Researchers Envision Ultrathin, Flexible Circuit Boards

September 03 2016 - 5:59AM

Dow Jones News

By Don Clark

SAN JOSE, Calif. -- Silicon Valley is rethinking one of its

least glamorous and most ubiquitous building blocks, the circuit

board, in a bet that flexible, form-fitting alternatives could

reshape electronics and spur more manufacturing in the U.S.

Backers envision ultrathin boards like skin patches that could

analyze the sweat of soldiers and pilots, wrap around gas pipelines

and act as leak detectors, or provide grids of flexible sensors

able to detect stress on airplane wings.

Such possibilities -- the focus of a new manufacturing

consortium here backed by the U.S. Department of Defense and others

-- require materials and production techniques that differ from

conventional circuit boards, made of stiff plastic.

In some cases, circuitry is imprinted on paper, plastic or other

organic materials using processes akin to inkjet printing. The

results, which can be as thin as temporary tattoos, can be tailored

for extended contact with the skin or in large formats applied to

walls or roofs.

The concept of applying printing techniques to electronics has

been around for more than a decade. Raghu Das, chief executive of

the research firm IDTechEx, said past efforts in the field largely

have failed because they attempted to replace silicon chips, which

remain less expensive and more powerful for many purposes.

Instead, researchers now are looking to replace the circuit

boards on which chips are placed, using techniques they call

flexible hybrid manufacturing. Techniques include wiring

semiconductors together on flexible surfaces, creating products

that are more versatile than existing circuit boards.

"All the other electronics out there is in a box," said Malcolm

Thompson, executive director of the San Jose institute known as

NextFlex. "We are out of the box."

Progress may not come quickly. Though suppliers of materials and

manufacturing technology are pushing the concept aggressively, Mr.

Das said flexible electronics has suffered from a dearth of

inventors applying the techniques in new products.

Besides expanding where technology can go, companies and

government officials hope the new approach can influence where it

is built.

Most high-volume production of chips and other electronic

devices long ago moved from Silicon Valley to China and other

lower-cost locations. But manufacturing specialists like Jabil

Circuit Inc. and Flextronics International Ltd. keep facilities in

the U.S. to help customers design products and build

prototypes.

Flexible hybrid manufacturing could offer more opportunities for

such work, some industry executives say, as companies devise new

gadgets that must be introduced quickly and evolve rapidly.

"We are very interested and curious about democratizing

manufacturing," said Janos Veres, program manager for novel and

printed electronics at Palo Alto Research Center Inc., a unit of

Xerox Corp. Flexible electronics, he said, "will open up a whole

new raft of business models."

Some executives hope U.S. companies develop proprietary know-how

to make flexible circuitry, which could make it harder for foreign

factories to produce the same products. "You don't want to share

it," said Daniel Gamota, vice president of Jabil's hardware

innovation group.

Techniques derived from printing are widely used to embed tiny

wires in places like car windshields, antennas, solar cells and

radio-frequency identification tags. Computer displays also are

being fabricated using plastic, including organic light-emitting

diodes. IDTechEx predicts flexible electronics revenue including

those displays will triple to $26.2 billion by 2020 from $8.6

billion this year.

One key development, Mr. Thompson said, has been techniques

devised by companies such as American Semiconductor Inc. and

Uniqarta Inc. to make thinner silicon wafers for chip production.

In some cases, the resulting chips can be rolled up like a piece of

paper.

The U.S. military's interest stems partly from a desire to

reduce the weight of gear soldiers must carry and to track their

condition. Mr. Thompson said flexible sweat-monitoring sensors can

detect chemicals that indicate fatigue on wearers on the

battlefield or in cockpits.

Boeing Co. on Wednesday showed off flexible antennas that could

be deployed on aircraft for radar and other applications. Other

efforts are aimed at intelligence agents who need to keep

information out of enemy hands. PARC engineers have worked under a

Pentagon research program to print information on glass that could

disintegrate into unreadable bits in response to a remote

command.

NextFlex, whose funding includes $75 million from the Defense

Department, is among several institutes the Obama administration

has set up to encourage collaboration in manufacturing technology.

The institute is installing tools to help experiment with

production techniques and funding development projects at corporate

and university labs.

Write to Don Clark at don.clark@wsj.com

(END) Dow Jones Newswires

September 03, 2016 05:44 ET (09:44 GMT)

Copyright (c) 2016 Dow Jones & Company, Inc.

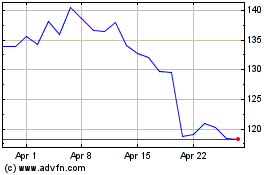

Jabil (NYSE:JBL)

Historical Stock Chart

From Jan 2025 to Feb 2025

Jabil (NYSE:JBL)

Historical Stock Chart

From Feb 2024 to Feb 2025