Abacus Mining & Exploration Corporation (TSX VENTURE:AME) ("Abacus") is pleased

to announce the results of the Feasibility Study ('FS') for the Ajax Copper-Gold

Project (the "Ajax Project") located southwest of Kamloops, B.C. The Ajax

Project is being developed through KGHM Ajax Mining Inc. ("KGHM Ajax"), owned

49% by Abacus and 51% by KGHM Polska Miedz S.A. ("KGHM"). The NI 43-101

Technical Report will be available on the Company's website (www.amemining.com)

and on SEDAR (www.sedar.com).

Base Case Highlights: (all economic figures in US$)

-- Total proven and probable mineral reserves of 3 billion lbs Cu and 2.7

million ozs Au at 0.27% Cu and 0.17 g/t Au based on $2.50 Cu and $1,085

Au

-- 23 year mine life at a processing rate of 60,000 t/d or 21.9 million

t/a at a LOM stripping ratio of 2.4:1

-- LOM production of 2.5 billion lbs Cu and 2.28 million ozs Au in

concentrate

-- Initial capital costs of $795 million, including contingency of $87

million

-- Cash cost per lb of copper of $1.28 net of gold credits

Economic Analysis:

The base case economic analysis produced by Wardrop, a Tetra Tech Company (Tetra

Tech) projects that the Ajax Project will have a pre-tax net present value of

$416 million (@ 8% discount rate) and internal rate of return of 14.5% based on

pre-tax 100% equity financing. The pre-tax economic results for the base case

and additional case scenarios are presented in the following table.

Table 1: Summary of Ajax Project Pre-Tax Economic Results

---------------------------------------------------------------------------

Alternate Alternate

Base Case Case Case

Scenario Scenario1 Scenario2

---------------------------------------------------------------------------

Cu US$/lb $2.75 $3.00 $ 3.50

---------------------------------------------------------------------------

Au US$/oz $1,085 $1,300 $1,700

---------------------------------------------------------------------------

Exchange Rate (US$:C$) 0.92 0.94 0.98

---------------------------------------------------------------------------

Pre-tax Internal Rate of Return 14.5% 19.5% 30.3%

---------------------------------------------------------------------------

Cash Cost per lb Cu

(net of gold credits) $1.28 $1.11 $0.79

---------------------------------------------------------------------------

Pre-Tax Net Present Value

(8% discount rate) $416 million $818 million $1,601 million

---------------------------------------------------------------------------

Payback Years 7.8 3.8 2.2

---------------------------------------------------------------------------

James D. Excell, President & CEO of Abacus, commented, "The FS confirms the

economic viability of the Ajax Project at long term copper and gold prices, and

demonstrates the leverage to increases in metal prices. At recent market prices

the Project is very robust and the NPV nearly quadruples from the base case with

an associated 2.2 year payback of initial capital.

The delivery of the FS is a pivotal milestone for Abacus and advances the Ajax

Project along the critical path to production start-up targeted for 2015. The

Ajax Mine economics compare very favorably to the leading copper projects being

developed around the world given its long-life, location, open-pit mining and

conventional processing. The mine also represents a small portion of the 8,000

hectare copper-gold camp. We look forward to developing the Ajax Project with

our world class partner, KGHM."

Joint Venture Next Steps

Upon deemed delivery of the FS to KGHM, expected on or about December 31, 2011,

KGHM will have a maximum of 90 days to acquire a further 29% in the Joint

Venture company for a cash consideration equal to 29% of the Proven and Probable

copper equivalent reserve in the FS, to a maximum of US$35 million, towards use

by Abacus for its share of project capital. Thereafter, KGHM will arrange the

financing for its (80%) proportionate interest in the project capital, and

Abacus has the option to arrange its own financing for its (20%) proportionate

interest or elect to have KGHM do so on commercially reasonable terms.

In the event that KGHM chooses not to increase its interest in the joint

venture, Abacus then has 90 days to elect to purchase KGHM's 51% interest for

US$37 million, and 90 days thereafter to close on this purchase. Should Abacus

choose not to purchase KGHM's interest in its entirety, Abacus' interest in the

Joint Venture can be increased to 51% by paying approximately US$1.5 million to

KGHM.

