SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

Columbia Sportswear Company

(Exact name of registrant as specified in its charter)

|

|

|

|

|

|

Oregon |

|

000-23939 |

|

93-0498284 |

|

(State or other jurisdiction

of incorporation) |

|

(Commission

File Number) |

|

(IRS Employer

Identification No.) |

14375 NW Science Park Drive

Portland, Oregon 97229

(Address of principal executive offices) (Zip Code)

Registrant’s telephone number, including area code 503-985-4000

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

|

x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

1

Section 1 – Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report, Exhibit

This Specialized Disclosure Report on Form SD (“Form SD”) of Columbia Sportswear Company (“Columbia”, “Company”, “we”, or “us”) for the year ended December 31, 2014 is presented to comply with Rule 13p-1 under the Securities Exchange Act of 1934 (“Conflict Minerals Rule”). The Conflict Minerals Rule defines “conflict minerals” as columbite-tantalite (coltan), cassiterite, gold, wolframite, or their derivatives, which are limited to tantalum, tin, and tungsten. Pursuant to the Conflict Minerals Rule, we are required to conduct a good faith reasonable country of origin inquiry designed to determine whether any of the conflict minerals necessary to the functionality or production of our products originated in the Democratic Republic of the Congo (“DRC”) or an adjoining country, collectively defined as the “Covered Countries”. Unless otherwise defined, terms used in this Form SD and the related Conflict Minerals Report filed as Exhibit 1.01 hereto are defined in the Conflict Minerals Rule.

A description of our efforts to determine whether any of the necessary conflict minerals in our products originated in the Covered Countries is included in our Conflict Minerals Report, filed as Exhibit 1.01 to this Form SD.

Columbia has adopted a Conflict Minerals policy statement which is available at www.columbia.com in the Corporate Responsibility section of the website. The content of any website referred to in this Form SD is included for general information only and is not incorporated by reference in this Form SD. This Form SD and the Conflict Minerals Report are publicly available at www.columbia.com in the Corporate Responsibility section of the website and filed with the Securities and Exchange Commission at www.sec.gov.

Item 1.02 Exhibit

The Conflict Minerals Report required by Item 1.01 is filed as Exhibit 1.01 to this Form SD.

Section 2 – Exhibits

Item 2.01 Exhibits

Exhibit 1.01 – Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form.

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned hereunto duly authorized.

|

|

|

COLUMBIA SPORTSWEAR COMPANY |

|

|

|

|

|

Dated: May 29, 2015 |

|

By: |

|

/S/ BRYAN L. TIMM |

|

|

|

|

|

Bryan L. Timm |

|

|

|

|

|

President and Chief Operating Officer |

2

Exhibit 1.01

Columbia Sportswear Company

Conflict Minerals Report

For The Year Ended December 31, 2014

This Conflict Minerals Report of Columbia Sportswear Company (“Columbia”, “the Company,” “we,” “us,” or “our”) for the year ended December 31, 2014 is presented to comply with Rule 13p-1 under the Securities Exchange Act of 1934, as amended (“Conflict Minerals Rule”). This report has been prepared by the management of Columbia to provide transparency on its use of certain minerals, referred to in the Conflict Minerals Rule as “conflict minerals”, which comprise columbitetantalite (coltan), cassiterite, gold, wolframite, or their derivatives, which are limited to tantalum, tin, and tungsten (“3TG”) where such minerals are necessary to the functionality or production of our products.

Pursuant to the Conflict Minerals Rule, we are required to conduct a good faith reasonable country of origin inquiry designed to determine whether any of the 3TG minerals necessary to the functionality or production of our products originated in the Democratic Republic of the Congo (“DRC”) or an adjoining country, collectively defined as the “Covered Countries”. Unless otherwise defined, terms used in this Report are defined in the Conflict Minerals Rule. This Report has not been subject to an independent private sector audit as allowed under Rule 13p-1.

PART I. COMPANY OVERVIEW

Columbia is an innovator in the global outdoor and active lifestyle apparel, footwear, accessories and equipment industry. Founded in 1938 in Portland, Oregon, Columbia products are sold in approximately 100 countries and have earned an international reputation for innovation, quality and performance. Columbia products feature innovative technologies and designs that protect outdoor enthusiasts from the elements, increase comfort, and make outdoor activities more enjoyable. In addition to the Columbia® brand, Columbia Sportswear Company also owns the brands Mountain Hardwear®, Sorel®, Montrail®, prAna®, and OutDry®.

