FORM 6 - K

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Report of Foreign Private Issuer

Pursuant to Rule 13a - 16 or 15d - 16 of

the Securities Exchange Act of 1934

As of 7/12/2023

Ternium S.A.

(Translation of Registrant’s name into English)

Ternium S.A.

26, Boulevard Royal - 4th floor

L-2449 Luxembourg

(352) 2668-3152

(Address of principal executive offices)

Indicate by check mark whether the registrant files or will file annual reports under cover Form 20-F or 40-F.

Form 20-F a Form 40-F __

Indicate by check mark whether the registrant by furnishing the information contained in this Form is also thereby furnishing the information to the Commission pursuant to Rule 12G3-2(b) under the Securities Exchange Act of 1934.

Yes __ No a

If “Yes” is marked, indicate below the file number assigned to the registrant in connection with Rule 12g3-2(b):

Not applicable

The attached material is being furnished to the Securities and Exchange Commission pursuant to Rule 13a-16 and Form 6-K under the Securities Exchange Act of 1934, as amended.

This report contains Ternium S.A.’s Sustainability Report 2022.

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the Registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

TERNIUM S.A.

By: /s/ Guillermo Etchepareborda By: /s/ Sebastián Martí

Name: Guillermo Etchepareborda Name: Sebastián Martí

Title: Attorney in Fact Title: Attorney in Fact

Dated: July 12, 2023

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | |

| | CONTENTS | |

| | | | | | | | | | | | |

| |

4  | | | |

| | |

16. Ternium at a Glance 18. Delivering Our Business Strategy 30. Leading the Development of the Mexican Steel Industry 32. Economic & Financial Performance | |

| | | | 14 | | | |

| | | | | | |

| | | | | | | | | | |

| | CHAIRMAN’S LETTER | | | THE COMPANY | | | |

| | | | | | | | | | |

| |

8  | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | | | |

| | OUR SUSTAINABILITY JOURNEY | | | | | | | |

| | | | | | | | |

| | | | | | | | | | |

| | 12. Ternium’s Approach to Climate Change | | | | | | |

| | | | | | | |

| | | | | | | |

| | |

| | | |

| |

| | 36 | | | 130 | |

| | | | |

| | | | | | | | | | | | |

| | ESG: ENVIRONMENTAL_SOCIAL_GOVERNANCE | | | ANNEXES | |

| | | | | | | | | | | | |

| | 38. Addressing Climate Challenges: Strategies for a Sustainable Future 52. Minimizing Our Environmental Footprint 64. Improving Our Safety Performance 80. Realizing Our People’s Full Potential 92. Helping Our Communities Thrive 108. Strengthening Our Value Chain 118. Commitment to Integrity | | | 132. Annex 1: GRI, SASB & TCFD Indexes 139. Annex 2: UN Sustainable Development Goals 143. Annex 3: Historical Data | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | | | |

| | | | | | | | | | | | |

| | Ternium S.A. (the “Company”) is a Luxembourg company

and its American Depositary Shares, or ADSs, are listed

on the New York Stock Exchange (NYSE: TX). We refer

to Ternium S.A. and its consolidated subsidiaries as

“we,” “our” or “Ternium.” | | The financial and operational information contained in this report is based on Ternium’s operational data and on the Company’s consolidated financial statements, which were prepared in accordance with IFRS and IFRIC interpretations as issued by the IASB and adopted by the European Union and presented in U.S. dollars ($) and metric tons. | |

| | |

| | | | | | | | | | | | |

| | | | | | | | | | | | |

| | | | | | | | |

| | |

4. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 5 |

| | | |

Following an exceptional 2021, 2022 was another good year for Ternium as it navigated a highly volatile geopolitical and economic landscape in our region and at a global level. The war in Ukraine, rising inflationary pressures, the gradual slowdown in the global economy, as well as the economic instability in Argentina, created a challenging environment for our company.

In spite of these challenges, Ternium posted solid financial results for the year, with an EBITDA of $3.4 billion and net income of $2.1 billion on shipments of 11.9 million tons. Net sales were similar to those of 2021 despite slightly lower shipments, reflecting the benefits of integrating slab production in Brazil with finished production in Mexico. Free cash flow was particularly encouraging at $2.2 billion and we accumulated a net cash position of $2.6 billion by the end of the year. A dividend of $2.70 per ADS was approved for the year.

Despite the ongoing global uncertainty, we are moving forward with our agenda of growth and sustainability. Ternium, with its solid financial and unique industrial and commercial footprint, is well positioned to grow as a supplier of high quality steel products for the industrial sector throughout the Americas and to support nearshoring and industrial development opportunities.

Earlier this year, we announced significant investments which will continue to transform Ternium in the years ahead. Over the next three years, we will invest $2.2 billion in electric arc furnace (EAF) steelmaking and direct reduction of iron ore (DRI) facilities with a capacity of 2.6 million tons per year of steel slabs and 2.1 million tons per year of DRI. This investment will complete the integration of our flat-rolled steel production operations at Pesquería, Mexico, and will complement the ongoing expansion of our high value added production capacity in cold rolling, galvanizing and additional advanced finishing lines, including the expansion of our R&D center.

The investment in Pesquería is aimed at (i) strengthening our capabilities to supply Mexico’s industrial sector with its opportunities for growth due to the nearshoring of industrial supply chains, (ii) meeting “melted and poured” requirements under the USMCA trade agreement, and (iii) advancing towards our 2030 decarbonization target.

Ternium is already a steel producer with a relatively low level of CO2 emissions intensity, and is fully committed to further advance towards the decarbonization of its operations and to reducing their environmental footprint. Renewable energy is an important element in our decarbonization strategy and we are targeting to source 40% of our purchased electricity requirements from renewable energy as part of our 2030 decarbonization target. This year we will be investing $160 million in a wind farm in Argentina, which will supply 65% of our requirements

| | | | | | | | |

| | |

6. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

for purchased electricity in the country. We expect the wind farm to begin operations in the second half of 2024.

This month, we increased our investment in Usiminas by acquiring part of the participation held by Nippon Steel Corporation in the Usiminas controlling group. As a result of this transaction, we now hold 51.5% of Usiminas’ control group, which holds the majority of the company’s voting rights, with the right to nominate the CEO and a majority of the Board of Directors, and 25.1% of the total shares. With our increased involvement in the company’s management, we aim to increase Usiminas’ competitiveness and strengthen its position in the Brazilian flat steel market.

Combining our strong regional presence in the Americas, and our downstream capabilities for producing the most value-added products, we are in a unique position for supplying the needs of the manufacturing, construction, and energy sectors in a region that should play a key role in the repositioning of the global supply chain in the coming years.

Although our performance in safety has been recognized by worldsteel and most of our safety indicators have improved, with our lost time injury frequency rate falling to its lowest ever level, we deeply regret that three fatalities occurred in our operations over the past 12 months. These events have led us to question deeply all our procedures, actions and training activities to ensure that safety is prioritized above all else throughout our operations, that our people have the training and tools to proactively reduce risks and prevent hazards, and that everyone is encouraged to identify opportunities for improvement.

We are increasing our investment in education programs for the communities around our plants with the decision to build a Roberto Rocca Technical School in the community of Santa Cruz, Rio de Janeiro, where we have our Brazilian slab-making facility. The new school will complement the existing Roberto Rocca Technical Schools in Pesquería, Mexico and in Campana, Argentina. By establishing beacons of excellence and leveraging network effects, we are contributing to improve standards in technical schools widely across our communities as well as encouraging local students to fulfil their potential independently of their means.

