Maintenance Suppliers Giving Customers More Than Mops, Buckets

July 05 2011 - 1:21PM

Dow Jones News

W.W. Grainger Inc. (GWW) doesn't mind when its customers sharpen

their pencils on the cost of what Grainger sells.

Grainger is North America's largest distributor of maintenance

and operating supplies to factories, office buildings, hospitals

and other institutions. Grainger, Fastenal Co. (FAST), MSC

Industrial Direct Co.(MSM) and other large supply companies have

been racking up outsized gains in sales and profits lately after

the economic recession prompted their customers to take a closer

look at how they buy cleaning supplies, screws, light bulbs, safety

glasses, step ladders and thousands of other ancillary items.

Companies found they could lower their expenses by trimming

their in-house purchasing agents, reducing the number of suppliers

they use and shifting more orders to larger supply companies with

big product lines and the know-how to manage their customers'

inventories of supplies. The move might not merit much notice in

other industries. But in the dowdy supply industry where small,

regional companies account for about three-quarters of the

industry's $140 billion in annual sales, the shift toward larger

players has been seismic.

"That behavior change is happening in a way that we haven't seen

before," said Grainger Chairman and Chief Executive James Ryan

during an interview with Dow Jones Newswires. "As customers

consolidate their supplier bases, there are winners and losers. For

us, it's been a catalyst for growth. Customers stuck with us during

the downturn and we got a lot of new customers."

Grainger's sales last year grew by 15.4% over 2009 to $7.18

billion, more than double the growth rate of the industrial supply

sector in North America. The company's net income rose 19% to a

record $510.8 million, or $7.05 a share. In 2011, its sales are

expected to expand by nearly 10%, compared with about a 7% increase

forecast for the industry. Analysts expect profit to rise by 20%

from 2010.

Even higher growth rates are anticipated for Fastenal, the

industry's second largest company by sales, and MSC, the sector's

third largest. Both have more exposure to cyclical manufacturing

than Grainger and experienced larger sales declines during the

recession.

For the first nine months of MSC's 2011 fiscal year, net income

is up 50% from 2010 to $159.3 million, or $2.50 a share. Net sales

have grown 21% to $1.49 billion.

"There's still a lot of earnings power left in these

businesses," said Ryan Merkel, an analyst with William Blair &

Co.

The recession left many small and regional supply shops hurting

for the capital to maintain or increase the items they keep in

stock. MSC, which specializes in supplies for metalworking, seized

on this weakness by increasing its sales force, expanding its

product lines and investing in its online sales capacity.

"These investments have enhanced our ability to provide

customers with solutions and services that our smaller, less

capitalized competitors can't offer," said MSC Chairman and Chief

Executive David Sandler during a conference call Friday. "The

fragmented nature of our industry … gives us tremendous runway for

continued growth."

Grainger also has been adding product lines, increasing the

items it stocks to more than 350,000 from 82,000 five years ago.

The Illinois-based company also completed the realignment of its

600 branch stores in 2008, adding more than 1 million square feet

of floor space. Grainger has improved its online order capabilities

and systems for tracking and processing orders.

Grainger estimates companies buy as much as $12 billion a year

worth of maintenance and repair supplies--everything from light

bulbs to sponges--that never get used. The items languish

indefinitely in tool cribs, stock rooms and janitors' closets.

While Grainger and other suppliers benefit from that inefficient

purchasing, Ryan maintains there's an even bigger opportunity in

managing customers' inventories of supplies.

"We can help them get their costs down and they are much more

receptive to that," said Ryan, who joined Grainger in 1980 and has

been CEO since 2008. "We still have to be competitive on the price

[for the items] on the invoice, but more and more customers are

looking at their total procurement costs."

David Ronda, operations manager for Micropump Inc., reduced the

number of local companies in the Portland, Ore., area he ordered

supplies from about two years ago and gave Grainger responsibility

for five categories of maintenance, repair and operations supplies,

or MRO.

Grainger provides the 100,000-square-foot plant with janitorial

supplies; sand paper; gloves and ear plugs; and the components

Ronda's employees use to make test benches for the pumps Micropump

manufactures. Ronda said the move improved the efficiency of his

purchasing and contributed to the nonlabor and noncapital operating

costs for the plant falling to $300,000 last year from $1.1 million

in 2006. Moreover, Ronda's 12-member staff no longer spends time on

filing requisitions because Grainger now manages supply volumes

inside the plant.

"To keep them doing what they do best, I can't have them

ordering parts," Ronda said. "We're not making MRO. It's an

overhead cost."

The test of how much Grainger and other large suppliers have

permanently transformed themselves will likely occur when

industrial growth starts to slow. Maintenance and operations

suppliers are susceptible to the same cyclical downturns as their

customers. Idle plants and smaller work forces need fewer supplies.

Ryan believes Grainger's ability to manage its customers' supply

inventories will make the company more essential to customers

during a slump than a company that just distributes mops and

buckets.

"Grainger has built a business for exactly what's going on in

this industry now," Ryan said.

-By Bob Tita, Dow Jones Newswires; 312-750-4129;

robert.tita@dowjones.com

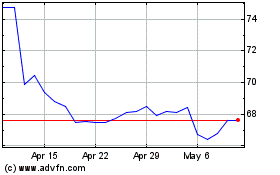

Fastenal (NASDAQ:FAST)

Historical Stock Chart

From May 2024 to Jun 2024

Fastenal (NASDAQ:FAST)

Historical Stock Chart

From Jun 2023 to Jun 2024