TIDMCRCL

RNS Number : 6895L

Corcel PLC

17 May 2022

/

Corcel PLC

("Corcel" or the "Company")

Wowo Gap JORC Resource

17 May 2022

Corcel, the natural resource exploration and development company

with interests in battery metals and flexible energy generation and

storage, is pleased to announce the completion of a JORC mineral

resource estimate at the Company's recently acquired Wowo Gap

nickel/cobalt project in Papua New Guinea ("PNG"), where the

Company owns a 100% interest. The establishment of a JORC resource

is a critical technical step in preparing the mining lease

application, validates Corcel's underlying rationale for the asset

acquisition and confirms Wo Wo Gap as a similar size and grade

deposit to the Company's sister project at Mambare, also in

PNG.

Highlights:

o JORC 2012 code mineral resource estimate ("MRE") of 110m

tonnes with 0.81% Ni and 0.06% Co (891,000t contained Ni and

66,000t contained Co)

o Mineralisation is continuous and laterally extensive - shallow

nature of deposit and limited overburden is amenable to low-cost

open pit mining

o Robust geological model with mineralisation well constrained

within the host saprolite and limonite layers

o Tonnage and grade reported above the 0.7% Ni cut-off compare

favourably with similar projects that have achieved production

Mineral Resource Estimate:

Using a 0.7% nickel cut-off grade, the deposit is estimated to

contain 110 million tonnes at 0.81% nickel (Ni) for 891,000 tonnes

of contained Ni and 0.06% cobalt (Co) for 66,000 tonnes of

contained Co. Tonnage is quoted on a dry basis.

Table 1. Wowo Gap Mineral Resource estimate by lithology type

and classification at 0.7% Ni cut-off.

Lithology Type Classification Million Ni% Co% Thousand Thousand

Tonnes Tonnes Tonnes

contained Contained

Ni Co

-------------------- ---------------- -------- ----- ----- ----------- -----------

Limonite/Saprolite Indicated 63 0.85 0.08 540 50

Inferred 9 0.84 0.07 76 6.3

------------------------------------- -------- ----- ----- ----------- -----------

Rocky Saprolite Inferred 38 0.75 0.02 280 7.6

---------------- -------- ----- ----- ----------- -----------

Total Indicated 63 0.85 0.08 540 44

Inferred 47 0.77 0.03 360 14

------------------------------------- -------- ----- ----- ----------- -----------

Total 110 0.81 0.06 890 66

------------------------------------- -------- ----- ----- ----------- -----------

*The project operator is Niugini Nickel Ltd.

** The Company's interest in Wowo Gap is 100% and consequently

Gross and Net resource to the Company are the same

Niugini Nickel commissioned independent consulting geologists

Queen and Associates and H&S Consultants Pty Ltd (HSC) as

Competent Persons to complete a resource estimate for the Wowo Gap

nickel laterite deposit incorporating 2015 drilling and Ground

Penetrating Radar (GPR) data that were not used in the previous

resource estimate.

The Competent Persons deem that there are reasonable prospects

for eventual economic extraction of the mineralisation.

Property Description and Access:

The project is located within EL 1165, approximately 200

kilometres east of Port Moresby and 35 kilometres from the village

of Wanigela, situated on Collingwood Bay (Figure 1).

http://www.rns-pdf.londonstockexchange.com/rns/6895L_1-2022-5-16.pdf

There is no road access to site, with personnel and equipment

transported to site by either helicopter, or by plane to a local

village airstrip, followed by a day's walk to site by locally hired

porters. The small village of Embessa is located approximately 10

kilometres northwest from site on the Musa River and serviced by an

airstrip suitable for light aircraft. Fuel, supplies and equipment

can be ferried direct to the site or from Embessa by helicopter

transport with up to 5,000 kg payload capacity. If development

proceeds, it is contemplated to construct an ore haul road directly

to Collingwood Bay, some 40 km to the east.

Prospect Geology:

The Wowo Gap nickel laterite is a result of deep weathering of

ultramafic rocks of the Papuan Ultramafic Belt (PUB). In the Didana

Range (Low and High) the ultramafic rocks consist of tectonite

ultramafics, cumulate ultramafics and gabbro and granular gabbro

(Figure 2).

http://www.rns-pdf.londonstockexchange.com/rns/6895L_1-2022-5-16.pdf

The tectonite ultramafics crop out at the eastern end of the Didana

Range adjacent to and within the western section of the Wowo Gap

Project. The Sivai Breccia, co-host of the Wowo Gap mineralisation,

flanks the tectonite ultramafic at the eastern end of the Didana

Range adjacent to the Bereruma Fault. The ultramafic breccia also

occurs along the south side of the Didana Range on the Ansuna and

Boge Plateau.

The nickel laterites are derived from the leaching of ultramafic

bedrock. In the project area the complete lateritic profile is

preserved, with partial truncation associated with recent drainage

systems. The depth of weathering varies according to rock type and

the degree of brecciation. The lateritic profile is typically 10 to

15 metres thick, increasing locally to more than 30 metres above

the Sivai Breccia.

The laterite profile (Figure 3)

http://www.rns-pdf.londonstockexchange.com/rns/6895L_1-2022-5-16.pdf

is typically 10m to 18m thick and composed of an upper iron-rich

saprolite horizon (referred to as limonite) with high (>40%) to

very high (>60%) Fe2O3 content but relatively low (<6%) MgO.

It is the limonite horizon that contains enriched levels of cobalt,

chromium and manganese values. Beneath the limonite is MgO-rich

(>6 - 40%) earthy saprolite (referred to as saprolite) horizon

with relatively low (<40%) Fe2O3 content. Below this in the

regolith profile is the rocky saprolite (saprock), clearly

identifiable because of corestones of partially weathered

ultramafic bedrock.

Project History:

Nickel laterite mineralisation in the Didana Range was first

noted in a 1958 Australian Bureau of Mineral Resources (BMR)

reconnaissance survey of the area including Wowo Gap. Nickel

mineralisation was reported in auger samples of breccia which

returned values of up to 1.3% Ni, derived from a peridotite

ultramafic having up to 0.18% Ni background values. This initial

discovery was followed by several companies including United States

Metals Refining Company (1967-1968), Papua Nickel Exploration

(1970) and BRGM (1971-1972). The current period of exploration

started when Niugini Nickel acquired the project in 1996. Since

acquiring the project Niugini Nickel has carried out considerable

work including geological mapping, resampling of pits, rock chip

sampling, drainage sampling, several drilling programmes, a LiDAR

survey over the whole of the mineralized area, two Ground

Penetrating Radar (GPR) surveys (2007 and 2014), metallurgical test

work and several Resource estimates.