In this report, you can learn more about how Ternium embeds sustainability principles in all aspects of its management. This stems from the long-term vision of our founding shareholders and a resolute focus on strengthening the positioning and competitiveness of our operations.

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 7 |

| | | |

The guiding elements that shape the vision include the quality of our products and services, the relation with our local communities for which health, safety and respect for the environment are critical, the resilience and competitiveness of our value chain, and the central role of our people in our success.

Our employees are at the center of our efforts and achievements. I would like to give a special thanks to them for their ongoing efforts and achievements over the past year. I would also like to thank our customers, suppliers and shareholders for their continued support.

July 12, 2023

Paolo Rocca

Chairman

| | | | | | | | |

| | |

8. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | | | | | | | | | | | | | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | OUR SUSTAINABILITY JOURNEY | |

| | | |

| | | |

| | | |

| | | | | |

| | | | | |

|

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 9 |

| | | |

| | |

The concept of sustainability has been an integral part of our strategy for many years. At its core, it encompasses the principles of technical and operational excellence, as well as the preservation of people's safety. Safety is our primary value and extends to all those who perform roles within our facilities. To achieve these objectives, Ternium relies on the talent of its employees, and our efforts are focused on developing that potential, which is diverse and rich due to the multicultural nature of the countries in which we operate and are at the origins of our company.

We are thrilled to embark on a new phase of development with the Pesquería Industrial Center project at its base, representing the convergence of our vision for the future of the industry. The new DRI-EAF steel shop will be equipped with the latest technologies to accelerate Ternium's ongoing commitment to decarbonize its operations, including carbon capture capabilities and readiness to switch from natural gas to hydrogen for DRI production. In addition, all water utilized in the new facility’s production process will be sourced from wastewater treated for industrial use.

Our growth must be in harmony with the development of our communities, and education plays a key role in this aspect. In line with this commitment, we are strengthening our educational programs by building a new technical school in Santa Cruz, Brazil, and enhancing our existing programs to create more opportunities for all.

|

|

MÁXIMO VEDOYA CEO |

| | | | | | | | |

| | |

10. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

Ternium is a flat and long steel producer with a strong presence in the Americas. Ternium’s facilities are located in Mexico, Brazil, Argentina, Colombia, southern United States, and Central America. Additionally, the company is taking management responsibility over Usiminas, a leading flat steel manufacturing company in the Brazilian market, by increasing its participation in the company's controlling group.

Ternium has grown along a strategy mainly based on organic investments and acquisitions, consolidating its regional markets by seeking import substitution and expanding its commercial presence. As growth accelerated, Ternium broadened its product offerings and developed more sophisticated products to meet increasingly demanding markets, including the need for high-strength and ultra-lightweight steel for the automotive industry.

At the heart of our current growth strategy is our Industrial Center in Pesquería, Mexico. Built from the ground up and fully based on a sustainability philosophy, the Pesquería Industrial Center combines the latest technological developments to achieve efficient, high-quality production with a strong focus on people's safety along with an environmentally conscious approach.

The recently announced upstream capacity project will enable the company to better meet industry needs and

will be equipped with CO2 capture modules as well as the possibility of using green hydrogen when market conditions permit, allowing Ternium to further advance its decarbonization roadmap.

On this topic, in 2021, we set a medium-term goal to reduce our emissions intensity by 20% by 2030 compared to the 2018 baseline (scopes 1 and 2) along with a clearly defined roadmap based on six fundamental axes: energy efficiency; the use of renewable energies; the development of new raw materials in collaboration with business partners to replace coal and traditional iron ore pellets; the use of low-emission technologies; the expansion of CO2 capture and utilization capacity in existing plants, along with an increase in the use of scrap in the metal mix. We are also exploring other initiatives as part of our ambition to achieve carbon neutrality.

It is to be noted that all these initiatives have been feasible mainly thanks to the diverse talent we have fostered in our company over the years. Ternium is committed to developing its human capital, retaining talent, and ensuring equity among those who work within the company.

Sustainability is not a new topic for Ternium. ProPymes, the company’s support program for small and medium-sized suppliers and customers, has been in place for over 20 years. This program reflects our interest in growing together with our business partners and creating a resilient value chain even in times of adversity, such as the 2001 crisis in Argentina, when this program was created. Additionally, we continue to advance in our community growth programs, primarily focusing on education as a driver of change and social mobility.

Ternium reports to international agencies about its management approach and performance metrics on different Environmental, Social, and Governance (ESG) issues. In 2022, Ecovadis, a provider of business sustainability ratings, ranked Ternium within the 90th percentile in the "Manufacture of basic iron and steel" industry based on our policies, procedures, and actions related to environmental and labor practices, sustainable procurement and ethics. We also report to the Carbon Disclosure Project (CDP), an international non-profit organization that runs a global environmental disclosure system, on specific climate-change-related issues. In 2022, CDP rated Ternium with an A- in its Climate Change questionnaire thus including the company in the leadership category. This includes demonstrating adherence to best practices for strategy and action outlined in frameworks like the TCFD (Task Force on Climate-related Financial Disclosures).

Ternium has been acknowledged as a Sustainability Champion by the World Steel Association for five consecutive years and was recognized with the Steelie Award 2022 in the "Excellence in Education and Training" category. These relevant acknowledgments validate the company's commitment to sustainable growth and continuous improvement.

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 11 |

| | | |

| | |

|

Pesquería Industrial Center in Mexico: At the forefront of the industry while maintaining an environmental focus |

|

SUSTAINABILITY REPORTING

This report provides a comprehensive description

of Ternium’s integrated strategy, including the progress made during 2022 in various economic, environmental, social, and governance aspects.

It also highlights how company actions are contributing in achieving the Sustainable Development Goals defined by the UN in 2015.

The content of this sustainability report reflects the material topics established in 2019 after conducting a materiality assessment as well as the annual updates arising from interactions with our stakeholders.

It is prepared in reference to the international standards set by GRI (Global Reporting Initiative) and SASB (Sustainability Accounting Standards Board), the guidelines of the worldsteel association, and follows the recommendations of the TCFD (Task Force on Climate-related Financial Disclosures) regarding climate change reporting.

| | | | | |

| In 2022, worldsteel distinguished Ternium under its Climate Action Recognition Program for the company’s support and contributions to worldsteel’s initiatives to reduce carbon dioxide emissions. |

| | | | | | | | |

| | |

12. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | TERNIUM’S APPROACH TO CLIMATE CHANGE | | | |

| | | | |

| | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

|

OUR GOAL | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | |

|

The company is committed to achieve a 20% reduction in emission intensity rates (scopes 1 and 2) from its steelmaking sites by 2030, compared to a 2018 baseline. | | | |

| | | |

| | | |

| | | |

| | | |

| | Plans for 20% Emission Intensity Reduction by 2030 | | | | | | | | |

| | | | | | | | | |

| | | PROJECTS EXECUTED | | | PROJECTS UNDER DEVELOPMENT | | | PROJECTS UNDER ANALYSIS | | | | | | | | |

| | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | INITIATIVES | | | | | MEXICO | BRAZIL | ARGENTINA | PROGRESS DURING 2022 | | | | | |

| | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | _Guerrero facility in Mexico certified under ISO 50001 _Blast furnace expert control system incorporated at Brazil’s facility (IA technology) _Increase of pulverized coal injection (PCI) in Brazil _Equipment changes aimed at enhancing the energy efficiency of the production system | | | |

| | | Energy efficiency projects | | | | | | | | | | | |

| | | | | | | | | |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

| | | Scrap in the

metallic mix | | | | | | | | | _Increase of the scrapyard capacity in Brazil The company recycled an aggregate of 2.8 million tons of scrap in 2022 | | | |

| | | | | | | | | | | |

| | | | | | | | | | | |

| | | Alternative raw materials-biomass | | | | | | | | _Tryouts for mineral coal substitutes at an industrial scale with focus on biocarbon | | | |

| | | | | | | | |

| | | | | | | | |

| | | Renewable

energy | | | | | | | | _Recently announced wind-farm project in Argentina and execution of smaller onsite projects | | | |

| | | | | | | | |

| | | | | | | | |

| | | Carbon Capture

and Usage (CCU) | | | | | | | | | | | _First phase of CCU expansion in Mexico completed in 2021. Ongoing studies to increase CCU in Mexico and plans to build a pilot plant in Brazil | | | |

| | | | | | | | | | | |

| | | | | | | | |

| | | | | | | | | | | | | | |

| | | Low carbon technology | | | | | | | | | _Announced EAF Project in Mexico based on DRI-EAF Technology | | | |

| | | | | | | | | | |

| | | | | | | | | | |

| | FRAMEWORK | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | Governance Board surveillance Ternium’s Vice-Chairman appointed in 2021 to oversee decarbonization roadmap progress. |

