UNITED

STATES

SECURITIES

AND EXCHANGE COMMISSION

Washington,

D.C. 20549

FORM

SD

Specialized

Disclosure Report

Textron

Inc.

(Exact name

of registrant as specified in its charter)

| |

|

|

|

|

| Delaware |

|

1-5480 |

|

05-0315468 |

(State

or other jurisdiction

of

incorporation or organization) |

|

(Commission

File

Number) |

|

(IRS

Employer

Identification

No.) |

| |

|

|

| 40

Westminster Street, Providence, RI |

|

02903 |

| (Address

of principal executive offices) |

|

(Zip

Code) |

| |

|

|

E. Robert

Lupone

Executive

Vice President, General Counsel and Secretary

(401) 457-2555

(Name and

telephone number, including area code, of the

person to

contact in connection with this report)

Check

the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information

in this form applies:

| þ |

Rule 13p-1 under

the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2023. |

Section 1 – Conflict

Minerals Disclosure

Item 1.01 Conflict Minerals

Disclosure and Report

Conflict Minerals Disclosure

A

copy of Textron Inc.’s Conflict Minerals Report filed

for the calendar year ended December 31, 2023 is publicly available at http://investor.textron.com/investors/corporate-governance/default.aspx.

Item 1.02 Exhibit

Textron Inc.’s Conflict

Minerals Report for the calendar year ended December 31, 2023 is filed as Exhibit 1.01 hereto.

Section 2 – Exhibits

Item 2.01 Exhibits

Exhibit

1.01 Textron Inc. Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form.

SIGNATURES

Pursuant to the requirements of the

Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized

undersigned.

| |

textron

INC. |

| |

|

|

| |

BY: |

/s/

E. Robert Lupone

|

| |

|

E. Robert Lupone, |

| |

|

Executive Vice President, General Counsel

and Secretary |

| |

|

|

Date:

May 23, 2024

Exhibit 1.01

TEXTRON

INC.

Conflict

Minerals Report

For

the Year Ended December 31, 2023

Introduction

Textron Inc. is providing

this report for the year ended December 31, 2023 to comply with Rule 13p-1 under the Securities Exchange Act of 1934 (the “Rule”).

The Rule imposes certain reporting obligations on SEC registrants that manufacture or contract to manufacture products containing

conflict minerals that are necessary to the functionality or production of those products. The term “conflict mineral”

means columbite-tantalite, also known as coltan, cassiterite, gold and wolframite, or their derivatives, which are limited to

tantalum, tin and tungsten (collectively, “3TGs”).

Company and Product

Overview

Textron is a $13.7 billion

multi-industry company operating in numerous countries around the world. Our businesses manufacture a variety of complex products

including (a) at our Textron Aviation segment, business jets, turboprop and piston aircraft, military trainer and defense aircraft,

(b) at our Bell segment, helicopters and tiltrotor aircraft, (c) at our Textron Systems segment, unmanned aircraft systems, electronic

systems and solutions, advanced marine craft, piston aircraft engines, weapons and related components, armored and speciality

vehicles, (d) at our Industrial segment, fuel systems and related components, clear vision systems and battery systems for use

in electric and hybrid electric vehicles, specialized vehicles such as golf cars, off-road utility vehicles, light transportation

vehicles, powersports products, aviation ground support equipment, professional turf-maintenance equipment and specialized turf-care

equipment, and (e) at our Textron eAviation segment, light aircraft and gliders with both electric and combustion engines. References

to “Textron”, “we” and “our” in this Report refer to Textron Inc. and its consolidated subsidiaries.

Covered Products

We conducted a review of the products

that we manufacture or contract to be manufactured and found that our products contain 3TGs within numerous components, such as

jet engines, circuit boards, electronics, brake components and wiring, and 3TGs generally are required for the products’

functionality or production as specified under the Rule.

Reasonable Country of

Origin Inquiry

We conducted a Reasonable

Country of Origin Inquiry (“RCOI”) to seek to ascertain whether the 3TGs in our products originated from the Democratic

Republic of the Congo or an adjoining country (known collectively as the “Covered Countries”) or are from recycled

or scrap sources.

