Form 6-K - Report of foreign issuer [Rules 13a-16 and 15d-16]

January 29 2024 - 4:43PM

Edgar (US Regulatory)

United States

Securities and Exchange Commission

Washington, D.C. 20549

FORM 6-K

Report of Foreign Private Issuer

Pursuant to Rule 13a-16 or 15d-16

of the

Securities Exchange Act of 1934

For the month of

January 2024

Vale S.A.

Praia de Botafogo nº 186, 18º andar,

Botafogo

22250-145 Rio de Janeiro, RJ, Brazil

(Address of principal executive office)

(Indicate by check mark whether the registrant files

or will file annual reports under cover of Form 20-F or Form 40-F.)

(Check One)

Form 20-F x Form 40-F ¨

Vale’s production and sales in 4Q23 and 2023

Rio

de Janeiro, January 29th, 2024

| • | Vale’s Q4 performance was marked by solid

production and sales in all businesses. In December, iron ore achieved its highest monthly output since 2018. Copper production increased

by 50% y/y, the highest level since 2018. In nickel, price realization was 7% above LME prices. |

| • | Iron ore production totaled 89.4 Mt in Q4, increasing

by 11% y/y. In 2023, production reached 321.2 Mt, above our 315 Mt guidance, and 4.3% higher y/y as a result of: (i) continued initiatives

to improve asset reliability at S11D; (ii) solid performance at Itabira and Vargem Grande complexes; and (iii) higher third-party purchases. |

| • | Pellets production totaled 9.9 Mt in Q4, 19% higher

y/y. In 2023, production reached 36.5 Mt, 14% higher y/y, supported by higher pellet feed production at Brucutu. Briquettes production

started in Q4, an important step in Vale’s strategy to support steelmaking decarbonization by expanding the iron ore agglomerates

supply. |

| • | Copper production totaled 99.1 kt in Q4, increasing

by 50% y/y. In 2023, production increased by 29% y/y, totaling 326.6 kt, slightly above our revised 325 kt guidance. The improved performance

was mainly a result of Salobo 3’s successful ramp-up, with production at the Salobo complex increasing by 87% y/y in Q4, as well

as the better performance of Sossego’s plant. |

| • | Nickel production decreased by 5% in Q4 vs a year

ago, while it also decreased 8% in 2023, totaling 164.9 kt, in-line with guidance. The lower production was anticipated considering the

transition to underground mining at Voisey’s Bay as well as the planned furnace rebuild at Onça Puma. |

Production summary

| |

|

|

|

|

|

% change |

2024 guidance |

2023 guidance |

| 000’ metric tons |

4Q23 |

3Q23 |

4Q22 |

2023 |

2022 |

4Q23/3Q23 |

4Q23/4Q22 |

2023/2022 |

| Iron ore1 |

89,397 |

86,238 |

80,852 |

321,154 |

307,793 |

3.7% |

10.6% |

4.3% |

310-320 Mt |

~315 Mt |

| Pellets |

9,851 |

9,175 |

8,261 |

36,455 |

32,111 |

7.4% |

19.2% |

13.5% |

38-42 Mt2 |

~37 Mt2 |

| Copper |

99.1 |

81.6 |

66.3 |

326.6 |

253.1 |

21.4% |

49.5% |

29.0% |

320-355 kt |

~325 kt |

| Nickel |

44.9 |

42.1 |

47.4 |

164.9 |

179.1 |

6.7% |

-5.3% |

-7.9% |

160-175 kt |

~165 kt |

|

1

Including third-party purchases, run-of-mine and feed for pelletizing plants.