Decarbonization committee Quarterly meetings with the CEO to review performance, projects and worldwide developments. | Strategy Scenario analysis and an internal carbon price for project evaluations. Price determined at $80/ton of CO2. | Risks Reviewed quarterly by Critical Risks Committee. Physical risk vulnerability analysis conducted by 3rd party (2021-2022) | Metrics GHG emissions Verified by a 3rd party under GHG Protocol and worldsteel’s methodology. | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 13 |

| | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | |

| | | | | | |

| | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | HIGHLIGHTS OF THE COMPANY’S LATEST MEDIUM-TERM INITIATIVES | | |

| | | | | | |

| | | |

|

LOW-CARBON TECHNOLOGIES FOR A SUSTAINABLE FUTURE New slab production capacity using the DRI-EAF route. The direct reduction module will include carbon capture capabilities and will be ready to switch from natural gas to green hydrogen whenever feasible. |

|

FIRST WINDMILL FARM: TRANSFORMING TERNIUM'S RENEWABLES LANDSCAPE Ternium will invest $160 million in a wind farm from which it will source electricity in Argentina. The wind farm is expected to reduce CO2 emissions by 92,500 tons per year and have a power capacity of 72 MW. | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | About the project | | About the project | | |

| | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | LOCATION | CAPACITY | | LOCATION | | | WIND TURBINES | | |

| | | | | Pesquería, Nuevo León, Mexico | DRI module: 2.1 million tons | | Olavarría,

Buenos Aires,

Argentina | 16 turbines | | |

| | | | | | |

| | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | |

| | | | | | | | | | | | | | |

| | | | | INVESTMENT $2.2 Billion | | | EAF- based steel shop 2.6 million tons | | INVESTMENT $160 million | | | NOMINAL CAPACITY 72 MW | |

| | | | | | | | | | |

| | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | The project also includes the construction of a port facility in Brownsville, Texas, for the handling of raw material | | The power generation capacity of the wind farm could increase in the future | | |

| | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | BEYOND 2030 | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | |

| | | | | The company has partnered with Tecpetrol and Tenova to study carbon

capture and storage solutions, as well as green hydrogen applications.

Ternium is also considering producing e-fuels, and evaluating initiatives

for the production and use of biomass, along with other nature-based

solutions to enhance atmospheric carbon capture like reforestation. | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | |

| | |

16. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | | | | | | | | | | | | | | | | | | | |

| | | | | | |

12 MILLION TONS OF STEEL SHIPMENTS (2022) | | | $16 BILLION OF NET SALES (2022) | | | +20,500 EMPLOYEES

|

| | | | | | |

9 COUNTRIES

| | | 6 INTEGRATED FACILITIES

| | | 12 DOWNSTREAM FACILITIES

|

| | | | | | |

28 SERVICE CENTERS | | | 23 DISTRIBUTION CENTERS

| | | |

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 17 |

| | | |

| | | | | | | | |

| | |

18. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | | | | | | | | | | | | | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | DELIVERING OUR

BUSINESS STRATEGY | |

| | | |

| | | |

| | | |

| | | | | |

| | | | SUSTAINABLE DEVELOPMENT GOALS | |

| | | | | |

| | | | | |

|

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 19 |

| | | |

| | | | | | | | | | | | | | | | | |

| | ELEMENTS OF OUR BUSINESS STRATEGY & ACTIONS | | | KPIs |

ELEMENTS OF OUR BUSINESS STRATEGY | _ __ | Focus on sophisticated steel products Pursue strategic growth opportunities Enhance Ternium´s competitiveness by: _ a full product range offering, _ operational excellence by incorporating cutting-edge technologies and integrating Ternium's industrial system _ differentiated services with a strong distribution network

| | | 11.9 MILLION-TON SHIPMENTS (2022) |

| |

| |

| |

| | |

| | |

| | | |

| | | $16.4 BILLION IN NET SALES (2022) |

| | |

| | |

| | |

| | |

| | |

| | | | |

| ACTIONS | _

_

_

_

_

_

_

_

| Initiating activities at the new hot-rolling mill in Pesquería in 2021 Announcing new downstream projects in 2022 with start-ups in 2024 and 2025, including a push-pull pickling line, a cold rolling mill, a hot-dip galvanizing line and additional finishing lines Launching an upstream project in our state-of-the-art industrial center in Pesquería, Mexico, in 2023 Establishing a new R&D center in Pesquería to further expand Ternium's capabilities Launching a wind farm project to replace 65% of the electricity purchased from third parties providers in Argentina Increasing Ternium's participation in Usiminas' control group (2023) Improving customer service systems through Ternium Activo and a marketing chatbot Developing the Smart Factory concept, including the implementation of new stages in the simulator program for training in safety and evaluation of industrial processes

| | | 21% EBITDA MARGIN (2022) |

| | |

| | |

| | |

| | |

| | |

| | | |

| | | $581 MILLION IN CAPITAL EXPENDITURES (2022) |

| | |

| | |

| | |

| | |

| | |

| | |

| | | |

| | |

| | |

| | |

| | |

| | |

| | | | |

| | | | |

| | | | | |

| | | | | |

| | | | | | | | |

| | |

20. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

STRENGTHENING TERNIUM'S PRODUCTION SYSTEM:

STRONG PRESENCE IN THE AMERICAS

Ternium’s goal is to increase value for stakeholders

by further consolidating its position as a top steel producer in Latin America and a prominent player in the Americas. Its business strategy consists of three key

elements: actively seeking growth opportunities, emphasizing the production of high value added products, and continuously striving for efficient and competitive industrial operations.

The company has a track record of strategic business

growth through acquisitions and organic expansion. In

Mexico, its primary market, Ternium initially acquired

two large industrial companies: Hylsamex and Grupo Imsa in 2005 and 2007, respectively. In 2013, Ternium established the Pesquería Industrial Center, a state-of-the-art greenfield project focused on advanced technology and sustainability. This expansion facilitated the company's diversified steel product portfolio, particularly for the automotive sector.

During the last twenty years, the Mexican market has

experienced significant growth, mainly driven by a dynamic manufacturing industry. According

to worldsteel’s data, apparent steel consumption in

Mexico increased at an average compound annual growth rate of 3% between 2000 and 2022. Moreover, the composition of steel supply in the country has created opportunities for import substitution.

In this context, Ternium made a series of investments

to strengthen and consolidate its presence in Mexico.

