Bonnell Aluminum Introduces Acid Etch Anodizing

January 14 2009 - 10:00AM

PR Newswire (US)

New anodizing process regarded as more environmentally friendly

with improved consistency characteristics NEWNAN, Ga., Jan. 14

/PRNewswire/ -- Committed to serving the growing demand of its

customers and strategic markets with consistent and sustainable

products, Bonnell Aluminum, North America's premier aluminum

extrusion supplier to the nonresidential building and construction

market, is announcing it is investing $1.1 million in the

conversion of all of its existing anodizing product lines to the

acid etch process. Acid etched anodic coatings will be available

exclusively starting April 1, 2009. Available in Class I and II,

clear, bronze, and black finish, acid etched anodic coating has

superior characteristics for finish consistency than typical

anodizing, resulting in a more uniform finished product.

"Manufacturers and installers of curtain walls components,

storefronts, automatic entry doors, walkway covers, and other

anodized building and construction applications will immediately

recognize the benefits of this superior finish," commented Ira

Endres, Bonnell's Director of Sales and Marketing. "While meeting

and exceeding all AAMA 611 specifications for anodizing, the acid

etch anodic process is far better in hiding extrusion surface

imperfections than caustic etch anodizing. It virtually eliminates

the appearance of visual streaks and die lines while providing a

superior uniform matte finish." More environmentally friendly and

greener than a conventional caustic etch process, the acid etch

process requires less etching time, which significantly reduces the

amount of waste sludge disposal by as much as 90%. In addition, the

process enables the use of a higher percent of recycled content in

extrusion billet while still maintaining high uniformity of finish.

This capital investment project is the second of importance in

recent months. In the 3rd quarter of 2008, Bonnell Aluminum

announced a $25 million expansion project for its Carthage,

Tennessee facility, with the addition of a 5,500 ton hydraulic

extrusion press, handling systems and ancillary equipment,

specifically engineered to extrude products requiring critical

surfaces for high profile exposed architectural applications. The

new press will be capable of producing aluminum extruded profiles

up to 16 inches of width. "2009 will be a year building significant

opportunities for architects, designers, and engineers," added

Endres. "Not only will Bonnell have the press range the commercial

architectural market has desired for many years, we will also be

supplying anodized finishes that are more environmentally friendly

in addition to providing a consistently better surface appearance.

Once again, Bonnell Aluminum is strengthening its position as the

market leader by providing its customers with the full product line

and services that set us apart from the competition." About Bonnell

Aluminum Bonnell is a subsidiary of Richmond Va., based Tredegar

Corporation (NYSE: TG) and is North America's premier aluminum

extrusion supplier to architectural nonresidential construction

markets. The company produces soft-alloy aluminum extrusions

primarily for building and construction, distribution,

transportation, machinery and equipment, electrical and consumer

durables markets. For additional information please visit

http://www.bonlalum.com/ . DATASOURCE: Bonnell Aluminum CONTACT:

Guy J. Charpentier, Marketing Manager, Bonnell Aluminum,

+1-770-254-7649 Web site: http://www.bonlalum.com/

Copyright

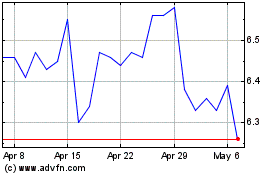

Tredegar (NYSE:TG)

Historical Stock Chart

From Dec 2024 to Jan 2025

Tredegar (NYSE:TG)

Historical Stock Chart

From Jan 2024 to Jan 2025