Our Products

Our principal products include apparel, footwear, accessories and equipment for use in a wide range of active lifestyle activities by men, women and youth. We develop and manage our merchandise in two principal categories:

|

· |

apparel, accessories and equipment; and |

Apparel, Accessories and Equipment

We design, develop, market and distribute apparel, accessories and equipment for men, women and youth under our Columbia brand and for men and women under our Mountain Hardwear and prAna brands. Many of our products incorporate the cumulative design, fabrication, fit and construction technologies that we have developed over several decades and that we continue to innovate. Our apparel, accessories and equipment are designed to be used during a wide variety of active lifestyle activities, such as skiing, snowboarding, hiking, climbing, mountaineering, camping, hunting, fishing, trail running, water sports, adventure travel, and yoga.

Footwear

We design, develop, market and distribute footwear products for men and women under our Columbia, Sorel and Montrail brands and for youth under our Columbia and Sorel brands. Our footwear products seek to address the needs of outdoor consumers who participate in activities that typically involve challenging or unusual terrain in a variety of weather and trail conditions. Our footwear products include durable, lightweight hiking boots, trail running shoes, rugged cold weather boots for activities on snow and ice, sandals for use in amphibious activities, and casual shoes for everyday use. Our Sorel brand primarily offers premium cold weather footwear for men, women and youth, with an increasing focus on the young, fashion-conscious female consumers.

In 2014, approximately 80% of our net sales were in the apparel, accessories and equipment category and approximately 20% were in the footwear category. In accordance with the Conflict Minerals Rule, we conducted an analysis of our products and found that small or trace quantities of 3TG minerals may be present in many of our products. Examples of where 3TG minerals could most commonly be found in our products include:

|

· |

As solder in buttons, zippers, and other fasteners; |

|

· |

As composite material in, or in coating on, buttons, zippers, hooks, and other fasteners, rivets and eyes; |

|

· |

As composite material in drawstring /shoelace grommets; |

|

· |

As a stabilizer in plastic materials; |

|

· |

As solder in outdoor equipment, like tent poles; |

|

· |

In electronics on apparel, footwear, and related products; |

|

· |

As composite material in glitter and other shiny, reflective materials placed on shoes and clothes; |

|

· |

In boot hooks used for lacing; |

|

· |

On features of gloves; and |

Conflict Minerals Due Diligence Program

At Columbia, we value ethical manufacturing practices and are committed to working with manufacturing partners who share these values. The 3TG minerals are present in many consumer products and may be present in our products. By educating our suppliers, we strive to ensure that 3TG minerals that may be used in our products are obtained from sources that avoid minerals mined under conditions of armed conflict and human rights abuses, particularly in the Covered Countries. In doing so, Columbia follows the Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas framework developed by the Organisation for Economic Co-operation and Development (OECD) in conducting inquiries to determine whether products include conflict minerals from the Covered Countries. In an effort to comply with the Conflict Minerals Rule, we have been an active participant in an industry task force that has collaborated among numerous industry groups impacted by the Conflict Minerals Rule.

2

Conflict Minerals Policy

We have adopted a position statement (“policy”) regarding the sourcing of 3TG minerals which is publicly available on our website at www.columbia.com in the Corporate Responsibility section of the website.

Columbia expects all of its suppliers to avoid use of 3TG minerals originating in the Covered Countries and mined under conditions of armed conflict and human rights abuses. Columbia’s policy requires suppliers to establish policies, due diligence frameworks, and management systems, consistent with the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, that are designed to accomplish this goal. Specifically, we expect suppliers to maintain records on the source and chain of custody for all 3TG minerals used in the manufacturing of our products and we may require suppliers to provide information with respect to their supply chain in order for us to be in compliance with the Conflict Minerals Rule. Our policy applies to all vendors, suppliers and licensees of Columbia and its divisions and affiliates. Suppliers providing product, trims or components to Columbia (or who otherwise contract to brand products with a Columbia-owned trademark) that include 3TG minerals are required to:

|

· |

Maintain adequate records regarding its supply chain sources, including adequate contact information; |

|

· |

Cooperate with Columbia and respond in a timely manner to information requests by Columbia with respect to the supplier’s sources of 3TG minerals; and |

|

· |

Certify, upon Columbia’s request, the sources of supplier’s 3TG minerals. |

Contacting Columbia

We have established a process to allow interested parties to contact us with questions, comments or concerns regarding our policy statement or practices. Our Conflict Minerals group may be reached by email at cm@columbia.com.