Because of our size, the

complexity of our products, and the depth, breadth, and constant evolution of our worldwide supply chain, it is difficult to identify

suppliers in our supply chain which are multiple steps removed from our direct (first-tier) suppliers, and we have no direct relationships

with mines, smelters or refiners of 3TGs. Accordingly, we rely on our direct suppliers to provide information on the origin of

the 3TGs contained in components and materials supplied to us by them – including sources of 3TGs that are supplied to them

from lower tier suppliers.

To implement our RCOI,

we established enterprise-wide conflict minerals procedures directing each business unit to take a number of steps to identify

suppliers (“in-scope suppliers”) of components or materials potentially containing 3TGs included in products we manufactured

or contracted to manufacture during 2023. As in prior years, in 2023 we retained a third-party service provider to assist us in

reviewing our supply chain and identifying risks.

Our third-party service provider

conducted a supply chain survey with over 1,700 in-scope suppliers using the Conflict Minerals Reporting Template (“CMRT”),

version 6.2 or higher. As part of the supplier survey, in-scope suppliers were contacted via our service provider’s software

platform that enables users to complete and track supplier communications and allows suppliers to upload completed CMRT forms

directly to the platform for assessment and management. Communications sent to in-scope suppliers through the platform included

training and education on the completion of the CMRT form.

Non-responsive in-scope

suppliers were contacted a number of times through the platform and then were also contacted by our service provider’s team.

Certain suppliers were also contacted by a representative of the applicable Textron business unit. Our program for 2023 continues

to include automated data validation on all submitted CMRTs. The goal of data validation is to increase the accuracy of submissions

and identify any contradictory answers in the CMRT. The survey responses were reviewed for completeness and consistency and our

service provider followed up with suppliers who provided incomplete or inconsistent responses. Ultimately, we received complete

and validated responses to our supply chain survey from approximately 66% of the in-scope suppliers.

Although approximately

66% of Textron’s in-scope suppliers responded to the RCOI, there are many suppliers that have not yet provided any smelter

or refiner information or have provided incomplete smelter or refiner data. For the suppliers that responded and provided smelter

or refiner data, our service provider reviewed all supplier responses that claimed in the declaration section of the CMRT to have

known DRC-sourced material.

Because the results of

our RCOI indicated that some of our products contain 3TGs which may have originated from the Covered Countries, in an effort to

locate mines with the greatest possible specificity, we performed due diligence measures on the source and chain of custody of

the 3TGs as described below.

Due Diligence

Design

of Our Due Diligence Framework

Our due diligence measures

have been designed to conform, in all material respects, with the framework in The Organisation for Economic Co-operation and

Development (OECD) Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas

and the related Supplements for gold and for tin, tantalum and tungsten (OECD Guidance).

Due

Diligence Process

In conformity with the

OECD’s five step process, we conducted the following activities during the 2023 reporting period:

Step 1. Company

Management Systems

We have established a management

system to support supply chain due diligence related to 3TGs which includes maintaining an internal conflict minerals team coordinated

by our Senior Executive Counsel, with representatives from each of our business units. The team follows our documented procedures

for our conflict minerals compliance program. These procedures cover the identification of suppliers to be surveyed and escalation

procedures, as described above, records retention, updating supplier lists and integrating acquired businesses into the program.

The team leader reports to our senior management on the status of our program as appropriate.

In addition, the team has agreed

upon a recommended conflict minerals contractual provision which our businesses seek to include in any new or amended contracts

with suppliers that may be relevant for our conflict minerals compliance program. This contractual provision requires suppliers

to provide us with the necessary 3TG information and to adopt a supply chain policy and procedure to conduct, and require its

suppliers to conduct, a reasonable country of origin inquiry and, if necessary, to perform due diligence to identify the facilities

used to process the 3TGs and make efforts to identify the location of each mine or location of origin of the 3TGs with the greatest

possible specificity.

Textron has adopted a Conflict

Minerals Policy Statement which can be found at http://investor.textron.com/investors/corporate-governance/default.aspx. In addition,

we recently adopted an expanded Textron Code of Conduct for Suppliers and Other Business Partners which also can be found at http://investor.textron.com/investors/corporate-governance/default.aspx.

