TIDMBMN

RNS Number : 8060U

Bushveld Minerals Limited

27 October 2017

Market Abuse Regulation (MAR) Disclosure

Certain information contained in this announcement would have

been deemed inside information for the purposes of Article 7 of

Regulation (EU) No 596/2014 until the release of this

announcement.

27 October 2017

Bushveld Minerals Ltd

("Bushveld" or the "Company")

Operational Update - Updated CPR and Mineral Resources at the

Mokopane Tin Project

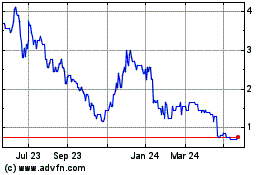

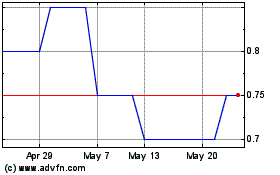

Bushveld Minerals Limited (AIM: BMN), a mineral development

company with a portfolio of vanadium and titanium-bearing iron ore,

tin and coal assets in Southern Africa, is pleased to announce the

release of an updated Competent Persons Report ("CPR") for the

Mokopane Tin Project. The CPR is an update of previously issued

reports and includes a revised cut-off grade for the Zaaiplaats

Deposit.

Highlights:

In anticipation of the demerger of Bushveld's tin assets to form

AfriTin Mining Limited, a newly formed company established for the

purpose of listing on AIM shortly, the Company is required to

update the CPR for the Mokopane Tin Project. The updated CPR was

prepared by The MSA Group and includes a Mineral Resource Estimate

("MRE") for the Groenfontein Deposit (prepared by Mr Dexter

Ferreira of Independent Resource Estimations) and an MRE for the

Zaaiplaats Deposit (prepared by Mr Alan Page and Dr Hennie Theart

of SRK Consulting and reviewed by Mr Jeremy Witley of the MSA

Group).

The following points are noted:

-- The MRE for the Groenfontein Deposit remains unchanged from

previous estimates, as reported in the original technical report

(26 September 2011, re-reported 4 June 2013).

-- The cut-off grade for the MRE at the Zaaiplaats deposit has

been revised from 0.07% Sn (as reported in the SRK MRE of 26

September 2013) to 0.1% Sn, in order to bring this cut-off grade

into alignment with the 0.1% cut-off for the Groenfontein

deposit.

-- The MRE for the Zaaiplaats Deposit (re-stated at a 0.1% Sn

cut-off) is 6.216 million tonnes at a grade of 0.124% in the

Inferred category and 0.017 million tonnes at 0.136% in the

Indicated category. This gives total Mineral Resources of 6.233

million tonnes at 0.124% Sn, with a total tin content of 7,753

tonnes.

-- While the reported total tonnage of contained tin at the

Zaaiplaats Deposit has been revised from 12,452 tonnes to 7,753

tonnes as a result of the higher cut-off grade, none of the other

parameters of the MRE have been changed, and the reported Mineral

Resources for the Zaaiplaats Deposits reflect the original MRE

prepared by SRK Consulting.

The unchanged MRE for the Groenfontein Deposit (stated at a 0.1%

cut-off) is shown below. Note that the Mineral Resources for the

Groenfontein Deposit have been re-reported in accordance with JORC

(2012), and details of Sampling Techniques and Data, Reporting of

Exploration Results and Estimation and Reporting of Mineral

Resources are reported as Appendix 1 in the form of JORC (2012)

Table 1.

Mineral Resources for the Groenfontein Deposit

as at July 2011 at a 0.1% Sn Cut Off

----------------------------------------------------------

Category Tonnes (millions) Sn Grade (%) Sn Tonnes

----------- ------------------ ------------- ----------

Measured 1.177 0.179 2,107

----------- ------------------ ------------- ----------

Indicated 1.918 0.140 2,685

----------- ------------------ ------------- ----------

Inferred 0.898 0.134 1,203

----------- ------------------ ------------- ----------

Total 3.993 0.150 5,995

----------- ------------------ ------------- ----------

The amended MRE for the Zaaiplaats Deposit (stated at a revised

0.1% cut-off) is shown below:

Zaaiplaats Mineral Resource as at 31 August

2013 (re-stated at 0.10 % Sn Cut Off).

----------------------------------------------------------

Category Tonnes (millions) Sn Grade (%) Sn Tonnes

----------- ------------------ ------------- ----------

Indicated 0.017 0.136 23

----------- ------------------ ------------- ----------

Inferred 6.216 0.124 7,730

----------- ------------------ ------------- ----------

Total 6.233 0.124 7,753

----------- ------------------ ------------- ----------

The Company is in the process of preparing an updated CPR on its

Uis Tin Project in Namibia. It is intended that AfriTin Mining

Limited will acquire the Uis Tin Project as a result of the

demerger from Bushveld. An announcement will be released upon

completion of the updated CPR.

Fortune Mojapelo, CEO of Bushveld Minerals, said:

"The re-reporting the Mineral Resource Estimates for the

Groenfontein and Zaaiplaats Deposits as part of an updated

Competent Persons Report for the Mokopane Tin Project is an

important step in the demerger of Bushveld Minerals to form AfriTin

Limited, which we feel will unlock shareholder value for the tin

assets currently within Bushveld."

Details of Sampling Techniques and Data, Reporting of

Exploration Results and Estimation and Reporting of Mineral

Resources for both the Groenfontein and Zaaiplaats Deposits are

outlined in Appendix 1 and Appendix 2 below.

Competent Persons Statement

References in this announcement to exploration results, Mineral

Resources, interpretations and prospects have been approved for

release by Mr Michael Cronwright, Mr Jeremy Witley and Mr Dexter

Ferreira.

The information in this announcement that relates to Mineral

Resources is based on information compiled by Mr Jeremy Witley of

The MSA Group, Johannesburg South Africa and Mr Dexter S. Ferreira.

Mr Witley is registered as Professional Scientist with the South

African Council for Professional Natural Scientific Professions

(SACNASP) which is a Recognised Professional Organisation (RPO). Mr

Witley is employed by MSA and has sufficient experience which is

relevant to the styles of mineralisation and types of deposit under

consideration and to the activity which he is undertaking to

qualify as a Competent Person as defined in the 2012 Edition of the

"Australasian Code for Reporting of Mineral Resources. Mr Witley

consents to the inclusion in the report of the matters based on his

information in the form and context in which it appears.

Mr Ferreira is registered as Professional Scientist with the

South African Council for Professional Natural Scientific

Professions (SACNASP) which is a Recognised Professional

Organisation (RPO). Mr Ferreira is employed by Independent Resource

Estimations (IRES) and has sufficient experience which is relevant

to the styles of mineralisation and types of deposit under

consideration and to the activity which he is undertaking to

qualify as a Competent Person as defined in the 2012 Edition of the

"Australasian Code for Reporting of Mineral Resources. Mr Ferreira

consents to the inclusion in the report of the matters based on his

information in the form and context in which it appears.