The product category units contained in this report are aggregated at the product category or highest level. An inquiry regarding a particular product style may be sent to

cmrreports@columbia.com.

Scope of Review

This report covers apparel, equipment, accessories and footwear products manufactured for Columbia and its subsidiaries in 2014, other than products specifically excluded as noted below. In accordance with the Conflict Minerals Rule and industry guidance, Columbia determined that certain items were excluded from reporting, including point-of-purchase displays, prototypes, packaging, hangers and samples. In addition, Columbia made determinations and documented decisions with respect to the exclusions from our scope of review of certain dyes, biocides and fungicides included in the product which are not indicated to include 3TG minerals. We also excluded from the scope of our report the following products because we do not believe we contract to manufacture the products:

|

· |

certain products manufactured by third-party licensees under trademark license agreements; |

3

|

· |

products manufactured pursuant to agreements for which Columbia has limited control over the content or manufacturing of the product, including certain products manufactured by our distributors for distribution in markets in their designated territory; and |

|

· |

certain products sourced through sourcing agents. |

Based on this scope of review, we conducted a reasonable country of origin inquiry and due diligence described below.

Supply Chain

Many of the products that we manufacture are highly technical and typically include components and trims from many suppliers. While we may nominate trim and component suppliers to be used by our vast network of finished-good manufacturers, in some cases we may not have direct contractual relationships with these trim and component suppliers. Generally, there are multiple tiers of vendors and suppliers between the 3TG mines and our direct finished-good suppliers. While most of our inquiries are directed to our indirect trim and component suppliers, in some cases we must rely on our direct suppliers to work with their upstream suppliers in order that they may provide us with accurate information about the origin of 3TG minerals in the trims and components included in the finished goods we purchase.

We do not own or operate manufacturing facilities and virtually all of our products are manufactured by independent factories located outside the United States. Our apparel, accessories and equipment are manufactured in approximately 17 countries, with Vietnam and China accounting for approximately 68% of our 2014 apparel, accessories and equipment production. Our footwear is manufactured in five countries, with China and Vietnam accounting for substantially all of our 2014 footwear production. We maintain contracts with most of our finished good suppliers and some of our trim and component suppliers. We have communicated to targeted suppliers our Conflict Minerals Policy and as we enter into new contracts or renew existing contracts, we are adding a clause that requires suppliers to comply with our policy statement and to cooperate with our efforts to identify the sources of 3TG minerals found in the products we purchase from them.

PART II. DUE DILIGENCE

Design of Program

Our program measures have been designed to conform, in all material respects, with the framework presented by the The Organisation for Economic Co-operation and Development (OECD) in the publication OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (OECD Guidance). Because of the complexity and size of our supply chain, we developed a risk-based approach that focused on suppliers that we believed were likely to provide us with trims, components and/or finished goods containing 3TG minerals.

Efforts to Determine Mine or Location of Origin

We requested that all suppliers identified as providing trims, components or goods that possibly include 3TG minerals to provide information to us regarding 3TG mineral use and smelter

4

sources using the template developed by the Electronic Industry Citizenship Coalition® (EICC®) and The Global e-Sustainability Initiative (GeSI), known as the EICC-GeSI Conflict Minerals Reporting Template (the “Template”). The Template was developed to facilitate disclosure and communication of information regarding smelters and refiners that provide material to a manufacturer’s supply chain. It includes questions regarding a direct supplier’s conflict minerals policy, its due diligence process, and information about its supply chain such as the names and locations of smelters and refiners as well as the origin of 3TG minerals used by those facilities. We believe adoption of this form facilitated a more consistent result in the information we received from vendors who are likely responding to the requests from many other manufacturers and use of the Template represents our reasonable best efforts to determine the mines or locations of origin of 3TG minerals in our supply chain. However, in large part, we must rely on the cooperation of other parties in our supply chain to comply with the Conflict Minerals Rule.

Due Diligence Measures Performed

1. Management Systems

Columbia’s efforts to assess its supply chain in compliance with the Conflict Minerals Rule began prior to adoption of the final rule, including early communications with vendors and participation in industry association groups for the purpose of interpreting the Conflict Minerals Rule requirements as applied to our industry. In 2013, Columbia engaged an independent consulting firm to conduct a compliance readiness assessment of our compliance framework, documentation and program management. The assessment was performed for the purpose of identifying any gaps with requirements and determining focus areas for further development and advancement of Columbia’s conflict minerals compliance program. Based on recommendations of the independent consultant in 2014, Columbia worked to improve gaps in the conflict minerals program by making training documentation easily available to all suppliers believed to be using 3TG, executing system improvements to more efficiently identify suppliers with 3TG, and engaging a third party service provider (“service provider”) to communicate with suppliers and process information.

