Growing use of additive manufacturing for

prototypes, tooling and end-use parts significantly reduces cost

and lead time compared to traditional methods

British defense, security, and aerospace giant BAE Systems (LON:

BA) has added a fourth Stratasys (NASDAQ: SSYS) F900 3D Printer to

its manufacturing site in Samlesbury, UK, in a continued effort to

reduce costs and improve production agility.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20200715005077/en/

Stratasys FDM additive manufacturing is

used across ground equipment operations for the Typhoon fighter

aircraft (Photo: Business Wire).

Along with its existing F900 line-up, the latest installation

will run around the clock as an integral part of BAE’s

transformative “Factory of the Future” initiative, a cutting-edge

facility in Lancashire which brings together the latest advances in

technology and manufacturing to work seamlessly with human

operators in a first-of-its-kind, fully connected way. Today,

Stratasys industrial-grade FDM additive manufacturing is used

across aircraft ground equipment operations for a wide range of

applications spanning space models and design verification

prototypes, manufacturing tools such as jigs and fixtures, and

final end-use parts.

Optimizing aircraft production with additive

manufacturing

According to BAE Systems, use of additive manufacturing across

these applications is making production more flexible, faster and

helping to reduce costs. Indeed, when using its F900 3D Printers to

manufacture production tools, the company says that it is

witnessing ‘significant cost and lead time reductions’ against

those of traditional manufacturing methods.

“Our Factory of the Future program is all about driving the

future of fighter aircraft production with disruptive technologies

and we’re working closely with our suppliers and wider industry to

meet the challenges the UK Government has set out to us. Stratasys

FDM additive manufacturing plays an important role in this

initiative, as it helps us meet our overall company objectives to

reduce costs and time-to-market,” says Greg Flanagan, Additive

Manufacturing Operations Lead, BAE Systems Air.

BAE Systems’ latest F900 installation will not only increase 3D

printing capacity, but also help exploit new 3D printing materials

for tooling applications. This includes carbon-fiber-filled FDM

Nylon 12CF material, which is used to create robust yet lightweight

repair and development tools for the production line.

According to Flanagan, FDM-based 3D printing technology in

particular offers an opportunity to decrease the up-front cost of

tooling for new products. This is especially so with items such as

drill tools, repair tools and other development tools that are

often needed in small numbers.

“This technology allows us to innovate many of our traditional

manufacturing processes,” he says. “We can rapidly 3D print one-off

parts for new products, replace tools more easily and

cost-effectively, and maintain production operations when hardware

is delayed. If supply chains become disrupted, having this

production power in-house also enables us to be more agile as a

business and continue to best serve the needs of our

customers.”

BAE Systems also has found great success in identifying

traditionally manufactured applications that can be enhanced, or in

some cases replaced, with high-performance 3D printing materials.

This includes utilizing durable ABS and ASA materials for a range

of aircraft ground equipment, such as cockpit floor covers for the

Typhoon fighter aircraft. “With our F900, the thermoplastic covers

can be made much faster than traditionally manufactured versions

and are a lot lighter and easier to move for the ground crew, so it

improves efficiencies within the maintenance, repair and overhaul

process. An added bonus is that they can be printed in red – the

color of all ‘remove before flight’ components,” he adds.

The latest F900 was purchased from Stratasys’ local partner

Laser Lines, through whom BAE Systems has been a Stratasys customer

since 2006.

Yann Rageul, Director Manufacturing Solutions EMEA at Stratasys,

said, “BAE System’s Factory of the Future program is a prime

example of innovative companies seeking to exploit the latest

advanced manufacturing technologies and processes to enhance

traditional production as we know it. We continue to collaborate

closely with the team at BAE to explore new solutions that further

expand the application use of additive manufacturing within

production – which will help to address and solve the company’s

current and future manufacturing challenges.”

Stratasys is a global leader in additive manufacturing or

3D printing technology and is the manufacturer of FDM®, PolyJet

Technology™, and stereolithography 3D printers. The company’s

technologies are used to create prototypes, manufacturing tools,

and production parts for industries, including aerospace,

automotive, healthcare, consumer products and education. For more

than 30 years, Stratasys products have helped manufacturers reduce

product-development time, cost, and time-to-market, as well as

reduce or eliminate tooling costs and improve product quality. The

Stratasys 3D printing ecosystem of solutions and expertise includes

3D printers, materials, software, expert services, and on-demand

parts production. Online at: www.stratasys.com.

To learn more about Stratasys, visit www.stratasys.com, the

Stratasys blog, Twitter, LinkedIn, or Facebook. Stratasys reserves

the right to utilize any of the foregoing social media platforms,

including the company's websites, to share material, non-public

information pursuant to the SEC's Regulation FD. To the extent

necessary and mandated by applicable law, Stratasys will also

include such information in its public disclosure filings.

Stratasys, FDM, F900 and FDM Nylon 12CF are trademarks of

Stratasys Ltd. and/or its affiliates. All other trademarks are the

property of their respective owners, and Stratasys assumes no

responsibility with regard to the selection, performance, or use of

these non-Stratasys products.

Attention Editors, if you publish reader-contact information,

please use:

- USA +800-801-6491

- Europe/Middle East/Africa +49-7229-7772-0

- Asia Pacific +852 3944-8888

View source

version on businesswire.com: https://www.businesswire.com/news/home/20200715005077/en/

Media Contacts Stratasys Corporate & North

America Aaron Pearson Aaron.pearson@stratasys.com +1

612-716-9228

Europe, Middle East, and Africa Jonathan Wake / Miguel

Afonso, Incus Media stratasys@incus-media.com +44 1737 215200

Asia Pacific and Japan Alice Chiu

alice.chiu@stratasys.com +852-9189-7273

Investor Relations Yonah Lloyd Yonah.lloyd@stratasys.com

+972-74-745-4919

Brazil, Central America and South America Erica Massini

Erica.massini@stratasys.com +55 (11) 2626-9229

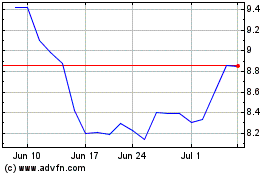

Stratasys (NASDAQ:SSYS)

Historical Stock Chart

From Oct 2024 to Nov 2024

Stratasys (NASDAQ:SSYS)

Historical Stock Chart

From Nov 2023 to Nov 2024