Overview

The World Steel industry is rather concentrated in structure, with

a few producers accounting for the lion’s share of sales.

Steel products are classified into four broad categories: flat

steel products, long steel products, scrap and semi-finished

products. Flat products include plates, hot-rolled strip and sheets

and cold-rolled strip and sheets. The long steel product category

comprises wire rods, beams, reinforced bars and merchant bars. The

products under both these categories are rolled from steel slabs,

which are considered as unfinished or semi-finished products that

are generally not sold.

Historically, the automotive and construction markets have remained

the largest consumers of steel, absorbing more than half of the

total steel produced. Large automakers such as

General

Motors Company (GM),

Ford Motor Company

(F),

Toyota Motor Corporation (TM) and

Honda Motor Company (HMC) depend upon the steel

industry. Other steel consuming industries include appliances,

agricultural implements, converters, containers, energy, electrical

equipment and industrial machinery.

Production

World crude steel production has continued to show a steady

increase since April 2009 on the back of a moderate rise in demand

and the resumption of work at idled facilities. China has emerged

as a major producer and consumer of steel.

According to the World Steel Association (WSA), world crude steel

production was 124 million metric tons (mmt) in September 2011, up

9.7% year over year.

ArcelorMittal (MT) -- a

leader in all major global carbon steel markets, including

automotive, construction, household appliances and packaging, with

leading R&D and technology -- produced 90.6 million tons of

crude steel in 2010, representing approximately 6% of world steel

output. In the first nine months of 2011, the company produced 70.2

million tons of crude steel.

In the first nine months of 2011, Asia produced 728.3 mmt of crude

steel, an increase of 9.5% versus the year-ago period. The European

Union (EU) produced 135.7 mmt of crude steel in the first three

quarters of 2011, up by 4.3% compared with the corresponding three

quarters in the previous year. North America’s crude steel

production in the first nine months of 2011 was 89.3 mmt, 6.1%

higher than the first nine months of 2010.

In the EU, Germany’s crude steel production for September 2011 was

3.7 mmt, an increase of 10.3% on September 2010. Italy produced 2.6

mmt of crude steel in September 2011, 11.5% higher than September

2010. France produced 1.3 mmt of crude steel in September 2011, up

4.2% compared to September 2010. China’s crude steel production for

September 2011 was 56.7 mmt, an increase of 16.5% year over

year.

Elsewhere in Asia, Japan produced 8.9 mmt of crude steel in

September 2011, a decrease of 3.8% compared to the same month last

year. South Korea’s crude steel production for September 2011 was

5.5 mmt, up 17.7% compared to September 2010.

The US produced 7.2 mmt of crude steel in September 2011, an

increase of 8.9% compared to September 2010.

Turkey produced 3.0 mmt of crude steel in September 2011, 16.9%

higher than September 2010.

Brazilian crude steel production for September 2011 was 2.8 mmt,

3.8% higher than September 2010.

The world crude steel capacity utilization ratio of the 64

countries in September 2011 rebounded slightly to 79.1%, 1.8

percentage points higher than in August 2011. Compared to September

2010, the utilization ratio in September 2011 increased by 3.5

percentage points.

Growth Trends

With the global economy picking up in late 2009, the steel industry

started seeing signs of improvement. However, given its economic

sensitivity, we expect global steel demand to improve gradually, in

line with the recovery in the user industries, especially

automotive and residential construction.

According to World Steel Association, in the first half of 2011,

the worldwide demand for steel has remained on the improving trend

line. This is despite a series of anticipated and unanticipated

negative developments: the ongoing euro area sovereign debt crisis,

the earthquakes in Japan , the political/social unrest in some

countries of the MENA region leading to the related surge in oil

prices and the tightening of government monetary measures in many

emerging economies.

Today the global economy is facing increased uncertainty over the

ongoing turmoil in the financial markets and how it will affect the

real economy. The WSA’s current forecast for 2012 assumes that

developing economies continue to drive global growth and the policy

response to the European sovereign debt crisis prevents increased

volatility in the equity and financial markets.

