VANCOUVER, BRITISH COLUMBIA (FRANKFURT: NBS)(OSLO: NAUR) is

pleased to announce the first NI 43-101 compliant iron resource and

highly encouraging preliminary metallurgical results for its

100%-owned Tapuli magnetite project, 5km from the Stora Sahavaara

magnetite deposit in Norrbotten District, northern Sweden. The

resource has been modeled using a cut off of 15.0% Fe:

- Total Indicated resources are 54.4 million tonnes with an

average grade of 27.7 % Fe.

- Total Inferred resources are 47.6 million tonnes with an

average grade of 26.3 % Fe.

The mineralization remains open below 300m. A NI 43-101

compliant report on the Tapuli resource calculation will be filed

on www.sedar.com within 45 days.

Initial metallurgical test work has produced excellent early

results. The work, performed on a composite drill core sample taken

from seven drill holes from across the resource, indicates that a

high-grade concentrate, up to 69% Total Iron (Fet) and less than

0.03%S, can be produced using a simple flow sheet that comprises

magnetic separation only and does not require a flotation stage.

The concentrate should be suitable as pellet feed, is relatively

coarse grained, and should be transportable by road, rail or ship

year round after filtration.

Buck Morrow, the President of Northland, said:

"Today's news is our third resource calculation on a significant

magnetite body in the last 12 months. Our work has significantly

expanded the historic resource of 60 million tonnes at 29% iron

which was defined by the SGU in the late 1960s. The early results

of the metallurgy are some of the best we've received to date from

our projects and the Tapuli metallurgical flow sheet looks

straightforward. We can now move to the detailed engineering and

planning stage with Tapuli and Stora Sahavaara. An aggressive

winter drilling program is now taking place at Tapuli. In addition

to taking large diameter core samples for further metallurgical

testing, we will continue our drilling at both projects over the

next 12 months with the aim of moving tonnes into the measured

resource category and of expanding both resources. Both magnetite

bodies remain open for expansion."

The Tapuli magnetite deposit occurs as a semi-continuous

mineralized zone beneath an average of 11m of till. The

mineralization has been separated into 7 mineralized lenses, Tapuli

South, Tapuli Central Upper and Lower, Tapuli North Upper and Lower

and Palotieva Upper and Lower respectively. The dip of the

mineralized bodies ranges from 45 to 60 degrees towards the WNW and

NW. Magnetite occurs as relatively continuous lenses which have

been delineated at surface along strike for over 2,000 meters with

true widths within the Central lens of over 200 meters.

GeoVista AB note in their summary that the project has the

potential for commercial exploitation given:

- the scale of the deposit, which could be combined with other

major magnetite deposits also being evaluated by Northland within a

radius of some 40 kilometers, including ... the Stora Sahavaara

magnetite deposit, five kilometers to the south, and the

Hannukainen magnetite deposit in the neighboring Kolari ironstone

district of Finland;

- the potential to realize major cost savings on initial project

capital requirements, if a development decision is made, by

rehabilitating and feeding into existing infrastructure in

neighboring Finland;

- potential low waste to ore mining ratio; and

- recent, substantial increases in the price for iron ore.

Metallurgical Test Work

Northland has completed metallurgical test programs at SGS in

Truro, UK, under the supervision of Corus Consulting, and at the

Geological Survey of Finland Mineral Processing in Outokumpu,

Finland. The test work investigated the liberation characteristics

of the Tapuli iron mineralization using Davis Tube Tests (DDT)

along with additional dry and wet magnetic separation techniques,

and was completed using mineralized drill core samples (900m of

core) from 7 drill holes taken across the Tapuli resource.

The work produced magnetite concentrates with in excess of 69%

total iron (Fet) and less than 0.03%S and demonstrates that a

saleable product can be made from the iron resource using a simple

flow sheet that comprises magnetic separation only and does not

require a sulphide flotation stage. Furthermore, the liberation of

the Tapuli ore appears such that resultant concentrate should be

relatively coarse: the effective liberation size lies somewhere

between 106 and 250 microns. This concentrate should be

transportable by road, rail or ship year round after filtration and

should be saleable as a pellet feed; or even for use as a part-feed

to a sinter plant. From the data gathered to date we anticipate

good recoveries of 85-90% Fet, with magnetite recovery over

90%.

A bulk sample of 25 tonnes of magnetite drill core is currently

being collected for pilot scale tests for flow sheet development

and to produce at least 4 tonnes of concentrate for additional

metallurgical test work.

The table below provides a more detailed analysis of the average

concentrate generated from the test work at 106 micron grind size

and demonstrates that the Tapuli resource can make a high grade,

low acid gangue concentrate suitable as feed for pelletizing

operations (Note all assays except sulphur were completed using

XRF).

Table 1: average concentrate composition for Tapuli magnetite concentrate.

All elements reported as %.

---------------------------------------------------------------------------

Fet S SiO2 Al2O3 MnO CaO MgO P2O5 K2O TiO2 Na2O Cr2O3 Zn Pb V2O5

---------------------------------------------------------------------------

69.1 0.027 0.65 0.2 0.1 0.06 2.0 0.03 less 0.11 0.1 0.02 0.02 less 0.06

than than

0.03 0.01

---------------------------------------------------------------------------

Resource Calculation Methodology

Mineral resources for the Tapuli deposit were prepared and

categorized for reporting purposes by Thomas Lindholm of GeoVista

AB, following the guidelines of the JORC Code.

