. Iron and Tungsten accelerators are added to the

sample and a stream of oxygen is passed over the sample in the

induction furnace. As the sample is heated, sulfur dioxide released

from the sample is measured by an IR detection system and the Total

Sulphur content is determined. (MSA Code SPM-210). MSALABS

(Langley) is an independent, international ISO/IEC 17025:2005

accredited laboratory.

Pulps and rejects of holes with significant assay intervals are

stored at Western Mineral Storage. The remaining split core is

indexed and stored at Northisle logging and office facility in Port

Hardy, BC.

Drill Results in this news release are length weighted

averages.

Qualified Persons and Data Verification

Robin Tolbert, P.Geo., Vice President Exploration of Northisle,

and a Qualified Person as defined by National Instrument 43-101

Standards of Disclosure for Mineral Projects, has reviewed and

approved the scientific and technical disclosure contained in this

news release and has verified the data disclosed, including the

sampling, analytical and test data underlying the disclosure.

About Northisle

Northisle Copper and Gold Inc. is a Vancouver-based company

whose mission is to become Canada’s leading sustainable mineral

resource company for the future. Northisle, through its 100% owned

subsidiary North Island Mining Corp., owns the North Island

Project, which is one of the most promising copper and gold

porphyry projects in Canada. The North Island Project is located

near Port Hardy, British Columbia on a more than 34,000-hectare

block of mineral titles 100% owned by Northisle stretching 50

kilometres northwest from the now closed Island Copper Mine

operated by BHP Billiton. Northisle completed an updated

preliminary economic assessment for the North Island Project in

2021 and is now focused on continued advancement of the project

while exploring within this highly prospective land package.

For more information on Northisle please visit the Company’s

website at www.northisle.ca.

Cautionary Note Regarding Adjacent and Historical Property

Disclosure

This news release contains information regarding adjacent and

historical properties and deposits. Investors are cautioned that

adjacent mineral deposits or systems, or past performance of

historical mines, do not necessarily indicate and certainly do not

prove the existence, nature or extent of mineral deposits on the

North Island Project.

Cautionary Statements regarding Forward-Looking

Information

Certain information in this news release constitutes

forward-looking statements under applicable securities law. Any

statements that are contained in this news release that are not

statements of historical fact may be deemed to be forward-looking

statements. Forward-looking statements are often identified by

terms such as “may”, “should”, “anticipate”, “expect”, “intend” and

similar expressions. Forward-looking statements in this news

release include, but are not limited to, statements relating to the

MRE; plans and expectations regarding the 2024 exploration program;

plans and expectations regarding future project development; timing

of key catalysts; planned activities, including further drilling,

at the North Island Project; the Company’s anticipated exploration

activities; and the Company’s plans for advancement of the North

Island Project. Forward-looking statements necessarily involve

known and unknown risks, including, without limitation, Northisle’s

ability to implement its business strategies; risks associated with

mineral exploration and production; risks associated with general

economic conditions; adverse industry events; stakeholder

engagement; marketing and transportation costs; loss of markets;

volatility of commodity prices; inability to access sufficient

capital from internal and external sources, and/or inability to

access sufficient capital on favourable terms; industry and

government regulation; changes in legislation, income tax and

regulatory matters; competition; currency and interest rate

fluctuations; and other risks. Readers are cautioned that the

foregoing list is not exhaustive.

Readers are further cautioned not to place undue reliance on

forward-looking statements as there can be no assurance that the

plans, intentions, or expectations upon which they are placed will

occur. Such information, although considered reasonable by

management at the time of preparation, may prove to be incorrect

and actual results may differ materially from those anticipated.

Forward-looking statements contained in this news release are

expressly qualified by this cautionary statement.

The forward-looking statements contained in this news release

represent the expectations of management of Northisle as of the

date of this news release, and, accordingly, are subject to change

after such date. Northisle does not undertake any obligation to

update or revise any forward-looking statements, whether as a

result of new information, future events or otherwise, except as

expressly required by applicable securities law.

Neither the TSX Venture Exchange nor its Regulation Services

Provider (as that term is defined in the policies of the TSX

Venture Exchange) accepts responsibility for the adequacy or

accuracy of this news release.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20240819045342/en/

On behalf of Northisle Copper and Gold Inc. Nicholas Van Dyk,

CFA Chief Financial Officer Tel: (778) 655-9582 Email:

info@northisle.ca www.northisle.ca

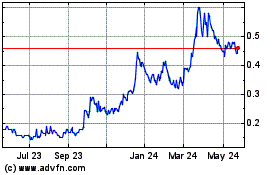

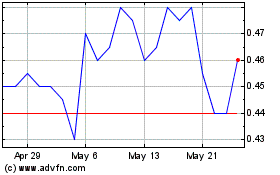

NorthIsle Copper and Gold (TSXV:NCX)

Historical Stock Chart

From Oct 2024 to Nov 2024

NorthIsle Copper and Gold (TSXV:NCX)

Historical Stock Chart

From Nov 2023 to Nov 2024