UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

______________________

FORM SD

______________________

Specialized Disclosure Report

______________________

ASML Holding N.V.

(Exact name of registrant as specified in its charter)

______________________

| | | | | | | | | | | | | | |

The Netherlands | | 001-33463 | | Not Applicable |

(State or other jurisdiction of incorporation) | | (Commission File Number) | | (IRS Employer Identification No.) |

De Run 6501

5504 DR Veldhoven

The Netherlands

(Address of principal executive offices) (Zip Code)

James A. McDonald

Skadden, Arps, Slate, Meagher & Flom (UK) LLP

22 Bishopsgate, London, EC2N 4BQ

+44 (0)20 7519 7000

(Name and telephone number, including area code, of the person to contact in connection with this report.)

______________________

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

x Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period January 1 to December 31, 2023.

Section 1 - Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

A copy of the Conflict Minerals Report of ASML Holding N.V. (“ASML”) for the period from January 1, 2023 to December 31, 2023. is filed herewith as Exhibit 1.01, and is publicly available at www.asml.com (https://www.asml.com/en/company/sustainability/responsible-supply-chain) as well as the SEC’s EDGAR database at www.sec.gov.

Item 1.02 Exhibit

ASML's Conflict Minerals Report is filed herewith as Exhibit 1.01 to this Form SD.

Section 2 - Exhibits

Item 2.01 Exhibits

| | | | | | | | |

| Exhibit No. | | Description of Exhibit |

| | |

| 1.01 | | Conflict Minerals Report as required by Item 1.01 and 1.02 of this Form SD.

|

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

| | | | | | | | |

| | ASML HOLDING N.V. (Registrant) |

| | |

| | |

Date: May 31, 2024 | By: | /s/ Christophe D. Fouquet |

| | Christophe D. Fouquet |

| | Chief Executive Officer |

ASML HOLDING N.V.

CONFLICT MINERALS REPORT

For The Year Ended December 31, 2023

This Conflict Minerals Report for ASML Holding N.V. (“ASML”, “we”, “us” or “our”) covers the reporting period from January 1, 2023 to December 31, 2023, and is filed in compliance with Rule 13p-1 of the Securities Exchange Act of 1934 (the “Rule”). The Rule was adopted by the Securities Exchange Commission (the “SEC”) to implement reporting requirements related to “conflict minerals”. Conflict minerals are defined under the Rule as columbite-tantalite (coltan), cassiterite, wolframite, gold and their derivatives, which are currently limited to tin, tantalum and tungsten (“3TG minerals” or “conflict minerals”). This Conflict Minerals Report (“CMR”), filed as Exhibit 1.01 to our Specialized Disclosure Report on Form SD, is focused on the minerals tin, tantalum, tungsten and gold, as these are the 3TG minerals that we use to manufacture our products and that are needed for our products to function.

Form SD provides that if 3TG minerals are necessary to the functionality or production of a product manufactured by an SEC registrant, such registrant is required to conduct in good faith a reasonable country of origin inquiry (“RCOI”) that is reasonably designed to determine whether any such conflict minerals that are necessary to the functionality or production of products originated in the Democratic Republic of the Congo (the “DRC”) or an adjoining country (collectively, the “Covered Countries”), and such registrant is also required to describe the RCOI and disclose the results thereof.

We need certain 3TG minerals to manufacture our products, and our products need certain 3TG minerals to function.

Statements in this CMR are based on our RCOI and our due diligence activities performed in good faith for the reporting period from January 1, 2023 to December 31, 2023 and are based on information available at the time of this filing, unless otherwise indicated. Factors that could affect the accuracy of these statements include incomplete supplier data or available smelter and/or refiner (collectively referred to as “smelter(s)”) data, errors or omissions by suppliers or smelters, certifications of smelters, and other factors. Terms used but not defined herein have the meaning ascribed thereto in the Rule and Form SD.

We are committed to responsible sourcing of materials in our supply chain and support international efforts to ensure the mining and trading of 3TG minerals from conflict-affected and high-risk areas does not contribute to conditions of armed conflict and/or serious human rights abuses in the DRC or its adjoining countries as defined in Form SD.

Business Overview

ASML is a leading supplier to the semiconductor industry, providing chipmakers with hardware, software and services – to mass produce patterns of integrated circuits (microchips) through lithography. Globally, microchips power a broad range of electronic, communication and information technology products.