2

Iron ore agglomerates guidance, including iron ore pellets and briquettes. |

Sales summary

| |

|

|

|

|

|

% change |

| 000’ metric tons |

4Q23 |

3Q23 |

4Q22 |

2023 |

2022 |

4Q23/3Q23 |

4Q23/4Q22 |

2023/2022 |

| Iron ore fines1 |

77,885 |

69,714 |

81,202 |

256,789 |

260,663 |

11.7% |

-4.1% |

-1.5% |

| Iron ore pellets |

10,285 |

8,613 |

8,789 |

35,840 |

33,164 |

19.4% |

17.0% |

8.1% |

| Iron ore ROM |

2,158 |

2,232 |

1,963 |

8,290 |

8,216 |

-3.3% |

9.9% |

0.9% |

| Copper |

97.5 |

73.8 |

71.6 |

307.8 |

243.9 |

32.1% |

36.2% |

26.2% |

| Nickel |

47.9 |

39.2 |

58.2 |

167.9 |

180.8 |

22.2% |

-17.7% |

-7.1% |

|

1

Including third-party purchases.

|

Price realization summary

| |

|

|

|

|

|

% change |

| US$/t |

4Q23 |

3Q23 |

4Q22 |

2023 |

2022 |

4Q23/3Q23 |

4Q23/4Q22 |

2023/2022 |

| Iron ore fines (CFR/FOB, wmt) |

118.3 |

105.1 |

95.6 |

108.1 |

108.1 |

12.6% |

23.7% |

- |

| Iron ore pellets (CFR/FOB, wmt) |

163.4 |

161.2 |

165.6 |

161.9 |

188.6 |

1.4% |

-1.3% |

-14.2% |

| Copper1 |

7,941 |

7,731 |

8,774 |

7,960 |

8,052 |

2.7% |

-9.5% |

-1.1% |

| Nickel |

18,420 |

21,237 |

24,454 |

21,830 |

23,669 |

-13.3% |

-24.7% |

-7.8% |

|

1

Average realized price for copper operations only (Salobo and Sossego). Average realized copper price for all operations, including copper

sales originated from nickel operations, was US$ 7,867/t in 4Q23 and US$ 7,903/t in

2023. |

Business highlights

in 4Q23

Iron Ore and Pellets operations

| · | Northern System production increased by 3.8 Mt y/y and

0.7 Mt q/q, reflecting positive results from continued initiatives to improve asset reliability

and operational stability at Serra Norte and S11D. |

|

| | |

| · | The Southeastern System output was 3.2 Mt higher y/y

and 1.2 Mt higher q/q, driven by (i) Conceição concentration plants' improved

performance in Itabira; (ii) higher mining equipment availability at Alegria; and (iii) higher third-party purchases. |

| · | Southern System production increased by 1.6 Mt y/y and

1.2 Mt q/q, mainly driven by (i) improved performance at the Vargem Grande Complex; and (ii)

higher third-party purchases, partially offset by lower production at Viga, which resumed operations in late November, as well as lower

run-of-mine output. |

| · | Pellet production increased by 1.6 Mt y/y and 0.7 Mt

q/q, driven by an increase in pellet feed supply from Brucutu, resulting in higher pellet output

from the Tubarão plants, partially offset by planned maintenance at the São Luis and Oman plants in October. In Q4, Vale

started producing iron ore briquettes at the Tubarão Complex, and volumes will start to be recorded in 1H24. |

| · | Iron ore fines and pellet sales reached 88.2 Mt in the

quarter, 9.8 Mt higher q/q and flat y/y, driven by higher production and inventory sales, taking

advantage of favorable market conditions. |

|

| | |

| · | The average realized iron ore fines price was US$ 118.3/t, US$ 13.2/t higher q/q, largely attributed to higher benchmark iron ore prices and a positive impact from forward price adjustments. The

average realized iron ore pellet price was US$ 163.4/t, relatively flat q/q, as the positive effect from higher benchmark iron

ore prices was offset by lower quarterly pellet premiums. |

| · | The all-in premium totaled US$ 1.6/t[1],

US$ 2.2/t lower q/q and US$ 3.8/t lower y/y. Given market conditions in Q4, with lower discounts for high-silica products as well as lower

premiums for high-grade products, Vale decided to increase high-silica products’ share in the sales mix, while rebalancing premium

iron ore inventories (IOCJ and BRBF), maximizing its product portfolio value. |

[1]

Iron ore premium of US$ -1.1/t and the weighted average contribution of the pellet business of US$ 2.6/t.

