Transformation powered by additive

manufacturing helps GM move faster, cut costs, and produce safer,

lighter-weight manufacturing aids

Retooling production for ventilators aided by

Stratasys FDM systems

As the COVID-19 pandemic has ripped through much of the world

this year, 3D printing has emerged as an agile and effective

technology for producing personal protective equipment, medical

equipment prototypes and nose swabs. But GM, which has been

steadily upping its investments in 3D printing over the past couple

years, is betting that the business benefits will continue long

after the current crisis subsides. The company added 17

production-grade Stratasys (NASDAQ: SSYS) FDM® 3D printers to its

fleet at the end of 2019 and has been turning to 3D printed tooling

for speed, weight reduction and cost efficiency on its production

lines.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20200803005445/en/

GM 3D printed tooling used for critical

care ventilators on Stratasys systems. (Photo: Business Wire)

“With the pace of change in modern industry accelerating and

business uncertainty increasing, 3D printing technology is helping

us meet these challenges and become more nimble as a company,” said

GM’s director of additive manufacturing, Ron Daul. “We’ve been on

this journey for more than 30 years, but 3D printing is becoming

even more widespread at our company, with more than 700 employees

now trained to use the technology. Additive manufacturing is

consistently providing us more rapid and efficient product

development, tooling and assembly aids, with even more benefits to

come.”

An April 2020 study by SME Media* found that 25 percent of U.S.

manufacturing professionals were planning to change their supply

chains in response to the pandemic, and 3D printing was the top

choice (with robotics) of 11 manufacturing technologies for

post-COVID investment. The technology can be used to 3D print spare

parts, produce end-use parts closer to assembly, help manufacturing

lines retool faster, and develop new and better prototypes more

quickly.

GM is moving faster than some companies to seize a competitive

advantage. The company has used 3D printing since 1989 for

prototyping. In fact, 75 percent of the parts in the prototype of

its 2020 Chevrolet Corvette were 3D-printed, and GM now has 3D

printers installed in many production facilities around the world.

The company is increasingly moving beyond prototyping to

production-related applications like tooling.

A big test of this application came in April when GM entered

into contract with the U.S. Department of Health and Human Services

to deliver a 30,000-unit order for critical care ventilators, in

conjunction with Ventec Life Systems, by the end of August. The

company reverse-engineered part data for tooling fixtures from the

original ventilator manufacturer, and started 3D printing them the

next day. All 3D printed tooling used for critical care ventilators

was 3D printed on Stratasys systems. When the company requires more

3D printing capacity, there is an automatic offload path to

Stratasys Direct Manufacturing for parts on demand. This helps GM

run at a high utilization rate for its existing machines, expanding

in-house capacity when it can ensure it has a sustained need for

it.

Material innovation and machine repeatability have made a

difference. For example, Nylon12 Carbon Fiber is a composite

material containing 35 percent chopped carbon fiber by weight,

which translates to an exceptionally high strength-to-weight ratio,

even in places subjected to heavy vibrations. As a result, heavy

parts that would have previously required metal can now be 3D

printed in polymers. And production-grade systems like the

Stratasys F900 have been designed to not only perform to a high

degree of precision but also consistency so that every part is as

identical as possible.

“GM is making the smart investments in 3D printing to succeed in

this new normal of uncertainty and disruption,” said Stratasys

Americas President Rich Garrity. “As a result, GM has manufacturing

lines that are more adaptable and less expensive, and products that

are developed faster and better. They are a clear model for the

future of additive manufacturing in the automotive industry.”

General Motors (NYSE:GM) is a global company committed to

delivering safer, better and more sustainable ways for people to

get around. General Motors, its subsidiaries and its joint venture

entities sell vehicles under the Chevrolet, Buick, GMC, Cadillac,

Holden, Baojun and Wuling brands. More information on the company

and its subsidiaries, including OnStar, a global leader in vehicle

safety and security services, can be found at

http://www.gm.com.

Stratasys is a global leader in additive manufacturing or

3D printing technology and is the manufacturer of FDM®, PolyJet™,

and stereolithography 3D printers. The company’s technologies are

used to create prototypes, manufacturing tools, and production

parts for industries including aerospace, automotive, healthcare,

consumer products and education. For more than 30 years, Stratasys

products have helped manufacturers reduce product-development time,

cost, and time-to-market, as well as reduce or eliminate tooling

costs and improve product quality. The Stratasys 3D printing

ecosystem of solutions and expertise includes 3D printers,

materials, software, expert services, and on-demand parts

production. Online at: www.stratasys.com.

* SME Media, 2020 COVID-19 Future Outlook

Study, conducted April 1-4 2020

Stratasys, FDM, PolyJet, and Fortus 450mc are trademarks of

Stratasys Ltd. and/or its affiliates. All other trademarks are the

property of their respective owners, and Stratasys assumes no

responsibility with regard to the selection, performance, or use of

these non-Stratasys products.

Attention editors, if you publish reader-contact information,

please use:

- USA +800-801-6491

- Europe/Middle East/Africa +49-7229-7772-0

- Asia Pacific +852 3944-8888

View source

version on businesswire.com: https://www.businesswire.com/news/home/20200803005445/en/

Media Contacts Stratasys Corporate & North

America Aaron Pearson aaron.pearson@stratasys.com +1

612-716-9228

Investor Relations Yonah Lloyd yonah.lloyd@stratasys.com

+972-54-4382464

Europe, Middle East, and Africa Jonathan Wake /

Miguel Afonso, Incus Media stratasys@incus-media.com +44 1737

215200

Asia Pacific and Japan Alice Chiu

alice.chiu@stratasys.com +852 9189 7273

Brazil, Central America and South America Erica Massini

Erica.massini@stratasys.com +55 (11) 2626-9229

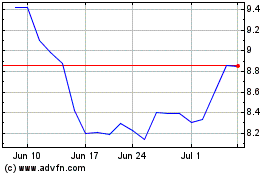

Stratasys (NASDAQ:SSYS)

Historical Stock Chart

From Oct 2024 to Nov 2024

Stratasys (NASDAQ:SSYS)

Historical Stock Chart

From Nov 2023 to Nov 2024