At ASML, we take a holistic approach to lithography technology. We integrate lithography systems with computational tools, metrology and inspection systems, and process control software solutions. This holistic approach to lithography technology enables us to provide chipmakers with support and solutions at every stage of the chipmaking process, from early design and development to high-volume production.

Our holistic lithography product portfolio

•In 1991, before EUV, before immersion and even before our TWINSCAN systems, we launched the PAS 5500, which proved to be our breakthrough platform. This system, equipped with i-line, KrF and ArF light sources for processing wafers up to 200 mm in diameter, significantly reduced microchip manufacturing times for our customers. Its modular design enabled them to produce multiple generations of advanced chips with a resolution down to 90 nm using the same system. Although PAS 5500 systems are no longer produced, they are still in use today – our refurbished products business refurbishes and upgrades our older lithography systems to extend their lives and offer associated services.

•Deep ultraviolet (DUV) lithography systems are the workhorses of the industry, producing the majority of layers in microchips. Supporting numerous market segments, we offer immersion as well as dry lithography systems (XT and NXT platform), and a range of light sources to offer all wavelengths currently used in the semiconductor industry – argon fluoride (ArF) for 193 nm wavelength, krypton fluoride (KrF) for 248 nm and mercury gas discharge lamp (i-line) for 365 nm. Our systems lead the industry in productivity, imaging and overlay performance to help manufacture a broad range of semiconductor nodes and technologies, and support the industry’s cost- and energy-efficient scaling.

•Using light at a wavelength of 13.5 nm, our TWINSCAN NXE platform with a numerical aperture (NA) of 0.33 is the industry’s first high-volume production platform for EUV lithography, currently offering 13 nm resolution with off-axis illumination and 2 nm match machine overlay performance. With our TWINSCAN EXE – or High NA – platform, we offer the latest generation in EUV lithography. The innovative new optical system of this platform, with a higher NA of 0.55, provides higher contrast and a resolution of just 8 nm.

•Our metrology and inspection systems allow chipmakers to measure the patterns that they print on the wafer to see how well they match the intended pattern. Our portfolio enables chipmakers to monitor most steps of bringing a chip to market, from R&D to mass production.

•By bringing together the different elements of our holistic lithography portfolio, we help our customers understand and correct for potential issues that could cause variations or errors. This helps minimize any deviation between the intended and printed features of a microchip layout, thereby optimizing the lithography system’s performance, stability and yield, – including maximizing the number of good wafers per day – and enabling ever smaller chip features.

Use of 3TG minerals

Like many companies in the semiconductor industry, our products contain certain minerals and metals necessary to the functionality or production of our products, including 3TG minerals. We need 3TG minerals to manufacture our products, and our products need 3TG minerals to function, mainly in the electronics and optics categories. We use gold, for example, in coating critical electronic connectors, and tin for welding electronic components and creating EUV light.

Our supply chain

We outsource the production of several components that are necessary for the manufacturing of our systems. Therefore, we collaborate with our suppliers for the development, manufacturing and delivery of unique parts and modules used in our lithography systems. The sourcing of 3TG minerals used in our products goes beyond our tier 1 suppliers. There are several tiers of suppliers between ASML and any smelter of conflict minerals, and even more tiers when tracing a mineral or metal all the way back to the mines of origin. We do not have a direct purchasing relationship with miners or smelters.

Due Diligence Program

We base our due diligence measures on the guidelines of the five-step framework set forth by the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (“OECD Guidance”) as summarized below.

1: Establish strong company management system

•Policy: Conflict minerals is an integrated part of our Human Rights Policy which is supported by our Code of Conduct and Anti-Bribery and Anti-Corruption policy, all of which are available on our company website at www.asml.com. The website and the information accessible through it are not incorporated into this Form SD.

•Governance: To ensure compliance with the conflict minerals regulations, we formed a Conflict Minerals Team (the “CM Team”), comprising experts from the Strategic Sourcing & Procurement, Development & Engineering, Legal & Compliance, ESG Sustainability and Finance Annual & ESG reporting teams. This inter-departmental CM Team agrees on an approach to meet ASML’s ambition with respect to conflict minerals and ensures that an RCOI and due diligence is carried out in accordance with applicable conflict minerals regulations and guidelines. The results of our due diligence activities are monitored and reviewed by members of the CM Team and discussed with our Chief Executive Officer (“CEO”) and other members of senior management.