The first investment addressed the insufficiency of slabs production in Ternium´s industrial scheme in Mexico, given the higher downstream installed capacity. In 2017, Ternium acquired a slab mill in Rio de Janeiro, Brazil, with a production capacity of 5 million tons per year. This acquisition increased the company's total crude steel production capacity by approximately 70% to 12.4

million tons. Currently, the main destination of Brazilian slabs is the Pesquería facility in Mexico and a small portion is sold in the Brazilian market.

57%

OF TERNIUM'S STEEL SHIPMENTS

WERE SOLD IN MEXICO (2022)

37%

INCREASE IN SHIPMENTS IN MEXICO

SINCE INAUGURATION OF PESQUERÍA

INDUSTRIAL CENTER IN 2013

Ternium’s second investment focused on expanding

its product range and incorporating higher value added

products to cater to a more demanding market. In 2021, the new advanced hot rolling mill in the Pesquería Industrial Center started operations and we built a research and development center to support the manufacturing activity. This has led to a significant reduction in testing and certification time for highly specialized industries, including the automotive sector.The complete project includes other downstream facilities like a push-pull pickling line, a cold-rolling mill, a hot-dip galvanizing line and finishing lines, which are slated to begin operations in 2024 and 2025.

Recent developments have prompted a reevaluation of the Pesquería Industrial Center's capabilities, leading to further enhancements. As an example, the rule of origin of the USMCA (United States-Mexico-Canada Agreement) trade agreement, states that duty-free trade in the automotive sector is only available for goods that can be considered as originated from anyone of the member countries starting from 2027.

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 21 |

| | | |

| | |

|

Pesquería New Hot Rolling Mill - The process of coil formation is carried out through hot rolling equipment. |

|

As a result, in early 2023, Ternium announced the

construction of a new steelmaking facility comprising

an electric-arc-furnace-based steel shop, a DRI

module and a port. These facilities are set to produce high quality steels required for demanding applications, particularly in the automotive industry. The project is scheduled to commence operations in 2026, significantly increasing the company´s competitive position in the Mexican market. Notably, the new DRI module will incorporate carbon capture capabilities and be adaptable for transitioning from natural gas to hydrogen use when feasible, aligning with Ternium’s medium-term decarbonization goals.

As the market grows and trends like the nearshoring of the steel value chain emerge, Ternium reinforce its commitment to the industry by delivering high-quality steels and enhancing its commercial services.

Ternium strengthens its presence in Latin America

Ternium’s objective is to identify and pursue strategic opportunities for growth, enabling the company to strengthen its position in key markets throughout the

Americas. The focus is on enhancing its industrial system integration across operations in Mexico, Brazil, the US, Argentina, Colombia, and other countries. This involves broadening the range of value-added products and improving its production and distribution capabilities.

In Argentina, Ternium is the leader in the country's flat steel industry, which is the third largest in Latin America. With manufacturing customers accounting for around half of the local flat steel consumption, there are ample opportunities to offer value-added products and services. Through initiatives like the ProPymes program, the company has fostered strong connections within the local industrial cluster and supported the growth of medium and small enterprises, positioning itself favorably in the competitive landscape.

In Colombia, the fourth largest steel market in Latin

America, Ternium has expanded its capacity by

establishing a reinforcing bar facility in Palmar

de Varela in 2020. Additionally, the company owns finishing lines and service centers in Guatemala,

| | | | | | | | |

| | |

22. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | | | | | | | | | | | | | | | | |

| | | | | |

| INGREASING OUR PARTICIPATION

IN THE USIMINAS CONTROL GROUP | |

| | | | | |

| In March 2023, Ternium announced an agreement with Nippon Steel to acquire a portion of its stockholding, thus increasing Ternium’s stake in Usiminas’s control group.

The Usiminas control group holds the majority of the company's voting rights. With the recent closing of this transaction, Ternium now holds an aggregate participation of 51.5% in the control group. The Usiminas control group has also agreed a new governance structure. Ternium and its related companies will nominate a majority of the Usiminas board of directors, the CEO and four other members of Usiminas board of officers.

Usiminas is one of Brazil’s major producers of flat steel products, including iron ore mining, steel production, and steel processing and customization. In 2022, Usiminas shipped 4.2 million tons of steel products, of which 86% were directed to the Brazilian market, and 8.6 million tons of iron ore, with total net sales of BRL 32.5 billion. | |

| |

| |

|

| 1ST FLAT STEEL PRODUCER IN BRAZIL (AÇO BRASIL 2022 FIGURES) | |

| | | | | |

| | | | | |

| | 51.5% TERNIUM'S PARTICIPATION IN USIMINAS' CONTROL GROUP | |

| | | | | |

El Salvador, Nicaragua and Costa Rica, providing a widespread presence in Central America.

With its industrial footprint, network of distribution centers and commercial offices, Ternium is well equipped to offer differentiated logistics and stock management services. This gives the company a competitive advantage in major steel markets.

DELIVERING SOPHISTICATED STEEL PRODUCTS

Ternium’s product development roadmap aims to increase the participation of higher margin value added products in the sales mix, with a special focus on the expansion of Ternium’s offering of resistant and lightweight steel products for low carbon economy applications.

The start-up of the new hot-rolling mill in 2021

represented a technological leap forward in Ternium Mexico’s steel production capacity and strengthened

its positioning in the high-end market sector. In this

sense, the development of substrates for galvanized top quality exposed parts with very high drawability requirements was one of the milestones achieved during the first months of operation of the new hot-rolling mill.

In 2022, the company intensified the product development activities to expand its high-end product portfolio for customers in the automotive, metal mechanic, home appliance, energy and electric motors industries. During the year we completed the design of new substrates to replace some of the hot-rolled steel products procured from third parties. This development will allow Ternium to become fully compliant with the new USMCA rules of origin in connection with the supply of galvanized products to the automotive industry. We also developed new hot-rolled steel products prototypes for the automotive industry to replace imported material. This industry holds a significant share in Ternium's shipments in Mexico, representing 24% in 2022.

Ternium also launched innovative coated steel coils that combine eco-friendly materials with energy-saving solutions for the construction sector. The company expanded its product range by developing coiled plates up to one inch, catering to the needs of the structural steel market.

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 23 |

| | | |

Moreover, the company advanced its project to incorporate co-laminated finishing to its product offering. This new technology will enable us to offer steel products with superior aesthetic attributes for architectural and appliances designs. We are undergoing the product certification process and expect to start production soon.

Additionally, new features were introduced to the pre-painted products for motor casings, with the potential for implementation in home appliances. These new features provide new coating types that closely resemble stainless steel.

Ternium is utilizing its newly established R&D center in Pesquería, Mexico to secure steel product certifications for industrial customers. The facility has been accredited to ensure compliance with international regulations and customer specifications. In 2022, Ternium obtained 89

new product approvals for the automotive sector,

mainly attributed to the operation of its modern hot-rolling mill in Pesquería. This marks a substantial growth compared to the previous year. Additionally, the hot-rolling mill achieved ISO 9001 certification as a first step to being certified in 2023 under IATF 16949.

Ternium empowers future technological advancements with enhanced R&D capabilities

Ternium operates research facilities with laboratories in Mexico, Brazil and Argentina. These labs are used to conduct product performance tests and simulate

production processes. The incorporation of the R&D

Center in Pesquería, which features physical modeling,

simulation of industrial processes, robotized testing,

and full-scale welding processes, has enhanced the

company's ability to evaluate technical characteristics

and explore new product functionalities.

| | |

|

Ternium's Pesquería R&D Center: Technical evaluation and innovation with advanced facilities for physical modeling, process simulation, and testing. |

| | | | | | | | |

| | |

24. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | |

|

|

Innovative steels for Vaca Muerta In 2022, Ternium and its sister company Tenaris collaborated in developing new steels for welded tube manufacturing in gas and oil infrastructure projects at the Vaca Muerta shale field in southern Argentina. |

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 25 |

| | | |

In 2022, Ternium made further investments to strengthen its R&D infrastructure. The second phase of the R&D project in Pesquería, Mexico was launched, and advanced electronic microscopes were installed in the laboratories of Argentina and Brazil. This allowed the company to bring the microscopy service in-house, previously outsourced to third parties. As a result, Ternium was able to accelerate optimization efforts in steelmaking operations, with a focus on producing environmentally friendly steels and ensuring the reliability of its products.