This Mineral Resource estimate is based on the results of three

drilling campaigns:

o diamond core drilling [2003-2008]

o tungsten carbide-tipped core drilling [2010-2011], and

o diamond core and custom auger core drilling [2014-2015].

These drilling campaigns totalled 3,174 meters of diamond core,

2,901 meters of auger/carbide core, and 731 meters of wacker

drilling (Figures 4, 5, and 6). Sample lengths were generally 1m

with the shortest sample being 0.3m and the longest 2m; sampling

was done on half core. All drill core samples were sent to Intertek

in Lae for sample preparation, with the pulps being sent to

Intertek Jakarta for fusion XRF analysis for Ni, Co, Al2O3, CaO,

Cr2O3, Fe2O3, K2O, LOI, MgO, MnO, Na2O, P2O5, SiO2 and LOI. Total

number of samples assayed was 7874.

This Mineral Resource estimate is also based on two GPR surveys

(2007 and 2014). In addition to the drilling data, GPR was used to

define two of the geological boundaries, the boundary between

limonite/saprolite and the rocky saprolite and the boundary between

rocky saprolite and bedrock (Figure 7)

http://www.rns-pdf.londonstockexchange.com/rns/6895L_1-2022-5-16.pdf

The GPR lines in 2007 were between 200 and 300 metres apart while

the 2014 survey reduced the spacing to 100 metres over a portion of

the area (Figure 8)

http://www.rns-pdf.londonstockexchange.com/rns/6895L_1-2022-5-16.pdf

For grade estimation the laterite layers were simplified into

overburden (Qva), limonite/non rocky saprolite and rocky saprolite

which in turn were used to guide and control the mineral resource

estimate. Samples from each hole were used and were composited to

the full width of the layer, making one composite per layer for

each of the three layer; the mineralised domains were limited to

the three interpreted geological layers as noted above. Nickel and

cobalt grades from the composites where estimated using the

ordinary kriging (OK) estimation technique in Micromine software.

The mineralised domains were limited to the three interpreted

geological layers as noted above. The grade distributions for

nickel and cobalt are not strongly skewed so OK was an appropriate

estimation method; there are no extreme values requiring grade

cutting.

Resource classification is based on both the overall footprint

of the GPR coverage and drilling. A polygon covering the area with

nominal 300 m x 200 m drill spacing along with the GPR coverage was

used to flag the block model as follows:

o any Qva or limonite-saprolite blocks within it are classified

as Indicated,

o rocky saprolite blocks are classified as Inferred regardless

of the polygon, and

o any blocks outside of classification polygon are classified as

Inferred.

Density is based on the results of a limited number of samples

collected during the 2010-2011 and 2014-2015 drilling campaigns.

Based on this data a dry bulk density of 1.0 t/m3 has been used for

the "clay profile" (limonite-saprolite layer), and 2.0 t/m3 for the

rocky saprolite profile.

A nominal cut-off grade of 0.70% Ni was applied to define the

Mineral Resources, which is based on a review of comparable nickel

laterite deposits elsewhere.

The current mining plan proposal is to produce a bulk product

suitable for smelting that will be transported offsite for

processing. It has been assumed that mine waste will be relatively

low in total volume and comprise the 0.5 m to 10 m soil and

volcanic ash overburden layer. This material is likely to be used

for rehabilitation purposes after mining is complete. Low-grade

material, mostly limonitic in composition, may be stockpiled in

mined-out areas.

Reasonable Prospects Hurdle:

Clause 20 of the JORC Code (2012) requires that all reports of

Mineral Resources must have reasonable prospects for eventual

economic extraction, regardless of the classification of the

Mineral Resource. The Competent Persons deem there are reasonable

prospects for eventual economic extraction of the mineralisation on

the following basis:

o The mineralisation is continuous and laterally extensive. The

shallow nature of the deposit and limited overburden means the

deposit is amenable to low-cost open pit mining.

o The geological model is robust, with mineralisation well

constrained within the host saprolite and limonite layers.

o The Competent Person considers that the tonnage and grade

reported above the 0.7% Ni cut-off compare favourably with similar

projects that have successfully achieved production. This opinion

is based on experience with tropical nickel laterite deposits in

Papua New Guinea at all stages of project development.

Comparison to Previous Resource:

In 2011 Resource Mining Corporation (ASX:RMI) released a Mineral

Resource estimate for the Wowo Gap deposit (

https://tinyurl.com/yc6zwjbw ).

Table 2. Wowo Gap 2011 Mineral Resource estimate by

classification at 0.8% Ni cut-off.

2011 Mineral Resource Mt Nickel Cobalt

Estimate at a 0.8% Ni (%) (%)

cut-off

Indicated 72 1.03 0.07

------ --------- ---------

Inferred 53 1.09 0.06

------ --------- ---------

Total 125 1.06 0.07

------ --------- ---------

Contained Metal (kt) 1,325 83

------ --------- ---------

The Mineral Resource estimate in this release has a number of

differences from the 2011 Mineral Resource that have resulted in

changes to the estimated grades and tonnages. The most significant

of those changes include:

o Trimming of margins - The 2011 estimate was reported using a

very wide margin (300 m) on the edge of the drilling area. This

resulted in holes on the edge of the drilling having more influence

than holes in the centre of the drilling. The 2022 model, in

keeping with industry best practice, trims this margin to 150 m or

roughly half the average hole spacing. As there are several higher

grade and thickness holes on the eastern edge of the drilling,

restricting the margin has resulted in a reduction of both tonnes

and grade.

o Better definition of the overburden/volcanic ash - The

previous estimate identified the overburden/volcanic ash solely

based on the drill hole logs. The 2015 drilling gave us confidence

we could use geochemical criteria (high Al2O3 and lower Ni grade)

to objectively define the overburden. The overburden in the 2022

model is more widespread and is less poddy than in the previous

model. This has contributed to the reduction in tonnage but has

minimal impact on grade.

o Regression to the mean - The 2015 GPR and drilling program

focused on an area with higher grades and thickness. As more drill

sampling and GPR data was collected in the area, this area dropped

back toward the mean of the deposit. The area is still "higher"

grade but the drilling and GPR have reduced the extent and the

degree to which it departs from the mean grade and thickness.

o Reporting at a lower cut-off grade - The previous cut-off

grade of 0.8% was based on historic processing and mining

assumptions that emphasized the rocky saprolite portion of the

Resource over the non-rocky limonite and saprolite layers. Lowering

the cut-off grade will impose few assumptions on the Resource and

will allow the mining engineers greater flexibility when it comes

to developing a mine plan and a Reserve estimate.

