- FREYR has completed its first production trial of unit cells

using the full capabilities of the Casting and Unit Cell Assembly

at the Customer Qualification Plant (“CQP”). With this, FREYR is

the first company globally to successfully demonstrate the

functionality of giga scale production line equipment for the

second generation of the 24M Technologies SemiSolidTM

platform.

- This achievement at the CQP positions FREYR as a leading

industrialization partner for advanced, novel and U.S. IP-based

Lithium-Ion battery production technologies.

- The CQP team will now move on to producing unit cells using

the full automation of the production line equipment in a

continuous process. Following that milestone, the teams at the CQP

plan to proceed to manufacturing multi-layer pouch battery cells in

Q2 2024 for customers while continuously improving the

electrochemical and electromechanical performance of the technology

platform.

- The FREYR teams at the CQP will continue to fine tune

processes before commencing continuous operation to harvest

production data and product quality evaluations at scale through

powder preparation, slurry mixing, electrode casting, unit cell

merge, stacking, pouch singulation, charging, formation and

aging.

FREYR Battery (NYSE: FREY) (“FREYR” or the “Company”), a

developer of clean, next-generation battery cell production

capacity, has provided an update this morning on the Company’s

operational progress at the Customer Qualification Plant (“CQP”) in

Mo i Rana, Norway.

FREYR conducts successful unit cell production trials at

CQP

FREYR’s teams, vendors, and partners at the CQP have reached the

Company’s most significant technical milestone to date by producing

unit cells with the full functionality of the Casting and Unit Cell

Assembly machine, the novel component of the SemiSolid™ platform.

While significant work remains to further streamline automation,

improve material composition, and to complete the final stages of

commissioning, this accomplishment marks the completion of critical

path equipment commissioning and is expected to enable FREYR to

begin increasing production speeds and manufacturing multi-layer

battery sample cells in Q2 2024.

“This is a material step forward for our team at Asset Mo.

Having demonstrated our ability to manufacture cells with the

next-generation Casting and Unit Cell Assembly, we are now poised

to move into trial production using a continuous process. This next

milestone will then enable our teams to perform data and

performance analysis of the unit cells, surge production speeds,

and proceed to manufacturing mechanically complete sample cells in

Q2,” commented Mike Brose, FREYR’s Head of the Asset Mo team.

“Today’s announcement is a reflection of the tremendous collective

effort by FREYR’s people, vendors, and partners in Mo – I wish to

thank and congratulate everyone involved for their dedication,

creativity, and selflessness in helping us reach this important

milestone.”

Overview of the SemiSolidTM manufacturing process

Unlike conventional lithium-ion battery manufacturing, which

involves producing electrodes on separate equipment before

assembling them into cells which are subsequently filled with

electrolyte, the SemiSolidTM technology employs a continuous and

integrated process. The SemiSolidTM process starts with electrode

coating and proceeds to electrode stacking. The next-generation

SemiSolidTM production line equipment (“PLE”) then creates

independent “unit cells,” each containing a cathode, anode, and

separator.

The subsequent steps required to produce a complete cell in a

pouch – which is a stack of multiple unit cells, have already been

developed and validated on the SemiSolidTM platform. As such,

today’s announcement that FREYR and its partners have begun

producing these unit cells with the full automation of the Casting

and Unit Cell Assembly constitutes a significant technical

achievement.

“On behalf of the Mpac team, I extend our congratulations to

FREYR on achieving this important milestone,” commented Adam

Holland, CEO of Mpac Group plc. “Mpac is proud to contribute to

FREYR’s mission to create a sustainable future with next-generation

battery technology.”

This production trial was enabled by the successful integration

of casting webs across the cathode, anode, and merge units of the

Casting and Unit Assembly equipment using the highly advanced

Multi-Carrier System (“MCS”), which is the largest of its kind

globally according to FREYR’s automation partner Siemens AG.

Brian Holliday, Managing Director at Siemens Digital Industries,

commented, “This has been an amazing team effort between FREYR,

Mpac, Festo and Siemens working together at the leading edge to

highly automate battery production. The result is a huge step

forward for a next generation technology that is designed to

enhance the industry’s sustainability.”

Next steps at the CQP

Following this successful production trial at the CQP, FREYR is

following a three-step road map to producing sample cells in Q2

2024:

- Conduct a cell production trial using a continuous process with

no interruptions to fine tune the equipment;

- Surge production speeds for short periods of time to

demonstrate GWh scale manufacturing capability for the casting of

electrodes; and

- Produce multi-layer, mechanically in-spec pouch battery sample

cells in Q2 2024.

“I am proud to report this latest achievement at the CQP,” added

Birger Steen, FREYR’s Chief Executive Officer. “By proving our

ability to navigate electromechanical challenges of producing

batteries on novel manufacturing equipment, we are demonstrating

FREYR’s technical and operational qualifications as an emerging

industrialization partner of choice in the battery industry. The

team is now moving to the next step on our road map, which is to

replicate what we have just done in a continuous process before

commencing production of multi-layer pouch battery sample

cells.”

The CQP’s long-range potential

Conventional lithium-ion battery technology is estimated to

account virtually all the current global commercial production,

with only 6% originating from the U.S, according to a recent report

from the International Energy Agency. As such, the development of

novel, U.S.-based technologies such as the SemiSolidTM platform has

the potential to enhance regional energy security and long-term

competitiveness of U.S. battery producers. In conjunction with

today’s milestone, FREYR is evaluating additional opportunities to

leverage the CQP to incubate additional technological advances in

cooperation with key stakeholders in the U.S.