WSA expects to see growth performance varying widely across

regions. Not surprisingly, the recovery of steel demand in the

developed world is expected to be slow, while most of the emerging

and developing world should continue to enjoy robust growth in

steel demand.

China’s apparent steel use in 2011 is expected to increase by 7.5%

to 643.2 mmt following an 8.5% growth in 2010. In 2012, steel

demand is expected to maintain a 6.0% growth, which will bring

China’s apparent steel use to 681.6 mmt.

In 2011, India’s steel use is forecast to grow by 4.3% to reach

67.7 mmt due to economic growth. In 2012, the growth rate is

forecast to accelerate to 7.9%.

Apparent steel use in the US is forecast to rebound strongly by

11.6% in 2011. In 2012, steel use in the US is expected to grow by

5.2% to 93.8 mmt, bringing it back to 87% of the 2007 level. For

NAFTA as a whole, apparent steel use will grow by 9.0% and 4.9% in

2011 and 2012, respectively.

In Central and South America, apparent steel use is forecast to

grow by 4.7% in 2011 to reach a historical high of 47.8 mmt. In

2012, the region’s apparent steel use is forecast to grow by 9.8%

to reach 52.4 mmt, almost 28% higher than the 2007 level.

European countries continued to show divergent recovery paths in

2011. While steel demand in Germany and Poland are expected to grow

at impressive rates, steel demand in Spain in contrast is expected

to record a sluggish 1.7% recovery.

Overall, apparent steel use in the EU is projected to increase by

7.0% in 2011 to 155.0 mmt. In 2012, the growth of steel demand is

expected to stall in most of the European countries with the

notable exception of Poland, which is forecast to post an

impressive 9.5% growth. Overall, apparent steel use in the EU is

forecast to grow by 2.5% to around 158.9 mmt in 2012, bringing it

back to only 80% of the 2007 peak.

Japan’s steel use is expected to decline by 2.7% to 61.8 mmt in

2011 due mainly to the disruptions caused by the earthquake. In

2012 apparent steel use in Japan is forecast to show a growth of

0.8% to reach 62.3 mmt, 77% of the 2007 level.

In the CIS, apparent steel use is forecast to grow by a strong

14.4% in 2011 and then by 7.5% in 2012. These projections will

bring the region’s apparent steel use in 2012 to almost 60 mmt, a

new high for the region.

Steel demand in the MENA region is expected to fall by 0.9% in

2011, mainly due to downward revisions from North African

countries. However, boosted by high oil prices, steel use in the

region is forecast to resume growth in 2012 at a rate of 8.7%.

Given that the political situation in the region is far from

settled, there exist considerable uncertainties about the current

forecasts for this region.

As per WSA’s forecast by 2012, steel use in the developed world

will still be at 15% below the 2007 level whereas in the emerging

and developing economies, it will be 44% above. In 2012, the

emerging and developing economies will account for 73% of world

steel demand in contrast to 61% in 2007.

The steel industry has recorded high growth rates in both

production and consumption over the past few years, benefiting from

soaring steel demand in the automobile and construction sectors

before the recession. Moreover, cost effective and highly efficient

steel-making technologies have lifted the demand for US steel in

the Middle Eastern and Asian countries.

Here, we will discuss the recent results of a few companies, whose

results were aided by higher selling prices and increased

shipments, and their growth expectations.

ArcelorMittal reported diluted net earnings of 19 cents per share

in the third quarter of 2011, much below the Zacks Consensus

Estimate of 51 cents and last year’s 89 cents per share. Total

steel shipments in the third quarter of 2011 were 21.1 million

metric tons compared with 20.5 million metric tons in the year-ago

quarter.

Quarterly revenues increased 22.6% year over year to $24.2 billion

from $19.7 billion in the year-ago quarter and decreased 3.6%

sequentially from $25.1 billion. Sales were down sequentially

primarily due to lower average steel selling prices (-1.7%) and

lower volume of shipments (-4.9%).

