UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

Specialized Disclosure Report

Commission

File Number 001-00566

GREIF, INC.

(Exact name of registrant as specified in its charter)

|

|

|

| Delaware |

|

31-4388903 |

| (State or other jurisdiction of

incorporation or organization) |

|

(I.R.S. Employer

Identification No.) |

|

|

| 425 Winter Road, Delaware, Ohio |

|

43015 |

| (Address of principal executive offices) |

|

(Zip Code) |

|

|

| Dennis Hoffman |

|

(740) 549-6000 |

| (Name and telephone number, including area code, of the person to contact in connection with this report.) |

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the

information in this form applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

Section 1 – CONFLICT MINERALS DISCLOSURE

Greif, Inc. (the “Company,” “Greif,” “we,” “us” or “our”) evaluated its current product lines as required by

Rule 13p-1 under the Securities Exchange Act of 1934, and our Conflict Minerals Report is provided as Exhibit 1.01 to this Form SD. A copy of our Conflict Minerals Report may also be found publicly on our internet website at:

www.greif.com/Suppliers.

Item 1.01: Conflict Minerals Disclosure and Report

Greif is a leading global producer of industrial packaging products and services with manufacturing facilities located in over 50 countries. We are also a

leading global producer of flexible intermediate bulk containers. We also produce containerboard and corrugated products for niche markets in North America. We sell timber to third parties from our timberland in the southeastern United States that

we manage to maximize long-term value.

Certain of the Company’s operations manufacture products in which tin, tantalum, tungsten and/or gold may be

necessary to the functionality or production of those products.

Conflict Minerals Disclosure

A copy of this Form SD and attached Conflict Minerals Report in accordance with Rule 12b-12 (17 CFR 240.12b-12) can be found publicly on our internet website

under the Suppliers section at: http://www.greif.com.

Item 1.02 Exhibits

The Conflict Minerals Report required by Item 1.01 is filed as Exhibit 1.01 to this Form SD.

Section 2 – EXHIBITS

Exhibit 1.01 –

Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form SD.

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned

thereunto duly authorized.

|

|

|

|

|

|

|

| Date: June 1, 2015 |

|

|

|

By: /s/ Peter G. Watson |

|

|

|

|

Peter G. Watson Chief Operating

Officer |

2

Exhibit 1.01

Greif, Inc.

Conflict

Minerals Report

For the Calendar Year Ended December 31, 2014

This report is intended to comply with Rule 13p-1 under the Securities Exchange Act of 1934 (the “Rule”). The Rule was adopted by the Securities and

Exchange Commission (the “SEC”) to implement reporting and disclosure requirements related to conflict minerals as directed by the Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010. The Rule imposes certain reporting

obligations on SEC registrants whose manufactured products contain conflict minerals which are necessary to the functionality or production of their products. Conflict Minerals are defined as cassiterite, columbite-tantalite, wolframite, gold and

their derivatives, which are limited to tin, tantalum, tungsten, and gold (“3TG”) for the purposes of this assessment. These requirements apply to registrants whatever the geographic origin of the conflict minerals and whether or not they

fund armed conflict.

As used in this report, the terms “Greif,” “the Company,” “we,” “us” and “our”

refer to Greif, Inc. and its subsidiaries.

| 1. |

Products. The Company produces the following products: rigid industrial packaging products that include steel, plastic and fibre containers, reconditioned containers, intermediate bulk containers and packaging

accessories such as closure systems, flanges, plugs, caps and capseals, screwcaps and nozzles; flexible packaging products such as flexible intermediate bulk containers; and paper products such as containerboard and corrugated products. Based upon

our internal assessment, the flexible packaging products and paper products we produce are composed primarily of resin, pulpwood, old corrugated containers for recycling and containerboard and do not contain conflict minerals. In addition, our

reconditioned container products are manufactured from post-industrial use packaging, which is a recycled source. Accordingly, for the purposes of this assessment only rigid industrial packaging products (excluding reconditioned products) and

packaging accessories were considered. |

| 2. |

Policy. Greif has adopted a conflict minerals policy that reflects its dedication to working with our customers and suppliers to source in a responsible manner the materials we use in manufacturing our products.