Copper operations

| · | Salobo copper production increased by 25.6 kt y/y and 5.6 kt q/q, with the Salobo 3 ramp-up and the continuous increase in plant availability and productivity at the Salobo 1&2 plants. Salobo Complex

throughput achieved a pace of 32.3 Mtpy during a 90-day period (August-November). |

|

| | |

| · | Sossego copper production increased by 6.1 kt y/y and 4.3 kt q/q, as the mining plan moved into higher-grade zones. In December, Sossego achieved record results: (i) the best monthly rate at the SAG mill

since 2021, and (ii) the best milling rate since 2020, as well as the highest copper contained production since 2021, achieved in November. |

| · | Copper production

in Canada increased by 1.0 kt y/y and 7.5 kt q/q, mainly driven by higher

copper precipitate production in Thompson and increased copper production in

Voisey’s Bay, as underground mining operations ramp up. |

| · | Copper sales[2]

totaled 97.5 kt in the quarter, 25.9 kt higher y/y and 23.7 kt q/q,

driven by higher production. |

| · | Average copper realized price

was US$ 7,941/t, 2.7% higher q/q, mainly a result of positive provisional price adjustments,

as the average LME reference price was lower than the average forward curve at the end of the quarter. |

[2]

Sales volumes are lower than production volumes due to payable copper vs. contained copper: part of the copper contained in the concentrates

is lost in the smelting and refining process, hence payable quantities of copper are approximately 3.5% lower than contained volumes.

Nickel operations

| · | Finished nickel production from Sudbury-sourced ore decreased by 1.1 kt y/y, mainly due to the longer planned maintenance

at Creighton mine for partial repair of the shaft, which impacted timing and flow of ore feed material to mill. Production

increased by 1.9 kt q/q, following annual mine maintenance performed in Q3. |

|

| | |

| · | Finished nickel production from Thompson-sourced ore increased by 0.8 kt y/y and 1.9 kt q/q, mainly as a result of intermediate product recovery

from precipitates as part of the circular mining initiative. |

| · | Finished nickel production from Voisey’s Bay-sourced

ore decreased by 1.1 kt y/y and 0.4 kt q/q driven by the ongoing planned transition from the

Ovoid open pit mine depletion to the underground VBME project ramp-up. Contained nickel in ore mined increased by 2.2 kt y/y as the underground

mines continue to ramp up. |

| · | Finished nickel production from third parties increased

by 1.6 kt y/y and 1.8 kt q/q. The consumption of third-party feed is in line with the strategy

to maximize the utilization and performance of our downstream operations. |

| · | Finished nickel production from

Indonesia-sourced material increased by 1.8 kt y/y and 2.7 kt q/q, mainly reflecting the higher

availability of nickel in matte from Indonesia. Nickel in matte production was 19.1 kt in the quarter, the highest since 4Q21, as it continues

to benefit from the improved mine and furnace performance. |

| · | Nickel production at Onça Puma decreased

by 4.5 kt y/y and 5.2 kt q/q as operations are halted for the

furnace rebuild to be completed in 1Q24. |

| · | Nickel sales totaled 47.9 kt in the quarter, 3.0 kt

higher than quarterly production, as expected, mainly due to inventory

sales built in Q3 to cover the Onça Puma furnace rebuild. |

| · | Average nickel realized price was

US$ 18,420/t, down 13.3% q/q, mainly due to 15.2% lower LME reference prices

q/q. The average realized nickel price in Q4 was 7% higher than the LME reference price, mainly due to the impact of positive hedging

results and the higher share of Class I products in sales mix, sold at higher premiums. |