The company’s EBITDA in the second half of 2011 is expected to

exceed the level achieved in the comparable period of 2010. The

company expects shipments in fourth quarter 2011 to be lower

sequentially, reflecting economic uncertainties leading to

customers adopting a “wait and see” approach.

Higher iron ore and coal volumes will continue to be a positive

underlying driver. The company’s iron ore and coal production is

expected to increase by 10% and 20% respectively, by the end of

2011 as compared with 2010.

In light of the recent market uncertainty, the company is focusing

on core growth capital expenditure. This will result in

postponement of some planned steel investments. Accordingly,

full-year 2011 capital expenditure is expected to be below the

previously targeted level of $5.5 billion. Our long-term

recommendation on ArcelorMittal remains Outperform, though it has a

Zacks #3 Rank (Hold).

The commercial metals company

AK Steel Holding

(AKS) posted its third-quarter 2011 results, delivering a net loss

of $3.5 million or $0.03 cents compared with a net loss of $59.2

million or $0.54 cents during the year-ago quarter. However,

results were below the Zacks Consensus Estimate of $0.00 cents per

share.

Net sales, as reported by the company, were $1,585.8 million on the

shipments of 1,368,800 tons versus $1,575.9 million and 1,465,800

tons in the prior-year quarter. Net sales also missed the Zacks

Estimate of $1,662 million. Average selling price for the third

quarter of 2011 was $1,158 per ton, up 8% year over year, but down

2% sequentially.

Value-added shipments for stainless/electrical increased to 229.3

tons compared with 226.9 tons in the prior-year quarter.

Value-added shipments for Coated, Cold-rolled and Tubular product

decreased to 577.2, 278.3 and 32.4 tons, respectively, compared

with 624.4, 322.5 and 33.2 tons, respectively, in the year-earlier

quarter.

Non-value-added shipments including Hot-rolled increased to 222.6

tons from 213.6 tons in the year-earlier quarter. Non-value-added

shipments including secondary products decreased to 29.0 tons from

45.2 tons in the prior-year quarter. AK Steel currently retains a

Zacks #3 Rank (short-term Hold rating). Our long-term

recommendation also remains Neutral.

Allegheny Technologies Inc. (ATI) also earned

$70.6 million or 63 cents per share (excluding acquisition related

expenses of $8.3 million, net of tax) in the third quarter of 2011

up from $1.0 million or 1 cent in the same quarter of 2010. Results

exceeded the Zacks Consensus Estimate of 61 cents.

Sales in the quarter increased 28% to $1.35 billion, driven by

higher shipments for most high-value products, higher raw material

surcharges and increases in average base selling prices for many

products. However, sales were lower than the Zacks Consensus

Estimate of $1.39 billion.

Segment operating profit surged 157% to $161.8 million, or 12.0% of

sales, from $63.0 million, or 6.0% of sales, in the third quarter

of 2010.

Allegheny expects to continue to benefit from its new alloys and

products, diversified global growth markets and differentiated

product mix over the next 3 to 5 years. Demand is expected to be

strong for its mill products and highly engineered forged and cast

components from the aerospace market.

Strong growth is also expected from the oil and gas/chemical

process industry for its titanium-based alloys, nickel-based alloys

and specialty alloys, and tungsten products. We currently have a

Neutral long-term recommendation on the stock, which is the same as

reflected in the Zacks #3 Rank (Hold) rating.

Nucor Corporation (NUE) reported net earnings of

$181.5 million, or 57 cents per diluted share (excluding special

items) in the third quarter of 2011, beating the Zacks Consensus

Estimate of 51 cents per share. This was a significant increase

from $23.5 million, or 7 cents per diluted share (excluding special

items) reported in the year-ago quarter. Nucor’s third-quarter

earnings exceeded those of last year's quarter, but they declined

from the second quarter of this year on lower steel prices and

significantly lower metal margins.