Under the policy, the Company reviewed the use of conflict minerals in our products and our global supply chain management system in accordance, in all material respects, with the general principles of the Organization for Economic Co-Operation and

Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas. |

In

accordance with its conflict minerals policy, Greif requires that our suppliers (a) assist us in complying with the SEC regulations related to conflict minerals by providing reasonably requested information from time to time and

(b) undertake all reasonable due diligence within their supply chains to determine the origin of conflict minerals and meet all applicable SEC reporting requirements. In addition, the conflict minerals policy requires our suppliers to

(c) establish conflict minerals policies that affirm our commitment to ethical business practices and that are consistent with the OECD Framework and (d) cooperate with Greif and/or its representatives in connection with any on-site

inspections or audits of suppliers’ due diligence procedures and systems related to conflict minerals, although those components of the policy have not yet been implemented.

In addition, Greif has adopted a Supplier Code of Conduct that encourages all suppliers to procure raw materials and services in an ethical

manner that supports sustainable business practices. Links to the Greif, Inc. Conflict Minerals Policy Statement and Supplier Code of Conduct can be found at www.greif.com/Suppliers.

| 3. |

Steps Taken to Identify Risks in the Supply Chain and the Reasonable Country of Origin Inquiry (“RCOI”). Greif has adopted a methodology and due diligence process that is materially based on the Five

Step Framework for Risk-Based Due Diligence in the Mineral Supply Chain contained in the Organization for Economic Co-Operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk

Areas (the “OECD Framework”). The five steps of the OECD Framework are to: |

| |

• |

|

Establish strong company management systems; |

| |

• |

|

Identify and access risk in the supply chain; |

| |

• |

|

Design and implement a strategy to respond to identified risks; |

| |

• |

|

Carry out independent third-party audits of supply chain due diligence at identified points in the supply chain; and |

| |

• |

|

Report on supply chain due diligence. |

Greif has taken the following actions in furtherance of

the implementation of this methodology:

Establish strong company management systems

Greif has adopted a Conflict Minerals Policy Statement (See paragraph 2 above.). Greif has assembled an internal team of individuals from

various functional areas within the organization to execute the ongoing process of supply chain due diligence under the supervision of senior management personnel. The team is responsible for implementing a system of controls and transparency over

Greif’s supply chain that involves 3TG by (a) identifying Greif’s first-tier suppliers of 3TG and 3TG containing goods; (b) requesting information from these suppliers regarding their upstream suppliers and smelters, as well as

their conflict minerals policies and due diligence procedures; and (c) communicating Greif’s ongoing expectations of its suppliers relating to conflict minerals. In addition, Greif has adopted a Supplier Code of Conduct that encourages its

suppliers to procure all raw materials in an ethical manner supportive of sustainable business practices. The Supplier Code of Conduct contains a grievance mechanism to aid in facilitating supplier compliance.

Identify and access risk in the supply chain

Greif conducted an internal review to identify relevant first-tier raw material suppliers. The Company’s technical experts, production

managers and other employees reviewed the key components and raw materials contained in the products manufactured by the Company. Our analysis found that a limited number of Greif’s rigid industrial packaging products contain tin, tin plate or

electrolytic tin coatings (a) as a food contact material, (b) as a rust inhibitor, (c) to provide chemical resistance, (d) to improve processability or (e) to improve paint adhesion, making them necessary for the

functionality of the applicable product.

Those products include:

| |

• |

|

Tin-lined open head drums; |

| |

• |

|

Tinplated open head and tight head pails and cans; |

| |

• |

|

Coated and painted tinplate sheets; and |

| |

• |

|

Various closure products containing or coated with tin (flanges, plugs, paint caps, capseals, nozzles and screwcaps). |

After identifying the products that include 3TG, Greif mapped the materials to their respective vendors. As a downstream company, Greif

contacted its first-tier suppliers in an attempt to trace the origin of the 3TG used in Greif products to the applicable smelting facility. In 2014, Greif manufactured products containing 3TG purchased by the Company from 13 separate vendors. Each

supplier was requested to complete a template jointly developed by the Electronic Industry Citizenship Coalition® (EICC®) and the Global e-Sustainability Initiative (GeSI) (the “Template”). The Template was developed to facilitate

disclosure and communication of information regarding smelters that provide material to a company’s supply chain. It includes questions regarding a supplier’s conflict-free policy, engagement with its direct upstream suppliers, and a

listing of the smelters the supplier and its upstream suppliers use. Written instructions and recorded training illustrating the use of the Template are available on the website of the Conflict Free Sourcing Initiative, an initiative of the EICC and

GeSI (“CFSI”). The Template is being widely adopted by many companies in their due diligence processes related to conflict minerals.