Internal Team

We have established a management system to support supply chain due diligence related to compliance with the Conflict Minerals Rule. Our management system includes an executive steering committee sponsored by the President and Chief Operating Officer, and a team of key senior executives and subject matter experts from functions such as manufacturing, materials research, legal and accounting. The team of subject matter experts is responsible for implementing our Conflict Minerals compliance strategy and is led by our Director of Materials Research. Execution of the program was managed by the Materials Research department based upon previously developed program timelines and documentation of our compliance program activities. In addition, our Board of Directors has been periodically updated regarding our efforts to comply with the Conflict Minerals Rule.

Control systems

We do not have a direct relationship with 3TG smelters and refiners. However, we have collaborated with other manufacturers in our industry both directly and through active

5

participation in industry associations that have helped to shape industry-wide initiatives to develop reporting standards and further collaborate with other industry groups to support supply chain transparency efforts. In addition to our management structure, our controls include:

|

· |

A documented Conflict Minerals position statement approved by executive management related to our sourcing of 3TG minerals; |

|

· |

Internal and vendor training programs covering Columbia’s policy and program requirements; |

|

· |

Centralized project team with senior management support from Legal, Finance, Materials Research and Manufacturing departments; |

|

· |

Engagement of a third party service provider assigned to conduct a reasonable country of origin inquiry and follow up on due diligence; |

|

· |

Assigned personnel in the regional offices to manage communication between suppliers and Columbia’s third party service provider when needed; |

|

· |

A notation in our Restricted Substance List that establishes the expectation that our suppliers avoid use of 3TG minerals derived from ore mined under conditions of armed conflict and human rights abuses in Covered Countries and requires suppliers to keep and provide records on the source and chain of custody for 3TG minerals used in the manufacturing of our products; |

|

· |

A Conflict Minerals contract clause that requires suppliers to provide us with information about their sources of 3TG minerals; |

|

· |

Quarterly updates to Executive management; |

|

· |

Periodic updates to the Board of Directors; and |

|

· |

An established grievance mechanism included in Columbia’s position statement to direct questions or concerns about Columbia’s conflict minerals program to a specific email address. |

Maintenance of records

We have established a central repository for information in order to facilitate access and retention of records. A retention policy is in place to ensure that relevant materials are preserved for appropriate periods.

Supplier Engagement

In 2014, our policy and Columbia’s requirements were communicated to 100 active finished goods and raw material vendors across our apparel and footwear supply chains compared to 40 targeted vendors in 2013. Training documentation was provided to these targeted suppliers to share general information about the Conflict Minerals Rule along with Columbia’s requirements

6

to vendors regarding this obligation. We outsourced the communication, reasonable country of origin inquiry and due diligence to a third party service provider. This support included answering any questions that suppliers had about the Template or any other due diligence requests from Columbia. When needed, we have leveraged our existing foreign liaison offices to facilitate engagement with our suppliers, including support in answering questions about the training materials and the third party service provider’s role in Columbia’s effort to comply with the Conflict Minerals Rule requirements. As part of its program, Columbia required vendors to complete (i) the Template, disclosing a high-level assessment of vendor’s use of 3TG minerals and (ii) a smelter list, documenting the vendor’s source of 3TG minerals, as cross referenced against the Conflict Free Smelter Program. In addition, we also requested a product list, including a list of the products sold to Columbia or its subsidiary where 3TG minerals were present.