Consolidated sales surged 27% year over year to $5.25 billion,

beating the Zacks Consensus Estimate of $4.86 billion. The growth

was attributable to an increase of 24% in average price per ton and

a rise of 3% in shipments (to 5.8 million tons) to outside

customers. The company’s end-markets such as automotive, heavy

equipment, energy and general manufacturing demonstrated strength

compared to 2010 but showed very little improvement compared with

the first half of 2011.

Steel mill shipments grew 9% to 4.2 million tons during the

quarter. The average scrap and scrap substitute cost per ton

accelerated 27% to $449.

Although Nucor expects to see only slight improvement in demand in

its non-residential construction markets through the end of 2011,

it remains optimistic about its combined construction businesses

(steel mills and downstream facilities) and anticipates that it

will continue to operate profitably.

Nucor expects fourth-quarter earnings to be below its third-quarter

level. The company expects margin compression in the sheet market

in the fourth quarter of 2011. Furthermore, the company forecasts a

smaller compression in plate margins due to imports. The magnitude

of margin compression will be favorably impacted by expected lower

scrap costs through the quarter.

The company has a Zacks #3 Rank (Hold) Rank on its stock.

Industry Capacity

The global steel industry is capital intensive, cyclical, highly

competitive and has historically been characterized by

overcapacity. Capacity utilization rates were, however, low (around

60%) at the beginning of 2009, in response to the much softer

demand. With steel demand picking up in the latter half of the

year, the world crude steel capacity utilization ratio in January

2011 was 75.6%, up from 73.3% in December 2010.

Steel makers continue to add capacity besides resuming operations

at the idled facilities, inspired by the expected rebound in steel

industry in the longer term.

Price Trends

The steel industry has long witnessed volatility in prices with a

large spot market. Steel prices rose steadily for most of 2008,

after which there was a downtrend. Lower prices had an adverse

effect on steel producers, who recorded lower revenues and margins,

and had to write down finished steel and raw material

inventories.

The period witnessed major steel producers slashing production to

minimize inventory accumulation.

U.S. Steel

Corporation (X), the eleventh-largest steel producer

worldwide, slashed production by almost 62% during the second

quarter of 2009, while Korean steel maker

POSCO

(PKX) cut production by about 15%. This was the first time in its

history that POSCO was forced to adopt such a measure, which is a

proof of the adverse operating environment.

Steel prices globally have fallen from highs marked earlier this

year in 2011 as the industry hasn't shaken off a pronounced

slowdown in purchasing and demand since mid-year. A weakening in

orders and buying sentiment first took hold this year in Europe,

before spreading to North America and Asia.

Although steel prices have been stabilizing since the latter part

of 2009, they are significantly below the pre-crisis level. We

believe that a sustained recovery in steel prices remains uncertain

in the backdrop of sluggish economic activity.

Factors Affecting Steel Prices

Chinese Imports: The steel industry is also affected by

fluctuations in steel imports–exports and tariffs. China is the

largest steel producer globally, and balances its domestic

production and consumption, which is an important factor in global

steel prices.

Consumers in the U.S. are importing cheaper steel from China, which

is forcing domestic steel producers to sell at lower prices, and

even at a loss, sometimes. To this end, the U.S. government has

been imposing anti-dumping duties on Chinese steel imports.

Economic Sustainability: Concerns about the sustainability

of economic recovery and queries regarding China’s growth momentum

come into play in the pricing equation. This relatively uncertain

Chinese outlook, coupled with a still tentative recovery in the

developed world, is expected to weigh on prices.

Threat from substitutes: Steel has many substitutes like

aluminum, which replaces it in the automotive markets. Cement,

composites, glass, plastic and wood are also used as steel

substitutes. This significantly influences market prices and demand

for steel products.

Raw Material Trends

The key input for steel production is iron ore. Apart from this,

coking coal and coke, scrap, electricity and natural gas are also

used as inputs in steel production. The raw materials industry is

highly concentrated with only three major players --

Vale (VALE),

Rio Tinto (RTP) and

BHP Billiton (BHP) -- having significant pricing

power. The risk lies in further consolidation among raw material

suppliers. For instance, the announced iron ore joint venture

between mining companies BHP Billiton and Rio Tinto would further

increase the pricing power of both the suppliers.