ANNEX

1 - Production and sales summary

Iron ore

| |

|

|

|

|

|

% change |

| 000’ metric tons |

4Q23 |

3Q233 |

4Q22 |

2023 |

2022 |

4Q23/3Q23 |

4Q23/4Q22 |

2023/2022 |

| Northern System |

48,852 |

48,188 |

45,097 |

172,968 |

171,555 |

1.4% |

8.3% |

0.8% |

| Serra Norte and Serra Leste |

28,702 |

28,833 |

26,486 |

97,986 |

102,298 |

-0.5% |

8.4% |

-4.2% |

| S11D |

20,150 |

19,355 |

18,611 |

74,982 |

69,257 |

4.1% |

8.3% |

8.3% |

| Southeastern System |

21,595 |

20,350 |

18,405 |

82,344 |

72,644 |

6.1% |

17.3% |

13.4% |

| Itabira (Cauê, Conceição and others) |

7,979 |

7,619 |

7,007 |

31,399 |

27,283 |

4.7% |

13.9% |

15.1% |

| Minas Centrais (Brucutu and others) |

6,658 |

5,939 |

5,395 |

24,546 |

20,759 |

12.1% |

23.4% |

18.2% |

| Mariana (Alegria, Timbopeba and others) |

6,959 |

6,791 |

6,003 |

26,398 |

24,602 |

2.5% |

15.9% |

7.3% |

| Southern System |

18,949 |

17,701 |

17,350 |

65,841 |

63,594 |

7.1% |

9.2% |

3.5% |

| Paraopeba (Mutuca, Fábrica and others) |

8,758 |

8,214 |

8,403 |

28,870 |

30,106 |

6.6% |

4.2% |

-4.1% |

| Vargem Grande (VGR, Pico and others) |

10,191 |

9,488 |

8,947 |

37,061 |

33,488 |

7.4% |

13.9% |

10.7% |

| IRON ORE PRODUCTION1 |

89,397 |

86,238 |

80,852 |

321,154 |

307,793 |

3.7% |

10.6% |

4.3% |

| OWN PRODUCTION |

81,585 |

79,073 |

75,872 |

297,170 |

289,330 |

3.2% |

7.5% |

2.7% |

| THIRD-PARTY PURCHASES |

7,812 |

7,165 |

4,980 |

23,984 |

18,463 |

9.0% |

56.9% |

29.9% |

| IRON ORE SALES |

90,328 |

80,559 |

91,954 |

300,919 |

302,042 |

12.1% |

-1.8% |

-0.4% |

| FINES SALES2 |

77,885 |

69,714 |

81,202 |

256,789 |

260,663 |

11.7% |

-4.1% |

-1.5% |

| PELLET SALES |

10,285 |

8,613 |

8,789 |

35,840 |

33,164 |

19.4% |

17.0% |

8.1% |

| ROM SALES |

2,158 |

2,232 |

1,963 |

8,290 |

8,216 |

-3.3% |

9.9% |

0.9% |

| SALES FROM 3RD PARTY PURCHASE |

7,807 |

6,646 |

5,051 |

23,580 |

18,497 |

17.5% |

54.6% |

27.5% |

|

1

Including third party purchases, run-of-mine and feed for pelletizing plants. Excluding Midwestern System volumes. Vale’s product

portfolio Fe content reached 62.1%, alumina 1.3% and silica 7.2% in 4Q23.

2

Including third-party purchases.

3

Third-party purchase distribution between Southeastern and Southern Systems complexes were reinstated. |

