AMI DODUCO Expands its European Silver Powder Production

February 05 2009 - 8:09AM

Business Wire

AMI DODUCO, a Technitrol (NYSE: TNL) company, announced the

completion of a two-year expansion of silver powder production and

recovery capacity in Europe.

Despite recent negative overall trends in industrial markets,

demand for silver powders globally has been driven by growth in

wind and solar energy, fuel cell and thermal management

technologies. Other innovative applications such as antibacterial

coatings, conductive polymer systems and ceramic and metallic

sinter materials are also less affected by the current market

downturn. They all call for silver powder of the highest purity and

in a variety of classifications.

AMI DODUCO has at its disposal a wide range of different

manufacturing processes to meet these requirements, including:

-- Atomization of molten silver, which produces a

high-tap-density powder made up of spherical particles;

-- Electrolysis, which produces dendritic to crystalline forms;

and

-- Precipitation, which chemically creates very fine

agglomerated powders with large specific surfaces.

These capabilities, coupled with AMI DODUCO�s technical

know-how, enable customers to specify exact blends of powders to

achieve performance characteristics within tolerances otherwise

unattainable.

Subsequently milling fine powders produces silver flakes with

special flow properties. In addition to the surface finish, the

subsequent processes depend on particle size distribution and

morphology.

Silver has the highest conductivity of all metals, a property it

brings to preparations and materials made from it. Once in powder

form, silver can be processed without further need for high

temperatures. With the appropriate production techniques, silver

powder products can then be used to create conductive paints,

adhesives and pastes.

Because silver powder production and silver recovery form a

closed loop, both are core activities at AMI DODUCO. Capacity has

been undergoing expansion since 2006:

-- 2006: Silver refining capacity is increased to 400 tons per

year, corresponding to 7% of the world market capacity;

-- 2007: Capacity for atomized powder is increased by 40%;

and

-- 2008: Capacities for electrolytically and chemically

deposited silver are doubled.

�All the relevant expertise is centralized at our facility in

Pforzheim, where we have a complete infrastructure for the

manufacture and reprocessing of silver materials for the electrical

industry,� said Christian J. Hagedorn, Vice President of Marketing

and Sales for AMI DODUCO � Europe. �Our investment will enable us

to anticipate market growth and ensure continued supply in

just-in-time fashion.�

AMI DODUCO is a global leader in electrical contact technology

and fabrication. The company supplies contacts and assemblies,

contact materials, electroplating and surface treatment services,

and precious metal refining and recycling to more than 3,000

customers. AMI DODUCO operates from locations in North America,

Europe and Asia. The company�s website is www.amidoduco.com.

Copyright � 2009 AMI DODUCO, Inc. All rights reserved. All brand

names and trademarks are properties of their respective

holders.

Cautionary Note: This message contains "forward looking

statements" within the meaning of the Private Securities Litigation

Reform Act of 1995. Actual results may differ materially. This

release should be read in conjunction with the factors set forth in

Technitrol's report on Form 10-Q for the quarter ended September

26, 2008 in Item 1a under the caption �Factors that May Affect

Our Future Results (Cautionary Statements for Purposes of the 'Safe

Harbor' Provisions of the Private Securities Litigation Reform Act

of 1995).

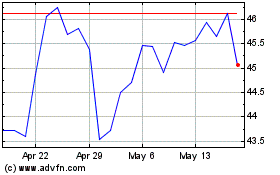

Travel plus Leisure (NYSE:TNL)

Historical Stock Chart

From Jun 2024 to Jul 2024

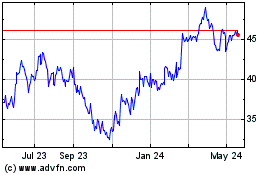

Travel plus Leisure (NYSE:TNL)

Historical Stock Chart

From Jul 2023 to Jul 2024