For detail of exploration drilling results, see the following

Resource Mining Corporation Ltd (ASX:RMI) announcements:

o 8 December 2010. Wowo Gap Project Exploration Program

Highlights

o 3 February 2011. Wowo Gap Project Exploration Program

Highlights

o 23 June 2011. Wowo Gap Project Exploration Program

Highlights

o 30 August 2011. Wowo Gap Project Exploration Program

Highlights

o 4 March 2015. Exploration Update: Wowo Gap Nickel Laterite

Project

o 18 March 2015. Exploration Update: Wowo Gap Nickel Laterite

Project

o 29 April 2015. Wowo Gap exploration intersects high grade

Nickel up to 1m @ 3.51%Ni

o 21 May 2015. Wowo Gap exploration intersects high grade Nickel

up to 3m @ 1.87%Ni

Competent Persons and Qualified Persons Statement:

The information in this report that relates to Mineral Resources

is based on information compiled by Lawrence Queen and Luke Burlet.

Lawrence Queen is an employee of Queen and Associates, and Luke

Burlet is employed by H&S Consultants. Mr Queen is a Member of

the Australasian Institute of Mining and Metallurgy, and Mr Burlet

is a Member of the Australian Institute of Geoscientists. Mr Queen

and Mr Burlet have sufficient experience relevant to the style of

mineralisation and type of deposit under consideration and to the

activity which they are is undertaking to qualify as Competent

Persons as defined in the 2012 Edition of the Australasian Code for

the Reporting of Exploration Results, Mineral Resources and Ore

Reserves (JORC Code) and have sufficient relevant experience to

qualify as a qualified person as defined in the Guidance Note for

Mining, Oil and Gas Companies as published by AIM. Mr Queen and Mr

Burlet have reviewed the information in this announcement and

consent to the disclosure of the information in this report in the

form and context in which it appears.

For further information, please contact:

Scott Kaintz 020 7747 9960 Corcel Plc CEO

James Joyce / Andrew de Andrade 0207 220 1666 WH Ireland Ltd NOMAD & Broker

Simon Woods 0207 3900 230 Vigo Communications IR

The information contained within this announcement is deemed to

constitute inside information as stipulated under the retained EU

law version of the Market Abuse Regulation (EU) No. 596/2014 (the

"UK MAR") which is part of UK law by virtue of the European Union

(Withdrawal) Act 2018. The information is disclosed in accordance

with the Company's obligations under Article 17 of the UK MAR. Upon

the publication of this announcement, this inside information is

now considered to be in the public domain.

Glossary of Technical Terms:

"auger drill" a type of drill which uses a corkscrew type bit to

recover samples from unconsolidated materials;

"block model" Refers to the process of creating a 3D spatial

array of estimations. The parameter that is being estimated may be

the thickness of the ore, the grade of the ore, or some other

property that is useful for the evaluation of the resource. These

estimations are based on a weighted average of the values

associated with the surrounding control points. A variety of

interpolation methods or "algorithms" are available for performing

these estimations. A popular technique is ordinary Kriging;

"bulk density" is the mass per unit volume of a solid, including

the voids in a bulk sample of the material;

"Co" cobalt;

"Competent Person" a 'Competent Person' is a minerals industry

professional who is a Member or Fellow of The Australasian

Institute of Mining and Metallurgy, or of the Australian Institute

of Geoscientists, or of a 'Recognised Professional Organisation'

(RPO), as included in a list available on the JORC and ASX

websites. These organisations have enforceable disciplinary

processes including the powers to suspend or expel a members;

"core recovery" amount of rock recovered when diamond core

drilling usually expressed as a percentage;

"cut-off grade" a grade level below which the material is not of

economic interest and considered to be uneconomical to mine and

process. The minimum grade of mineralisation used to establish

reserves;

"development" often refers to the construction of a new mine or;

Is the underground work carried out for the purpose of reaching and

opening up a mineral deposit includes shaft sinking, cross-cutting,

drifting and raising;

"diamond drillhole" a drillhole which is drilled used a diamond

impregnated bit so that a cylindrical sample of solid rock (drill

core) can be recovered;

"Ground Penetrating Radar" a geophysical method that uses radar

pulses to image the subsurface;

"Indicated Resource" that part of a Mineral Resource for which

quantity, grade or quality, densities, shape and physical

characteristics, can be estimated with a level of confidence

sufficient to allow the appropriate application of technical and

economic parameters, to support mine planning and evaluation of the

economic viability of the deposit. The estimate is based on

detailed and reliable exploration and testing information gathered

through appropriate techniques from locations such as outcrops,

trenches, pits, workings and drill holes that are spaced closely

enough for geological and grade continuity to be reasonably

assumed;

"Inferred Resource" that part of a Mineral Resource for which

quantity and grade or quality can be estimated on the basis of

geological evidence and limited sampling and reasonably assumed,

but not verified, geological and grade continuity. The estimate is

based on limited information and sampling gathered through

appropriate techniques from locations such as outcrops, trenches,

pits, workings and drill holes;

"JORC" the Australasian Code for Reporting of Exploration

Results, Mineral Resources and Ore Reserves, as published by the

Joint Ore Reserves Committee of The Australasian Institute of

Mining and Metallurgy, Australian Institute of Geoscientists and

Minerals Council of Australia;

"JORC (2012)" the 2012 edition of the JORC code;

"laterite" a laterite is a residual soil rich in iron and

aluminum hydroxides which develops in a humid tropical climate.

Where these soils are enriched in nickel they are referred to as a

nickel laterite;

"lithology" the lithology of a rock unit is a description of its

physical characteristics visible at outcrop, in hand or core

samples or with low magnification microscopy, such as colour,

texture, grain size, or composition;

"m" metre;

"Mineral Resource" a concentration or occurrence of material of

economic interest in or on the earth's crust in such form and

quantity that there are reasonable and realistic prospects for

eventual economic extraction. The location, quantity, grade,

continuity, and other geological characteristics of a Mineral

Resource are known, estimated from specific geological evidence and

knowledge, or interpreted from a well-constrained and portrayed

geological model;

"Ni" nickel;

"open pit" a mine that is entirely on the surface. Also referred

to as open-cut or opencast mine;

"overburden" material of any nature, consolidated or

unconsolidated, that overlies a deposit of ore that is to be

mined;

"oxidation" a chemical reaction in which substances combine with

oxygen for form an oxide. For example, the combination of iron with

oxygen to form an iron oxide (rust) or copper and oxygen produce

copper oxide; the green coating on old pennies. The opposite of

oxidation is reduction.

"QAQC" Quality assurance and Quality control of the geological

sample database;

"Reverse Circulation- RC drilling" A percussion drilling

technique that produces chip samples that are removed from the

drillhole by compressed air pushing the sample up the inside of the

drill rods. Considered superior to aircore drilling; generating

better quality samples

"strike length" the horizontal distance along the long axis of a

structural surface, rock unit, mineral deposit or geochemical

anomaly;

"t" tonnes;

"variogram" a function of the distance and direction separating

two locations that is used to quantify dependence. The variogram is

defined as the variance of the difference between two variables at

two locations. The variogram generally increases with distance and

is described by nugget, sill, and range parameters. If the data is

stationary, then the variogram and the covariance are theoretically

related to each other.

