AMI DODUCO Showcases Hybrid Component Wire Bonding Technology at hybridica Fair

December 16 2008 - 8:04AM

Business Wire

At the recent hybridica fair in Munich, AMI DODUCO�s Joachim Ganz,

Ph.D., presented, �Materials and Surfaces for Wire Bonding in the

Manufacture of Hybrid Housings.� The paper covered AMI DODUCO�s

range of competencies in materials and surfaces for wire bonding, a

critical process in the production of increasingly ever-present

hybrid metal/plastic components used in automotive applications.

More than 60% of the metal stampings for controls and sensors are

now bonded to injection-molded plastic parts during production.

Combining metals with plastics protects electronic controls and

sensors from damaging environmental influences while ensuring

proper electrical interfacing to the peripherals. Automobiles and

other vehicles are using increasing numbers of electronic controls

in order to operate more efficiently and effectively. �The

automobile industry is under extreme pressure to innovate,� said

AMI DODUCO�s Christian Hagedorn, Vice President of Marketing and

Sales for Europe. �Further reductions in fuel consumption and

exhaust emissions � as dictated by regulatory authorities � can be

achieved only by incorporating additional data management systems

within the vehicle. These extra sensor, control and regulation

systems call for highly efficient bonding technologies. The market

for hybrid metal/plastic bonding technology is therefore set to

expand exponentially once global demand recovers from recession.�

Ganz�s paper concluded that aluminum-plated copper semi-finished

products provide the most effective bonding of the thick wiring in

the power supplies of electrical devices, maximizing reliability

and performance. In the case of housings for sensor systems,

nickel/gold plated surfaces are best-suited to bonding thin gold

wiring that is commonly used. The development and manufacture of

hybrid components is one of the key disciplines of high-tech

engineering and encompasses the entire value creation chain from

the material itself, to tool making and design through to metal and

plastics production and surface engineering. For these

applications, AMI DODUCO offers a wide-ranging portfolio of

matching products and services such as electroplating, contact

materials, stamping, aluminum plating, tool making and plastics

engineering. Sourcing all these capabilities from a single supplier

enables customized advanced technology solutions that maximize

performance and cost-effectiveness. AMI DODUCO is a global leader

in electrical contact technology and fabrication. The company

supplies contacts and assemblies, contact materials, electroplating

and surface treatment services, and precious metal refining and

recycling to more than 3,000 customers. AMI DODUCO operates from

locations in North America, Europe and Asia. The company�s website

is www.amidoduco.com. Copyright � 2008 AMI DODUCO, Inc. All rights

reserved. All brand names and trademarks are properties of their

respective holders. Cautionary Note: This message contains "forward

looking statements" within the meaning of the Private Securities

Litigation Reform Act of 1995. Actual results may differ

materially. This release should be read in conjunction with the

factors set forth in Technitrol's report on Form 10-Q for the

quarter ended September 26, 2008 in Item 1a under the caption

�Factors that May Affect Our Future Results (Cautionary Statements

for Purposes of the 'Safe Harbor' Provisions of the Private

Securities Litigation Reform Act of 1995).�

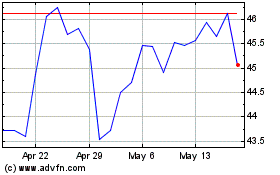

Travel plus Leisure (NYSE:TNL)

Historical Stock Chart

From Jun 2024 to Jul 2024

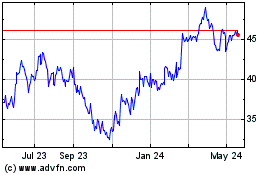

Travel plus Leisure (NYSE:TNL)

Historical Stock Chart

From Jul 2023 to Jul 2024