Pellets

| |

|

|

|

|

|

% change |

| 000’ metric tons |

4Q23 |

3Q23 |

4Q22 |

2023 |

2022 |

4Q23/3Q23 |

4Q23/4Q22 |

2023/2022 |

| Northern System |

735 |

1,037 |

739 |

3,221 |

3,212 |

-29.1% |

-0.5% |

0.3% |

| São Luis |

735 |

1,037 |

739 |

3,221 |

3,212 |

-29.1% |

-0.5% |

0.3% |

| Southeastern System |

5,618 |

4,403 |

3,616 |

19,323 |

14,677 |

27.6% |

55.4% |

31.7% |

| Itabrasco (Tubarão 3) |

739 |

801 |

960 |

3,495 |

2,725 |

-7.7% |

-23.0% |

28.3% |

| Hispanobras (Tubarão 4) |

892 |

720 |

- |

1,669 |

- |

23.9% |

n.m. |

n.m. |

| Nibrasco (Tubarão 5 and 6) |

1,585 |

837 |

1,131 |

4,760 |

3,465 |

89.4% |

40.1% |

37.4% |

| Kobrasco (Tubarão 7) |

899 |

557 |

178 |

3,204 |

3,034 |

61.4% |

405.1% |

5.6% |

| Tubarão 8 |

1,503 |

1,488 |

1,347 |

6,195 |

5,451 |

1.0% |

-11.6% |

13.6% |

| Southern System |

1,175 |

1,107 |

1,222 |

4,629 |

4,305 |

6.1% |

-3.8% |

7.5% |

| Fábrica |

- |

- |

- |

- |

- |

- |

- |

- |

| Vargem Grande |

1,175 |

1,107 |

1,222 |

4,629 |

4,305 |

6.1% |

-3.8% |

7.5% |

| Oman |

2,323 |

2,628 |

2,684 |

9,283 |

9,919 |

-11.6% |

-13.5% |

-6.4% |

| PELLET PRODUCTION |

9,851 |

9,175 |

8,261 |

36,455 |

32,111 |

7.4% |

19.2% |

13.5% |

| PELLET SALES |

10,285 |

8,613 |

8,789 |

35,840 |

33,164 |

19.4% |

17.0% |

8.1% |

Copper - Finished production

by source

| |

|

|

|

|

|

% change |

| 000’ metric tons |

4Q23 |

3Q23 |

4Q22 |

2023 |

2022 |

4Q23/3Q23 |

4Q23/4Q22 |

2023/2022 |

| Brazil |

76.7 |

66.7 |

44.9 |

247.2 |

171.0 |

15.0% |

70.8% |

44.6% |

| Salobo |

55.2 |

49.6 |

29.6 |

180.4 |

127.8 |

11.3% |

86.5% |

41.2% |

| Sossego |

21.4 |

17.1 |

15.3 |

66.8 |

43.2 |

25.1% |

39.9% |

54.6% |

| Canada |

22.4 |

14.9 |

21.4 |

79.4 |

82.1 |

50.3% |

4.7% |

-3.3% |

| Sudbury |

15.4 |

9.4 |

16.1 |

57.9 |

59.2 |

63.8% |

-4.3% |

-2.2% |

| Thompson |

2.9 |

1.6 |

1.2 |

4.7 |

5.3 |

81.3% |

141.7% |

-11.3% |

| Voisey's Bay |

2.7 |

2.7 |

1.9 |

9.6 |

10.8 |

0.0% |

42.1% |

-11.1% |

| Feed from third parties1 |

1.4 |

1.2 |

2.2 |

7.2 |

6.8 |

16.7% |

-36.4% |

5.9% |

| COPPER PRODUCTION |

99.1 |

81.6 |

66.3 |

326.6 |

253.1 |

21.4% |

49.5% |

29.0% |

| COPPER SALES |

97.5 |

73.8 |

71.6 |

307.8 |

243.9 |

32.1% |

36.2% |

26.2% |

| Copper Sales Brazil |

76.3 |

61.8 |

44.7 |

234.0 |

166.3 |

23.5% |

70.7% |

40.7% |

| Copper Sales Canada |

21.2 |

12.0 |

26.9 |

73.8 |

77.5 |

76.7% |

-21.2% |

-4.8% |

|

1

External feed purchased from third parties and processed into copper in our Canadian operation. |