Ternium forms strategic partnerships for joint research

Ternium’s in-house research activities are complemented by its involvement in a global network of industry consortia, universities, and research centers. One notable example is its membership in WorldAutoSteel, an organization comprising major steel producers worldwide. Ternium actively participated in the engineering core team of the Steel E-Motive project, sponsored by WorldAutoSteel, in the design of cost-effective, safe, and sustainable autonomous and connected electric vehicles using cutting-edge engineering and advanced high-strength steel technologies.

Additionally, Ternium partners with universities on joint initiatives, fostering the involvement of researchers and students from prestigious institutions in early-stage development projects. These research initiatives cover the entire production cycle, including primary steelmaking, metallurgy, rolling and coating processes.

In 2022, the company continued developing joint projects along its value chain. They included the development of new steel products with Tenaris, a related company, for the manufacturing of welded pipes designed for Monterrey’s new water pipeline in Mexico and for infrastructure projects at Argentina’s Vaca Muerta oil and gas shale formation. The synergies identified in developing projects with leading industrial companies enable Ternium to anticipate market requirements, plan new processes, incorporate new equipment and technology, and build strong customer relationships.

| | | | | | | | | | | | | | |

| | | | |

| SECOND PHASE OF R&D CENTER IN PESQUERÍA, MEXICO | |

|

Ternium's newly inaugurated R&D center in Pesquería, Mexico (2021), entered the second phase of its investment project, which focuses on installing a new galvanizing simulator. This state-of-the-art equipment is expected to be fully operational by the first quarter of 2024, enabling the company’s capabilities to conduct in-house simulations that were previously outsourced to third-party facilities. This advancement will significantly expedite the development cycle for new coated products.

| |

| | | | |

| | | | |

| | | $14.5 MILLION OF CUMULATIVE INVESTMENT IN R&D IN PESQUERÍA (2022) | |

| | | | |

Ternium’s customer technical assistance activities are focused on maximizing the performance of steel products and the efficiency of manufacturing processes in the steel industry’s value chain, supported by the company’s product R&D capabilities. In this regard, the

company has jointly developed new steels with a customer and a service supplier for a tray prototype designed for rock transportation. Additionally, Ternium has jointly developed structural steels with a plate producer for wind energy towers, as well as galvanized steels with a manufacturer of solar panels for supporting structures.

| | | | | | | | |

| | |

26. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

53%

OF TERNIUM SHIPMENTS IN MEXICO

WERE DESTINED TO THE INDUSTRIAL

SECTOR (2022)

48%

OF TERNIUM SHIPMENTS IN ARGENTINA

WERE DESTINED TO THE INDUSTRIAL

SECTOR (2022)

ENHANCING TERNIUM'S COMPETITIVE EDGE

Ternium’s broad range of value-added products, just-in-time delivery, inventory management and other services offered to customers in major steel markets are supported by the company’s service center, distribution, sales and marketing networks.

As part of its customer retention strategy, the company

regularly assesses customer satisfaction through

client surveys in its main markets. In 2022, customer

satisfaction rates stood at 83% in Mexico, 83% in

Argentina, and 94% in Colombia, based on a sample

that represented approximately 70% of the company's

shipments in each market.

Ternium operates its industrial system on a unified IT

platform, enabling seamless coordination in offering

a wide range of products and services to its customer

base. In 2022, the company implemented several

enhancements in its customer engagement tools.

| | |

|

Pushing new limits: Uniting industrial excellence and IT integration for seamless product and service coordination |

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 27 |

| | | |

The "Webservice" platform was upgraded to "Ternium Activo," which features an improved, personalized,

and faster navigation interface. Additionally, Ternium

is currently undertaking business-to-business (B2B)

developments with automotive clients to enhance

integration, reduce lead times, and eliminate manual

order input. These ongoing projects aim to deliver

significant benefits for both Ternium’s customers and

the company itself.

Throughout the year, the company made significant

progress in the development and implementation of

the Chatbot project, which was initiated in 2021

to address customer information needs. This tool harnesses the power of cognitive artificial intelligence

and seamlessly synchronizes with the company's

systems in real-time. Through platforms like

WhatsApp, customers can access valuable information

regarding Ternium’s production cycles, order updates,

logistics details, and account status. Initially focused

on customers in Mexico, the application has now expanded its availability to include counter sales in

Central America and the Caribbean. Moreover, a pilot

project is scheduled for launch during 2023, targeting

customers in Argentina.

In addition to developing a full range of steel products

and delivering differentiated services to Ternium’s

customer base, it aims to enhance the company’s

competitive position by seeking excellence in

operational performance. The quest for operational

excellence relies on the cross implementation of

Ternium’s managerial, commercial and production best

practices.

Throughout 2022, Ternium made progress in testing

the migration of its SAP system to the SAP HANA

version. This comprehensive project covers the

functionalities of Maintenance, Accounting, Costs,

Inventory, and Procurement, and aims to unify the

entire company under a single system.

One of the major challenges for the implementation of this system has been the multicultural nature of the

| | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | |

| DIGITAL PLATFORM UPGRADE ENHANCES CUSTOMER EXPERIENCE | |

| | | |

| In 2022, Ternium launched its new platform, Ternium Activo, as the primary point of contact with its customers. Customers can conduct all their commercial transactions, check status, review credit history, and more through this digital platform.

The development focused on three aspects: visual impact, structure and functionality, and personalization. Ternium Activo aims to provide | | | users with a personalized experience, simplifying processes and providing self-management support tools.

Currently implemented for all customers in Argentina, Ternium plans to expand it to Mexico and integrate it into all other countries where the company operates. | |

| | | | | | | |

| | 129 FEATURES AVAILABLE ON THE PLATFORM | | | 3,800 USERS REGISTERED ON THE PLATFORM UP TO DATE | +95% OF CUSTOMER ORDERS IN ARGENTINA PLACED THROUGH THE PLATFORM | |

| | | | | | | |

| | | | | | | | |

| | |

28. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

Ternium expects to implement

SAP HANA for the entire company

by 2024. This project unites Maintenance, Accounting, Costs, Inventory and Procurement functions under one integrated system.

participants, as it involves all Ternium personnel worldwide.

The company also collaborates in providing technological assistance to related companies. In 2022, we initiated an important project to improve the operation and maintenance of a related company´s blast furnaces in Brazil, extending our best practices.

COMPETITIVENESS AGENDA: SMART FACTORY

SMART is the acronym for Social, Mobile, Analytics, Robotics and (internet of) Things. Ternium is making progress in the deployment of new digital technologies that are leading to step improvements in its operating performance. These new solutions are based on the processing and analysis of a constant stream of information and knowledge from Ternium’s industrial operations (data and events provided by meters, cameras and drones).

In order to support Ternium’s analytics needs across

all business functions, the company has implemented a

Data Lake, a single technological platform that meets

all the company’s big data and analytics requirements.