Design and implementation of a strategy to respond to identified risks

Upon receipt of the completed Templates or alternative data and certifications received from the vendors, all information was reviewed for

completeness, inconsistencies and “red flags” (as defined in the OECD Framework) and all reported 3TG processing facilities were compared to independently verified smelter lists. We relied on these supplier responses to provide us with

information about the source of conflict minerals contained in the goods supplied to us. Our direct suppliers are similarly reliant upon information provided by their suppliers. No “red flags” were identified in this process and we

determined that our greatest risk resides with the first-tier suppliers who failed to identify smelters in their response to our request.

2

Independent third-party audits

Greif does not have a direct relationship with 3TG smelters and refiners, nor do we perform direct audits of the entities that provide our

supply chain with 3TG materials. However, we do rely upon the industry (for example, EICC and CFSI) efforts to influence smelters and refineries to get audited and certified through CFSI’s Conflict Free Smelter program.

Report on supply chain due diligence

Greif has compiled its results and filed this report in accordance with Rule 13p-1 through the use of the Form SD and the attachment of a

Conflict Minerals Report. Further information is also available by reviewing the Greif Conflict Minerals Policy Statement which is located at www.greif.com/Suppliers.

| 4. |

Results for the 2014 Calendar Year. |

13 first-tier 3TG suppliers were contacted as part

of our RCOI and asked to complete the Template. Greif received responses from all 13 suppliers (12 first-tier suppliers completed the Templates and 1 first-tier supplier submitted other data or certifications), a response rate of 100%. Of the 18

smelters identified by our suppliers as the origin of 3TG materials used in our products, 16 were contained on the CFSI conflict-free smelter list as compliant or previously compliant and currently undergoing a re-audit, 1 was actively engaged in

the CFSI audit process and 1 was located in Rondônia, Brazil and is affiliated with a mine in the same vicinity. Two suppliers that completed the Template failed to identify the smelter(s) supplying them with tin and 1 supplier responded with

a certificate that did not disclose the source of its 3TG. Therefore, we were unable to identify all of the smelters or mines of origin that produce the tin that is used in our products. For more definitive results please see Attachment A to

this Conflict Minerals Report.

| 5. |

Steps Greif Will Take Subsequent to the End of Calendar Year 2014. |

The due diligence

and risk assessment process discussed above is ongoing. As Greif continues to conduct due diligence on its products and implement the conflict minerals policy within its global supply chain organization and processes, it will continue to develop and

refine procedures to meet the goals and adhere to values set forth in the policy outlined above.

| 6. |

Independent Private Sector Audit. |

The information in this report has not been audited

by an independent private sector auditor.