The information in this announcement that relates to Exploration

Results, is based on information compiled by Mr Michael Cronwright

of The MSA Group, Johannesburg, South Africa. Mr Cronwright has

sufficient experience relevant to the style of mineralisation and

type of deposit under consideration and to the activity he is

undertaking to qualify as a Competent Person as defined in the 2012

Edition of the "Australasian Code for Reporting of Exploration

Results, Mineral Resources and Ore Reserves". Mr Cronwright

consents to the inclusion in the report of the matters based on his

information in the form and context in which it appears.

APPIX 1: JORC (2012) TABLE 1 - GROENFONTEIN

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

Criteria JORC Code explanation Commentary

============ =========================================================== ============================================================

Sampling

techniques * Nature and quality of sampling (e.g. cut channels, * At Groenfontein the samples were taken from 53 HQ

random chips, or specific specialised industry diameter (63.5mm) diamond core boreholes drilled.

standard measurement tools appropriate to the

minerals under investigation, such as down hole gamma

sondes, or handheld XRF instruments, etc.). These * The recovery logs of the core and a quick-geological

examples should not be taken as limiting the broad log was done on site.

meaning of sampling.

* The metre marking, detailed geological logging and

* Include reference to measures taken to ensure sample sample mark-up and reference/cut line was done at the

representivity and the appropriate calibration of any core yard.

measurement tools or systems used.

* The objective of core sampling was to provide

* Aspects of the determination of mineralisation that suitable samples for laboratory analyses of the

are Material to the Public Report. selected mineralised zones identified during logging.

* In cases where 'industry standard' work has been done * Core was split in half by a diamond saw at the core

this would be relatively simple (e.g. 'reverse yard facility. Half was submitted for assay and half

circulation drilling was used to obtain 1 m samples retained for reference purposes.

from which 3 kg was pulverised to produce a 30 g

charge for fire assay'). In other cases more

explanation may be required, such as where there is * Sample lengths were standardised to 1 m intervals.

coarse gold that has inherent sampling problems. However, sample lengths in well-mineralised zones or

Unusual commodities or mineralisation types (e.g. zones with variable mineralisation were matched

submarine nodules) may warrant disclosure of detailed accordingly and these normally varied between 0.15 m

information. to 1.0 m. Sample intervals were chosen at the

supervising geologist's discretion.

* Certified reference materials (produced by AMIS),

blanks and field duplicates were inserted by the lab

into each batch at a frequency of

* The CRMs used were AMIS0020 and AMIS0021

============ =========================================================== ============================================================

Drilling

techniques * Drill type (e.g. core, reverse circulation, open-hole * A total of 53 cored boreholes were drilled vertically,

hammer, rotary air blast, auger, Bangka, sonic, etc.) HQ in size (63.5 mm internal diameter) with a PQ size

and details (e.g. core diameter, triple or standard (85 mm internal diameter) within the weathered zone;

tube, depth of diamond tails, face-sampling bit or core were not orientated.

other type, whether core is oriented and if so, by

what method, etc.).

============ =========================================================== ============================================================

Drill

sample * Method of recording and assessing core and chip * Recovery logs were prepared for each drill run at the

recovery sample recoveries and results assessed. drill rig in order to monitor the core recovery.

* Measures taken to maximise sample recovery and ensure * Core recovery was expected to be >90% and this was

representative nature of the samples. achieved in all cases.

* Whether a relationship exists between sample recovery

and grade and whether sample bias may have occurred

due to preferential loss/gain of fine/coarse

material.

============ =========================================================== ============================================================

Logging

* Whether core and chip samples have been geologically * A preliminary quick geological log was prepared at

and geotechnically logged to a level of detail to the drill rig

support appropriate Mineral Resource estimation,

mining studies and metallurgical studies.

* Detailed geological logging including lithological

logging, geotechnical

* Whether logging is qualitative or quantitative in

nature. Core (or costean, channel, etc.) photography.

* Geological logging only commenced once the core was

washed, cleaned, photographed, geotechnically logged

* The total length and percentage of the relevant and split.

intersections logged.

* The following procedures were applied during

geological logging:

* Core was sprayed with water in order to assist with

the identification and description of lithology,

mineralisation, alteration, colour and texture.

* Different colours were used in the log sheets to

indicate different information on the core:

* Yellow - Comments on the lithology, colour,

alteration, veins, mineralogy etc.

* Red - Utilised to mark ore minerals such as

sulphides. Cassiterite is mostly disseminated

throughout the core.

* Blue - Indicated cutting marks, specifically for

sampling.

* The core logging process was facilitated by the use

of a geological log sheet designed according to

standard look-up tables and formats, to guide the

geologist through a standard set of logging

requirements.

* See CPR sections 9.2.3 and 9.2.5

* The work is undertaken according the logging

standards developed by Greenhills, which are in line

with international best practice.

* The CP considers that the level of detail and quality

of the work is appropriate to support the current

mineral resource estimation.

============ =========================================================== ============================================================

Sub-sampling

techniques * If core, whether cut or sawn and whether quarter, * The objective of core sampling was to provide

and sample half or all core taken. suitable samples for laboratory analyses of the

preparation selected mineralised zones identified during logging.

* If non-core, whether riffled, tube sampled, rotary

split, etc. and whether sampled wet or dry. * Sample lengths were standardised to 1 m intervals.

However, sample lengths in well-mineralised zones or

zones with variable mineralisation were matched

* For all sample types, the nature, quality and accordingly and these normally varied between 0.15 m

appropriateness of the sample preparation technique. to 1.0 m. Sample intervals were chosen at the

supervising geologist's discretion.

* Quality control procedures adopted for all

sub-sampling stages to maximise representivity of * The half core samples were crushed and milled at Set

samples. Point Laboratories in Mokopane - See CPR Section

9.2.8.1

* Measures taken to ensure that the sampling is

representative of the in situ material collected, * Pulp duplicates, blanks and standard material

including for instance results for field (produced by AMIS) were inserted in identical packets

duplicate/second-half sampling. to the samples, one per 20 normal samples for each of

the blanks, standards and lab duplicates. This was

done under the supervision of a qualified geologist

* Whether sample sizes are appropriate to the grain or experienced geotechnician from VMIC.

size of the material being sampled.

============ =========================================================== ============================================================

Quality All samples were analysed

of assay * The nature, quality and appropriateness of the by using XRF - pressed

data and assaying and laboratory procedures used and whether pellets and with fusions

laboratory the technique is considered partial or total. done for samples with

tests values of >0.5% Sn.

* Specific Gravity determinations were also performed

* For geophysical tools, spectrometers, handheld XRF on the pulps by Set Point using gas pycnometry.

instruments, etc., the parameters used in determining

the analysis including instrument make and model,

reading times, calibrations factors applied and their * No independent QA/QC procedures were implemented by

derivation, etc. Greenhills for the Groenfontein exploration

programme.