The Swedish Geological Survey (SGU) began to investigate the

Tapuli and Palotieva deposits in 1965. Core drilling was completed

between 1965 and 1969. Twenty-six holes were drilled on the Tapuli

occurrence, totaling 6,280 meters; of these the majority has

density determinations. Northland's 2007 drilling program added 37

holes for a total of 5,697 meters. All the drill holes were

integrated into the current database, which contained a total of

5,603 iron analyses. A verification exercise was conducted on the

historic data, which included: locating and verifying the location

of drill collars and a review of drill hole surveys and orientation

data. Two historic drill holes were twinned to verify lithological

and assay reliability with good correlation.

Because the Tapuli-area deposits had been explored previously,

Northland was able to move directly to in-fill and deeper hole

drilling and did not undertake any significant mapping or surface

sampling, nor additional detailed geochemical surveys.

Drill core samples were 1 to 2 meter intervals in general,

depending on the mineralization (recent holes generally have 1m

intervals, historical holes typically have 1m or 2m intervals, but

can be considerably longer). All assays were composited to 10m for

use in the interpolation. Different mineralized lenses were defined

using a 15% Fe grade envelope. A total of 7 different mineralized

lenses were delineated and modelled.

The block model was rotated to N55 degrees E to accommodate for

the general strike direction of the deposit. The Block size was

defined as 10 x 20 x 2m (X x Y x Z), at the evaluation each block

was cut against the surface of the modelled wireframe to avoid

volume differences between wireframe model and block model. Block

grades were interpolated in 3 passes using Inverse distance with a

power of 3, with a minimum of 3 and a maximum of 8 samples, with a

maximum of 2 samples from the same hole. For the first pass an

ellipse of 75 x 75 x 10m was used, the second pass used 150 x 150 x

20m and the third and final pass used a 500 x 500 x 40m

ellipse.

Because the mineralized lenses are currently defined by a

50-100m x 100m drilling grid, no measured resources are defined. It

is anticipated that an additional 10 to 15 holes drilled on the

mid-sections within the main Central Tapuli deposit will convert

approximately 50% of the indicated resources to the measured

category.

Indicated mineral resources are defined as those portions of the

deposit generally drilled on a grid of 50-60m x 100m. Inferred

mineral resources are defined as those portions of the deposit

located outside of the indicated resources but inside the

interpreted mineralized zones. Search ellipse 500 x 500 x 40m.

A density function was developed from 1,579 density

determinations carried out on drill core. The density was assigned

to each block according to its grade of Fe as follows below:

Density equals 3.021 + 0.0061 x Fe + 0.00015 x Fe squared +

2.324 x 10 to the power of -6 x Fe cubed

The QA/QC program for Northland's drilling consisted of

inserting blank-samples and duplicate-samples into the sample

train. The ALS Chemex analytical laboratory analyzed the samples in

batches of 81. In each batch, three blanks and three duplicates

samples were inserted to test for cross contamination and

reproducibility of results respectively.

Qualified Person

Thomas Lindholm is the Qualified Person as defined in NI 43-101

responsible for the preparation of all sections in the report

entitled "NI 43-101 Technical Report - Tapuli Resource Estimate"

for Northland Exploration Sweden AB. Mr. Lindholm is employed by

GeoVista AB in Lulea, Sweden and holds an M.Sc. (Mining

Engineering, exploration) from the University of Lulea, Sweden and

is a member of the Australasian Institute of Mining and Metallurgy.

He has worked in minerals exploration and mining for over 25 years

including more than 10 years as a mine development engineer

responsible for resource estimation in open pit and underground

mine projects.

Dibya Kanti Mukhopadadhyay MSc., member of the Australasian

Institute of Mining and Metallurgy, employed by Micon International

Co Limited, also a Qualified Person as defined in NI 43-101, has

verified the grade interpolation protocol for the resource model

calculation.

The metallurgical work was performed under the supervision of

Paul Marsden, VP Metallurgical Development and Operations for

Northland. Mr. Marsden is a member of the IMMM, a Chartered

Engineer and a Chartered Scientist and is the Qualified Person as

defined in NI 43-101 responsible for overseeing the design and

execution of the metallurgical test work program at Tapuli. Mr.

Marsden has verified that the results presented here have been

accurately summarized from the results reported to Northland.

About Northland (www.northlandresourcesinc.com)

Northland is a well-structured, debt free junior exploration

company with a portfolio of high quality iron, gold, and base metal

exploration projects in Sweden and Finland.

ON BEHALF OF THE BOARD

Buck Morrow

NORTHLAND RESOURCES INC.

The TSX Venture Exchange does not accept responsibility for the

adequacy or accuracy of this release.

Contacts: Northland Resources Inc. Buck Morrow President Toll

Free: 1-866-719-8962 Northland Resources Inc. Ralph Rushton

Investor Relations - North America Toll Free: 1-866-719-8962

Website: www.northlandresourcesinc.com

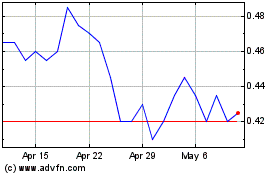

Nevgold (TSXV:NAU)

Historical Stock Chart

From Apr 2024 to May 2024

Nevgold (TSXV:NAU)

Historical Stock Chart

From May 2023 to May 2024