To improve supplier education

and training, we utilized our third-party service provider’s learning management system which provided all in-scope suppliers

access to our service provider’s Conflict Minerals training course. This training is tracked and evaluated based on completion.

All suppliers are encouraged to complete all modules within this course.

In addition, we maintain

a telephone Helpline, available 24 hours per day, seven days per week, as well as online reporting capability, as described in

our Business Conduct Guidelines, that enables anonymous reporting, through an independent third-party, of suspected or known violations

of our Business Conduct Guidelines, law or company policy. Textron’s Code of Conduct for Suppliers and Other Business Partners

also provides access to these reporting mechanisms.

Step 2. Identification

and Assessment of Supply Chain Risks

We have worked to identify

and assess our supply chain risk through the CMRT survey process. There are a variety of risks identified throughout the survey

process, including the risk presented by the lack of sourcing information due to non-responsive suppliers and suppliers providing

incomplete or inconsistent responses. The smelter and refiner data collected through the CMRT highlights actual sourcing risk,

such as a smelter or refiner sourcing from the Covered Countries and not yet certified as in conformance with third-party standards

for responsible minerals procurement, or of even higher risk, a smelter or refiner which has not yet begun the audit process to

receive certification.

Step 3. Strategy

to Respond to Identified Risks

While many risks exist

in the search for the origin of the conflict minerals used in components and materials supplied to Textron, as noted above, one

of our identified risks is the inability to obtain complete and accurate information from our suppliers in order to make determinations

about our products. There are numerous initiatives working to improve transparency and accountability at the smelter and refinery

levels of the supply chain, however, we can only benefit from the information being developed by these initiatives if our suppliers

are able to trace back the conflict minerals in their products to a specific smelter or refiner.

In our new or amended contractual

agreements with our direct suppliers, we have requested the inclusion of a contractual provision which requires suppliers to provide

us with the necessary 3TG information and to adopt a supply chain policy and procedure to conduct, and require its suppliers to

conduct, a reasonable country of origin inquiry and, if necessary, to perform due diligence to identify the facilities used to

process the 3TGs and make efforts to identify the location of each mine or location of origin of the 3TGs with the greatest possible

specificity.

This objective also is reflected

in our Conflict Minerals Policy Statement, which indicates that we encourage our suppliers to undertake reasonable due diligence

with their supply chains in an effort to assure their conflict minerals are being sourced from mines and smelters/refiners which

have been certified by an independent third party as “conflict free” if sourced within the Covered Countries. Our

Policy Statement further states that “if we determine that any of our products or components contain 3TG from a mine or

facility in a Covered Country that is not “conflict free”, we will evaluate our options, including but not limited

to reassessment of the supplier relationship.” In addition, Textron’s Code of Conduct for Suppliers and Other Business

Partners provides that our suppliers shall have a due diligence process to reasonably assure that any material considered to be

a conflict mineral in the products they manufacture does not directly or indirectly finance or benefit armed groups that are perpetrators

of serious human rights abuses in the Democratic Republic of the Congo or an adjoining country. Further, suppliers shall exercise

due diligence on the source and chain of custody of these minerals and make their due diligence measures available to us upon

request.

If, over time, we obtain

more detailed information from our suppliers with regard to the origin of the 3TGs contained in components and materials supplied

to us by them, we will evaluate how to respond to identified risks in our supply chain, including, if appropriate, escalating

identified risks to management for consideration of further action. During 2023, we did not identify any instances where it was

necessary to escalate identified risks to management for further action.

Step

4. Independent Third-Party Audit of Facilities’ Due Diligence Practices

As discussed above, we

do not have direct relationships with smelters or refiners, and we do not perform direct audits of these entities’ supply

chains. We intend to rely on the development and implementation of independent third-party audits of smelters’ and refiners’

sourcing, such as the Responsible Minerals Assurance Process.

Step 5. Report on

Supply Chain Due Diligence

This Report is submitted

to the SEC annually and is publicly available at http://investor.textron.com/investors/corporate-governance/default.aspx.