“Today, we have demonstrated the ability of FREYR’s teams and

global partners to scale a novel U.S. IP centric battery technology

platform,” said Tom Einar Jensen, Co-founder and Executive Chair of

FREYR. “As complex and difficult as any battery scaling journey is,

we are very much aware that our work is just beginning, even though

this represents a proud moment for the company.”

Mr. Jensen added, “The cost of imported battery solutions to our

target markets are highly dynamic, so the development of U.S.

origin technologies at scale is critical if the U.S. is to

establish a viable competitive position in the global battery

ecosystem. Currently, 95% of battery solutions for the energy

storage market are imported from Asia. With the energy transition

accelerating in the U.S., homegrown supply of critical energy

infrastructure is a fundamental pillar to regional energy security

as well as job creation and sustained economic growth. Our

aspiration is that the CQP, as a first of its kind facility based

on U.S. Intellectual Property, could ultimately serve a unique role

as a center of innovation and scaling platform for competitive

battery solutions and the backbone of a new, increasingly localized

energy system.”

About FREYR Battery

FREYR Battery is a developer of clean, next-generation battery

cell production capacity. The Company’s mission is to accelerate

the decarbonization of global energy and transportation systems by

producing sustainable, cost-competitive batteries. FREYR seeks to

serve the primary markets of energy storage systems (“ESS”) and

commercial mobility, and the Company maintains an ambition to serve

the passenger electric vehicles market (“EV”). FREYR is operating

its Customer Qualification Plant (“CQP”) for technology development

in Mo i Rana, Norway, and the Company is commencing development of

the Giga America battery manufacturing project in Coweta County,

Georgia, in the U.S. To learn more about FREYR, please visit

www.freyrbattery.com.

Cautionary Statement Concerning Forward-Looking

Statements

All statements, other than statements of present or historical

fact included in this letter, including, without limitation, the

development, construction, timeline, capacity, and other usefulness

of FREYR Battery’s (“FREYR”) production facilities or

gigafactories; FREYR’s ability to complete cell production trial

using a continuous process, surge production speeds to demonstrate

GWh scale manufacturing capability for the casting of electrodes,

and to produce multi-layer pouch battery sample cells in its

Customer Qualification Plant (“CQP”) and to achieve targeted

improvements and the commencement of automated production of sample

cells ; FREYR’s ability to complete the technical requirements to

stay on track with its anticipated completion cadence at the CQP;

FREYR’s ability to carry out any successful future trials,

implementation or integration of cathode testing and other

technology to reach automated cell production; and the

implementation and effectiveness of FREYR’s overall business and

technology strategies are forward-looking statements.

These forward-looking statements involve significant risks and

uncertainties that could cause the actual results to differ

materially from the expected results. Most of these factors are

outside FREYR’s control and are difficult to predict. Additional

information about factors that could materially affect FREYR is set

forth under the “Risk Factors” section in (i) FREYR’s Registration

Statement on Form S-3 filed with the Securities and Exchange

Commission (the “SEC”) on September 1, 2022, (ii) FREYR Battery,

Inc.’s Registration Statement on Form S-4 filed with the SEC on

September 8, 2023 and subsequent amendments thereto filed on

October 13, 2023, October 19, 2023, and October 31, 2023, (iii)

FREYR’s Annual Report on Form 10-K filed with the SEC on February

29, 2024, and (iv) FREYR’s Quarterly Reports on Form 10-Q filed

with the SEC on May 8, 2024 and available on the SEC’s website at

www.sec.gov. Except as otherwise required by applicable law, FREYR

disclaims any duty to update any forward-looking statements, all of

which are expressly qualified by the statements in this section, to

reflect events or circumstances after the date of this

presentation. Should underlying assumptions prove incorrect, actual

results and projections could differ materially from those

expressed in any forward-looking statements.

FREYR intends to use its website as a channel of distribution to

disclose information which may be of interest or material to

investors and to communicate with investors and the public. Such

disclosures will be included on FREYR’s website in the ‘Investor

Relations’ sections. FREYR also intends to use certain social media

channels, including, but not limited to, X (former Twitter) and

LinkedIn, as means of communicating with the public and investors

about FREYR, its progress, products, and other matters. While not

all the information that FREYR posts to its digital platforms may

be deemed to be of a material nature, some information may be. As a

result, FREYR encourages investors and others interested to review

the information that it posts and to monitor such portions of

FREYR’s website and social media channels on a regular basis, in

addition to following FREYR’s press releases, SEC filings, and

public conference calls and webcasts. The contents of FREYR’s

website and other social media channels shall not be deemed

incorporated by reference in any filing under the Securities Act of

1933, as amended.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20240522357636/en/

Investor contact: Jeffrey Spittel Vice President,

Investor Relations jeffrey.spittel@freyrbattery.com Tel: (+1) 409

599-5706

Media contact: Amy Jaick Global Head of Communications

amy.jaick@freyrbattery.com Tel: (+1) 973 713-5585

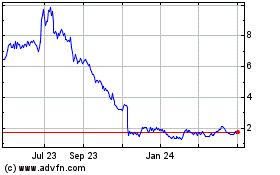

FREYR Battery (NYSE:FREY)

Historical Stock Chart

From Oct 2024 to Nov 2024

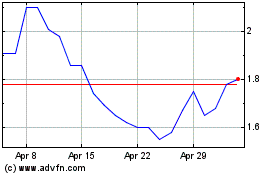

FREYR Battery (NYSE:FREY)

Historical Stock Chart

From Nov 2023 to Nov 2024