3

Attachment A

List of Product Categories Containing 3TG

|

|

|

|

|

|

|

| Product Categories |

|

Greif Manufacturing Location |

|

Smelters Identified by 1st Tier

Suppliers |

|

Smelter Location |

| |

| Tin Lined Open Head Drum |

|

Merced, California (USA) |

|

Yunnan Tin Co.4 |

|

China |

|

|

|

PT Timah3 |

|

Indonesia |

| |

| Tinplate Open Head Pails |

|

Buenos Aires, Argentina |

|

Mineraçào Taboca S.A. 3 |

|

Brazil |

|

|

|

| Tinplate Tight Head Pails |

|

|

|

Minsur3 |

|

Peru |

|

|

|

|

PT Tinindo Inter Nusa3 |

|

Indonesia |

|

|

|

|

Yunnan Tin Co.4 |

|

China |

|

|

|

|

PT Timah3 |

|

Indonesia |

|

|

|

|

PT Wahana Perkit Jaya3 |

|

Indonesia |

|

|

|

|

White Solder Metalurgia e Mineraçào Ltda.3 |

|

Brazil |

|

|

|

|

Rui Da Hung5 |

|

Taiwan |

|

|

|

|

PT Mitra Stania Prima3 |

|

Indonesia |

|

|

|

|

Metallo Chimique3 |

|

Belgium (recycled) |

|

|

|

|

Cooper Santo3 |

|

Brazil |

|

|

|

|

Mineraçào Taboca S.A. 3 |

|

Brazil |

|

|

|

|

Malaysia Smelting Corp.4 |

|

Malaysia |

|

|

Halsteren, Netherlands1,2 |

|

EM Vinto3 |

|

Bolivia |

|

|

|

|

|

Singapore1 |

|

None specified |

|

|

| |

| Tinplate Cans Tinplate Sheets |

|

Halsteren, Netherlands1,2 |

|

See smelter information for Halsteren, NL above. |

| |

| Painted Capseals |

|

Amsterdam, Netherlands1 |

|

Raw material sourced through Halsteren, NL facility. See smelter information for Halsteren, NL above. |

| |

|

|

Araucaria, Brazil |

|

White Solder Metalurgia e Mineraçào Ltda.3 |

|

Brazil |

|

|

Melt Metais e Ligas S/A3 |

|

Brazil |

|

|

Estanho de Rondônia S.A. |

|

Brazil |

|

|

|

|

|

Zhenjiang, China |

|

Yunnan Tin Co.4 |

|

China |

| |

| Tinplated Flanges and Plugs |

|

Amsterdam, Netherlands1 |

|

Raw material sourced through Halsteren, NL facility. See smelter information for Halsteren, NL above. |

| |

|

|

Carol Stream, IL |

|

Thaisarco3 |

|

Thailand |

|

|

Malaysia Smelting Corp.4 |

|

Malaysia |

|

|

Minsur3 |

|

Peru |

|

|

OMSA4 |

|

Bolivia |

|

|

Mineraçào Taboca S.A. 3 |

|

Brazil |

|

|

|

PT Bukit Timah3 |

|

Indonesia |

| |

| Nozzles and Screwcaps |

|

Penrith, Australia1 |

|

PT Timah3 |

|

Indonesia |

|

|

Thaisarco3 |

|

Thailand |

| |

| Uni-Grip Paint Caps |

|

Carol Stream, IL1 |

|

None specified |

|

— |

| |

| 3rd Party Manufactured Steel Drum Closures |

|

Various North America Locations1 |

|

None specified |

|

— |

| |

| 3rd Party Manufactured Painted Capseals, Nozzles and Screwcaps |

|

Various Global Locations (sourced from Thurbe

New Mumbai, India) |

|

Malaysia Smelting Corp.4

Thaisarco3 |

|

Malaysia Thailand |

| |

|

|

|

Various Global Locations (sourced from

Bangalore, India) |

|

PT Timah3

Thaisarco3 |

|

Indonesia

Thailand |

| |

| 1 |

Did not receive complete smelter lists from all first-tier suppliers with respect to the applicable product category. |

| 2 |

The Halsteren, NL facility was sold by the Company in July 2014. |

| 3 |

Denotes a tin smelter designated as “conflict free” by CFSI as of May 26, 2015. |

| 4 |

Denotes a tin smelter designated as “conflict free” by CFSI whose certification has lapsed and is being re-audited as of May 26, 2015. |

| 5 |

Denotes a tin smelter designated as “Active” by CFSI and is undergoing the CFSI audit process as of April 30, 2015. |

4

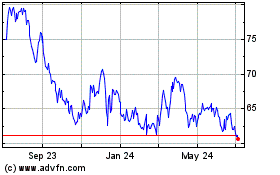

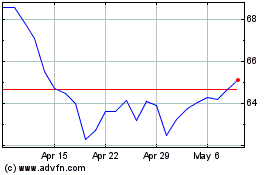

Greif (NYSE:GEF.B)

Historical Stock Chart

From Jun 2024 to Jul 2024

Greif (NYSE:GEF.B)

Historical Stock Chart

From Jul 2023 to Jul 2024