Nano Dimension Ltd. (“Nano Dimension”, Nasdaq: NNDM), an

industry-leader in

Additively

Manufactured

Electronics (

AME),

Printed

Electronics

(

PE), and

Micro

Additive

Manufacturing

(

Micro-

AM), today introduces its new DragonFly IV

printer and FLIGHT software platform.

Nano Dimension is the leading provider of

intelligent machines for the fabrication of AME. The new DragonFly

IV system, combined with FLIGHT software, delivers new levels of

quality, efficiency, and print resolution in the 3D printed

electronics sector - providing increased flexibility to design any

3D geometry and create innovative new products.

DragonFly IV is a Dielectric &

Conductive-Materials Additive Manufacturing System aimed for

fabrication of High-Performance Electronic Devices (Hi-PEDs®) by

depositing the proprietary materials simultaneously, while

concurrently integrating in-situ capacitors, antennas, coils,

transformers, and electro-mechanical components.

J.A.M.E.S GmbH from Munich, Germany, is a joint

venture with Hensoldt and a DragonFly IV beta-customer. Its Chief

Executive Officer, Andreas Muller, commented: “The DragonFly IV is

a milestone within the evolution of AME technology. Nano

Dimension’s latest system, combined with the new FLIGHT software,

enables the completion of complex jobs like no other AME system

before. The J.A.M.E.S electronic design engineers’ community will

greatly benefit from better access to AME solutions enabled by the

FLIGHT software platform and the first-of-a-kind collaboration of

ECAD/MCAD 3D design and testing.”

DragonFly IV 3D-AME Printer

DragonFly IV delivers improved accuracy of

traces, spacing, and vias, improved PCB product quality, and the

ability to design and produce 3D Hi-PEDs® in a one-step production

process.

New capabilities include:

- Integration with Nano Dimension’s new FLIGHT software

- Integration of 3D elements in PCB

- 3D designed Hi-PEDs®

- Support of HDI level elements

- 75µm traces; 100µm spacing; 150µm via

- Enhanced print quality, optimizing yield with predictable

conductivity

- Low thickness variation <5%

“DragonFly IV is the latest innovation in our

present line of AME products. Combined with the FLIGHT software, it

expands the electronic & mechanical performance envelop of AME

devices and the fabrication ability thereof” said Yoav Stern,

Chairman and Chief Executive Officer of Nano Dimension. “With the

ability to leverage rapid and environmentally friendly additive

manufacturing processes, customers can change and metamorphose

form, fit, and function. DragonFly IV will enable agile and rapid

customization and personalization, as well as allows for the

innovative structuring of electronics in the third dimension. Nano

Dimension is bringing a completely new design and fabrication

paradigms shifts to the electronics industry.”

FLIGHT Software Package

Nano Dimension’s new FLIGHT software suite

provides a comprehensive first-of-a-kind ability to incorporate

ECAD designs into real 3D MCAD designs, as well as intelligent

verification, slicing, and job control solutions. FLIGHT enables

the 3D design of electrical and mechanical features in 3-dimensions

while ensuring that the new product designs comply with the

system’s requirements and can then proceed directly to fabrication

on the DragonFly IV.

The Flight Software Suite consists of 3 components:

1-FLIGHT Plan: Allows designers to develop viable

3D AME using both existing 2D design data, and novel 3D data. Tests

show that this reduces the 3D AME design time by up to 10

times.

- Integrates 3D MCAD and ECAD capabilities for 3D

Electro-Mechanical design

- Imports existing designs from major ECAD systems

- Enables the use of customers’ existing design tools

2-FLIGHT Check: This application enables design rule

checks so that the designs meet the DragonFly IV requirements and

are ready for printing.

- Unifies design rules for ECAD that meet the constraints of

DragonFly IV

- Reduces design iteration cycles

3-FLIGHT Control: Delivers an entirely new pre-production

solution that enables concurrent fabrication of both 2D and 3D

multi-material Hi- PEDs®, improving productivity.

- Integrates system and job management toolsets

- Supports new file formats (STL & ODB++)

- Improves user experience through better rendering accuracy and

user interface

Availability

Both DragonFly IV and FLIGHT are available for

order. To find out more, visit Nano Dimension at the productronica

show, which will take place on November 16-19, 2021, in Munich,

Germany, or at (website link for products).

About Nano Dimension

Nano Dimension’s (Nasdaq: NNDM) vision is to

transform the electronics and similar additive manufacturing

sectors through the development and delivery of environmentally

friendly and economically efficient additive manufacturing,

Industry 4.0 solution, while enabling a

one-production-step-conversion of digital designs into

functioning devices - on-demand, anytime, anywhere.