•Control system: We utilize a system of controls through the use of due diligence tools that are developed by the Responsible Minerals Initiative (“RMI”), such as the Conflict Minerals Reporting Template (“CMRT”) and the RMI Active and Conformant Facilities List (“RMI Smelters list”), which is validated through the Responsible Minerals Assurance Process (“RMAP”). This system is intended to identify smelters that have systems in place to assure sourcing of only conflict-free minerals.

•Supplier engagement: ASML became a member of the Responsible Business Alliance (“RBA”) in 2011 and adopted the RBA Code of Conduct as the Code with which suppliers must comply. In addition, the supplier handbook sets out expectations for suppliers. We require our suppliers to establish similar due diligence programs for their own supply chain. We communicate with in-scope suppliers (as described below) in a variety of ways, including the distribution of supplier newsletters, supplier handbooks and engagement via the RBA platform to require and validate compliance with the RBA Code of Conduct and raise awareness for adequate due diligence.

•Grievance mechanism: We encourage everyone, including suppliers and other stakeholders to express, in good faith, any concerns they might have regarding possible violations of our Code of Conduct, our company’s policies or the law. We have a Speak Up system available, which can be found on our company website, to report breaches anonymously.

2: Identify and assess risks in the supply chain

•Our supply chain conflict mineral due diligence is risk based, as described in the bullet points below.

•With the support of our Product Regulatory and Compliance experts from Development & Engineering, we executed a scoping assessment to determine which purchased parts might contain 3TG minerals. This information together with the direct spending volumes were input to select those suppliers in scope to be surveyed using the CMRT.

•Annually, we ask in-scope suppliers to complete a CMRT in order to collect information about the smelters of 3TG used in our products.

•We assess the CMRTs received from our in-scope suppliers for red flags, completeness and reasonableness based on OECD Guidance for Conflict-Affected and High Risk Areas globally, including the Covered Countries.

•We assess whether each smelter disclosed by our in-scope suppliers was a conformant, active or standard smelter by checking against the smelter data provided by the RMI to its members.

•We communicate with in-scope suppliers the reported smelters which were not yet identified as RMAP conformant. We request our in-scope suppliers to mitigate risks linked to non-conformant smelters and promote commitment to conflict-free minerals with their suppliers.

•In our broader supply chain due diligence processes, we use the RBA Risk Assessment Platform to identify inherent risks related to labor (including human rights), ethics, health & safety and environmental matters standards across our supply base. In the event a high risk is identified, we engage with the supplier and conduct a more detailed analysis. We are including human rights and environmental considerations in our supplier audit program.

3: Design and implement a strategy to respond to identified risks

•As part of our RBA membership, we support initiatives which foster better working conditions and raw material production. We also support the RMI, including the RMAP. The RMAP is designed to provide assurance on smelters due diligence processes.

•In addition to working closely with our own suppliers and other original equipment manufacturers (“OEMs”), we also participate in global initiatives led by the RBA to address the industry-wide concerns surrounding conflict minerals. These organizations support information sharing among suppliers and OEMs, including the identification and conflict-free status of 3TG smelters.

4: Carry out independent third-party audit

•As a member of the RBA, we rely upon the RMI for information regarding smelters and their conformance with RMAP standards. RMAP uses an independent third-party assessment to validate smelters' management processes for responsible mineral procurement.

•We use information provided by in-scope suppliers in their CMRTs and the RMI Smelters list to identify the country of origin of the smelters utilized by suppliers and to validate their conformance with RMAP standards for responsible minerals procurement.

5: Report annually on supply chain due diligence

•We file and publish a CMR annually, and it is publicly available on our company website.

•We report annually on our responsible supply chain activities in our Annual Report.

Results of the Reasonable Country of Origin Inquiry

In accordance with the Rule, ASML conducted in good faith a reasonable RCOI to determine whether any of the conflict minerals that are necessary to the functionality and production of our products may have originated in the Covered Countries.

Because the information that we obtained from our in-scope suppliers was incomplete, other than as set forth below with respect to the conflict minerals that were either necessary to the production of our products or necessary to the products’ functionality, we were unable to fully determine the countries of origin of the conflict minerals or the facilities used to process them.

The results of the RCOI indicated that some of the 3TG minerals necessary to the functionality or production of our products may have originated in the Covered Countries and may not be derived from recycled or scrap sources.