"variogram model" a model that is the sum of two or more

component models, such as nugget, spherical, etc. Adding a nugget

component to one of the other models is the most common nested

model, but more complex combinations are occasionally used;

"wacker" a semi-mechanised deep overburden soil sampling method

commonly used in PNG;

"weathering" disintegration or alteration of rock in its natural

or original position at or near the Earth's surface through

physical, chemical, and biological processes induced or modified by

wind, water, and climate.

JORC Code, 2012 Edition - Table 1 report

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

Criteria JORC Code explanation Commentary

Sampling

techniques * Nature and quality of sampling (eg cut channels, * All the samples used in this Mineral Resource

random chips, or specific specialised industry Estimate are from drill core. The core was obtained

standard measurement tools appropriate to the over three main drill campaigns.

minerals under investigation, such as down hole gamma

sondes, or handheld XRF instruments, etc). These

examples should not be taken as limiting the broad o Wacker drilling - 153 holes totaling 731 m. 3 cm

meaning of sampling. diameter core- (nominal AQ). Only tested

the non-rocky laterite.

o Diamond core- (2003-2008 and 2014-201 5)161 holes

* Include reference to measures taken to ensure sample totaling 3174.2 m. HQ or NQ core.

representivity and the appropriate calibration of any o Tungsten carbide coring (2010-2011)- 297 holes totaling

measurement tools or systems used. 1745.8 m. Only tested the non-rocky

laterite.

o Auger core (2014-2015)- 125 holes totaling 944.5 m. Only

* Aspects of the determination of mineralisation that tested the non-rocky laterite.

are Material to the Public Report. * The drill methods were chosen to provide a sample of

the friable laterite that was relatively undisturbed

.

* In cases where 'industry standard' work has been done

this would be relatively simple (eg 'reverse

circulation drilling was used to obtain 1 m samples

from which 3 kg was pulverised to produce a 30 g

charge for fire assay'). In other cases more

explanation may be required, such as where there is

coarse gold that has inherent sampling problems.

Unusual commodities or mineralisation types (eg

submarine nodules) may warrant disclosure of detailed

information.

============================================================

Drilling

techniques * Drill type (eg core, reverse circulation, open-hole * This Mineral Resource Estimate is based on results

hammer, rotary air blast, auger, Bangka, sonic, etc) diamond core drilling (2003 - 2008), tungsten

and details (eg core diameter, triple or standard carbide-tipped core drilling (2010-2011), and

tube, depth of diamond tails, face-sampling bit or (2014-2015) diamond core and custom auger core

other type, whether core is oriented and if so, by drilling. All holes are vertical.

what method, etc).

Drill sample

recovery * Method of recording and assessing core and chip * As the core is recovered from the triple tube (NQ3),

sample recoveries and results assessed. core recoveries are typically very good. The

recoveries were logged and recorded in the database.

* Measures taken to maximise sample recovery and ensure

representative nature of the samples. * Core is recovered from the triple tube (NQ3) drilling

to ensure good recovery.

* Whether a relationship exists between sample recovery

and grade and whether sample bias may have occurred * Overall recoveries are>90% and there are no

due to preferential loss/gain of fine/coarse significant sample recovery problems.

material.

============================================================

Logging

* Whether core and chip samples have been geologically * Logging of the core recorded lithology, mineralogy,

and geotechnically logged to a level of detail to weathering, colour and other features of the samples.

support appropriate Mineral Resource estimation, The core from each core run were placed in plastic

mining studies and metallurgical studies. core trays for logging and photographed, then

sampled.

* Whether logging is qualitative or quantitative in

nature. Core (or costean, channel, etc) photography. Geotechnical logging was not conducted for mineralization purposes as

there is no structural

control to the mineralization.

* The total length and percentage of the relevant * The logging is both qualitative and quantitative in

intersections logged. nature including records of lithology, (ore layer

type), mineralogy, textures, oxidation state and

colour. Visual estimates of percentages of key

minerals associated with nickel mineralization and

their appearance and percent volume of rock in

diamond core samples of the rocky saprolite. All core

was photographed. 31 pits were also dug and sampled

as supporting evidence but not used in the Resource

estimation.

* All holes drilled were logged.

Sub-sampling

techniques * If core, whether cut or sawn and whether quarter, * Core samples were collected from half core, on

and sample half or all core taken. typical 1 metre lengths through the laterite profile.

preparation

* If non-core, whether riffled, tube sampled, rotary * No non-core samples were taken.

split, etc and whether sampled wet or dry.

* The samples were submitted to Intertek Laboratory in

* For all sample types, the nature, quality, and Lae, Papua New Guinea (PNG) for preparation. All

appropriateness of the sample preparation technique. samples received were weighed and wet weight recorded,

then dried at 105degC for at least 16 hours. Samples

were then crushed with 95% passing -2 mm. Crushed

* Quality control procedures adopted for all samples were then riffle split, with a split taken

sub-sampling stages to maximise representivity of for fine pulverising to 95% passing -200 m, with the

samples. remainder retained as coarse residue. For samples of

less than 1.5 kg, no coarse residue was retained. The

pulverised (pulp) samples were forwarded to Intertek

* Measures taken to ensure that the sampling is Laboratory in Jakarta, Indonesia for assay of Ni, Co,

representative of the in situ material collected, Al(2) O(3) , CaO, Cr(2) O(3) , Fe(2) O(3) , K(2) O,

including for instance results for field LOI, MgO, MnO, Na(2) O, P(2) O(5) , SiO(2) and LOI by

duplicate/second-half sampling. fusion XRF. The sample preparation technique is

considered

* Whether sample sizes are appropriate to the grain

size of the material being sampled. appropriate for the style of mineralisation under consideration.

* Certified reference materials were used at a rate of

1 standard per 20 samples and a field duplicate is

collected from the unsampled half core for every

second hole.

* The bulk of the laterite is made of silt to clay size

particle so sample size is appropriate for the

granularity of the sampled target mineral.

============================================================

Quality of

assay data * The nature, quality and appropriateness of the * The core samples were sent to Intertek in Lae for

and assaying and laboratory procedures used and whether sample preparation, with the pulps being sent to

laboratory the technique is considered partial or total. Intertek Jakarta for fusion XRF analysis for Ni, Co,

tests Al(2) O(3) , CaO, Cr(2) O(3) , Fe(2) O(3) , K(2) O,

LOI, MgO, MnO, Na(2) O, P(2) O(5) , SiO(2) and LOI.