Nano Dimension plans to execute on this vision

by building an eco-friendly and intelligent distributed network of

additively manufacturing self-learning & self-improving

systems, which are designed to deliver a superior ROI to their

owners as well as to Nano Dimension shareholders and

stakeholders.

The DragonFly IV® system serves

cross-industry High-Performance Electronic

Devices (Hi-PEDs®) fabrication needs,

by depositing proprietary conductive and dielectric materials

simultaneously, while concurrently integrating in-situ capacitors,

antennas, coils, transformers, and electromechanical components.

The outcomes are Hi-PEDs® which are integral enablers

of autonomous intelligent drones, cars, satellites, smartphones,

and in vivo medical devices. These products enable iterative

development, IP safety, fast time-to-market, and device performance

gains. With DragonFly IV®, a revolution happens at the click of a

button, allowing customers to go from CAD to a functional device in

a matter of hours instead of weeks; creating products with better

performance; reducing the size and weight of electronic parts and

devices; enabling innovation; and, critically important, protecting

IP, all the while limiting environmental pollution and chemical

waste.

Nano Dimension’s Fabrica 2.0 micro

additive manufacturing system enables the production of microparts

based on a Digital Light Processor (DLP) engine that achieves

repeatable micron levels resolution. The Fabrica 2.0 is engineered

with a patented array of sensors that allows a closed feedback

loop, using proprietary materials to achieve very high accuracy

while remaining a cost-effective mass manufacturing solution. It is

used in the areas of micron-level resolution of medical devices,

micro-optics, semi-conductors, micro-electronics,

micro-electro-mechanical systems (MEMS), microfluidics, and life

sciences instruments.

For more information, please visit

www.nano-di.com.

In November 2021, Nano Dimension announced the acquisition of

Essemtec AG, located in Lucerne Canton, Switzerland.

Essemtec develops production equipment for electronic assembly. The

company’s core business is in adaptive, highly flexible SMT

pick-and-place equipment, materials dispenser suitable for both

high speed dispensing and micro dispensing as well as an

intelligent production material storage and logistics system. Read

more at:

https://investors.nano-di.com/press-releases/news-details/2021/Nano-Dimension-Acquires-Essemtec-AG-Surface-Mount-Pick--Place-Systems-Supplier-for-the-PCB-and-OEM-Industries/default.aspx

Forward-Looking Statements

This press release contains forward-looking

statements within the meaning of the “safe harbor” provisions of

the Private Securities Litigation Reform Act of 1995 and other

Federal securities laws. Words such as “expects,” “anticipates,”

“intends,” “plans,” “believes,” “seeks,” “estimates” and similar

expressions or variations of such words are intended to identify

forward-looking statements. For example, Nano Dimension is using

forward-looking statements in this press release when it discusses

the benefits of the DragonFly IV system and FLIGHT software, that

the J.A.M.E.S community will greatly benefit from a better access

to AME solutions enabled by the FLIGHT software platform, that

DragonFly IV will enable agile and rapid customization or

personalization, and that Nano Dimension is bringing a completely

new paradigm of opportunity to the electronics industry. Because

such statements deal with future events and are based on Nano

Dimension's current expectations, they are subject to various risks

and uncertainties. Actual results, performance, or achievements of

Nano Dimension could differ materially from those described in or

implied by the statements in this press release. The

forward-looking statements contained or implied in this press

release are subject to other risks and uncertainties, including

those discussed under the heading “Risk Factors” in Nano

Dimension’s annual report on Form 20-F filed with the Securities

and Exchange Commission (“SEC”) on March 11, 2021, and in any

subsequent filings with the SEC. Except as otherwise required by

law, Nano Dimension undertakes no obligation to publicly release

any revisions to these forward-looking statements to reflect events

or circumstances after the date hereof or to reflect the occurrence

of unanticipated events. References and links to websites have been

provided as a convenience, and the information contained on such

websites is not incorporated by reference into this press release.

Nano Dimension is not responsible for the contents of third-party

websites.

NANO DIMENSION INVESTOR RELATIONS CONTACT

Yael Sandler, CFO | ir@nano-di.com

U.S. Investor Relations:

Dave GentryRedChip Companies Inc.Dave@redchip.com407-491-4498 or

1-800-RED-CHIP (733-2447)

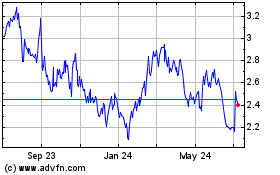

Nano Dimension (NASDAQ:NNDM)

Historical Stock Chart

From Mar 2024 to Apr 2024

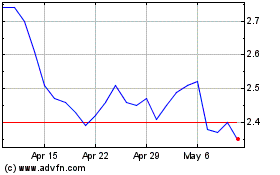

Nano Dimension (NASDAQ:NNDM)

Historical Stock Chart

From Apr 2023 to Apr 2024