* Nature of quality control procedures adopted (e.g.

standards, blanks, duplicates, external laboratory * SPL's QA/QC procedures and a summary of an audit of

checks) and whether acceptable levels of accuracy (ie the results is provided in CPR Section 9.4.1.2

lack of bias) and precision have been established.

* The following internal QA/QC procedure was followed:

o QA/QC samples inserted

(every twenty samples

submitted contain one

blank and one standard,

inserted at random positions)

o the blank material

used is commercially

sourced (AMIS 0108),

which contains no detectable

Sn;

o the Certified Reference

Material ("CRM") used

was commercially sourced

AMIS 0021 which has

0.270% +/-0.026% Sn

with a SG of 2.74 +/-0.22

g/cc and AMIS 0020 with

0.69% +/-0.04% Sn;

o field duplicates-

one out of the 20 samples,

are sent in with the

next sample batch;

o in addition one in

twenty original samples

and duplicate pulp samples

were also submitted

to an umpire laboratory;

and

o the samples are submitted

to SPL in Isando Johannesburg

for analysis for Sn,

Cu and W by XRF.

============ =========================================================== ============================================================

Verification

of sampling * The verification of significant intersections by * All logging and sampling was managed by a Senior

and assaying either independent or alternative company personnel. Geologist from Greenhills and independent checks by a

geologist from The MSA Group.

* The use of twinned holes.

* All hardcopies have been retained and stored at the

coreshed in Mokopane

* Documentation of primary data, data entry procedures,

data verification, data storage (physical and

electronic) protocols. * Electronic copies reside in XLS/Access format and

backups kept at the Greenhills head office in Illovo,

Johannesburg....

* Discuss any adjustment to assay data.

* The exploration programme entailed the drilling and

sampling of 53 drill holes (22 twinned with historic

drill holes) during 2011.

* Analytical data obtained from the 22 twinned drill

holes were compared to the historical drill hole

assay data in order to justify the incorporation of

the historical data into the Mineral Resource

estimation exercise. Twinning of drill holes followed

by the application of comparative and correlative

statistics by Independent Resource Estimations (IRES)

determined that the old data is "useable".

Statistical analysis between the previous drilling

results and the 22 twin drill holes from the current

programme indicate a very good correlation.

============ =========================================================== ============================================================

Location

of data * Accuracy and quality of surveys used to locate drill * All drill holes were drilled vertically and no

points holes (collar and down-hole surveys), trenches, mine orientation of the core was carried out.

workings and other locations used in Mineral Resource

estimation.

* Downhole surveys were not routinely done as initial

downhole surveys indicated little or no material

* Specification of the grid system used. deviation of the drill holes

* Quality and adequacy of topographic control. * Drill holes drilled during this project, as well as

visible historical drill holes, visible old mine

workings and shafts were surveyed by Exact Survey

Services using a real time differential GPS.

* All existing historic drill hole data was transformed

from the Cape System LO29/Clarke to LO29/WGS and

visible historic drill holes were also re-surveyed.

* All the drill holes were surveyed on the edge of the

casing and the elevation determined on the top of the

concrete cover.

* The survey was conducted using a single control

beacon (located on the farm Solomon's Tempel)

approximately 1.5 km from the drilling site.

============ =========================================================== ============================================================

Data spacing

and * Data spacing for reporting of Exploration Results. * The deposit is well drilled in the near surface

distribution mineralised areas on a grid spacing of approximately

30 m. In the less well drilled areas holes are spaced

* Whether the data spacing and distribution is approximately 100 m apart.

sufficient to establish the degree of geological and

grade continuity appropriate for the Mineral Resource

and Ore Reserve estimation procedure(s) and * Drilling to 30 m is sufficient to establish grade

classifications applied. continuity consistent with that expected in a

Measured Mineral Resource. The less well drilled

areas are sufficiently drilled to establish

* Whether sample compositing has been applied. continuity consistent with that expected in an

Indicated or Inferred Mineral Resource.

============ =========================================================== ============================================================

Orientation

of data * Whether the orientation of sampling achieves unbiased * At Groenfontein the mineralisation occurs as

in relation sampling of possible structures and the extent to lenticular ore bodies occur in the Lease Granite

to which this is known, considering the deposit type. immediately below the pegmatite zone and appear to be

geological the product of "bubbles" of tin bearing fluids which

structure were trapped beneath the impermeable pegmatite. The

* If the relationship between the drilling orientation mineralisation is broadly stratabound in Lease

and the orientation of key mineralised structures is Granites which dips to the west and southwest on the

considered to have introduced a sampling bias, this property (see section 6)

should be assessed and reported if material.

* The drill hole grid (current and historically) were

drilled along a NW-SE trend parallel to the strike of

the granites and geochemical anomaly identified in

the 1970's (see section 8.3.1) and is considered

appropriate.

============ =========================================================== ============================================================

Sample * See section 9.2.7

security * The measures taken to ensure sample security.

============ =========================================================== ============================================================

Audits

or reviews * The results of any audits or reviews of sampling * The CP, Mr Michael Cronwright (Exploration Results)

techniques and data. of The MSA Group, has reviewed the sampling, logging

practices. Mineral Resource estimation method was

reviewed by Mr Jeremy Witley of the MSA Group.

* At the time of the exploration in 2011 the work was

reviewed by the CP, Dr L. Liebenberg

============ =========================================================== ============================================================

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this

section.)

Criteria JORC Code explanation Commentary

============== =============================================================== ===========================================================

Mineral

tenement * Type, reference name/number, location and ownership * The Prospecting Right, LP2206 PR was granted to

and land including agreements or material issues with third Greenhills on 14 July 2017 for a period of 5 years

tenure parties such as joint ventures, partnerships, ending on 13 July 20156, and ceded to Renetype (Pty)

status overriding royalties, native title interests, Ltd in terms of Section 11(1) of the MPRDA on 1

historical sites, wilderness or national park and December 2011.

environmental settings.

* Acknowledgement of renewal of the Prospecting Right

* The security of the tenure held at the time of by the DMR was received on 17 July 2015 and approval

reporting along with any known impediments to thereof for an additional 3 years is still pending

obtaining a licence to operate in the area.

* See CPR Section 4

============== =============================================================== ===========================================================

Exploration

done by * Acknowledgment and appraisal of exploration by other * Historical exploration has been carried out as

other parties. detailed in the CPR Section 8

parties

============== =============================================================== ===========================================================

Geology

* Deposit type, geological setting and style of * Included in theCPR in Sections 6 and 7

mineralisation.

============== =============================================================== ===========================================================

Drill

hole * A summary of all information material to the * Included in the CPR in Appendix 3 and 4

Information understanding of the exploration results including a

tabulation of the following information for all

Material drill holes:

o easting and northing

of the drill hole collar

o elevation or RL (Reduced

Level - elevation above

sea level in metres)

of the drill hole collar

o dip and azimuth of

the hole

o down hole length

and interception depth

o hole length.

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

============== =============================================================== ===========================================================

Data

aggregation * In reporting Exploration Results, weighting averaging * Drill hole intersections were reported using downhole

methods techniques, maximum and/or minimum grade truncations length weighted averaging methods.

