Report of Foreign Issuer Pursuant to Rule 13a-16 or 15d-16 (6-k)

December 01 2021 - 7:21AM

Edgar (US Regulatory)

United States

Securities and Exchange Commission

Washington, D.C. 20549

FORM 6-K

Report of Foreign Private Issuer

Pursuant to Rule 13a-16 or 15d-16

of the

Securities Exchange Act of 1934

For the month of

November 2021

Vale S.A.

Praia de Botafogo nº 186, 18º andar,

Botafogo

22250-145 Rio de Janeiro, RJ, Brazil

(Address of principal executive office)

(Indicate by check mark whether the registrant files

or will file annual reports under cover of Form 20-F or Form 40-F.)

(Check One) Form 20-F x

Form 40-F ¨

(Indicate by check mark if the registrant is submitting the Form 6-K

in paper as permitted by Regulation S-T Rule 101(b)(1))

(Check One) Yes ¨ No

x

(Indicate by check mark if the registrant is submitting the Form 6-K

in paper as permitted by Regulation S-T Rule 101(b)(7))

(Check

One) Yes ¨ No x

(Indicate by check mark whether the registrant by furnishing the information

contained in this Form is also thereby furnishing information to the Commission pursuant to Rule 12g3-2(b) under the Securities Exchange

Act of 1934.)

(Check One) Yes ¨ No x

(If “Yes” is marked, indicate below the file number assigned

to the registrant in connection with Rule 12g3-2(b). 82- .)

|

|

1

|

|

|

2

Disclaimer

“This presentation may include statements that present Vale's expectations about future events or

results. All statements, when based upon expectations about the future involve various risks and

uncertainties. Vale cannot guarantee that such statements will prove correct. These risks and

uncertainties include factors related to the following: (a) the countries where we operate, especially

Brazil and Canada; (b) the global economy; (c) the capital markets; (d) the mining and metals prices

and their dependence on global industrial production, which is cyclical by nature; (e) global

competition in the markets in which Vale operates; and (f) the estimation of mineral resources and

reserves, the exploration of mineral reserves and resources and the development of mining facilities,

our ability to obtain or renew licenses, the depletion and exhaustion of mines and mineral reserves

and resources. To obtain further information on factors that may lead to results different from those

forecast by Vale, please consult the reports Vale files with the U.S. Securities and Exchange

Commission (SEC), the Brazilian Comissão de Valores Mobiliários (CVM) and in particular the factors

discussed under “Forward-Looking Statements” and “Risk Factors” in Vale’s annual report on Form

20-F.”

“Cautionary Note to U.S. Investors – Vale currently complies with SEC Industry Guide 7 in its reporting

of mineral reserves in SEC filings. SEC Industry Guide 7 permits mining companies, in their filings with

the SEC, to disclose only those mineral deposits that a company can economically and legally extract

or produce. We present certain information in this presentation that are not proven or probable

reserves, as defined by SEC Industry Guide 7, and we cannot assure you that these materials will be

converted into proven or probable reserves, as defined by SEC Industry Guide 7. Starting in its next

annual report on Form 20-F, Vale will comply with Subpart 1300 of Regulation S-K, which will replace

SEC Industry Guide 7. Subpart 1300 of Regulation S-K permits mining companies, in their filings with

the SEC, to disclose “mineral reserves”, “mineral resources” and “exploration targets” that are based

upon and accurately reflects information and supporting documentation of a qualified person. We

present certain information in this presentation that are not based upon information or documentation

of a qualified person, and that will not be permitted in an SEC filing under Subpart 1300 of Regulation

S-K. These materials are not mineral reserves, mineral resources or exploration targets, as defined by

the SEC, and we cannot assure you that these materials will be converted into mineral reserves,

mineral resources or exploration targets, as defined by the SEC. U.S. Investors should consider

closely the disclosure in our Annual Report on Form 20-K, which may be obtained from us, from our

website or at http://http://us.sec.gov/edgar.shtml.”