Detailed FS Summary

The independent Ajax Project Feasibility Study which was commissioned in May

2010 in accordance with National Instrument 43-101, supports a 60,000 tonne per

day conventional milling plant, producing a copper-gold concentrate containing

25% Cu and 18 g/t Au. The Study was led by Tetra Tech as the project's lead

consultant, in conjunction with a team of globally recognized consultants:

Tetra Tech - overall management, mineral processing,

infrastructure, and financial analysis

AMEC Americas Ltd. - geology, mineral resource estimate,

mineral reserve estimate, and mine design

Knight Piesold Ltd. - environmental studies, permitting, and

social or community impact

Golder Associates Ltd. - tailings handling, thickening and

tailings area water management

BGC Engineering Inc. - pit slope designs and site geotechnical

investigation

G&T Metallurgical Services Ltd. - metallurgical test work

Krupp Polysius - High Pressure Grinding Rolls (HPGR) pilot

test work for the process design

The FS encompasses trade-off studies that were performed to optimize

life-of-mine operations since the July 31, 2009 Preliminary Economic Assessment

(PEA). Since the PEA level report was issued, further confirmatory metallurgical

testing and variability analysis work have been completed. This FS builds on the

results and premises of the previous findings, as well as the subsequent test

work programs between 2009 and 2011.

Some of the key optimizations from the trade-off studies include crushers and

conveyors for in-pit crushing and conveying of both ore and waste, high pressure

grinding rolls, and high density tailings deposition. These methods have had the

effect of reducing costs and improving recoveries as well as location logistics

to reduce the environmental footprint.

1) Mineral Resource Estimates

Mineral Resources take into account geologic, mining, processing and economic

constraints, and have been confined within appropriate LG pitshells, and

therefore are classified in accordance with the 2010 CIM Definition Standards

for Mineral Resources and Mineral Reserves.

Mineral Resources are reported using a copper price of US $2.88/lb and a gold

price of US$1,200/oz.

AMEC reported the Mineral Resources at a Base Case CuEq grade of 0.20%.

Mineral Resource Estimate at Selected CuEq Cut-offs

Effective Date May 26, 2011, Timothy O. Kuhl, SME Registered Member

---------------------------------------------------------------------------

Cutoff Ton- Cu- Au NSR Contained Metal

CuEq nes- Eq Cu (g/ (US$/ CuEq Cu Au

(%) (Mt) (%) (%) t) t) ('000 lb) ('000 lb) (oz)

---------------------------------------------------------------------------

Measured 0.1 322.5 0.38 0.27 0.17 13.83 2,667,000 1,933,000 1,734,600

0.2 255.8 0.42 0.31 0.19 15.71 2,389,000 1,734,000 1,555,400

---------------------------------------------------------------------------

Indicated 0.1 336.2 0.36 0.26 0.17 16.7 2,665,000 1,897,000 1,818,100

0.2 256.2 0.42 0.3 0.2 19.98 2,399,000 1,712,000 1,637,400

---------------------------------------------------------------------------

Measured 0.1 658.7 0.37 0.26 0.17 15.3 5,331,000 3,830,000 3,552,600

+ Indicated 0.2 512 0.42 0.31 0.19 17.85 4,788,000 3,446,000 3,192,800

---------------------------------------------------------------------------

Inferred 0.1 115.7 0.3 0.21 0.13 13.39 753,000 538,000 499,200

0.2 73.7 0.38 0.27 0.17 17.46 613,000 439,000 405,700

---------------------------------------------------------------------------

Note 1. Mineral Resources are contained within a conceptual Measured,

Indicated and Inferred optimized pitshell using the following assumptions:

maximum copper recovery of 91.17% and maximum gold recovery of 86.49% based

on the following equations: CuRec = (-74.812 x (Cu%^2)) + (85.727 x Cu%)

+ 66.668 and AuRec = 92.586 x Au(g/t)^0.064; assumed throughput rate of

60,000 t/d; Whittle constraining shell slopes between pit slope angle

ranging from 38 degrees to 49 degrees, waste and processed material mining

costs of US$1.08/t, fill waste mining costs of US$0.89/t, total processing

costs including reclamation of US$3.23/t, general and administrative costs

of US$0.52/t, gold price of US$1,200/oz, and copper price of US$2.88/lb.

Note 2. Copper equivalency was calculated using the formula CuEq = (((%Cu)

x (CuRec) x (22.0462) x ($lbCu) + (g/t / Au) x (AuRec) x (1/31.1035) x

($ozAu))) / ((CuRec) x (22.0462) x ($lbCu))).

Note 3. Rounding as required by reporting guidelines may result in apparent

summation differences between tonnes, grade and contained metal content.