(e.g. cutting of high grades) and cut-off grades are

usually Material and should be stated.

* A cut-off grade of 0.1 % Sn was applied and an upper

limit of 0.7 % Sn (see CPR Table 11--5, Sections 9.2

* Where aggregate intercepts incorporate short lengths and 11.1.10)

of high grade results and longer lengths of low grade

results, the procedure used for such aggregation

should be stated and some typical examples of such

aggregations should be shown in detail.

* The assumptions used for any reporting of metal

equivalent values should be clearly stated.

============== =============================================================== ===========================================================

Relationship

between * These relationships are particularly important in the * Downhole lengths are reported and the true length.

mineralisation reporting of Exploration Results.

widths

and intercept

lengths * If the geometry of the mineralisation with respect to

the drill hole angle is known, its nature should be

reported.

* If it is not known and only the down hole lengths are

reported, there should be a clear statement to this

effect (e.g. 'down hole length, true width not

known').

============== =============================================================== ===========================================================

Diagrams

* Appropriate maps and sections (with scales) and * Maps and cross sections are attached in the body of

tabulations of intercepts should be included for any the report

significant discovery being reported These should

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

============== =============================================================== ===========================================================

Balanced

reporting * Where comprehensive reporting of all Exploration * The Company states that all results have been

Results is not practicable, representative reporting reported and comply with balanced reporting.

of both low and high grades and/or widths should be

practiced to avoid misleading reporting of

Exploration Results.

============== =============================================================== ===========================================================

Other

substantive * Other exploration data, if meaningful and material, * Not material to this report.

exploration should be reported including (but not limited to):

data geological observations; geophysical survey results;

geochemical survey results; bulk samples - size and

method of treatment; metallurgical test results; bulk

density, groundwater, geotechnical and rock

characteristics; potential deleterious or

contaminating substances.

============== =============================================================== ===========================================================

Further * See CPR Section 15.3

work * The nature and scale of planned further work (e.g.

tests for lateral extensions or depth extensions or

large-scale step-out drilling).

* Diagrams clearly highlighting the areas of possible

extensions, including the main geological

interpretations and future drilling areas, provided

this information is not commercially sensitive.

============== =============================================================== ===========================================================

Section 3 Estimation and Reporting of Mineral Resources

(Criteria listed in section 1, and where relevant in section 2,

also apply to this section.)

Criteria JORC Code explanation Commentary

============== =========================================================== =================================================================

Database The following data verification

integrity * Measures taken to ensure that data has not been was carried out:

corrupted by, for example, transcription or keying * checking whether any gaps or overlaps occurred with

errors, between its initial collection and its use the sample positions in the database;

for Mineral Resource estimation purposes.

* the assay data were interrogated for zero grades and

* Data validation procedures used. other obviously erroneous data such as negative

grades;

* drill hole collar names were checked in order to

ensure no duplication of hole ID;

* The location of each surface drill hole was checked

and verified by site staff as well as the

lithological and assay tagging within those drill

holes;

* Survey points denoting the locations of the holes

were received and plotted in three dimensions using

Datamine alongside images obtained from the mine site

in order to assess whether or not the drill hole

collars were in the correct place.

============== =========================================================== =================================================================

Site visits

* Comment on any site visits undertaken by the * A site visit was made on 11 April 2011 to the

Competent Person and the outcome of those visits. Mokopane Tin Project by Dr Leon Liebenberg DSc MSc

Pr.Sci.Nat, a 'Competent Person' as that term is

defined in the JORC Code, and Mr Mike Lynn MSc of MSA,

* If no site visits have been undertaken indicate why accompanied by Professors Morris and Richard Viljoen,

this is the case. representatives of Greenhills, and also 'Competent

Persons'. A visit was made to the historical marked

drill locations and current verification drilling

activities on the property, and to the core store

situated in the nearby town of Mokopane.

* A site visit was carried out by Michael Cronwright of

MSA on 13 June 2017.

============== =========================================================== =================================================================

Geological

interpretation * Confidence in (or conversely, the uncertainty of) the * The overall geological interpretation is simplistic

geological interpretation of the mineral deposit. and local controls on grade distribution are not well

understood.

* Nature of the data used and of any assumptions made.

* Drilling data was used to interpret the geology

together with knowledge gained during historical

* The effect, if any, of alternative interpretations on mining in various reports.

Mineral Resource estimation.

* The mineralisation occurs within a single rock type

* The use of geology in guiding and controlling Mineral and was not constrained.

Resource estimation.

* A number of mineralised intersections along the

* The factors affecting continuity both of grade and western flank of the project area occur near the

geology. contact of the pegmatitic granite with the Lease

Granite were constrained using a digital terrain

model ("DTM"). This allowed for the separation of

mineralisation populations and prevented smearing of

the contact mineralisation with the disseminated

mineralisation.

* A more constrained interpretation could impact on the

grade and tonnage of the deposit, potentially with a

lower tonnage at higher grade.

============== =========================================================== =================================================================

Dimensions

* The extent and variability of the Mineral Resource * The mineralisation dips gently to the southwest, from

expressed as length (along strike or otherwise), plan flat to 10deg.

width, and depth below surface to the upper and lower

limits of the Mineral Resource.

* The Mineral Resource has been modelled as several

sheets of mineralisation between 2 m and 20 m thick.

* The Mineral Resource above the reported cut-off grade

occurs over a strike length of approximately 1 km and

between 250 m and 380 m on dip.

* The Mineral Resource occurs from surface to less than

60 m below surface.

============== =========================================================== =================================================================

Estimation

and modelling * The nature and appropriateness of the estimation * Datamine software was used to construct the

techniques technique(s) applied and key assumptions, including geological model and wireframe and GSLIB was used to

treatment of extreme grade values, domaining, estimate metal grades and estimate the Mineral

interpolation parameters and maximum distance of Resource.

extrapolation from data points. If a computer

assisted estimation method was chosen include a

description of computer software and parameters used. * The grades were estimated using Ordinary Kriging of

tin grades of 1 m composites into a three dimensional

block model.

* The availability of check estimates, previous

estimates and/or mine production records and whether

the Mineral Resource estimate takes appropriate * The block model cell size is 10 mX by 10 mY by 2 mZ.

account of such data.

* Distances between drill holes are typically between

* The assumptions made regarding recovery of approximately 20 m and 40 m.

by-products.

* Samples were selected for estimation using a search

* Estimation of deleterious elements or other non-grade ellipse orientated in the plane of mineralisation

variables of economic significance (e.g. sulphur for with the major direction being 140deg in the

acid mine drainage characterisation). horizontal plane, the semi-major being 50 degin the

horizontal plane and the shortest direction being

vertical.

* In the case of block model interpolation, the block

size in relation to the average sample spacing and

the search employed. * The estimate was carried out in three passes

* Any assumptions behind modelling of selective mining * Pass 1 - minimum of three and a maximum of ten

units. composites were required to be selected within the

flat search ellipse of 50 m by 25 m by 1 m. Maximum

of two composites per drill hole.

