Sigma Additive Solutions Announces Launch of Software Module for Standardizing Machine Health Data Logs

November 03 2022 - 8:31AM

Business Wire

Next Generation Open Architecture Offering Will

Streamline Processes, Advance Digital Quality Workflows &

Enable Additive Industry Users to Gain Consistency Across Their

Sites and Supply Chains

Sigma Additive Solutions, Inc. (NASDAQ:SASI) ("Sigma", "we,"

"our," or the "Company"), a leading developer of quality assurance

software to the commercial 3D printing industry, announced today

that it is releasing a beta version of the PrintRite3D® Machine

Health module. This new solution marks the beginning of the

company’s software-only approach to quality assurance by allowing

users to take disparate machine log files and standardize them.

Built upon Sigma’s PrintRite3D monitoring and analytics technology,

the company is creating a framework for connecting and

standardizing distinct sensors and images into a cohesive product

suite.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20221103005528/en/

Machine Health from Sigma Additive

Solutions (Graphic: Business Wire)

Features of the new solution include:

- A path to scale for integrated sensor fusion of camera, thermal

camera, melt pool data, and more

- Ability to link machines by API or upload all machine sensor

.csv log files

- Creation of a common standards-based file format for analytics,

visualization, and reporting, agnostic of machine type

- A single cohesive environment for all in-process quality data,

customizable to unique production requirements

- Deep insight, analytics, and reporting of machine sensor

data

- Dashboard visualization showing key metrics

“This is an exciting announcement, not only for Sigma, but for

the entire additive industry,” remarked Jacob Brunsberg, Sigma’s

President and Chief Executive Officer. He added, “Today,

proprietary quality control approaches of various additive machine

manufacturers often lead to inconsistency in quality assurance

across manufacturing operations. The objective of the initial

module, and all future modules, is to help drive a standards-based

approach to additive manufacturing, allowing users to gain

consistency across their sites and supply chains. Allowing users to

take disparate machine log files and standardize them is an

important first step in connecting distinct sensors and images into

a cohesive product suite.”

“A truly holistic approach to quality is just what the industry

needs,” stated Ivan Madera, Chief Executive Officer of Morf3D. “As

a member of the Sigma Additive Product Advisory Council, I am

thrilled to have early access to the launch of the Machine Health

and future modules, and to put them to work in our facility.

Standardizing machine logs will streamline processes and advance

digital quality workflows. Having a single interface, streaming

data from all connected machines, moves the industry forward into a

digital future and away from hours of work from manually

collecting, converting, processing, and analyzing all the

individual aspects of quality.”

Darren Beckett, CTO of Sigma, added “Sensor fusion – conjoining

data types – will provide improved confidence in defect detection,

root cause analysis and mitigation, allowing everyone to interpret

control charts and other data types/sources uniformly. Our

engineering team has spent over 10 years developing the technology

to provide a framework for standards-based data exchange, metrics,

and analytics. We are committed to an open architecture philosophy

and acting as a third-party agnostic option, connectable to the

broader installed base of the additive industry.”

About Sigma Additive Solutions

Sigma Additive Solutions, Inc. is a leading provider of

in-process quality assurance (IPQA™) solutions to the additive

manufacturing industry. Sigma specializes in the development and

commercialization of real-time monitoring and analytics known as

PrintRite3D® for 3D metal and polymer advanced manufacturing

technologies. PrintRite3D detects and classifies defects and

anomalies real-time during the manufacturing process, enabling

significant cost-savings and production efficiencies by reducing

waste, increasing yield and shortening cycle times. Sigma believes

its software solutions will be a major catalyst for the

acceleration and adoption of industrial 3D printing. For more

information, please visit www.sigmaadditive.com.

Forward-Looking Statements

This press release contains "forward-looking statements" within

the meaning of Section 27A of the Securities Act of 1933, as

amended, and Section 21E of the Securities Exchange Act of 1934, as

amended. Statements preceded by, followed by or that otherwise

include the words "believe," "anticipate," "estimate," "expect,"

"intend," "plan," "project," "prospects," "outlook," and similar

words or expressions, or future or conditional verbs such as

"will," "should," "would," "may," and "could" are generally

forward-looking in nature and not historical facts. These

forward-looking statements involve known and unknown risks,

uncertainties and other factors. Among the important factors that

could cause actual results to differ materially from those

indicated by such forward-looking statements are risks relating to,

among other things, market and other conditions, Sigma’s business

and financial condition, the extent of the market's acceptance of

PrintRite3D®, Sigma’s ability to satisfy its capital needs through

increasing its revenue and obtaining additional financing, and

general economic, industry or political conditions in the United

States or internationally. Sigma disclaims any intention to, and

undertakes no obligation to, revise any forward-looking statements,

whether as a result of new information, a future event, or

otherwise. For additional risks and uncertainties that could impact

Sigma’s forward-looking statements, please see disclosures

contained in Sigma's public filings with the SEC, including the

"Risk Factors" in Sigma's Annual Report on Form 10-K, which may be

viewed at www.sec.gov.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20221103005528/en/

Chris Tyson Executive Vice President MZ Group - MZ North America

949-491-8235 SASI@mzgroup.us www.mzgroup.us

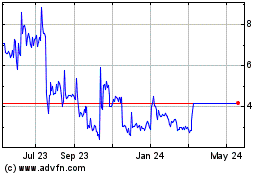

Sigma Additive Solutions (NASDAQ:SASI)

Historical Stock Chart

From Jan 2025 to Feb 2025

Sigma Additive Solutions (NASDAQ:SASI)

Historical Stock Chart

From Feb 2024 to Feb 2025