Note 4. Tonnage and grade measurements are in metric units. Contained gold

and silver ounces are reported as troy ounces, contained copper pounds as

Imperial pounds.

2) Mineral Reserve Estimates

The Proven and Probable Mineral Reserves as of October 31, 2011 consists of 503

million tonnes grading 0.27% Cu and 0.17 g/t Au (0.37% CuEq) containing

approximately 3 billion lbs of copper and 2.7 million ounces of gold.

Mineral Reserve Statement

Effective Date 31 October 2011, R. Mendoza Reyes, P.Eng.

---------------------------------------------------------------------------

Average Copper Contained

Cut-Off Grades Equivalent Metal

Confidence Grade Tonnes Cu Au CuEq Copper Gold

Category (US$/t) (Mt) (%) (g/t) (%) (M lb) (k oz)

---------------------------------------------------------------------------

Proven Mineral Reserve 4.53 279.5 0.27 0.17 0.38 1,680 1,520

Probable Mineral Reserve 4.53 223.5 0.26 0.17 0.37 1,280 1,230

---------------------------------------------------------------------------

Total Proven & Probable

Mineral Reserves 4.53 503.0 0.27 0.17 0.37 2,960 2,750

---------------------------------------------------------------------------

Note 1. Mineral Reserves are estimated using a cut-off of US$4.53/t NSR, a

copper price of US$2.50/lb, and a gold price of US$1,085/oz. The NSR is

calculated by adding the NSR attributable to copper to the NSR attributable

to gold and then subtracting the freight costs, which include land freight,

port charges, ocean freight and miscellaneous costs. The attributable

copper is calculated using the metallurgical recovery obtained by the

formula: CuRec (%) = -74.812 (i) Cu(%)2 + 85.727 (i) Cu(%) + 66.668 with a

maximum copper recovery of 91.17%. The attributable gold is calculated

using metallurgical recovery obtained by the formula: AuRec (%) = 92.586

(i) Au(g/t)0.0649 with a maximum gold recovery of 86.49%.

Note 2. Mineral Reserves are constrained within a pit shell, optimized

using assumptions of a weighted average mining cost of US$1.32/t (ranging

from US$0.92/t to US$2.50/t for the different mining benches); a processing

cost of US$3.38/t plus US$0.51/t general and administrative costs, and

US$0.05/t allocation for closure costs; and pit slope angles that vary from

40 degrees to 49 degrees.

Note 3. A 0.5% mining loss factor was applied to account for dilution;

diluted grades are estimated at 1.7% lower than the in-situ grades.

Note 4. The life of mine, waste to ore strip ratio is 2.40. The assumed

life-of-mine throughput rate is 60 kt/d.

Note 5. The copper equivalency is calculated using the equation CuEq =

((%Cu) (CuRec) (22.0462) ($lbCu) + (g/t / Au) (AuRec) (1/31.1035) ($ozAu))

/ ((CuRec) (22.0462) ($lbCu)).

Note 6. Rounding as required by reporting guidelines may result in apparent

summation differences between tonnes, grade and contained metal content.

Note 7. Tonnage and grade measurements are in metric units. Contained gold

ounces are reported as troy ounces; contained copper pounds are Imperial

pounds.

The mill copper feed grades generally vary between 0.13% and 0.63% Cu, while the

gold grades generally vary between 0.05 g/t and 0.59 g/t Au of the mill feed.

The Year 1 to 5 composite plant mill feed estimate was replicated in a sample

which was tested during the most recent test program. This sample has a feed

grade value of 0.29% Cu and 0.16 g/t Au. These feed values were used as the

basis of design for the plant.

3) Life of Mine Plan

The FS supports production of a total of 2.5 billion lbs of copper and 2.28

million ozs of gold in concentrate or an average of approximately 109 million

lbs of copper and 99,000 ozs of gold annually. The proposed mine plan envisages

a conventional open pit operation extracting 60,000 t/d or 21.9 million t/a of

ore. The mine plan is based on the extraction of 503 million tonnes of ore for

processing during 23 years of operation at an overall LOM stripping ratio of

2.4:1 waste to ore. Total material movement from the pit during the life of the

mine is estimated at 1,701 million tonnes. The average LOM head grade of process

feed is 0.27% Cu and 0.170 g/t Au (0.37% CuEq) which equates to a NSR of $14.68

per tonne.

Mining will be accomplished using a conventional truck and shovel operation, in

conjunction with an in-pit crushing and conveying (IPCC) system. IPCC is a

system where the mined material is reduced in size by crushing to make it

suitable to be transported by belt conveyors out of the pit. After the PEA, IPCC

was identified as a potential cost reduction implementation for the Ajax Project

when compared with a truck-haul option only.