* For geophysical tools, spectrometers, handheld XRF This method is considered a total assay.

instruments, etc, the parameters used in determining

the analysis including instrument make and model,

reading times, calibrations factors applied and their * No portable XRF machines were used to determine any

derivation, etc. element concentrations used in the grade

determinations.

* Nature of quality control procedures adopted (eg

standards, blanks, duplicates, external laboratory * Sample preparation checks for fineness were carried

checks) and whether acceptable levels of accuracy (ie out by the laboratory as part of their internal

lack of bias) and precision have been established. procedures to ensure the grind size of 85% passing 75

micron was being attained.

* Laboratory QAQC involves the use of internal lab

standards using certified reference material, blanks,

splits, and replicates as part of the in-house

procedures.

* Certified reference materials were used in the

2014-2015 drilling program, with a certified standard

added to every second hole.

* Field duplicate samples were submitted from alternate

holes.

Verification

of sampling * The verification of significant intersections by * No verification was carried out.

and assaying either independent or alternative company personnel.

* In 2010 - 2011, a second twin hole was drilled within

* The use of twinned holes. one metre of the original hole for every fourth or

fifth hole drilled. These samples were sent to

Ultratrace Laboratories for fusion XRF analysis.

* Documentation of primary data, data entry procedures, Comparison of the twin hole data was used to estimate

data verification, data storage (physical and short range variance (0.52).

electronic) protocols.

* Logging data was collected using a set of standard

* Discuss any adjustment to assay data. paper logging sheets which were entered into

Maxwell's Logchief logging software.

* The information was sent to Mr M Hill in the Perth

office for validation and forwarded to Maxwell's for

importing into the Datashed Database.

* There was no adjustment to any assay data.

============================================================

Location of

data points * Accuracy and quality of surveys used to locate drill * Diamond holes from both the 2003 - 2004 and 2007

holes (collar and down-hole surveys), trenches, mine drilling programs were surveyed by Arman Larmer

workings and other locations used in Mineral Resource Surveys Ltd Consulting Surveyors (PNG) using a Wild

estimation. 805 Total Station, traversing from survey control

stations which were located using an Omnistar DGPS

with a reported accuracy of +/- 0.1 metres.

* Specification of the grid system used.

Drill holes in 2008, 2010, 2011 and 2014 were surveyed by a handheld

* Quality and adequacy of topographic control. GPS. Horizontal accuracy

is estimated to be +/- 5 meters.

* All spatial data is recorded in AMG84, zone 55

* Topographic control is based on a digital elevation

model derived from a LiDAR survey flown by Digital

Mapping Australia Pty Ltd (DiMap) in April 2007.

Data spacing

and * Data spacing for reporting of Exploration Results. * Nominal drilling spacing for most of the area is 300

distribution metres x 200 metres.

* Whether the data spacing and distribution is

sufficient to establish the degree of geological and For the areas covered by the 2014-2015 drilling the nominal drill hole

grade continuity appropriate for the Mineral Resource spacing is 200 metres

and Ore Reserve estimation procedure(s) and on 100 metres spaced east - west lines.

classifications applied. * Each of the laterite layers shows low variability and

long range (100s of metres) continuity of the

economically important elements (Ni & Co). The data

* Whether sample compositing has been applied. spacing and distribution is sufficient to demonstrate

spatial and grade continuity of the mineralized

horizons to support the definition of

Inferred/Indicated Mineral Resources under the 2012

JORC code

* Samples were composited based on mineralization type

(Overburden/Volcanic Ash, Limonite, non-rocky

Saprolite, and Rocky Saprolite)

============================================================

Orientation

of data in * Whether the orientation of sampling achieves unbiased * Lateritic nickel mineralisation develops broadly

relation to sampling of possible structures and the extent to parallel to the topographic surface and vertical

geological which this is known, considering the deposit type. drilling orientation is generally unbiased.

structure

* If the relationship between the drilling orientation * No sampling bias from drillhole orientation is

and the orientation of key mineralised structures is expected. The drillholes are vertical, with

considered to have introduced a sampling bias, this mineralisation generally horizontal and not obviously

should be assessed and reported if material. related to structure.

Sample

security * The measures taken to ensure sample security. * Chain of custody was managed by RMC. Samples were

stored on site and delivered to an independent

transport company in Port Moresby, PNG which

delivered them to the assay laboratory in Lae, PNG

the following day.

============================================================

Audits or

reviews * The results of any audits or reviews of sampling * An independent due diligence study of the exploration

techniques and data. procedures used on the Wowo Gap nickel laterite

project was carried out by Robin Rankin of GeoRes in

April 2011. This review concluded the work by Niugini

Nickle was well founded and completely applicable to

good exploration of a nickel laterite type deposit.

* In 2015 Torridon Exploration carried out an

independent audit of the 2014-2015 drilling program.

The review found the exploration drilling program was

appropriate for a nickel laterite deposit and

conformed to accepted industry practice.

============= ============================================================ ============================================================================

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this

section.)

Criteria JORC Code explanation Commentary

Mineral

tenement and * Type, reference name/number, location and ownership * The Wowo Gap nickel laterite project is located near

land tenure including agreements or material issues with third Embessa in the Oro Province of Papua New Guinea. The

status parties such as joint ventures, partnerships, project is contained within EL 1165, which is owned

overriding royalties, native title interests, by Niugini Nickel Limited, a wholly owned subsidiary

historical sites, wilderness or national park and of Corcel Plc, a UK company listed on the Alternative

environmental settings. Investment Market of the London Stock Exchange.

Royalties payable on gross revenues are expected to

be 1% PNG government. There are no native title,

* The security of the tenure held at the time of historical, national park, or other impediments.

reporting along with any known impediments to

obtaining a licence to operate in the area.

* The tenement is currently in good standing pending

renewal.

Exploration

done by other * Acknowledgment and appraisal of exploration by other * Nickel laterite mineralization in the area around

parties parties. Wowo Gap was first reported by the BMR in 1958. Auger

samples of breccia assayed up 1.3% Ni,

Geology The Wowo Gap mineralization is a wet tropical nickel

* Deposit type, geological setting, and style of laterite. In the project area an east

mineralisation. dipping lateritic profile has developed over the

underlying ultramafics. The complete lateritic

profile is preserved, with partial truncation associated

with recent drainage systems. The

depth of weathering varies according to rock type and

the degree of brecciation. The lateritic

profile is typically 10 to 15 metres thick, occasionally

more than 30 metres above the Sivai

Breccia.

The laterite profile is typically 10m to 18m thick and

composed of an upper iron-rich saprolite

horizon (referred to as limonite) with high a (>40%) to

very high (>60%) Fe(2) O(3) content

but relatively low (<6%) MgO. It is the limonite horizon

that contains enriched levels of

cobalt, chromium and manganese values. Beneath the

limonite is MgO-rich (>6 - 40%) earthy

saprolite (referred to as saprolite) horizon with

relatively low (<40%) Fe(2) O(3) content.