* Any assumptions about correlation between variables.

* Pass 2- minimum of three and a maximum of ten

* Description of how the geological interpretation was composites were required to be selected within the

used to control the resource estimates. flat search ellipse of 120 m by 60 m by 2 m. Maximum

of two composites per drill hole.

* Discussion of basis for using or not using grade

cutting or capping. * Pass 3 - minimum of three and a maximum of ten

composites were required to be selected within the

flat search ellipse of 200 m by 90 m by 3 m. Maximum

* The process of validation, the checking process used, of two composites per drill hole.

the comparison of model data to drill hole data, and

use of reconciliation data if available.

* A top-cut of 0.70% Sn was applied to the 1 m

composite data. 38 out of 4866 samples were affected

by the top-cut. A number of statistical charts were

examined for outlier data in order to derive the

top-cut value.

* The Mineral Resource generally occurs within the

variable spaced drilled area and the extents are

limited in areas by barren drill holes. Extrapolation

to less than 100 m away from drill holes occurs in

some areas, depending on the number of samples

available to satisfy the search criteria.

* Selective Mining Units were not estimated.

* No deleterious elements or bi-products were estimated

* The model was validated by trend analysis ("Swath

Plots") that compare the model with the input data

along a number of corridors through the model and

cross validation, which interrogates the difference

between the samples in the block with the block

estimate.

============== =========================================================== =================================================================

Moisture

* Whether the tonnages are estimated on a dry basis or * Tonnages were estimated on a dry basis

with natural moisture, and the method of

determination of the moisture content.

============== =========================================================== =================================================================

Cut-off

parameters * The basis of the adopted cut-off grade(s) or quality * A preferred cut-off grade of 0.1% tin has been

parameters applied. applied by benchmarking the project against other

projects worldwide, and by applying an average cash

buyer (London Metal Exchange) tin value over the past

three years (USD 18,000).

============== =========================================================== =================================================================

Mining

factors * Assumptions made regarding possible mining methods, * Portions of the deposit could be mined by open-pit

or assumptions minimum mining dimensions and internal (or, if methods. The deposit is wide and occurs close to

applicable, external) mining dilution. It is always surface.

necessary as part of the process of determining

reasonable prospects for eventual economic extraction

to consider potential mining methods, but the

assumptions made regarding mining methods and

parameters when estimating Mineral Resources may not

always be rigorous. Where this is the case, this

should be reported with an explanation of the basis

of the mining assumptions made.

============== =========================================================== =================================================================

Metallurgical

factors * The basis for assumptions or predictions regarding * Cassiterite is amenable to gravity concentration

or assumptions metallurgical amenability. It is always necessary as methods

part of the process of determining reasonable

prospects for eventual economic extraction to

consider potential metallurgical methods, but the

assumptions regarding metallurgical treatment

processes and parameters made when reporting Mineral

Resources may not always be rigorous. Where this is

the case, this should be reported with an explanation

of the basis of the metallurgical assumptions made.

============== =========================================================== =================================================================

Environmental

factors * Assumptions made regarding possible waste and process * It is assumed that tailings and waste-rock dumps

or assumptions residue disposal options. It is always necessary as would be constructed on site as both deposits have

part of the process of determining reasonable experienced previous mining and are disturbed

prospects for eventual economic extraction to

consider the potential environmental impacts of the

mining and processing operation. While at this stage

the determination of potential environmental impacts,

particularly for a greenfields project, may not

always be well advanced, the status of early

consideration of these potential environmental

impacts should be reported. Where these aspects have

not been considered this should be reported with an

explanation of the environmental assumptions made.

============== =========================================================== =================================================================

Bulk density

* Whether assumed or determined. If assumed, the basis * A specific gravity value of 2.65 was applied to the

for the assumptions. If determined, the method used, model in order to convert block volumes into

whether wet or dry, the frequency of the measurements tonnages. This figure is an average value based on

, the gas pycnometry data derived from the sample

the nature, size and representativeness of the pulps.

samples.

* The bulk density for bulk material must have been

measured by methods that adequately account for void

spaces (vugs, porosity, etc.), moisture and

differences between rock and alteration zones within

the deposit.

* Discuss assumptions for bulk density estimates used

in the evaluation process of the different materials.

============== =========================================================== =================================================================

Classification

* The basis for the classification of the Mineral * Block estimates estimated within the first variogram

Resources into varying confidence categories. range of the double structure spherical models were

classified as being within the Measured Mineral

Resource category. The principle range of 50 m

* Whether appropriate account has been taken of all approximately represents two thirds of the total

relevant factors (ie relative confidence in variance. Visual inspection of these blocks will

tonnage/grade estimations, reliability of input data, reveal that they are quite contiguous along strike

confidence in continuity of geology and metal values, throughout the deposit, and not prevalent in isolated

quality, quantity and distribution of the data). clusters.

* Whether the result appropriately reflects the * Mineral Resources estimated via the second structure

Competent Person's view of the deposit. of the double spherical model were classified as

Indicated

* Mineral Resources estimated at about one and half

times the longest variogram ranges were classified as

Inferred.

============== =========================================================== =================================================================

Audits

or reviews * The results of any audits or reviews of Mineral * No audits of the estimate have been carried out.

Resource estimates.

============== =========================================================== =================================================================

Discussion

of relative * Where appropriate a statement of the relative * The estimates are of a global nature, recoverable

accuracy/ accuracy and confidence level in the Mineral Resource resource estimation having not been carried out.

confidence estimate using an approach or procedure deemed

appropriate by the Competent Person. For example, the

application of statistical or geostatistical

procedures to quantify the relative accuracy of the

resource within stated confidence limits, or, if such

an approach is not deemed appropriate, a qualitative

discussion of the factors that could affect the

relative accuracy and confidence of the estimate.

* The statement should specify whether it relates to

global or local estimates, and, if local, state the

relevant tonnages, which should be relevant to

technical and economic evaluation. Documentation

should include assumptions made and the procedures

used.

* These statements of relative accuracy and confidence

of the estimate should be compared with production

data, where available.

============== =========================================================== =================================================================

APPIX 2: JORC (2012) TABLE 1 - ZAAIPLAATS

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

Criteria JORC Code explanation Commentary

============ =========================================================== ================================================================

Sampling

techniques * Nature and quality of sampling (e.g. cut channels, * 15 channels were sampled by Greenhills by chip

random chips, or specific specialised industry sampling underground and a further 15 from open pit

standard measurement tools appropriate to the workings. Samples were taken over 1 m intervals.

minerals under investigation, such as down hole gamma

sondes, or handheld XRF instruments, etc.). These

examples should not be taken as limiting the broad * 43 BQ size diamond drill holes (36.5 mm core

meaning of sampling. diameter) were completed by Greenhills on a grid of

approximately 50 m by 50 m. The holes range in depth

from 19.95 m to 141.11 m and a total of 2,067.26 m

* Include reference to measures taken to ensure sample were drilled in 2012 and 2013. The drill holes were

representivity and the appropriate calibration of any samples at 1 m intervals, although the length varies

measurement tools or systems used. in order to account for mineralisation intensity and

lithological changes. The cores were cut

longitudinally in half.