Due Diligence Results

Many of the responses received

from suppliers which indicated that they source 3TGs from a Covered Country provided data at the company or divisional level,

rather than at the part or component level. As a result, we have been unable to determine whether the 3TGs reported by these suppliers

were contained in components supplied to us (as opposed to other components supplied by our suppliers but not purchased by us).

We are therefore unable to directly link, based on the due diligence measures described in this Report, 3TGs contained in Textron

products to 3TGs originating from a Covered Country.

Facilities

Used to Process the 3TGs

Certain of the supplier responses

in the CMRT included the names of facilities listed as smelters or refiners. We do not typically have a direct relationship with

3TG smelters and refiners and do not perform or direct audits of these entities within our supply chain. Our service provider

compared the facilities listed in the responses in the CMRT to the list of smelters maintained by the Responsible Minerals Initiative

(“RMI”) to ensure that the facilities met the RMI definition of a 3TGs processing facility that was operational during

the 2023 calendar year. As of May 17, 2023, we have validated in this manner that 362 smelters or refiners provided in our supplier

CMRTs are included on these lists.

If a supplier indicated that a facility

was certified as “RMAP Conformant”, meaning in conformance with RMI’s Responsible Minerals Assurance Process

standards, our service provider confirmed that it was listed as such by RMI. Of the smelters and refiners listed by suppliers

via the CMRTs which have been validated as described, 226 have been confirmed as RMAP Conformant and 12 have actively begun the

process to be validated as Conformant. The CMRTs in the aggregate claim that 134 of the RMAP Conformant smelters source 3TGs from

the Covered Countries, however we cannot confirm this information. Many of the CMRTs did not provide information regarding the

country of origin of 3TGs, and such information is generally not available through public information sources related to the smelters

and refiners.

Many suppliers are still unable to

provide the smelters or refiners used for components supplied by them to us and, even where facilities were identified, the suppliers

did not always provide complete information on the facility, including smelter identification numbers, so that we were unable

to immediately validate the smelter as described above and, as previously noted, many of the responses indicated an “unknown”

status in terms of determining the origin of 3TGs.

Efforts

to Determine Mine or Location of Origin

For the reasons explained

above, we rely on our direct suppliers to provide information on the origin of the 3TGs contained in components and materials

they supply to us. As noted above, our program has initially focused on gathering smelter and refiner information via the CMRT

survey process and, as the program progresses, if feasible, we intend to work toward obtaining from our suppliers all necessary

smelter and refiner identification information. This information will facilitate the validation and disclosure of the smelters

and refiners as well as the tracing of the 3TGs to their location of origin. However, to date we only have smelter and facility

information and no information with regard to the mine or specific location of origin of the 3TGs in our products or whether they

come from recycled or scrap sources, as we understand that generally that information is kept confidential by the refiners and

smelters.

We believe that the inquiries

and investigations described above represent a reasonable effort to determine the mines or locations of origin of the 3TGs in

our Covered Products, including seeking information about 3TG smelters and refiners in our supply chain through requesting that

our suppliers complete the CMRT and verifying those smelters and refiners with the expanding RMI lists to the extent possible.

Steps to be Taken to Mitigate

Risk

We intend to take and continue

the following actions to mitigate the risk that our necessary 3TGs benefit armed groups:

| · | Direct

each of our business units to request our recommended contractual provision requiring

our suppliers to conduct due diligence on their supply chains and to provide information

to us about the source of their 3TGs, as described above. This provision is intended

to be included in new and renewed supplier contracts on a going forward basis. |

| · | Establish

a screening process for new suppliers to our businesses so that new suppliers will be

added to our in-scope supplier list if appropriate as they begin a relationship with

the business. |

| · | Direct

suppliers to training resources to attempt to increase the response rate and improve

the content of the supplier survey responses. |

| · | Work

toward obtaining from our suppliers additional smelter and refiner identification information.

|

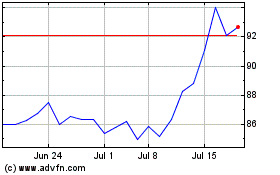

Textron (NYSE:TXT)

Historical Stock Chart

From May 2024 to Jun 2024

Textron (NYSE:TXT)

Historical Stock Chart

From Jun 2023 to Jun 2024