2. Identify and Assess Risk in the Supply Chain

For purposes of complying with the Conflict Minerals Rule, we adopted a risk-based approach which began with a review of all products with potential presence of 3TG minerals, as discussed in Scope of Review, above. However, we did not exclude any products based on a determination of whether the 3TG mineral is necessary to the functionality or production of the product. Our reasonable country of origin inquiry was based on identification of the suppliers manufacturing trims, components or finished goods for Columbia that could contain 3TG minerals. Based on the Conflict Minerals Rule requirements and OECD framework and a thorough review of Columbia’s program, we identified risks to the goal of compliance with the Conflict Minerals Rule and analyzed them for possible effects. Our program design includes documented control activities designed to mitigate those risks. In addition, we have mechanisms in place that are designed to identify changes that may affect our ability to achieve our objectives related to Conflict Mineral program compliance. Risk factors inherent to our process that could affect our conflict minerals activities include:

|

· |

Major changes in our operating processes or foreign sourcing operations; |

|

· |

Inaccurate classification of materials and trims that may result in incorrect final report results; |

|

· |

Inaccuracy of our database of suppliers and appropriate contacts that are specific to the conflict minerals program, and inability to accurately identify all local manufacturing and licensing arrangements specific to regions outside the United States; |

|

· |

Introduction of new product lines, products, or other business activities; |

|

· |

Disruption of our information systems or incompatibility of our systems with our suppliers’ systems; |

|

· |

Adequacy of internal controls to prevent noncompliance with the Conflict Minerals Rule; |

7

|

· |

Timeliness, completeness and availability of supply chain information following business acquisitions; and |

|

· |

Adverse impacts to the company's relationships with its suppliers due to costs and burden of compliance. |

Other external factors that could affect our conflict minerals activities include:

|

· |

Changes or developments in legislation, regulations, rulings, and court decisions; |

|

· |

Availability of information from our suppliers; |

|

· |

Reliability of representations by suppliers indicating the facility at which its conflict minerals were processed and accuracy in demonstrating that those conflict minerals did not originate in the Covered Countries or came from recycled or scrap sources; and |

|

· |

Suppliers being unable or unwilling to provide us with the information we need to comply with the Conflict Minerals Rule on a timely basis or at all. |

Survey Responses

Our conflict mineral reporting process involves:

|

· |

Identifying trims and components used in our products that could contain 3TG minerals; |

|

· |

Reviewing, when available, the bill of materials for trims and components that could contain 3TG minerals; |

|

· |

Identifying suppliers of trims and components or finished goods that could incorporate materials that could contain 3TG minerals; |

|

· |

Establishing suppliers that are included in the scope of our 3TG minerals reporting process in accordance with the Conflict Minerals Rule; and |

|

· |

Instructing our service provider to distribute Templates to finished good and component suppliers to determine if these vendors have product that potentially contains 3TG minerals from Covered Countries. |

During this process, we evaluated and determined which of our suppliers might provide us with products or components that contain 3TG. Our service provider distributed Templates and materials to 100 suppliers, representing primarily trim and component suppliers. We received responses from 85 suppliers, for a response rate of 85%. Of the responding suppliers, approximately 13% indicated one or more of the 3TG minerals were necessary to the functionality or production of the products they supply to Columbia.

8

Approximately 80% of the responses received provided data at a company or divisional level. The remaining suppliers declared that information was provided either at a product level or in a user defined category. Because a majority of the responses were made at the company level, each of the 3TG and related smelters identified in the responses may not specifically relate to Columbia’s products.

Our third party service provider reviewed the supplier responses against risk factors and criteria we developed to determine which suppliers fell under a particular response classification. Supplier responses were evaluated for plausibility, gaps and inconsistencies within the data reported by those suppliers as well as incomplete smelter information. Additional supplier contacts were conducted to attempt to resolve the following “quality control” (QC) flags:

|

· |

One or more smelter or refiners (SORs) were listed for an unused metal; |

|

· |

SOR information was not provided for a used metal, or SOR information provided was not a verified metal processor; |

|

· |

Supplier answered yes to sourcing from the Covered Countries, but none of the SORs listed are known to source from the region; |

|

· |

Supplier indicated that they have not received conflict minerals data for each metal from all relevant suppliers; |

|

· |

Supplier indicated they have not identified all of the SORs used for the products included in the declaration scope; |

|

· |

Supplier indicated they have not provided all applicable SOR information received; and |

|

· |

Supplier indicated 100% of the 3TG for products covered by the declaration originates from scrap/recycled sources, but one or more SORs listed are not known to be exclusive recyclers. |

Based on our third party service provider’s analysis, there was an indication of Covered Country sourcing for 11 out of 38 verified smelters or refiners identified by Columbia’s suppliers.