* Aspects of the determination of mineralisation that

are Material to the Public Report.

* The half core samples were prepared at Set Point

Laboratory's (SPL) preparation facility in Mokopane

* In cases where 'industry standard' work has been done where they were crushed to 80%

this would be relatively simple (e.g. 'reverse

circulation drilling was used to obtain 1 m samples

from which 3 kg was pulverised to produce a 30 g * The chip sample pulps were prepared at SPL in

charge for fire assay'). In other cases more Mokopane and assayed using a handheld Niton XRF.

explanation may be required, such as where there is

coarse gold that has inherent sampling problems.

Unusual commodities or mineralisation types (e.g.

submarine nodules) may warrant disclosure of detailed

information.

============ =========================================================== ================================================================

Drilling

techniques * Drill type (e.g. core, reverse circulation, open-hole * 15 channels were sampled by Greenhills by chip

hammer, rotary air blast, auger, Bangka, sonic, etc.) sampling underground and a further 15 from open pit

and details (e.g. core diameter, triple or standard workings.

tube, depth of diamond tails, face-sampling bit or

other type, whether core is oriented and if so, by

what method, etc.). * 43 BQ size diamond drill holes (36.5 mm core

diameter) were completed by Greenhills on a grid of

approximately 50 m by 50 m. The holes range in depth

from 19.95 m to 141.11 m and a total of 2,067.26 m

were drilled in 2012 and 2013. Core were not

oriented.

============ =========================================================== ================================================================

Drill

sample * Method of recording and assessing core and chip * No vugs or enriched veins were sampled by the channel

recovery sample recoveries and results assessed. samples in order to ensure that the samples were

representative of the disseminated mineralisation.

Sample sections were re-sampled if the faces were not

* Measures taken to maximise sample recovery and ensure accurate enough and some were extended to cover the

representative nature of the samples. full extent of the mineralisation. SRK examined a

number of channel sample sections.

* Whether a relationship exists between sample recovery

and grade and whether sample bias may have occurred * The core recoveries for the drilling were in excess

due to preferential loss/gain of fine/coarse of 98%. Some holes had excellent recoveries of close

material. to 100%. The core observed by SRK was competent, and

relatively un-fractured, supporting the good core

recoveries reported.

============ =========================================================== ================================================================

Logging

* Whether core and chip samples have been geologically * All cores were geologically logged. The geologist

and geotechnically logged to a level of detail to noted lithology, colour, grain size, veins,

support appropriate Mineral Resource estimation, alteration, the percentages and sizes of mafic

mining studies and metallurgical studies. minerals, and ore minerals such as cassiterite and

sulphides, according to standard look-up tables and

formats.

* Whether logging is qualitative or quantitative in

nature. Core (or costean, channel, etc.) photography.

* Fracture angles, core lengths, core recoveries,

percentages of solid core, and Rock Quality

* The total length and percentage of the relevant Designation ("RQD") were recorded according to a

intersections logged. fixed procedure and by making use of a pro-forma

geotechnical log sheet.

* Cores were photographed once marked up and cleaned.

============ =========================================================== ================================================================

Sub-sampling

techniques * If core, whether cut or sawn and whether quarter, * The BQ size cores were cut longitudinally in half and

and sample half or all core taken. one half taken as the sample. Nominal 1 m sample

preparation length intervals were taken continuously through the

mineralised zones for both core and chip channel

* If non-core, whether riffled, tube sampled, rotary samples. Lengths were shortened where a change in

split, etc. and whether sampled wet or dry. geology or mineralisation intensity was observed.

* For all sample types, the nature, quality and * The half core samples and chip samples were prepared

appropriateness of the sample preparation technique. at Set Point Laboratory's (SPL) preparation facility

in Mokopane where they were crushed to 80%

* Quality control procedures adopted for all

sub-sampling stages to maximise representivity of * The sampling techniques and sizes used are considered

samples. appropriate for the fine grained cassiterite

mineralisation.

* Measures taken to ensure that the sampling is

representative of the in situ material collected, * No field duplicates (half core / adjacent twin

including for instance results for field channels) were done.

duplicate/second-half sampling.

* Whether sample sizes are appropriate to the grain

size of the material being sampled.

============ =========================================================== ================================================================

Quality

of assay * The nature, quality and appropriateness of the * All samples were first crushed and milled at Set

data assaying and laboratory procedures used and whether Point's sample prep lab in Mokopane and then the

and the technique is considered partial or total. pulps were assayed using a Nition XL3d handheld XRF,

laboratory and samples with values >0.01% Sn (100 ppm) were sent

tests to Set Point (Johannesburg) for assay.

* For geophysical tools, spectrometers, handheld XRF

instruments, etc., the parameters used in determining

the analysis including instrument make and model, * At the time of assaying Set Point was ISO17025

reading times, calibrations factors applied and their accredited for the sample preparation done, the

derivation, etc. analytical method used and the elements analysed for,

apart from Sn and W.

* Nature of quality control procedures adopted (e.g.

standards, blanks, duplicates, external laboratory * All samples were analysed by using XRF - pressed

checks) and whether acceptable levels of accuracy (ie pellets for samples with

lack of bias) and precision have been established.

* For XRF using pressed pellets, an aliquot (1.3 g) and

wax binder (11.7 g) are milled together. The

resulting mixture is put into an aluminium cup and

pressed for 15 seconds at 20 metric tons pressure for

15 seconds in a pellet press. The pressed pellet is

read on an XRF spectrometer.

* For XRF using fused disks an ignited sample mass of

1.1g is fused with 9.9g flux (lithium-tetra-borate)

and fused in a clean platinum dish. The fusion melt

is poured into a clean platinum mould and allowed to

solidify. The solidified disc is analysed by

calibrated XRF spectrometer using the "silicate"

program provided by the manufacturer of the

equipment.

* The laboratory's QA/QC programme consisted of

* For pressed pellet XRF, insertion of a CRM sample

every 30 to 40(th) field sample and one in-house

standard per 100 samples. One blank sample per 100

field samples. Three pulp duplicates per 100 field

samples.

* For fused disk XRF, a 75G Canadian CRM is used for

sample preparation quality control. A fused disc of

this material is inserted for every 30 to 40 samples

analysed. At least one duplicate is selected for

every batch or job analysed. Instrument control discs

are read together with all jobs to confirm the

calibration of the instrument at similar

concentration levels as that of the samples.

Additional repeats on the samples are also done by

SPL.

* For determination of SG using gas pycnometry two

samples with certified SGs of 4.15 and 2.66 are

tested daily and random duplicate samples are taken

from each batch.