Nickel - Finished

production by source

| |

|

|

|

|

|

% change |

| 000’ metric tons |

4Q23 |

3Q23 |

4Q22 |

2023 |

2022 |

4Q23/3Q23 |

4Q23/4Q22 |

2023/2022 |

| Canada |

16.7 |

13.3 |

18.2 |

59.5 |

73.3 |

25.6% |

-8.2% |

-18.8% |

| Sudbury |

10.0 |

8.1 |

11.1 |

38.2 |

39.0 |

23.5% |

-9.9% |

-2.1% |

| Thompson |

3.2 |

1.3 |

2.4 |

7.9 |

9.9 |

146.2% |

33.3% |

-20.2% |

| Voisey's Bay |

3.5 |

3.9 |

4.6 |

13.5 |

24.4 |

-10.3% |

-23.9% |

-44.7% |

| Indonesia |

19.8 |

17.1 |

18.0 |

64.1 |

63.9 |

15.8% |

10.0% |

0.3% |

| Brazil |

0.6 |

5.8 |

5.1 |

17.0 |

23.6 |

-89.7% |

-88.2% |

-28.0% |

| Feed from third-parties1 |

7.7 |

5.9 |

6.1 |

24.2 |

18.3 |

30.5% |

26.2% |

32.2% |

| NICKEL PRODUCTION |

44.9 |

42.1 |

47.4 |

164.9 |

179.1 |

6.7% |

-5.3% |

-7.9% |

| NICKEL

SALES |

47.9 |

39.2 |

58.2 |

167.9 |

180.8 |

22.2% |

-17.7% |

-7.1% |

1

External feed purchased from third parties and processed into finished nickel in our Canadian operations.

Energy Transition

Metals by-products - Finished production

| |

|

|

|

|

|

% change |

| |

4Q23 |

3Q23 |

4Q22 |

2023 |

2022 |

4Q23/3Q23 |

4Q23/4Q22 |

2023/2022 |

| COBALT (000’ metric tons) |

549 |

452 |

529 |

1,959 |

2,434 |

21.5% |

3.8% |

-19.5% |

| PLATINUM (000’ oz troy) |

31 |

24 |

25 |

125 |

102 |

29.2% |

24.0% |

22.5% |

| PALLADIUM (000’ oz troy) |

39 |

24 |

33 |

149 |

127 |

62.5% |

18.2% |

17.3% |

| GOLD (000’ oz troy)1 |

123 |

117 |

74 |

410 |

289 |

5.1% |

66.2% |

41.9% |

|

TOTAL BY-PRODUCTS

(000’ metric tons Cu eq.)2

3 |

45 |

38 |

34 |

156 |

134 |

18.4% |

32.4% |

16.4% |

|

1

Includes Gold from Copper and Nickel operations.

2

Includes Iridium, Rhodium, Ruthenium and Silver.

3

Copper equivalent tons calculated using average market metal prices for each quarter. Market reference prices: for copper and cobalt:

LME spot; for Gold and Silver: LME spot for 2Q22 (including 1H22) and NYMEX from 3Q22 onwards; for Platinum and Palladium: NYMEX spot;