Below this in the regolith profile is the rocky

saprolite (saprock), clearly identifiable

because of corestones of partially weathered ultramafic

bedrock.

Drill hole

Information * A summary of all information material to the * All the drill holes used for this Resource estimate

understanding of the exploration results including a were completed prior to the end of 2015. Details for

tabulation of the following information for all those holes were reported in ASX announcements that

Material drill holes: can be found on the Resource Mining Corporation

website

(https://resmin.com.au/investor-centre/asx-announceme

o easting and northing of the drill hole collar nts/)

o elevation or RL (Reduced Level - elevation above sea

level in metres) of the drill hole

collar

o dip and azimuth of the hole

o down hole length and interception depth

o hole length.

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

Data

aggregation * In reporting Exploration Results, weighting averaging * Only Mineral Resources are being reported. As no

methods techniques, maximum and/or minimum grade truncations exploration results are being reported, this section

(eg cutting of high grades) and cut-off grades are is not considered applicable.

usually Material and should be stated.

* Where aggregate intercepts incorporate short lengths

of high grade results and longer lengths of low grade

results, the procedure used for such aggregation

should be stated and some typical examples of such

aggregations should be shown in detail.

* The assumptions used for any reporting of metal

equivalent values should be clearly stated.

Relationship

between * These relationships are particularly important in the * Only Mineral Resources are being reported. As no

mineralisation reporting of Exploration Results. exploration results are being reported, this section

widths and is not considered applicable.

intercept

lengths * If the geometry of the mineralisation with respect to

the drill hole angle is known, its nature should be

reported.

* If it is not known and only the down hole lengths are

reported, there should be a clear statement to this

effect (eg 'down hole length, true width not known').

Diagrams

* Appropriate maps and sections (with scales) and * Only Mineral Resources are being reported. As no

tabulations of intercepts should be included for any exploration results are being reported, this section

significant discovery being reported These should is not considered applicable.

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

Balanced

reporting * Where comprehensive reporting of all Exploration * Only Mineral Resources are being reported. As no

Results is not practicable, representative reporting exploration results are being reported, this section

of both low and high grades and/or widths should be is not considered applicable.

practiced to avoid misleading reporting of

Exploration Results.

Other

substantive * Other exploration data, if meaningful and material, * Only Mineral Resources are being reported. As no

exploration should be reported including (but not limited to): exploration results are being reported, this section

data geological observations; geophysical survey results; is not considered applicable.

geochemical survey results; bulk samples - size and

method of treatment; metallurgical test results; bulk

density, groundwater, geotechnical and rock

characteristics; potential deleterious or

contaminating substances.

Further work

* The nature and scale of planned further work (eg * The portion of the Mineral Resource corresponding to

tests for lateral extensions or depth extensions or the area of the 2014 GPR cover meets many but not all

large-scale step-out drilling). of the criteria to be classified as Measured. Some

additional drilling, bulk density sampling, further

QAQC work and further resource modelling subdividing

* Diagrams clearly highlighting the areas of possible the laterite into limonite and saprolite layers may

extensions, including the main geological be sufficient to allow this portion of the Resource

interpretations and future drilling areas, provided to be reclassified

this information is not commercially sensitive.

=============== =============================================================== ============================================================

Section 3 Estimation and Reporting of Mineral Resources

(Criteria listed in section 1, and where relevant in section 2,

also apply to this section.)

Criteria JORC Code explanation Commentary

Database

integrity * Measures taken to ensure that data has not been * Logging data was collected using a set of standard

corrupted by, for example, transcription or keying paper logging sheets which were entered into

errors, between its initial collection and its use Maxwell's Logchief logging software.

for Mineral Resource estimation purposes.

* The information was sent to Mr M Hill in the Perth

* Data validation procedures used. office for validation and forwarded to Maxwell's for

importing into the Datashed Database.

* The WoWo drilling data was provided in a Microsoft

Access database. Ground Penetrating Radar (GPR)

surveys (2007 and 2014) and topographic data (LiDAR)

were provided in CSV format.

* A range of basic checks were performed by H&SC prior

to the resource estimates to ensure data consistency,

including, but not limited to, checks for From-To

interval errors, missing or duplicate collar surveys,

excessive down hole deviation, and extreme or unusual

assay values.

* A range of drilling methods have been used at WoWo

and incorporated into the resource modelling:

Hole Type total Year_min Year_max

(m)

pit 253 1971 2004

diamond 3,174 1972 2015

drill Hole

wacker 731 1999 2008

auger 2,901 2010 2015

* Independent consultant Larry Queen conducted a review

of the various drilling and sample types to confirm

that they are suitable to form the basis of the

Mineral Resource Estimates (MREs).

Site visits

* Comment on any site visits undertaken by the * No site visits have been made by the Competent

Competent Person and the outcome of those visits. Persons for this report as until recently, access to

the area has been impossible due to COVID19 travel

restrictions. However, Mr. Queen has over 30 years of

* If no site visits have been undertaken indicate why experience in PNG and has served as Competent Person

this is the case. for the similar Ramu Nickel Laterite and the Sewa Bay

Nickel Laterite. Mr Queen has reviewed all the

documentation from the previous work and is confident

Wowo Gap is broadly similar to other tropical

laterites in PNG.

Geological

interpretation * Confidence in (or conversely, the uncertainty of ) * The grade and lithological interpretation forms the

the geological interpretation of the mineral deposit. basis for the modelling. Grades have all been

estimated constrained within the lateritic layers

(rock types).

* Nature of the data used and of any assumptions made.

* Based on experience at other nickel laterites in PNG

* The effect, if any, of alternative interpretations on and the drill log and geochemical interpretation

Mineral Resource estimation. there is strong confidence in the geological

interpretation of the lateritic layers (rock types)

of the deposit. The upper layers, especially the

* The use of geology in guiding and controlling Mineral limonite layer, are usually continuous, with the

Resource estimation. absence of the limonite layer always due to erosion

especially around the incised streams. The grades

including cobalt, are usually continuous and show

* The factors affecting continuity both of grade and little lateral variability.

geology.

* Core recording, sample analysis and ground

penetrating radar (GPR) were applied to interpret the

geological domains of deposit. The

overburden/limonite boundary was created using grade

composites based on aluminium and nickel percentage.

Samples with greater than 20% Al(2) O(3) were

classified limonite. GPR data was used to define of

the bottom of limonite/saprolite top of rocky

saprolite.