* After assessing the results of SPLs QA/QC samples, it

was concluded that the assays carried out by SPL are

accurate and precise and free from significant

contamination.

* The company geologists routinely carried out its own

QA/QC checks external to the laboratory, consisting

of the insertion of CRM, blank and duplicate samples.

* After assessing the results of the external QA/QC

samples, it was concluded that the assays carried out

by SPL are accurate and precise and free from

significant contamination.

* The handheld Niton XRF assays that were completed on

the chip samples were verified by laboratory XRF

assaying of 25 samples by SPL. The handheld XRF

consistently under-reported the tin grade relative to

the laboratory assay and an overall bias of 19% was

noted. No corrections were applied to the data to

account for the bias as the absolute bias was

inconsistent.

============ =========================================================== ================================================================

Verification

of sampling * The verification of significant intersections by * No independent verification sampling was completed.

and assaying either independent or alternative company personnel.

* No twin-hole drilling was performed.

* The use of twinned holes.

* The logging was carried out by handwritten recording

* Documentation of primary data, data entry procedures, of observations on a standard template and later

data verification, data storage (physical and captured digitally in Microsoft Excel spreadsheets.

electronic) protocols. The data were transferred from site to the company

server on a weekly basis. The company server has a

back-up system.

* Discuss any adjustment to assay data.

* No adjustments to assay data were made.

============ =========================================================== ================================================================

Location

of data * Accuracy and quality of surveys used to locate drill * A contract surveyor (Exact Survey Services) located

points holes (collar and down-hole surveys), trenches, mine the final collar coordinates using a real time

workings and other locations used in Mineral Resource differential Trimble GPS.

estimation.

* The drill holes were not surveyed down-the-hole. The

* Specification of the grid system used. holes are short (40-100 m in length) and little

deviation is expected in the competent granite.

* Quality and adequacy of topographic control.

* The grid system used is WGS84 LO29.

* Bushveld Minerals commissioned Badger Mining and

Consulting (Pty) Ltd to conduct a detailed survey of

the old working of the Zaaiplaats Mine. This survey

included two open pits (a smaller western pit and a

larger eastern pit), and underground workings which

connect these two pits.

* The topographic surface was derived from SRTM data

that was modified using the surveyed collar locations

for an accurate fit with the collars.

* Topographic control, is adequate for the purpose of

Mineral Resource estimation but a higher resolution

survey will be required as the project progresses.

============ =========================================================== ================================================================

Data

spacing * Data spacing for reporting of Exploration Results. * The drill holes are drilled at an approximate spacing

and of 50 m over the deposit with more closely spaced

distribution channel sampling in the mine exposures.

* Whether the data spacing and distribution is

sufficient to establish the degree of geological and

grade continuity appropriate for the Mineral Resource * The data spacing and distribution are sufficient to

and Ore Reserve estimation procedure(s) and establish grade continuity consistent with that

classifications applied. expected in an Inferred Mineral Resource and an

Indicated Mineral Resource in places.

* Whether sample compositing has been applied.

* For the Exploration results reported in this document

the samples were composited over the mineralised

lengths for the chipped channel samples. Exploration

results not reported for drilling, these being

superseded by the Mineral Resource estimate for which

3 m composites were used.

============ =========================================================== ================================================================

Orientation

of data * Whether the orientation of sampling achieves unbiased * Drill holes were drilled vertically through

in relation sampling of possible structures and the extent to mineralisation that is interpreted to be gently

to which this is known, considering the deposit type. dipping (5deg to 20deg). Channel samples were chipped

geological in vertical sections.

structure

* If the relationship between the drilling orientation

and the orientation of key mineralised structures is * No bias was considered to have been introduced by the

considered to have introduced a sampling bias, this sampling orientation.

should be assessed and reported if material.

============ =========================================================== ================================================================

Sample

security * The measures taken to ensure sample security. * There is a documented chain of custody from the

drilling rigs to the core-yard and to SPL.

* Sample crushing and milling is carried out at an

independent commercial laboratory.

============ =========================================================== ================================================================

Audits

or reviews * The results of any audits or reviews of sampling * SRK examined the sampling that was carried out and

techniques and data. considered it acceptable.

============ =========================================================== ================================================================

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this

section.)

Criteria JORC Code explanation Commentary

============== =============================================================== ===========================================================

Mineral

tenement * Type, reference name/number, location and ownership * Prospecting Right (PR) LP 2205 PR with protocol

and land including agreements or material issues with third reference 47/2010, issued by the Department of

tenure parties such as joint ventures, partnerships, Minerals and Energy (DME) (now the Department on

status overriding royalties, native title interests, Mineral Resources (DMR) on 14 July 2010 in the name

historical sites, wilderness or national park and of VM Investment Company (Pty) Ltd (VMIC). Valid for

environmental settings. five years, from 14 July 2010 to 13 July 2015, grants

exclusive prospecting rights to the holder. The PR

gives VMIC the right to explore for tin, rare earth

* The security of the tenure held at the time of metals, fluorspar, molybdenum, gold, arsenic, uranium

reporting along with any known impediments to ,

obtaining a licence to operate in the area. zirconium, iron ore and zinc.

* On 1 December 2011 consent in terms Section 11(1) of

the MPRDA for the cession of the Prospecting Right to

Renetype (Pty) Ltd was granted.

* Acknowledgement of the renewal application was

received from the DMR on 17 July 2015 and is still

pending approval. Renewal will be for another 3

years.

* The acknowledgement states that the licence remains

in place until such time as a final decision is made

to either grant or reject the renewal application.

The renewal was still pending as at the effective

date of this report.

============== =============================================================== ===========================================================

Exploration

done * Acknowledgment and appraisal of exploration by other * Cassiterite was discovered in 1905 by prospectors on

by other parties. the farms Roodepoort 222KR, Groenfontein 227 KR and

parties Zaaiplaats 223KR.

* The Zaaiplaats Tin Mining Company produced

cassiterite concentrate and tin metal continuously

from its inception to its closure in 1989. 17,300

Tonnes of tin metal were produced from the farm

Zaaiplaats. 223KR

============== =============================================================== ===========================================================

Geology

* Deposit type, geological setting and style of * Tin mineralisation at the project is found in the

mineralisation. Lebowa Granite Suite, a voluminous suite of granitic

rocks found above the layered mafic rocks of the

Bushveld Complex.

* Tin mineralisation is restricted to the Lease and

Bobbejaankop Granites where it occurs in pipe-like

bodies, sub-horizontal lenticular bodies and as a

sub-horizontal disseminated low grade bodies within

both granites. All tin mineralisation is in the form

of cassiterite (SnO2) and is of endogenic and

syngenetic origin within the granites.

* The mineralisation for within the Mineral Resource is

disseminated and occurs in five sheets within the

Bobbejaankop Granite. The higher grade pipe and vein

style mineralisation have been out with the more

voluminous disseminated style of mineralisation

remaining.