Based on our review of our suppliers’ responses, including evaluation of the smelters and refiners identified by our suppliers, we have classified each of our 85 reporting suppliers as follows:

|

· |

one supplier was classified as “DRC Yes”, or having one or more processors listed by the supplier as known to source from a Covered Country, but it is not yet certified by a recognized body as “Conflict Free”; |

|

· |

two suppliers have been classified as “DRC Uncertain” based on responses indicating sourcing from a Covered Country or a country designated by OECD as a “Level 2 Country” (low to medium risk countries with some known or plausible involvement in smuggling, export or transit of minerals out of conflict affected regions), but some inconsistent information is known; |

9

|

· |

ten suppliers have been classified as either having “Inconsistent” or “Uncertain” information; |

|

· |

two suppliers have been classified as “DRC Conflict Free 3TG” because all metal processors identified by the suppliers as known to source from a Covered Country are certified by a recognized body as Conflict Free; |

|

· |

two suppliers have been classified as “DRC Free 3TG”, as none of the metal processors identified by the supplier are known to source from a Covered Country; and |

|

· |

sixty-eight suppliers responded as not using 3TG in their products. |

Columbia is focusing its efforts on educating all suppliers who fall under the “DRC Yes”, “DRC Uncertain”, “Uncertain”, and “Inconsistent” categories as well as all suppliers that did not complete a response Template for the 2014 reporting year. Our supplier that falls under the “DRC Yes” classification is currently implementing a program to get all of its smelters certified. Because this has not yet been completed, this supplier remains under the “yes” classification but once the process is completed, the supplier would become classified as “DRC Conflict Free 3TG.”

Smelters or Refiners and Country of Origin of 3TG Minerals

Some of our suppliers provided a list of smelters used to process 3TG minerals contained in the goods supplied to all of their customers, including Columbia. Where the smelter name was provided, our service provider performed additional research (internet, industry and government associations) and outreach (email and telephone) directly with these companies to confirm the data provided by the supplier. Based on our service provider’s smelter/refiner database there was an indication of Covered Country sourcing for 11 out of 38 verified smelters and refiners. For purposes of this report, we have included gold smelters or refiners and related countries of origin identified by suppliers, however, to Columbia’s knowledge, gold is not present in our products and there were no responses specific to Columbia’s products indicating otherwise. Because most suppliers replied at a company level, we do not have specific information confirming whether our products included metals sourced from the smelters or refineries identified.

10

The following lists smelters or refiners with indications of Covered Country sourcing, along with the associated countries of origin and the relevant certification status. Our third party service provider relied on the following internationally accepted audit standards to determine which SORs are considered “DRC Conflict Free”: the CFSI Conflict-Free Smelter Program (“CFSI”), the London Bullion Market Association Good Delivery Program (“LBMA”) and the Responsible Jewelry Council Chain-of-Custody Certification (“RJC”).

|

|

|

|

|

Metal |

Smelter/Refiner |

Certification Status |

Mine Countries of Origin |

|

Tin |

CV United Smelting |

CFSI - Tin |

DRC- Congo (Kinshasa) |

|

Tin |

Empresa Metallurgica Vinto |

CFSI - Tin |

DRC- Congo (Kinshasa) |

|

Tungsten |

H.C. Starck GmbH |

CFSI-Progressing – Tungsten |

Rwanda |

|

Tin |

Malaysia Smelting Corporation (MSC) |

CFSI - Tin |

DRC- Congo (Kinshasa), Rwanda |

|

Tin |

Metallo Chimique |

CFSI - Tin |

DRC- Congo (Kinshasa) |

|

Tin |

Minsur |

CFSI - Tin |

DRC- Congo (Kinshasa), Rwanda |

|

Tin |

Operaciones Metalurgical S.A. |

CFSI - Tin |

DRC- Congo (Kinshasa) |

|

Tin |

PT Timah (Persero), Tbk |

CFSI - Tin |

DRC- Congo (Kinshasa) |

|

Gold |

Rand Refinery (Pty) Ltd |

CFSI - Gold, LBMA |

DRC- Congo (Kinshasa), Tanzania |

|

Tin |

Thaisarco |

CFSI - Tin |

DRC- Congo (Kinshasa), Rwanda |

|

Tin |

Yunnan Tin Company Limited |

CFSI - Tin |

DRC- Congo (Kinshasa) |

For those supply chains with SORs that are known or thought to be sourcing from Covered Countries, additional investigation was completed to determine the source and chain-of-custody of the regulated metals. If the SOR was not certified by the above-referenced internationally-recognized schemes, our third party service provider attempted to contact the SOR to gain more information about their sourcing practices, including countries of origin and transfer, and whether there are any internal due diligence procedures in place or other processes the SOR takes to track the chain-of-custody on the source of its mineral ores. Relevant information included in their reviews includes: whether the SOR has a documented, effective and communicated conflict-free policy, an accounting system to support a mass balance of materials processed, and traceability documentation. Internet research was also performed to determine whether there are any outside sources of information regarding the SOR’s sourcing practices. Up to three contact attempts were made by our third party service provider to SORs to gather information on mine country of origin and sourcing practices.