Description of Due Diligence Measures Performed

Due diligence has been performed in a manner consistent with the OECD Guidance as described above in the section “Due Diligence Program”. ASML regularly reviews and revises its supply chain due diligence processes with the aim of incorporating learnings from practice, feedback from stakeholders and requirements from standards and regulations.

This year we have changed the manner in which we present our due diligence results by reporting on the smelters identified as RMAP Conformant as opposed to the number of suppliers that are confirmed conflict minerals free. Even in well-managed supply chains human rights violations may occur, and therefore we believe that supply chains should not be definitively described as “conflict free”. The most important part of responsible sourcing is the evidence that companies are actively, continually checking their supply chains to look for red flags and risks, and when necessary, taking the appropriate steps to address these risks.

Results of the Due Diligence

In 2023, we increased the supplier scope and emphasis on the importance of the CMRT completion. Out of 329 in-scope suppliers, 46 suppliers did not provide us with a (complete) CMRT. Out of these 283 suppliers who provided a complete CMRT, 58 suppliers indicated that there were no 3TG minerals in the products that they supplied to ASML.

The remaining in-scope suppliers provided a complete CMRT with information that we use to determine the unique smelters in the supply chain (excluding duplicates). We identified 482 unique smelters in 2023, of which 236 are RMAP Conformant (as of May 2024).

Continuous improvements

We aim for RMAP Conformant smelters only in our supply chain.

We therefore continue to strengthen our due diligence process by requiring our suppliers:

•To improve their responses to our RCOI in terms of accuracy, timeliness and completeness.

•To correctly implement the due diligence requirements as specified in the RBA Code of Conduct.

•To push for audits of non-conformant smelters.

Cautionary Statements

This CMR contains statements obtained in reliance to information provided by our suppliers through our reasonable country of origin inquiry as well as our due diligence measures. We have no direct relationships or power of control over mines, smelters, or refiners. Therefore, we rely on our suppliers for the ultimate veracity of the information which they provide about the smelters or refiners whom they employ, and such information may be inaccurate, incomplete, or subject to other irregularities. Additionally, despite our continuous efforts, we may be unable to determine the precise (country of) origin of the 3TG minerals, included in all our products, or the facilities used to process them, due to 3TG minerals supply-chain complexities, the number of tiers of suppliers to trace the source and the limited number of RMAP conformant smelters for all 3TG minerals.

Forward Looking Statements

This document contains statements that are “forward-looking” within the meaning of the Private Securities Litigation Reform Act of 1995, including statements relating to our business and compliance efforts, including with respect to conflict minerals. You can generally identify these statements by the use of words like “may”, “could”, “should”, “believe”, “expect”, “plan”, “intend”, “continue”, “commitment” and variations of these words or comparable words. Such forward-looking statements includes statements relating to our business and our products, including expectations in connection with the TWINSCAN EXE platform, the features and performance of our systems, our conflicts minerals policies, RCOI, our commitments with respect sourcing of materials in our supply chain, our commitment to conflict free minerals and responsible mineral sourcing, our current due diligence procedures and plans to improve the due diligence process and results, including plans to expand the scope of our supplier audit program, plans to encourage suppliers to trace origins of 3TG minerals within their supply chain and other plans and intentions with regard to conflicts minerals and other non-historical statements.

Forward-looking statements do not guarantee future performance and involve risks and uncertainties. These risks and uncertainties include potential changes in our reporting obligations or practices under the Rule and related conflict minerals rules, our ability to implement certain processes and policies related to conflicts minerals, our ability to obtain information from our suppliers, our ability to effectively trace the origins of 3TG minerals, our ability to improve our due diligence process for conflict minerals, our ability to successfully meet our commitments in the field of conflicts minerals, risks relating to the performance of our tools and other risks indicated in the risk factors included in ASML’s Annual Report on Form 20-F and its other filings with the US Securities and Exchange Commission. These forward-looking statements are made only as of the date of this document. ASML does not undertake to update or revise the forward-looking statements, whether as a result of new information, future events or otherwise.

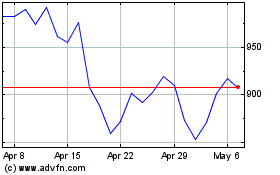

ASML Holding NV (NASDAQ:ASML)

Historical Stock Chart

From Jun 2024 to Jul 2024

ASML Holding NV (NASDAQ:ASML)

Historical Stock Chart

From Jul 2023 to Jul 2024