4) Capital and Operating Costs

The capital and operating cost estimates provided by AMEC, Tetra Tech and Golder

indicate an initial estimated capital cost of approximately $795 million,

inclusive of contingency of $87 million. The operating cost estimate will be

$1.32/t for mining and in-pit crushing and conveying, $3.46/t milled for

processing and tailings disposal and $0.53/t G&A cost.

Initial Estimated Capital US$ '000

---------------------------------------------------------------------------

Site general and substation 46,280

---------------------------------------------------------------------------

Mine pre-stripping 34,443

---------------------------------------------------------------------------

Mining equipment 80,443

---------------------------------------------------------------------------

Crushing 25,700

---------------------------------------------------------------------------

Conveying 11,764

---------------------------------------------------------------------------

Ore storage and HPGR 89,614

---------------------------------------------------------------------------

Concentrator 144,815

---------------------------------------------------------------------------

Tailings storage 79,493

---------------------------------------------------------------------------

Site services & utilities 15,304

---------------------------------------------------------------------------

Ancillary buildings 18,639

---------------------------------------------------------------------------

Plant site mobile fleet 4,437

---------------------------------------------------------------------------

Water supply from Lake 14,805

---------------------------------------------------------------------------

Total Direct Initial Capital 565,737

---------------------------------------------------------------------------

Project indirect 107,176

---------------------------------------------------------------------------

Owners costs 34,500

---------------------------------------------------------------------------

Contingency 87,570

---------------------------------------------------------------------------

TOTAL INITIAL ESTIMATED CAPITAL 794,983

---------------------------------------------------------------------------

Sustaining Capital US$ '000

---------------------------------------------------------------------------

Mining equipment 262,714

---------------------------------------------------------------------------

Crushing 62,400

---------------------------------------------------------------------------

Conveying 73,058

---------------------------------------------------------------------------

Stacking 57,987

---------------------------------------------------------------------------

Plant site 43,214

---------------------------------------------------------------------------

Tailings 104,642

---------------------------------------------------------------------------

TOTAL ESTIMATED SUSTAINING CAPITAL 604,015

---------------------------------------------------------------------------

Approximately $200 million is expected to be incurred in year 5 for in-pit

crushing and conveying.

Environmental & Permitting

The Project is currently in the early stages of an environmental assessment

process involving both federal and provincial government agencies and will be a

state-of-the-art operation designed to meet and exceed health, safety and

environmental requirements in Canada.

Knight Piesold initiated the environmental studies for the Ajax Project in 2007,

including ground and surface water quality and quantity, climatology, fish and

fish habitat, wildlife, and vegetation studies. The environmental study suggests

that proven mitigation methods will be effective in controlling environmental

effects. Acid base accounting was carried out as part of the environmental

baseline study, and the results indicate that the waste rock and ore are not

acid generating.

Abacus submitted a Project Description to the BC Environmental Assessment Office

(EAO) and the federal Canadian Environmental Assessment Agency (CEAA) in early

2011. The project description was accepted by EAO on February 25, 2011 and on

March 16, 2011 by CEAA.

The provincial Environmental Assessment Office issued an Order under Section 10

of the Environmental Assessment Act on February 25, 2011 indicating that the

Project must proceed through the provincial Environmental Assessment review. The

CEAA commenced a comprehensive study on May 25, 2011 and posted a Notice of

Commencement on the CEAA Registry on May 31, 2011. A federal project agreement

was signed on August 17, 2011. The draft Project Application Information

Requirements (dAIR) was provided to the EAO and CEAA on August 12, 2011 for

distribution to the Technical Working Group. The Proponent Application/

Environmental Impact Statement (EIS) is expected to be submitted in 2012.

Local Resources/Infrastructure

Local resources necessary for the exploration, development, and operation of the

Ajax property are located in Kamloops. Kamloops has a resource-based economy and

is a transportation hub for the Canadian National Railway (CNR) and Canadian

Pacific Railway (CPR). Numerous service and supply companies which service

resource industries are established in Kamloops, including several diamond

drilling companies, light-to heavy equipment contractors and a metallurgical

testing laboratory. Highway 1 services Kamloops and Highway 5 is situated within

6 km of the Ajax property. There is also an airport with daily scheduled flights

to Vancouver, Calgary, Kelowna and Prince George.