* The Wowo Gap deposit has been the subject of several

previous resource estimates, the most recent dated

December 2011 (

https://resmin.com.au/wp-content/uploads/docs/asx_announcements/2011/20111214%20Wowo%20

Gap%20Resource%20Upgrade.pdf

). All the resource models have been similar (i.e.

the laterite occurs as a layer-cake like deposit that

drapes over the topography.) and vary mostly in the

amount of supporting data (drill holes and GPR)

* The GPR data was used to interpret and define a

bottom of Limonite-non rocky Saprolite and a bottom

of rocky Saprolite surface. In the stream incised

areas where there was little, or no GPR data low

laterite thicknesses were used as defaults. This was

done as it was assumed the laterite profile would be

largely removed along the streams.

* The logged lithology and the geochemistry was also

used to define the zone of Quaternary overburden

(mainly volcanic ash, "Qva"), the logged zone of

limonite-non rocky saprolite and rocky saprolite.

* The Qva zone was used to define the bottom of

overburden. Thus three geological zones/layers were

defined, overburden (Qva), limonite-non rocky

saprolite and rocky saprolite which in turn were used

to guide and control the mineral resource estimate.

* The interpreted overburden/Qva thickness ranges

between 0 and 10m and averages 0.5m, the limonite-non

rocky saprolite between 0 and 23m and averages 3m,

and the rocky saprolite between 0 and 20m and

averages 3.8m

Dimensions

* The extent and variability of the Mineral Resource * The drilled laterite covers an area of 8700 metres

expressed as length (along strike or otherwise), plan N-S by 3300 to 4000 meters E-S. The average thickness

width, and depth below surface to the upper and lower of the laterite above the rocky saprolite is roughly

limits of the Mineral Resource. 7 metres with maximum thickness of 19 metres

Estimation and

modelling * The nature and appropriateness of the estimation * Nickel and cobalt grades were estimated with using

techniques technique(s) applied and key assumptions, including the ordinary kriging (OK) estimation technique in

treatment of extreme grade values, domaining, Micromine software. Samples from each hole were used

interpolation parameters and maximum distance of and composited to the full width of the layer, making

extrapolation from data points. If a computer 1 composite per layer for each of the three layer;

assisted estimation method was chosen include a the mineralised domains were limited to the three

description of computer software and parameters used. interpreted geological layers as noted above. The

grade distributions for nickel and cobalt are not

strongly skewed so OK was an appropriate estimation

* The availability of check estimates, previous method; there are no extreme values requiring grade

estimates and/or mine production records and whether cutting. The three layers were estimated separately,

the Mineral Resource estimate takes appropriate i.e., with hard boundaries. A two pass search

account of such data. strategy was used for OK estimation:

axis axis axis min min

* The assumptions made regarding recovery of Search 1 2 3 max samples total hole

by-products. radians radians radians

(m) (m) (m) per quadrant samples count

------- ------- ------- ------------ ------- -----

* Estimation of deleterious elements or other non-grade 1 40 1000 1000 6 4 4

variables of economic significance (eg sulphur for ------- ------- ------- ------------ ------- -----

acid mine drainage characterisation). 2 40 1200 1200 6 4 4

------- ------- ------- ------------ ------- -----

* In the case of block model interpolation, the block

size in relation to * The block model was setup as a 'grade thickness

model' where both grade and thickness are estimated

for each of the 3 layers. Due to the steep and widely

* the average sample spacing and the search employed. undulating terrain, the block model and input grade

and thickness data from drilled was 'flattened' to a

common dummy RL. This allowed a common search

* Any assumptions behind modelling of selective mining orientation to be used during the OK estimation

units. routine.

* Any assumptions about correlation between variables. * The orientation of the search ellipsoid and variogram

models was isotropic in the horizontal plane of the

flattened block model.

* Description of how the geological interpretation was

used to control the resource estimates.

* The maximum extrapolation distance would be close to

the maximum search radii of 900m.

* Discussion of basis for using or not using grade

cutting or capping.

* There is a previous estimate (Ravensgate, 2011) that

is broadly compatible with the current MREs, but

* The process of validation, the checking process used, substantial differences in the interpretation and

the comparison of model data to drill hole data, and modelling of mineralisation, as well as additional

use of reconciliation data if available. drilling and more extensive and more detailed GPR

technique, make detailed comparisons to the 2011 MRE

meaningless. The current MREs take appropriate

account of previous estimates, while acknowledging

substantial differences in methodology and data. H&SC

also ran a non-grade thickness model, still using OK,

but with set block heights and on a block fraction

basis. This block definition is more common in gold

or base metal models. The overall results of the

check model were closely comparable and gives

confidence in the grade- thickness methodology.

* The deposits remain unmined so there are no

production records for comparison.

* Only nickel and cobalt were estimated, so no

potential by-products or deleterious elements were

assessed; consequently, no assumptions are made

regarding the correlation of variables.

* Dry bulk density was assigned by geological layer

zone, based on average values for available

measurements quoted by Ravensgate (2011)

* The block size for the model is a constant 10x10 in

Easting and Northing with a variable block height for

each of the 3 geological layers. In this way the

block model is three blocks high at each 10x10 cell.

A 10x10 cell size was chosen as this considers the

steep and undulating terrain, thus largely avoiding

the need for block proportions or sub-blocking.

* The new model was validated in several ways - visual

comparison of block and drill hole grades,

statistical analysis (summary statistics),

examination of grade-tonnage data, and comparison

with previous estimates and the check model.

* Average estimated grades are lower than average

composite grades, reflecting clustering in the drill

hole data and slightly skewed grade distributions.

* All the validation checks suggest that the grade

estimates are reasonable when compared to the

composite grades, allowing for data clustering.

Moisture

* Whether the tonnages are estimated on a dry basis or * All tonnes reported in the Mineral Resource are

with natural moisture, and the method of

determination of the moisture content.

estimated on a dry basis.

The moisture and dry bulk density were measured using a cylinder of core. The volume of

the

sample was determined by measuring the length and diameter of the sample. The wet sample

is

weighed first, the sample is then dried in a drying oven under a constant temperature of

105degC,

and then the dry weight is determined. Moisture is given by (Wet Weight - Dry Weight)/Wet

Weight). The average moisture content was 39%

Cut-off

parameters * The basis of the adopted cut-off grade(s) or quality * A nominal cut-off grade of 0.7% Ni has been applied,

parameters applied. based on similar open-pit operations.

Mining factors

or assumptions * Assumptions made regarding possible mining methods, * The large, relatively flat and shallow nature of this

minimum mining dimensions and internal (or, if type of deposit dictates any mining would be by open

applicable, external) mining dilution. It is always pit methods. It has been assumed that the full strike

necessary as part of the process of determining length, width and depth of the modelled

reasonable prospects for eventual economic extraction mineralisation above the 0.7% Ni cut-off can be

to consider potential mining methods, but the economically mined.

assumptions made regarding mining methods and

parameters when estimating Mineral Resources may not

always be rigorous. Where this is the case, this

should be reported with an explanation of the basis

of the mining assumptions made.