for other PGMs: Johnson Matthey. |

ANNEX

2 – Energy Transition Metals: Maintenance scheduled in 2024

| Operation |

Q1 |

Q2 |

Q3 |

Q4 |

| Copper operations |

|

|

|

|

| Salobo |

|

|

|

|

| Salobo I&II |

< 1 week |

<1 week |

1.5 week |

<1 week |

| Salobo III |

1.5 week |

1.5 week |

1.5 week |

1 week |

| Sossego |

|

|

|

|

| Sossego |

4.5 weeks |

1 week |

2 weeks |

1 week |

| Nickel operations |

|

|

|

|

| Sudbury |

|

|

|

|

| Coleman |

|

|

4.5 weeks |

|

| Creighton |

|

|

9 weeks |

|

| Copper Cliff North |

|

|

4 weeks |

|

| Copper Cliff South |

|

|

1.5 week |

|

| Garson |

|

|

4 weeks |

|

| Totten |

|

|

2 weeks |

|

| Clarabelle mill |

|

|

4.5 weeks |

|

| Sudbury Smelter |

|

4 weeks |

|

|

| Sudbury Refinery |

|

6 weeks |

|

|

| Port Colborne (Co & PGMs) |

|

5 weeks |

|

|

| Thompson |

|

|

|

|

| Thompson mine |

|

|

4.5 weeks |

|

| Thompson mill |

|

|

4.5 weeks |

|

| Voisey’s Bay & Long Harbour |

| Voisey’s Bay |

|

2 weeks |

|

|

| Long Harbour Refinery |

|

4.5 weeks |

|

|

| Standalone Refineries |

|

|

|

|

| Clydach |

|

4.5 weeks |

|

|

| Matsusaka |

4.5 weeks |

|

|

|

| Indonesia |

|

|

|

|

| PTVI (furnaces/kilns only) |

3 weeks |

1 week |

4 weeks |

3 weeks |

| Brazil |

|

|

|

|

| Onça Puma |

9.5 weeks¹ |

<1 week |

<1 week |

<1 week |

¹ Refers

to the furnace rebuild. The ramp up after maintenance is not included in the number of weeks.

Note: The maintenance

schedule may be deliberately adjusted if it proves beneficial for operations and the overall business. The number of weeks is rounded

to 0.0 or 0.5 and may involve more than one maintenance activity within the quarter.

Further information on Vale can be found at: vale.com

Investor Relations

Vale IR: vale.ri@vale.com

Thiago Lofiego: thiago.lofiego@vale.com

Luciana Oliveti: luciana.oliveti@vale.com

Mariana Rocha: mariana.rocha@vale.com

Pedro Terra: pedro.terra@vale.com

This press release may include statements

about Vale's current expectations about future events or results (forward-looking statements), including in particular expectations for

production and sales of iron ore, nickel and copper on pages 1, 2, 3 and 4. Many of those forward-looking statements can be identified

by the use of forward-looking words such as "anticipate," "believe," "could," "expect," "should,"

"plan," "intend," "estimate" “will” and "potential," among others. All forward-looking

statements involve various risks and uncertainties. Vale cannot guarantee that these statements will prove correct. These risks and uncertainties

include, among others, factors related to: (a) the countries where Vale operates, especially Brazil and Canada; (b) the global economy;

(c) the capital markets; (d) the mining and metals prices and their dependence on global industrial production, which is cyclical by nature;

and (e) global competition in the markets in which Vale operates. Vale cautions you that actual results may differ materially from the

plans, objectives, expectations, estimates and intentions expressed in this presentation. Vale undertakes no obligation to publicly update

or revise any forward-looking statement, whether as a result of new information or future events or for any other reason. To obtain further

information on factors that may lead to results different from those forecast by Vale, please consult the reports that Vale files with

the U.S. Securities and Exchange Commission (SEC), the Brazilian Comissão de Valores Mobiliários (CVM) and, in particular,

the factors discussed under “Forward-Looking Statements” and “Risk Factors” in Vale’s annual report on Form

20-F.

Signatures

Pursuant to the requirements of the Securities

Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| |

Vale S.A.

(Registrant) |

| |

|

| |

By: |

/s/ Thiago Lofiego |

| Date: January 29, 2024 |

|

Director of Investor Relations |

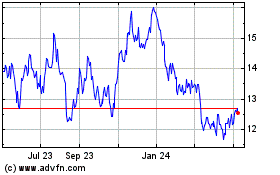

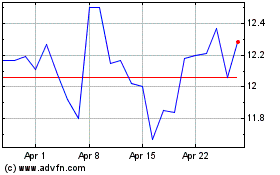

Vale (NYSE:VALE)

Historical Stock Chart

From Apr 2024 to May 2024

Vale (NYSE:VALE)

Historical Stock Chart

From May 2023 to May 2024