SMART factory applications include a wide array

of company functions such as order management,

administration, human resources, maintenance,

quality, and occupational health and safety. Solutions

encompass mobile and remote work; remote assistance

(augmented reality); personnel training (virtual reality

simulation); the execution of automated administrative

processes and tasks (robots); and the real-time

autonomous detection of unsafe conducts or situations,

the autonomous assessment of difficult-to-access

building structures and equipment, and the appraisal

of bulk material (automatic image interpretation

through artificial intelligence).

SMART factory applications also include the automated handling of steel products in the yards (RFID and WMS), and the prediction of failures in maintenance management (predictive analytics and data correlation). Ternium’s RFID system has been installed at several stockpile yards for identifying and tracking each coil from the moment it reaches the yards up to shipment, facilitating inspection procedures, improving inspectors’ safety and reducing operations lead times.

The slab continuous casters at the company’s Brazilian, Mexican and Argentine facilities use analytics and data correlation technology for maintenance purposes. The plan is to extend this technology to the company’s main flat steel hot-rolling, cold-rolling and galvanizing lines to shield strategic equipment and reduce interruptions, thus increasing the reliability of operations while lowering costs.

In 2022, the company's supply chain and systems teams developed a logistics center at the San Nicolas plant in Argentina, allowing real-time tracking and generating early alerts that enable timely decision making. The logistics center facilitates transport planning and real-time tracking of logistics execution, optimizing the use of warehouses and trucks.

Technology is present in all aspects of Ternium’s business, and one of the most significant and long-term impact activities is training. Among the most important objectives of using IT tools in training activities are the reduction of accident rates by reproducing high-severity incidents, improving work team performance by simulating everyday tasks and the tools used and by simulating the behavior of the main production lines to improve operating conditions or achieve new products in a controlled environment prior to industrial testing.

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 29 |

| | | |

| | | | | | | | | | | | | | |

| | | | |

| DEVELOPING A SUSTAINABLE

EXPORT SOLUTION | |

|

Ternium has undertaken a project aimed at improving operations and reducing environmental impact in the export of slabs from Brazil to Mexico. This collaborative effort involved Ternium’s Global Logistics team in Uruguay, as well as the Supply Chain teams in Mexico and Brazil.

The key component of this initiative was the installation of cranes equipped with magnets at the port of Brownsville, USA.

These cranes facilitate the efficient unloading of Ternium Brazil’s slabs, which are then transported to Ternium’s Industrial Center in Pesquería, Mexico.

The implementation of this process has resulted in a significant reduction in the use of wooden dunnage for cargo securing.

As a result, approximately 26,700 trees are saved each year, leading to both environmental benefits and increased operational productivity. | |

| | | | |

| | | | |

| | | $2.8 MILLION IN COST REDUCTION PER YEAR | |

| | | | |

SUSTAINABLE PROCUREMENT

While Ternium handles slab procurement directly,

the centralized procurement of raw materials and

industrial services is entrusted to Exiros, a company

established jointly with our related company, Tenaris.

By utilizing the combined purchasing power of both

companies, Exiros has built an extensive network

of suppliers, with nearly 49,000 registered and over

15,000 active vendors in 2022. Among these, 7,300

suppliers specifically cater to Ternium’s requirements.

The procurement services offered by Exiros are

certified under the ISO 9001 standard, ensuring a high

level of quality.

When evaluating suppliers, Ternium insists that all its business partners adhere to the same rigorous standards that the company upholds. These standards encompass ethical conduct, legal compliance and the fulfillment of health, safety, and environmental obligations. Alongside the Supplier Code of Conduct, Ternium has recently introduced a Sustainable Purchasing Policy to further engrave its dedication to sustainability throughout the supply chain. Ternium will actively oversee the implementation of these principles, either independently or with the assistance of third parties, as determined by the nature of the business relationship and its impact on Ternium’s operations.

Additionally, Exiros carries out yearly audits to

evaluate the health and safety practices of its suppliers.

These audits serve as a prerequisite for awarding or

renewing service contracts, and they play a crucial role

in long-term risk management. As of December 2022,

Exiros has successfully audited and certified 94% of its active service suppliers, who were classified based

on a rigorous criterion pertaining to health, safety,

and environmental risks. The audit process follows

Ternium’s standardized self-assessment procedure,

which has been specifically tailored for suppliers offering services. In 2022 alone, a total of 525 new audits were conducted.

| | | | | | | | |

| | |

30. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | LEADING THE DEVELOPMENT OF THE MEXICAN STEEL INDUSTRY | |

| | |

| | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | TERNIUM'S GROWTH STRATEGY | | | | | | | | | | |

| | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | Ternium aims at increasing stakeholder value by strengthening its position as a top steel producer across the Americas.

Strategy: differentiation, high-value added products,

efficient operations | | | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | Progressive growth in steel consumption in the Mexican market | | Import substitution opportunities for local industries | |

| | | | |

| | | | |

| | | 3% | ANNUAL GROWTH RATE (CAGR) OF APPARENT STEEL USE IN MEXICO FROM 2000 TO 2022 | | 40% | OF NET IMPORTS

PARTICIPATION IN THE COUNTRY’S APPARENT FLAT STEEL USE (2022) | |

| | | | |

| | | | |

| | | | | | | | | | | | | | | |

| | | |

| | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | Opportunity to serve manufacturing activity with high-value-added products | | Relocation of manufacturing activities within the steel value chain (nearshoring) | | Compliance with the rules of origin set under the USMCA agreement | |

| | | | |

| | | | | | | | | | | | | | $35B | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | 66% | OF INDUSTRIAL CUSTOMERS PARTICIPATION IN THE COUNTRY’S APPARENT FLAT STEEL USE (2022) | | $35B | INCREMENTAL ANNUAL EXPORTS OF GOODS AND SERVICES FROM MEXICO According to Inter-American Development Bank (IDB) | | 70% | OF THE STEEL PURCHASED BY OEMs MUST BE "MELTED AND POURED" IN THE USMCA REGION BY JULY 2027 | |

| | | | |

| | | | |

| | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | |

| | TERNIUM’S CURRENT PRODUCTION SYSTEM IN MEXICO | | | | | | | | |

| | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | STEEL | | | | | | | MINING | | | | | | | ENERGY | | | | | |

| | 12 STEEL PRODUCTION AND/OR PROCESSING UNITS | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | 100% INTEREST IN LAS ENCINAS | 50% INTEREST IN CONSORCIO PEÑA COLORADA | | 900 MW OF CAPACITY

| TERNIUM SECURES THE SUPPLY OF ELECTRICITY IN MEXICO WITH A 78% PARTICIPATION IN A POWER PLANT JOINT VENTURE (TECHGEN) | |

| | | |

| | | |

| | | |

| | | | |

| | 12 DISTRIBUTION CENTERS ACROSS THE COUNTRY | | |

| | |

| | |

| | |

| | |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 31 |

| | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | |

| | | RECENTLY ANNOUNCED PROJECTS IN THE USMCA REGION | | |

| | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | MID 2024 | | | | 1st HALF 2025 | | | END 2025 | | | | 1st HALF 2026 | | | | |

| | | | | | | | | | | | | | | |

| | | | | |

| | | | |

| | | | | | | | | | | | | | |

| | | | | | | | | | |

| | | | | | | | | | |

| | | | | | | | | | |

| | | | | | | | | | |

| | | Push-pull pickling line PRODUCTION CAPACITY 550,000 TPY | | Painting line PRODUCTION CAPACITY 120,000 TPY Sheverport, USA | | Cold-Roll line PRODUCTION CAPACITY 1.6 million TPY

Hot-dip galvanizing line PRODUCTION CAPACITY 600,000 TPY Pesquería, Mexico | | Upstream Project Pesquería, Mexico EAF-based steel shop PRODUCTION CAPACITY 2.6 million TPY