11

Our third party service provider also assigned red flags to SORs where there was evidence of sourcing from an OECD Level 2 country, or evidence of sourcing from countries which have unknown reserves for a given metal.

The following are the smelters or refiners with an indication of sourcing from an OECD Level 2 country, along with the associated countries of origin and relevant certification status:

|

|

|

|

|

Metal |

Smelter/Refiner |

Certification Status |

Mine Countries of Origin |

|

Tungsten

|

H.C. Starck GmbH

|

CFSI-Progressing - Tungsten |

Mozambique |

|

Gold |

Nadir Metal Rafineri San. Ve Tic. A.Ş. |

CFSI - Gold, LBMA |

United Arab Emirates |

12

The following is a list of smelters or refiners with indications of sourcing from an unknown reserve, along with the associated countries of origin and the relevant certification status:

|

|

|

|

|

Metal |

Smelter/Refiner |

Certification Status |

Mine Countries of Origin |

|

Tin |

Alpha |

CFSI - Tin |

Chile, Jersey, Taiwan, United States |

|

Gold |

Asahi Pretec Corporation |

CFSI - Gold, LBMA |

Hong Kong, Singapore |

|

Tin |

CV United Smelting |

CFSI - Tin |

Japan |

|

Tin |

Empresa Metallurgica Vinto |

CFSI - Tin |

Canada, Germany |

|

Tin |

Gejiu Non-Ferrous Metal Processing Co. Ltd. |

CFSI - Tin |

Canada, Japan |

|

Tungsten |

H.C. Starck GmbH |

CFSI-Progressing - Tungsten |

Estonia, Ethiopia, Germany, India, Japan, Mozambique, Namibia, Sierra Leone, Zimbabwe |

|

Gold |

Heraeus Ltd. Hong Kong |

CFSI - Gold, LBMA |

Germany, Hong Kong, Singapore, Switzerland, Taiwan |

|

Gold |

Heraeus Precious Metals GmbH & Co. KG |

CFSI - Gold, LBMA |

Germany, Hong Kong, Jersey, Switzerland |

|

Gold |

LS-NIKKO Copper Inc. |

CFSI - Gold, LBMA |

Hong Kong, Singapore |

|

Tin |

Malaysia Smelting Corporation (MSC) |

CFSI - Tin |

Canada, Chile, Japan, Switzerland |

|

Tin |

Metallo Chimique |

CFSI - Tin |

Belgium |

|

Gold |

Metalor Technologies SA |

CFSI - Gold, LBMA, RJC |

Hong Kong, Switzerland |

|

Gold |

Metalor USA Refining Corporation |

CFSI - Gold, LBMA, RJC |

Switzerland |

|

Tin |

Minsur |

CFSI - Tin |

Canada, Switzerland, United States |

|

Gold |

Nadir Metal Rafineri San. Ve Tic. A.Ş. |

CFSI - Gold, LBMA |

United Arab Emirates |

|

Gold |

Ohio Precious Metals, LLC |

CFSI - Gold, LBMA |

Hong Kong |

|

Tin |

Operaciones Metalurgical S.A. |

CFSI - Tin |

Canada, Japan, Philippines |

|

Tin |

PT Koba Tin |

|

Canada, Japan, Taiwan |

|

Tin |

PT Tambang Timah |

CFSI - Tin |

Canada, Chile, France, United States |

|

Tin |

PT Timah (Persero), Tbk |

CFSI - Tin |

Canada, India |

|

Gold |

Rand Refinery (Pty) Ltd |

CFSI - Gold, LBMA |

Hong Kong |

|

Gold |

Royal Canadian Mint |

CFSI - Gold, LBMA |

Germany, Switzerland |

|

Gold |

Tanaka Kikinzoku Kogyo K.K. |

CFSI - Gold, LBMA |

Belgium, Hong Kong, Singapore, Switzerland |

|

Tin |

Thaisarco |

CFSI - Tin |

Canada, Chile, Japan, Morocco, Poland |

|

Tin |

Yunnan Tin Company Limited |

CFSI - Tin |

Angola, Belgium, Canada, Ethiopia, Germany, Hong Kong |

13

3. Design and Implement a Strategy to Respond to Risks

We have implemented a risk management plan that educates our suppliers to enhance and improve the quality of responses and disclosures in future reporting periods. In furtherance of those objectives, we intend to take the following steps to improve the due diligence we conduct to further mitigate the risk that the 3TG minerals in our products directly or indirectly finance or benefit armed groups in the Covered Countries:

|

· |

Increase education of suppliers with an emphasis on suppliers who were classified as “Uncertain” or “Inconsistent”; |

|

· |

Continue evaluating and monitoring active suppliers to identify which suppliers provide us with products containing 3TG minerals and need to be included in our information request; and |

|

· |

Evaluate and recommend system and process improvements designed to improve tracking, vendor training, vendor identification, reasonable country of origin and due diligence efforts. |

4. Carry Out Independent Third Party Audit of Supply Chain Due Diligence at Identified Points in the Supply Chain

We do not typically have a direct relationship with 3TG mineral smelters and refiners and therefore do not perform or direct audits of these entities. Our current efforts are limited to cross referencing smelters identified by our suppliers against recognized conflict-free smelter certification programs. Columbia intends to monitor supply chain due diligence opportunities by continuing engagement in industry groups collaborating on these efforts. In future periods, we expect to continue engagement with our third party service provider and plan to engage an independent third party to conduct a private sector audit of our conflict minerals program.

5. Report on Supply Chain Due Diligence

Columbia has determined that during 2014, Columbia manufactured or contracted to manufacture products which include 3TG minerals that are necessary to the functionality or production of its products. Based on a reasonable country of origin inquiry and our due diligence efforts, we determined that one of the smelters identified by our supplier is known to source from a Covered Country and is not certified by a recognized body as “conflict-free”, however, we are unable to determine with certainty whether conflict minerals from the identified smelter were used in Columbia’s products. The smelter is in the process of obtaining a conflict-free certification. We are also working with other suppliers that are not using certified conflict-free smelters, or that do not have sufficient smelter or refiner information to conclude whether 3TG minerals used in our products originated in the Covered Countries. Because we do not have sufficient information to determine with certainty the source of all of the conflict minerals in our products or whether those minerals were used to benefit armed groups, we have determined all of our products to be DRC conflict undeterminable. This Conflict Minerals Report constitutes our annual report on our 3TG minerals due diligence and is available on our website www.columbia.com and is filed with the Securities and Exchange Commission on Form SD.

14

Forward-Looking Statements

This document contains forward-looking statements within the meaning of the federal securities laws, including statements regarding Columbia’s conflict minerals program. Words such as “expects,” “intends,” “plans,” “believes,” and “anticipates” and similar expressions are used to identify these forward-looking statements. These statements are not guarantees of future performance and involve certain risks, uncertainties and assumptions ("Risk Factors") that are difficult to predict with regard to timing, extent, likelihood and degree of occurrence. Therefore, actual results and outcomes may materially differ from what may be expressed or forecasted in such forward-looking statements. Risk Factors include, among others: reliability of representations by suppliers and suppliers being unable or unwilling to provide us with the information we need to comply with the Conflict Minerals Rule or not providing the information in a timely manner. Additional risk factors relating to Columbia’s business are discussed in Columbia’s reports filed with the Securities and Exchange Commission and exhibits thereto. The company cautions that forward-looking statements are inherently less reliable than historical information. The company does not undertake any duty to update any of the forward-looking statements after the date of this document to conform them to actual results or to reflect changes in events, circumstances or its expectations. New factors emerge from time to time and it is not possible for the company to predict all such factors, nor can it assess the impact of each such factor or the extent to which any factor, or combination of factors, may cause results to differ materially from those contained in any forward-looking statement.

15

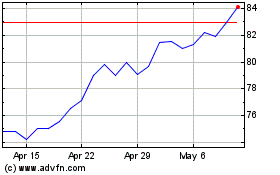

Columbia Sportswear (NASDAQ:COLM)

Historical Stock Chart

From Mar 2024 to Apr 2024

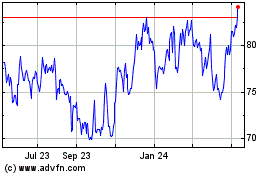

Columbia Sportswear (NASDAQ:COLM)

Historical Stock Chart

From Apr 2023 to Apr 2024