The WEAV3D, Clemson Composites Center &

Braskem Partnership won for their Rebar for Plastics® Lattice

Technology

Rebar for Plastics® combines Braskem's

polypropylene sheets with WEAV3D’s lattice technology to provide

new structural and automotive solutions requiring high-strength and

lightweight materials

Braskem (B3: BRKM3, BRKM5, and BRKM6; NYSE: BAK; LATIBEX: XBRK)

the largest polyolefins producer in the Americas, as well as a

global market leader and pioneer producer of biopolymers on an

industrial scale, and WEAV3D Inc., an advanced manufacturing and

materials startup, today announced Braskem's and WEAV3D Inc.'s

thermoplastic composite lattice technology, in partnership with the

Clemson Composites Center at Clemson University, were named first

place winners of the 2024 Altair Enlighten Award’s Future of

Lightweighting category. The award recognized the partnerships’

cost-effective lightweight solution to enhance the performance of

PP for structural automotive applications.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20240812821972/en/

Beltline Stiffener Photo Credit:

WEAV3D

Joel Carr, Technical Service and Development Engineering Team

Leader, Braskem America, stated, “Braskem is honored to be

recognized by Altair as the winner of the 2024 Future of

Lightweighting category which recognizes new material technologies

that have significant potential to transform and advance vehicle

lightweighting. The partnership between WEAV3D, Clemson Composites

Center, and Braskem combined to create a truly innovative material

that provides for more sustainable lightweight solution to help

reduce vehicle carbon emissions all while enhancing manufacturing

process value through material cost savings. This is a win-win for

our clients and the planet.”

The combination of WEAV3D composite lattice reinforcement with

Braskem PP enables lighter and less expensive thermoplastic

solutions than conventional organosheet, unlocking new

opportunities for the cost-effective replacement of sheet metal

structures with thermoplastics throughout the vehicle.

“We are incredibly grateful to Altair and CAR for selecting us

for such a prestigious award,” says Christopher Oberste, President

and Chief Engineer of WEAV3D Inc. “This award validates the

technical development and commercialization progress we have

achieved over the past several years and recognizes the importance

of WEAV3D’s cost-effective lightweighting technology as part of the

future of sustainable mobility. Using the right material in the

right place keeps cost and waste low, while still delivering

substantial weight savings and performance benefits to our

automotive customers.”

The Altair Enlighten Award honors the greatest sustainability

and lightweighting advancements that successfully reduce carbon

footprint, mitigate water and energy consumption, and leverage

material reuse and recycling efforts. The Enlighten Award showcases

the latest and greatest technology innovations dedicated to

sustainability and garners interest from industry, engineering,

policymakers, educators, students, and the public alike. The

Enlighten Award is presented annually in conjunction with the

Center for Automotive Research (CAR) and was presented this year on

August 6, 2024, at the CAR Management Briefing Seminars.

“We collaborated with WEAV3D and Braskem to develop an

industry-first high-rate structural automotive prototype that

showcases WEAV3D’s tunable woven composite technology and Braskem's

cost-effective PP resin, leveraging our extensive experience in

stamp-forming thermoplastic composites from the US Department of

Energy's Ultra-Lightweight Door program," says Sai Aditya Pradeep,

former Manufacturing Applications Engineer and Project Lead for

Clemson.

Benefits of using WEAV3D's Rebar for Plastics® and Braskem

Polypropylene vs. conventional composite organosheet:

- LIGHTWEIGHT – Reduces sheet blank weight by ~50% and

final part weight by ~23%

- COST EFFECTIVE – Reduces costs by ~50%

- EFFICIENT – Increases sheet yield from 25% to 45% by

weight, resulting in a 62% reduction in trim waste

For more information on WEAV3D's Rebar for Plastics® with

Braskem’s PP, visit

https://weav3d.com/cost-effective-automotive-body-structures.

Braskem will exhibit at the Society of Plastics Engineers (SPE)

TPO Global Automotive Conference in Troy, Michigan from September

29 - October 2, 2024.

ABOUT WEAV3D Inc.

WEAV3D Inc. is an innovator in composite materials,

manufacturing processes and processing equipment. Headquartered in

Norcross, GA, they originated as a technology startup within the

Materials Science and Engineering department at the Georgia

Institute of Technology. The patent-pending WEAV3D composite

forming process enables the production of optimized lattice

structures that can be combined with injection molding or

thermoforming processes to create lightweight structural composite

parts at a fraction of the cost and cycle time associated with

traditional composite manufacturing. These innovations enable

companies in industries such as automotive, aircraft, wind

turbines, and cargo transportation to produce parts that are

lighter, stronger and less expensive. For more information, visit

www.weav3d.com.

ABOUT CLEMSON UNIVERSITY

One of the most productive public research universities in the

nation, Clemson University enrolls 27,341 students across the State

of South Carolina and has an endowment of over $1 billion. The

University operates Extension offices in every county of the state

and has five Innovation Campuses and six Research and Education

Center locations. Classified as an R1 — Very High Research

University by the Carnegie Classification of Institutions of Higher

Education — Clemson is dedicated to teaching, research and service.

Our main campus, located in Upstate South Carolina, sits on 1,400

acres in the foothills of the Blue Ridge Mountains, along the

shores of Lake Hartwell. Through the research, outreach and

entrepreneurial projects led by our faculty and students, Clemson

University is driving economic development and improving quality of

life in South Carolina and beyond. For more information, visit

https://clemsoncomposites.com.

ABOUT BRASKEM

With a global vision of the future oriented toward people and

sustainability, Braskem is committed to contributing to the value

chain for strengthening the Circular Economy. The petrochemical

company’s almost 9,000 team members dedicate themselves every day

to improving people’s lives through sustainable chemicals and

plastics solutions. Braskem has an innovative DNA and a

comprehensive portfolio of plastic resins and chemical products for

diverse segments, such as food packaging, construction,

manufacturing, automotive, agribusiness, healthcare, and hygiene,

among others. With 40 industrial units in Brazil, the United

States, Mexico, and Germany, and exports its products to clients in

more than 70 countries.

Braskem America is an indirect wholly owned subsidiary of

Braskem S.A. headquartered in Philadelphia. The company is the

leading producer of polypropylene in the United States, with five

production plants located in Texas, Pennsylvania, and West

Virginia, an Innovation and Technology Center in Pittsburgh, and

operations in Lexington, MA focused on leveraging groundbreaking

developments in biotechnology and advanced materials. For more

information, visit www.braskem.com/usa.

Braskem on English social media:

www.facebook.com/BraskemGlobal

www.linkedin.com/company/braskem

View source

version on businesswire.com: https://www.businesswire.com/news/home/20240812821972/en/

For press information, please contact:

Braskem North America Stacy Torpey – (215) 841 3194 –

stacy.torpey@braskem.com

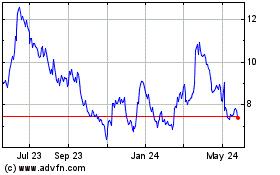

Braskem (NYSE:BAK)

Historical Stock Chart

From Oct 2024 to Nov 2024

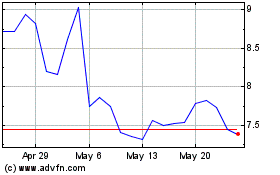

Braskem (NYSE:BAK)

Historical Stock Chart

From Nov 2023 to Nov 2024