DRI Module PRODUCTION CAPACITY 2.1 million TPY | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | Finishing lines Pesquería, Mexico | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | NEW UPSTREAM PRODUCTION CAPACITY PROJECT | | |

| | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | In 2023, Ternium announced a new steelmaking facility with an electric-arc-furnace-based steel shop & DRI module. The new DRI module will include carbon capture capabilities and readiness to switch from natural gas to hydrogen use. | | Operations are scheduled to start in 2026,

in line with Ternium's decarbonization goals

for the production of crude steel with low carbon content. | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | Port facility Construction for raw material handling | | | | | DRI module For the production of DRI | | | | | EAF-based steel shop Steel production

| | |

| | | | | | | | | | |

| | | | | | |

| | | | |

| | | | |

| | | | | | | | | | | |

$2.2 B Total investment | | |

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | Scrap yard Selection and preparation of metal scrap | | | | Consteel® Continuous scrap charging and preheating system | | |

| | | | 2026 Start-up expected in the 1st half

| | |

| | | | |

| | | | | | |

| | | | | | | | | | |

| | | | | | | | | | |

| | | | | | | | |

| | |

32. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | |

| ECONOMIC & FINANCIAL PERFORMANCE |

In 2022, Ternium achieved a high level of profitability and generated significant cash from operations. Net sales were $16.4 billion, including steel products net sales of $16.1 billion on steel shipments of 11.9 million tons, other products net sales of $322.8 million and iron ore products net sales of $410.8 million on iron ore shipments of 3.5 million tons. The majority of the iron ore production was consumed by our company's operations. Steel revenue per ton was $1,353, up $45 compared to revenue per ton in the prior year mainly reflecting a higher value sales mix in connection with the integration of Ternium’s industrial system.

During 2022, shipments in the Mexican market stood at 6.8 million tons, an increase of 5% compared to 2021, representing 57% of Ternium’s total steel shipments. Shipments in the Southern Region reached 2.4 million tons, or 20% of Ternium’s consolidated shipments in the steel segment, most of which were destined to the Argentine market. Shipments in the Other Markets region reached 2.7 million tons in 2022, or 23% of Ternium’s consolidated shipments in the steel segment.

Our major shipment destinations in the Other Markets region are usually the United States, Brazil, Colombia and Central America.

Operating income reached $2.7 billion, with Adjusted EBITDA of $3.4 billion. Adjusted EBITDA per ton reached $287 in 2022, decreasing $199 year-over-year on higher cost per ton, partially offset by slightly higher realized steel prices. The company’s net income in 2022 was $2.1 billion. Equity holders’ net income in 2022 was $1.8 billion, equivalent to earnings per ADS of $9.00.

Net cash provided by operating activities was $2.8 billion, with free cash flow of $2.2 billion after capital expenditures of $580.6 million. During 2022, Ternium advanced diverse projects throughout its main facilities, including those for further improving environmental and safety conditions and additional works in the new hot-rolling mill at the company’s Pesquería industrial center in Mexico. Ternium reached a net cash position of $2.6 billion at the end of December 2022.

| | | | | | | | | | | | | | | | | | | | |

| | | | | | |

| | | $1.2 BILLION IN EMPLOYEES | $581 MILLION IN CAPEX | $842 MILLION IN TAXES | $11.7 BILLION IN SUPPLIERS |

| $16.4

BILLION IN ECONOMIC VALUE GENERATED (2022) | | $21 MILLION IN COMMUNITY | $577 MILLION IN CAPITAL PROVIDERS | $16 MILLION IN RESEARCH & DEVELOPMENT | |

| | | | | | |

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 33 |

| | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| 2022 | | 2021 | | 2020 | | 2019 | | 2018 |

| STEEL SALES VOLUME (THOUSAND TONS) | | | | | | | | | |

Mexico | 6,843 | | | 6,534 | | | 5,913 | | | 6,305 | | | 6,545 | |

Southern Region | 2,362 | | | 2,503 | | | 1,924 | | | 1,938 | | | 2,301 | |

Other Markets | 2,691 | | | 3,028 | | | 3,523 | | | 4,268 | | | 4,105 | |

| Total | 11,896 | | | 12,065 | | | 11,360 | | | 12,511 | | | 12,951 | |

| | | | | | | | | |

| IRON ORE SALES VOLUME (THOUSAND TONS) | 3,457 | | | 3,809 | | | 3,797 | | | 3,576 | | | 3,616 | |

| | | | | | | | | |

| ECONOMIC AND FINANCIAL INDICATORS ($ MILLION) | | | | | | | | | |

| Net sales | 16,414 | | | 16,091 | | | 8,735 | | | 10,193 | | | 11,453 | |

| Operating income | 2,700 | | 5,271 | | | 1,080 | | | 865 | | | 2,108 | |

Adjusted EBITDA | 3,415 | | | 5,863 | | | 1,525 | | | 1,526 | | | 2,698 | |

| Profit for the year attributable to: | | | | | | | | | |

Owners of the Parent | 1,768 | | | 3,825 | | | 779 | | | 564 | | | 1,507 | |

Non-controlling interest | 325 | | | 542 | | | 89 | | | 66 | | | 156 | |

| Profit for the year | 2,093 | | | 4,367 | | | 868 | | | 630 | | | 1,663 | |

| | | | | | | | | |

| Capital expenditures | 581 | | | 524 | | | 560 | | | 1,052 | | | 520 | |

| Free cash flow | 2,172 | | | 2,154 | | | 1,201 | | | 595 | | | 1,219 | |

| | | | | | | | | |

| BALANCE SHEET ($ MILLION) | | | | | | | | | |

| Total assets | 17,492 | | | 17,098 | | | 12,856 | | | 12,936 | | | 12,548 | |

| Total liabilities | 3,723 | | | 4,863 | | | 4,413 | | | 5,221 | | | 5,063 | |

| Borrowings | 1,032 | | | 1,479 | | | 1,723 | | | 2,189 | | | 2,037 | |

| Net (cash) debt | (2,597) | | | (1,155) | | | 372 | | | 1,453 | | | 1,735 | |

| Capital and reserves attributable to the owners of the parent | 11,846 | | | 10,535 | | | 7,286 | | | 6,612 | | | 6,393 | |

| Non-controlling interest | 1,922 | | | 1,700 | | | 1,157 | | | 1,103 | | | 1,091 | |

| | | | | | | | | |

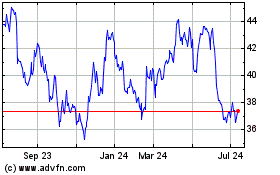

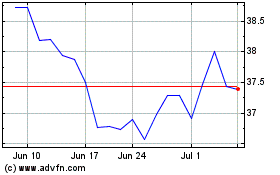

| STOCK DATA ($) | | | | | | | | | |

| Basic earnings per ADS | 9.00 | | | 19.49 | | | 3.97 | | | 2.87 | | | 7.67 | |

| Approved dividend per ADS | 2.70 | | | 2.60 | | | 2.10 | | | — | | | 1.20 | |

| | | | | | | | | |

Alternative performance measures

Non-IFRS measures should not be considered in isolation of, or as a substitute for, measures of performance prepared in accordance with IFRS. Non-IFRS measures do not have a standardized meaning under IFRS and, therefore, may not correspond to similar non-IFRS financial measures reported by other companies.

Adjusted EBITDA: equals net income of $2.1 billion adjusted to exclude net financial results of $70 million, income tax expense of $574 million, depreciation and amortization of $617 million, equity in results of non-consolidated

companies of $37 million (loss) and, in the fourth quarter of 2022, the impairment of Ternium's investment in Ternium Brasil of $99 million.