============== =============================================================== ===========================================================

Drill

hole * A summary of all information material to the * Detailed drill hole information is not material to

Information understanding of the exploration results including a this report, the exploration results having been

tabulation of the following information for all superseded by the Mineral Resource estimate.

Material drill holes:

o easting and northing

of the drill hole

collar

o elevation or RL

(Reduced Level - elevation

above sea level in

metres) of the drill

hole collar

o dip and azimuth

of the hole

o down hole length

and interception depth

o hole length.

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

============== =============================================================== ===========================================================

Data

aggregation * In reporting Exploration Results, weighting averaging * Detailed drill hole information is not material to

methods techniques, maximum and/or minimum grade truncations this report, the exploration results having been

(e.g. cutting of high grades) and cut-off grades are superseded by the Mineral Resource estimate.

usually Material and should be stated.

* Where aggregate intercepts incorporate short lengths

of high grade results and longer lengths of low grade

results, the procedure used for such aggregation

should be stated and some typical examples of such

aggregations should be shown in detail.

* The assumptions used for any reporting of metal

equivalent values should be clearly stated.

============== =============================================================== ===========================================================

Relationship

between * These relationships are particularly important in the * Detailed drill hole information is not material to

mineralisation reporting of Exploration Results. this report, the exploration results having been

widths superseded by the Mineral Resource estimate.

and intercept

lengths * If the geometry of the mineralisation with respect to

the drill hole angle is known, its nature should be

reported.

* If it is not known and only the down hole lengths are

reported, there should be a clear statement to this

effect (e.g. 'down hole length, true width not

known').

============== =============================================================== ===========================================================

Diagrams

* Appropriate maps and sections (with scales) and * Detailed drill hole information is not material to

tabulations of intercepts should be included for any this report, the exploration results having been

significant discovery being reported These should superseded by the Mineral Resource estimate.

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

============== =============================================================== ===========================================================

Balanced * Not applicable

reporting * Where comprehensive reporting of all Exploration

Results is not practicable, representative reporting

of both low and high grades and/or widths should be

practiced to avoid misleading reporting of

Exploration Results.

============== =============================================================== ===========================================================

Other

substantive * Other exploration data, if meaningful and material, * Not material to this report.

exploration should be reported including (but not limited to):

data geological observations; geophysical survey results;

geochemical survey results; bulk samples - size and

method of treatment; metallurgical test results; bulk

density, groundwater, geotechnical and rock

characteristics; potential deleterious or

contaminating substances.

============== =============================================================== ===========================================================

Further

work * The nature and scale of planned further work (e.g. * No further exploration work is planned at this stage.

tests for lateral extensions or depth extensions or

large-scale step-out drilling).

* Diagrams clearly highlighting the areas of possible

extensions, including the main geological

interpretations and future drilling areas, provided

this information is not commercially sensitive.

============== =============================================================== ===========================================================

Section 3 Estimation and Reporting of Mineral Resources

(Criteria listed in section 1, and where relevant in section 2,

also apply to this section.)

Criteria JORC Code explanation Commentary

============== =========================================================== ================================================================

Database

integrity * Measures taken to ensure that data has not been * SRK audited the database and was satisfied that the

corrupted by, for example, transcription or keying data are reliable.

errors, between its initial collection and its use

for Mineral Resource estimation purposes.

* The drill hole data were validated for gaps and

missing intervals, unusual collar coordinates and

* Data validation procedures used. consistency of drill hole names.

* Below detection limit samples were assigned a value

of half the detection limit.

============== =========================================================== ================================================================

Site

visits * Comment on any site visits undertaken by the * A site visit was undertaken by Mr A.S. Page of SRK on

Competent Person and the outcome of those visits. the 6th of March 2013 to the Zaaiplaats exploration

site, exploration core storage facility in Mokopane

and the Set Point sample preparation facility in

* If no site visits have been undertaken indicate why Mokopane. The Set Point Laboratories in Isando,

this is the case. Johannesburg, were also visited by Mr A.S Page and Dr

H. F. J. Theart on the 10th of May 2013.

* A site visit was carried out by Michael Cronwright of

MSA on 13 June 2017.

============== =========================================================== ================================================================

Geological

interpretation * Confidence in (or conversely, the uncertainty of) the * Confidence in the models is good.

geological interpretation of the mineral deposit.

* The geological model was constructed based on surface

* Nature of the data used and of any assumptions made. drilling and a small amount of underground and open

pit chip sampling. Reverse Circulation (RC) and

Diamond Drilling (DD) exploration drilling have

* The effect, if any, of alternative interpretations on historically been undertaken.

Mineral Resource estimation.

* In addition to the drilling database, used surveyed

* The use of geology in guiding and controlling Mineral contours of the two open pits and the underground

Resource estimation. workings. The latest surface topography contours were

obtained for the surface topography from the Chief

Directorate Surveys and Mapping ("CDSM") South Africa

* The factors affecting continuity both of grade and for the area covering the Zaaiplaats project and its

geology. surrounds.

* The wireframe models were constructed by linking

strings generated on dip and strike sections

interpreted by the company geologists that depict the

geology and sample grade distribution. The

mineralisation was defined using a tin grade

threshold of 0.01%.

* The five planer mineralised zones were interpreted

interrupted by an east west striking fault with a

throw of between 10 m and 20 m with scissor

displacement.

* No alternative interpretations were considered.

============== =========================================================== ================================================================

Dimensions

* The extent and variability of the Mineral Resource * The Mineral Resource Extends from surface to

expressed as length (along strike or otherwise), plan approximately 190 m below surface. The maximum extent

width, and depth below surface to the upper and lower on the dip plane is approximately 380 m and the

limits of the Mineral Resource. maximum strike length is 600 m.

* The mineralisation is open at depth.

* The mineralised zones are between approximately 5 m

and 20 m thick.

* The tabular mineralised zones generally dip between

5deg and 15deg to the northwest, with the steeper

dipping areas being to the southwest.

============== =========================================================== ================================================================

Estimation

and modelling * The nature and appropriateness of the estimation * Datamine Studio 3 (Datamine; Version 3.21) was used

techniques technique(s) applied and key assumptions, including to construct the geological solids, prepare assay

treatment of extreme grade values, domaining, data for geostatistical analysis, and construct the

interpolation parameters and maximum distance of block model. Datamine was used to estimate metal

extrapolation from data points. If a computer grades and estimate the Mineral Resources using

assisted estimation method was chosen include a Ordinary Kriging (OK). Isatis software was used for

description of computer software and parameters used. geostatistical analysis and variography.

* The availability of check estimates, previous * The estimation was carried out by ordinary kriging

estimates and/or mine production records and whether (OK) of the tin grades of 3 m composite sample data

the Mineral Resource estimate takes appropriate into block models. The individual M Zones were

account of such data. treated as individual domains whereby samples from

one domain were not allowed to influence another.

* The assumptions made regarding recovery of

by-products. * Parent cell size of 20 mX by 20 mY by 3 mZ. Diamond

core drilling was on 50 m spaced sections and

additional sample data were used from chip channel