Exploration/History

Abacus acquired the Afton property in 2002 from Teck Ltd. Historic drilling on

the Ajax property was concentrated in the areas of the open pit mines that were

in production in the 1980s and 1990s. Afton Mines Ltd., controlled by Teck,

commenced production at Ajax East and Ajax West in 1989. Production was

suspended in 1991 due to low metal prices. A second period of production began

in 1994 and was again suspended in 1997. During the periods of production, it is

estimated that 17 Mt was mined and 13 Mt milled.

Abacus undertook drilling campaigns from 2005 to 2010 consisting of diamond

drilling, more recently targeting extensions of mineralization along strike and

to depth. The approximate drill spacing is 50 x 50 m in the areas of

mineralization.

Conference Call Details

A conference call to discuss the results of the Ajax Project Feasibility Study

has been scheduled for Wednesday, December 21, 2011 at 4:30pm ET (1:30pm PT).

Dial-in numbers for North America are: toll free 1-866-226-1792 or 416-340-2216;

for International 1-800-9559-6849. To access the simultaneous webcast, visit

Abacus Mining's website at www.amemining.com. A playback version will be

available until Friday, January 13, 2012 at 1-800-408-3053 (N.A. toll free) or

905-694-9451 using the pass code 2014266.

Qualified Persons

In May 2010, Abacus commissioned a team of engineering consultants to complete

the Ajax Project Feasibility Study in accordance with National Instrument

43-101. Tetra Tech was retained as the lead consultant for the Study.

The mineral resources and reserves for the Ajax Project were estimated by AMEC

Americas Ltd. (AMEC) under the direction of Timothy O. Kuhl R.M. and Ramon

Mendoza Reyes, P.Eng. Mr. Kuhl as a qualified person for the purposes of

National Instrument 43-101, has reviewed and verified the data that pertains to

the resources in this press release. Mr. Mendoza Reyes as a qualified person for

the purposes of National Instrument 43-101, has reviewed and verified the data

that pertains to the reserves in this press release.

The technical information in this news release has been reviewed and approved by

Hassan Ghaffari, P.Eng., Senior Engineer with Tetra Tech and overall manager for

the Feasibility Study, and by Dave Laudrum, P.Geo., Abacus's Chief Geologist and

qualified person for the Ajax Project, both of whom are qualified persons within

the meaning of National Instrument 43-101.

The NI 43-101 Technical Report will be available on the Company's website

(www.amemining.com) and on SEDAR (www.sedar.com).

On Behalf of the Board,

ABACUS MINING AND EXPLORATION CORPORATION

James D. Excell, President & CEO

Forward-Looking Information

This release includes certain statements that are deemed "forward-looking

statements". All statements in this release, other than statements of historical

facts, that address events or developments that Abacus Mining and Exploration

Corp. (the "Company") expects to occur, are forward-looking statements.

Forward-looking statements are statements that are not historical facts and are

generally, but not always, identified by the words "expects", "plans",

"anticipates", "believes", "intends", "estimates", "projects", "potential" and

similar expressions, or that events or conditions "will", "would", "may",

"could" or "should" occur. Although the Company believes the expectations

expressed in such forward-looking statements are based on reasonable

assumptions, such statements are not guarantees of future performance and actual

results may differ materially from those in the forward-looking statements.

Factors that could cause the actual results to differ materially from those in

forward-looking statements include changes to commodity prices, mine and

metallurgical recovery, operating and capital costs,foreign exchange rate, and

ability to obtain required permits on a timely basis including permission from

Kinder Morgan to have access to the pipeline right-of-way, exploitation and

exploration successes, and continued availability of capital and financing, and

general economic, market or business conditions. Investors are cautioned that

any such statements are not guarantees of future performance and actual results

or developments may differ materially from those projected in the

forward-looking statements. Forward-looking statements are based on the beliefs,

estimates and opinions of the Company's management on the date the statements

are made. Except as required by applicable securities laws, the Company

undertakes no obligation to update these forward-looking statements in the event

that management's beliefs, estimates or opinions, or other factors, should

change.

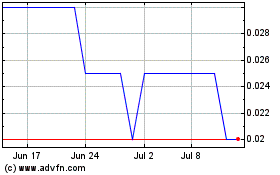

Abacus Mining and Explor... (TSXV:AME)

Historical Stock Chart

From May 2024 to Jun 2024

Abacus Mining and Explor... (TSXV:AME)

Historical Stock Chart

From Jun 2023 to Jun 2024