Free cash flow: Free cash flow equals net cash provided by operating activities of $2.8 billion less capital expenditures of $581 million in 2022.

Net (cash) debt: equals borrowings of $1.0 billion less the consolidated position of cash and cash equivalents and other investments of $3.7 billion in 2022.

Direct Economic Value Generated: equals net sales plus interest income, proceeds from the sale of property, plant & equipment, other operating income, equity in earnings of associated companies and inflation adjustment results, less other financial losses. “Employees” equals labor costs. “Taxes” equals current income tax expense plus cost of sales and SG&A taxes, less the effect of changes in tax law. “Suppliers” equals cost of sales plus SG&A, less labor costs, depreciation of property, plant and equipment, amortization of intangible assets, allowance for obsolescence, cost of sales and SG&A taxes, R&D expenditures and community investments. “Capital Providers” equals dividends paid in cash to company’s shareholders and non-controlling interest, plus interest expense.

| | | | | | | | |

| | |

34. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | |

|

|

Galvanizing line at the Pesquería Plant This robot functions as a "labeler", applying identification labels with chips to each coil produced. The labels are then read by the system providing real-time location information for each of the coils. |

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL

SOCIAL

GOVERNANCE | ANNEXES | 35 |

| | | |

| | |

STEEL SHIPMENTS MILLION TONS |

| | |

CAPITAL EXPEDITURES $ MILLION |

| | |

ANNUAL DIVIDENDS $ PER ADS |

| | | | | | | | |

| | |

38. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

| | | | | | | | | | | | | | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | ADDRESSING CLIMATE CHALLENGES: STRATEGIES FOR A SUSTAINABLE FUTURE | |

| | | |

| | | |

| | | |

| | | | | |

| | | | SUSTAINABLE DEVELOPMENT GOALS | |

| | | | | |

| | | | | |

|

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL SOCIAL GOVERNANCE | ANNEXES | 39 |

| | | |

| | | | | | | | | | | | | | | | | |

| | GOALS & ACTIONS

| | | KPIs |

GOALS | _ _

_ _ | Reduce by 20% the emission intensity rate for our steelmaking sites (scopes 1 and 2) by 2030 compared to 2018 baseline Plan and implement decarbonization strategies with the aspiration of achieving carbon neutrality in our products and operations, subject to technological feasibility and local market conditions Make an efficient use of energy resources Work alongside our supply chain to reduce GHG emission | | | $19.4 MILLION INVESTED IN DECARBONIZATION RELATED PROJECTS (2022) |

| |

| |

| |

| | |

| | |

| | |

| | | 1.7 CO2 PER TON OF CRUDE STEEL (SCOPES 1 & 2) |

| | | | |

| ACTIONS | _

_

_

_

_

_

_

_

_ | Establishing a climate change governance structure, including Board oversight and a decarbonization committee Incorporating a scenario analysis to assess asset vulnerability to physical risks Using an internal carbon price for project evaluation Developing a roadmap with key projects, annually reviewed, to achieve our 20% intensity reduction goal by 2030 Activating the upstream DRI-EAF project in Pesquería, Mexico, to reduce Terniums's average emissions intensity rate Launching a wind farm project in Argentina with operations beginning in the second half of 2024 Participating in initiatives to establish a decarbonization path for the steel industry Consolidating the company's energy efficiency program through locally defined initiatives under a unified corporate framework Strengthening the company's management system by including: –the certification under ISO 50001 standard, –a third-party verification of emissions under GHG Protocol and worldsteel methodology, –introduction of data processing systems to improve its granularity and analysis, –supplier data collection | | |

| |

| |

| | |

| | | 27% STEEL SCRAP CONTENT PER TON OF CRUDE STEEL |

| | |

| | |

| | |

| | |

| | |

| | | |

| | | 84% STEEL PRODUCED AT ISO 50001 CERTIFIED FACILITIES |

| | |

| | |

| | |

| | |

| | |

| | | |

| | | 22.7 GJ CONSUMED PER TON OF CRUDE STEEL |

| | |

| | |

| | | |

| | | | |

| | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | | | | |

| | |

40. TERNIUM_SUSTAINABILITY REPORT 2022 | CHAIRMAN´S LETTER | OUR SUSTAINABILITY JOURNEY |

| | |

THE ROLE OF THE STEEL INDUSTRY IN ADDRESSING CLIMATE CHANGE

Steel has played a critical role in shaping modern economies and societies. Its strength, versatility, and durability have made it a fundamental component in modern civilization, from buildings and bridges to cars and household appliances. However, the steel industry is also a major contributor to greenhouse gas emissions, accounting for 7% to 9% of global anthropogenic CO2 emissions according to worldsteel figures. As the world seeks to transition to a low-carbon economy and mitigate the effects of climate change, the steel industry faces the significant challenge of reducing its carbon footprint while attending to the likely increase in global steel demand.

In this context, one of the main challenges in decarbonizing the global steel industry has to do with the fact that most of its production processes heavily rely on coal and other fossil fuels. Currently, close to 71% of global steel production is made through the blast furnace route, with an average global intensity rate of 2.32 tons of CO2 per ton of crude steel (tCO2/t crude steel) according to 2021 worldsteel’s data. There are alternative production routes with lower emission intensity rates, such as electric arc furnaces based on direct reduced iron (DRI) or scrap, with global average intensity rates of 1.65 tCO2/t crude steel and 0.67 tCO2/t crude steel, respectively (2021 worldsteel´s data accounting for scopes 1, 2 and 3 based on its sectoral approach methodology).

However, the selection of the production route depends on the availability and the cost-efficiency of resources, given that the steel industry operates in a highly competitive scenario. As developing economies advance and infrastructure enters a replacement phase, the availability of obsolete scrap will increase, which in turn could support a shift from steelmaking technologies based on iron ore to those relying more heavily on steel scrap. Over time, this shift could have a significant impact on iron ore and steel scrap consumption trends globally.

On the energy side, while renewables availability has improved in the last years, major projects must be executed to replace traditional energy sources and market conditions must be set by local governments incentivizing this transition.

Steel, with its versatility, strength, durability, and infinite recyclability, stands as the foundation of a sustainable transition, enabling a circular economy, reducing environmental impact, and meeting evolving global needs.

Access and availability of renewable energy sources such as wind, solar, and hydropower are also an essential element in the transition to a low-carbon economy. Renewable energy plays a pivotal role in the production of green hydrogen as part of a more advanced stage of decarbonization projects. This is because the electrolysis process used to produce green hydrogen relies heavily on electricity, and if this electricity comes from non-renewable sources, the process may not be carbon-neutral as expected.

As the world shifts towards a low-carbon economy, the steel industry plays a critical role. It has the ability to produce steel to be used in renewable energy infrastructure, such as wind turbines and solar panels. Additionally, steel solutions like carbon capture and storage technology contribute to decarbonization efforts. Moreover, lightweight high-strength steel is vital for helping other industries, like automotive, decarbonize their activities.

| | | | | | | | | | | |

| | | |

| THE COMPANY | ENVIRONMENTAL SOCIAL GOVERNANCE | ANNEXES | 41 |

| | | |

| | |

|

Manizales plant, Colombia. 100% scrap-based facility for the production of long steel, Manizales is among Ternium's lowest emission intensity sites. |

|

With that spirit, reduction of emission intensity rate and improvement of energy efficiency in operations are top priorities in Ternium’s climate change agenda.

TERNIUM'S PATH TO REDUCE CARBON EMISSIONS:

A CLOSER LOOK AT THE COMPANY'S DECARBONIZATION ROADMAP