Steel makers would face higher production costs if suppliers shift

to sales based on spot prices from the long-term fixed price

contract system, as spot prices for most of the raw materials,

especially iron ore, remained high from 2006 through 2008.

Iron ore prices have remained volatile during most of 2010 and are

expected to rise sharply in 2011. ArcelorMittal’s iron ore and coal

mining projects have been a key focus in the recent years and this

focus is only expected to intensify in the medium term, as the

company has a goal to secure 100 million tons of iron ore supply

from its own mines and under strategic long-term supply contracts

on a cost-plus basis.

Consolidation

Mergers and acquisitions (M&A) have remained an important

growth strategy in the steel industry. M&A activities prevent

additional steel capacity, providing production efficiency and

economies of scale. The biggest example is Mittal Steel’s

acquisition of Arcelor in 2006. The Tata Steel and Corus merger in

2008 is another instance of industry consolidation.

Consolidation has been primarily driven by the urge to increase

global scale and operations, and access new markets. The industry

is likely to see more M&A activity in the coming years as the

industry players prepare themselves for a recovery in the long

run.

Zacks Recommendation

Prospects for 2012 have remained mildly positive despite high

levels of uncertainty surrounding the outlook for end-users in the

EU. Activity in the manufacturing sectors and in construction will

continue to grow, albeit in the case of the manufacturing industry

at a significantly slower pace than in 2010 and 2011.

Particularly in the first half of 2012, real steel consumption is

forecast to grow only modestly. From mid-2012 onwards improving

end-user fundamentals should result in a modest acceleration in

consumption growth.

In China, the government’s expansionary economic policies, easy

credit and construction initiatives have thus far sustained demand.

But with China attempting to rein in its overheated property sector

and engineer a soft landing for its economy, steel demand will most

likely soften noticeably in the coming months. This relatively

uncertain Chinese outlook, coupled with a still tentative recovery

in the developed world, is expected to weigh on prices.

In the short term, we are neutral on steel manufacturers like

AK Steel (AKS),

U.S. Steel (X)

and

Nucor (NUE).

AK Steel’s cost structure is higher than its peer group due to a

greater reliance on external supply of raw materials such as carbon

scrap, purchased slabs, iron ore and purchased coke. Iron ore is

the key raw material in steel manufacturing operations.

However, industry giants with integrated business models like U.S.

Steel and ArcelorMittal have an edge over their peers. Both steel

makers have substantial captive sources of iron ore and coal and

source about 75%–80% of their coke and iron ore requirements from

owned and/or operated facilities.

AK STEEL HLDG (AKS): Free Stock Analysis Report

ALLEGHENY TECH (ATI): Free Stock Analysis Report

BHP BILLITN LTD (BHP): Free Stock Analysis Report

FORD MOTOR CO (F): Free Stock Analysis Report

GENERAL MOTORS (GM): Free Stock Analysis Report

HONDA MOTOR (HMC): Free Stock Analysis Report

ARCELOR MITTAL (MT): Free Stock Analysis Report

NUCOR CORP (NUE): Free Stock Analysis Report

POSCO-ADR (PKX): Free Stock Analysis Report

TOYOTA MOTOR CP (TM): Free Stock Analysis Report

VALE RIO DO-ADR (VALE): Free Stock Analysis Report

UTD STATES STL (X): Free Stock Analysis Report

Zacks Investment Research

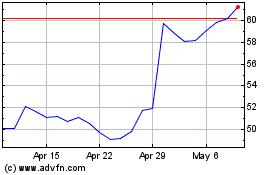

ATI (NYSE:ATI)

Historical Stock Chart

From May 2024 to Jun 2024

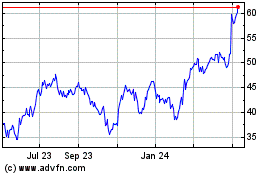

ATI (NYSE:ATI)

Historical Stock Chart

From Jun 2023 to Jun 2024