Metallurgical

factors or * The basis for assumptions or predictions regarding * Some information relating to nickel recovery from the

assumptions metallurgical amenability. It is always necessary as 'saprolite',

part of the process of determining reasonable

prospects for eventual economic extraction to

consider potential metallurgical methods, but the material is known as some of this material has been processed and undergone preliminary

assumptions regarding metallurgical treatment test

processes and parameters made when reporting Mineral work. Similar test work is required to be carried out for each of the project areas. At

Resources may not always be rigorous. Where this is this

the case, this should be reported with an explanation stage of the project no overall recoveries have been assumed for all the Wowo Gap Project

of the basis of the metallurgical assumptions made. Area deposits.

* For resource modelling no assumptions were made about

process methods or nickel recovery.

Environmen-tal

factors or * Assumptions made regarding possible waste and process * The current proposal is to produce a bulk product

assumptions residue disposal options. It is always necessary as suitable for smelting that will be transported

part of the process of determining reasonable offsite for processing. It has

prospects for eventual economic extraction to

consider the potential environmental impacts of the

mining and processing operation. While at this stage been assumed that mine waste will be relatively low in total volume and comprise the 1 m

the determination of potential environmental impacts, to

particularly for a greenfields project, may not 5 m soil and volcanic ash overburden layer. This material is likely to be used for

always be well advanced, the status of early rehabilitation

consideration of these potential environmental purposes after mining is complete. Low-grade material, mostly limonitic in composition,

impacts should be reported. Where these aspects have may

not been considered this should be reported with an be stockpiled, in mined-out areas.

explanation of the environmental assumptions made.

Bulk density

* Whether assumed or determined. If assumed, the basis * Density data was adopted from the Ravensgate 2011

for the assumptions. If determined, the method used, report as it appears this is the only source of

whether wet or dry, the frequency of the measurements determined density information. In their report they

, indicate the representative and preferred in-situ

the nature, size and representativeness of the bulk density for resource modelling is 1.0 t/m3 for

samples. the "clay profile" (limonite-saprolite layer), and

2,0 t/m3 for the rocky Saprolite profile. Queen &

H&SC have, based on their experience, used an assumed

* The bulk density for bulk material must have been default density 0.9 t/m3 for the volcanic ash. This

measured by methods that adequately account for void assumed density is unlikely to have a large impact on

spaces (vugs, porosity, etc), moisture and the overall MRE tonnage as the volcanic ash layer has

differences between rock and alteration zones within less overall volume compared to the other layers and

the deposit. does not contribute tonnage at cut-off grades above

about 0.7% Ni.

* Discuss assumptions for bulk density estimates used

in the evaluation process of the different materials.

Classification

* The basis for the classification of the Mineral * Resource classification is based on both the overall

Resources into varying confidence categories. footprint of the GPR coverage and drilling. A polygon

that encompasses this was used to flag the block

model as follows:

* Whether appropriate account has been taken of all

relevant factors (ie relative confidence in

tonnage/grade estimations, reliability of input data, * any Qva or Limonite-Saprolite blocks within it are

confidence in continuity of geology and metal values, classified as Indicated.

quality, quantity and distribution of the data).

* Rocky saprolite blocks classified as Inferred

* Whether the result appropriately reflects the regardless of the polygon.

Competent Person's view of the deposit.

* any blocks outside of classification polygon are

Inferred

* This classification scheme is considered to take

appropriate account of all relevant factors,

including the relative confidence in tonnage and

grade estimates, confidence in the continuity of

geology and metal values, and the quality, quantity

and distribution of the drilling and GPR data

* The classification appropriately reflects the

Competent Person's view of the deposit.

Audits or

reviews * The results of any audits or reviews of Mineral * The current model has not been audited by an

Resource estimates. independent third party

* This Mineral Resource estimate has been reviewed by

Queen and H&SC personnel and the resource report was

internally peer reviewed by H&SC. No material issues

were identified because of these reviews.

Discussion of

relative * Where appropriate a statement of the relative * The relative accuracy and confidence level in the

accuracy/ accuracy and confidence level in the Mineral Resource Mineral Resource estimates are in line with the

confidence estimate using an approach or procedure deemed generally accepted accuracy and confidence of the

appropriate by the Competent Person. For example, the nominated JORC Mineral Resource categories. This has

application of statistical or geostatistical been determined on a qualitative, rather than

procedures to quantify the relative accuracy of the quantitative, basis, and is based on the estimator's

resource within stated confidence limits, or, if such experience with similar deposits elsewhere. The main

an approach is not deemed appropriate, a qualitative factors that affect the relative accuracy and

discussion of the factors that could affect the confidence of the estimate are the drill hole spacing,

relative accuracy and confidence of the estimate. the style of mineralisation and bulk density

measurements.

* The statement should specify whether it relates to

global or local estimates, and, if local, state the * The estimates are local, in the sense that they are

relevant tonnages, which should be relevant to localised to model blocks of a size considered

technical and economic evaluation. Documentation appropriate for local grade estimation. The tonnages

should include assumptions made and the procedures relevant to technical and economic analysis are those

used. classified as Indicated Mineral Resources.

* These statements of relative accuracy and confidence * This deposit remains unmined so there are no

of the estimate should be compared with production production records for comparison.

data, where available.

=============== ============================================================ ==============================================================================================

This information is provided by RNS, the news service of the

London Stock Exchange. RNS is approved by the Financial Conduct

Authority to act as a Primary Information Provider in the United

Kingdom. Terms and conditions relating to the use and distribution

of this information may apply. For further information, please

contact rns@lseg.com or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms

and conditions, to analyse how you engage with the information

contained in this communication, and to share such analysis on an

anonymised basis with others as part of our commercial services.

For further information about how RNS and the London Stock Exchange

use the personal data you provide us, please see our Privacy

Policy.

END

MSCBKABPFBKDBPD

(END) Dow Jones Newswires

May 17, 2022 02:01 ET (06:01 GMT)

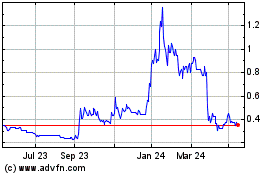

Corcel (LSE:CRCL)

Historical Stock Chart

From Jun 2024 to Jul 2024

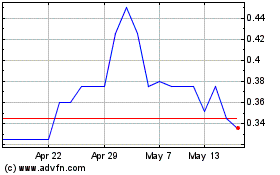

Corcel (LSE:CRCL)

Historical Stock Chart

From Jul 2023 to Jul 2024