|

|

|

3

Our Strategic Pillars

remain solid

Vale Day 2021

New pact with society

Safety and operational excellence

Base Metals transformation

Discipline in capital allocation

Maximize flight-to-quality in Iron Ore

Vale engineer Maria Aparecida Pinho Martins,

Gelado Program, Parauapebas (PA), Brazil

|

|

|

4

Reparation, People & Safety

Eduardo Bartolomeo, CEO

Carlos Medeiros, Executive Vice President

Safety and Operational Excellence

1

|

|

|

5

We will never forget

Brumadinho

“Sowing Hope” Project for emotional

support to affected people

|

|

|

6 Click here to watch a video

|

|

|

7

1

Brumadinho, a fair and quick reparation

Individuals with indemnification agreements²

In thousands

4.6

12.0 4.7

2.7

2019 2019-

2021E

2020 2021E³

Income Transfer Program for local communities

Water security for the affected region

~55% of total payments¹

as per the Integral Reparation Agreement

Reparation, People & Safety

Projects demanded by the affected communities

98% of the victims

with at least one family member with

indemnification settlement

¹ Considers the agreement’s economic value of R$ 37.7 billion in February 2021, adjusted by the inflation until November 2021. Payments include previous disbursements and judicial deposits, as per the agreement. ² Individuals

covered by indemnification agreements entered into with Vale. ³ Average of individuals covered by agreements from January to October 2021, annualized.

|

|

|

8

Boosting changes for a talent-driven,

inclusive organization

Our targets

66% 33%

reduction in women

voluntary turnover

of black trainees hired

in the 2021 program

80%

additional women in the

workforce²

+4,500

increase in senior

female leaders

80%

managers active in

culture transformation1

99%

critical roles with

successors mapped

40% leadership roles

in Brazil occupied by

black employees by 2026

26% of women’s workforce representation

anticipated to 2025 (from 2030)

Currently at 18.7% (vs 13.5% in 2019)

1 Reparation, People & Safety

¹ Expected to achieve 95% by December 2021. ² December 2019 to November 19, 2021.

|

|

|

9

Cultural transformation monthly assessed

to ensure progress

Echoes Pulse – Employees' perception of key behaviors

+16,000

employees take part

of Echoes Pulse

82% 85%

+3

Obsession with safety

and risk management

Active listening and

engagement with society

Ownership

for the whole

Empowerment

with accountability

Open and

transparent dialogue

64%

71%

+7

65%

70%

+5

61%

67%

+6

68%

62%

+6

Pulse 1 (Dec 2020)

Pulse 2 (Sep 2021)

1 Reparation, People & Safety

|

|

|

10

Cultural

transformation

is supported by

Vale’s

management

model

|

|

|

11

2021

1.08

2019

2.43

-56%

20.9

90.4

2019 2021

+333%

EFVM railway

Total recordable

injury frequency rate

- TRIFR

Maintenance Plan

Adherence - MPA (%)

1.67 1.37

2019 2021

-18%

52.8 72.4

2021 2019

+37%

Itabira Complex

4.23

2019

1.51

2021

-64%

2021

44.6

2019

83.6

+87%

Tubarão Port

Becoming a best-in-class reliable operator with VPS

VPS¹ Excellence

Index² 1.67

2019

2.62

2021

+57%

0.80

2.01

2021 2019

+151%

2.17 1.33

2019 2021

+63%

1 Reparation, People & Safety

Note: 2021 figures are cumulative (Jan until Oct 2021). ¹ VPS is Vale’s management model. ² The Excellence index measures the VPS deployment progress.

|

|

|

12

Building a sustainable performance in OH&S¹

66 57 44

25

63

35

25

15 10 5 0

2022 2020 2018 2019 2021 2023 2025 2024

Reduction of high-potential recordable injuries

N2 - absolute values² Target

N2

N2 (10M21)

Total recordable injury frequency rate

(TRIFR)

1.98 1.84 2.14 2.65 3.21

Vale Peer 1 Peer 3 Peer 2 Peer 4

TRIFR - 2020 comparison in mining

2.25 3.48

1.98 1.46

2019 2020 2021 2018

-35%

Peer compared to Vale

1

2

3

+62% +34% +8% -7%

1 Reparation, People & Safety

¹ OH&S stands for Occupational Health & Safety. ² Includes own employees and third parties.

|

|

|

13

. Replacement of liquid

chlorine by bleach

. Replacement of liquid

propane storage in

large volumes by on-

demand natural gas

. Replacement of liquid

chlorine by bleach

. Replacement of liquid

propane storage in

large volumes by on-

demand natural gas

. Reduction of ammonium

nitrate inventory

. Reduction of ammonium

nitrate inventory

Canada

Mozambique 1,298

6,757

7 72

874

597 253

1,993

2020 2021

Scope

Risk identification

Risk treatment

Risk monitoring

100% of Vale’s

sites assessed

850 potential material

unwanted events

2,172 immediate

actions

8,750 critical

controls

¹ Hazard Identification and Risk Assessment

1 Reparation, People & Safety

Strengthening risk management through HIRA¹

|

|

|

14

Eliminating upstream dams

5

8

14 16 16 19

29

5 7

12 13

17 20

27 30

2025 2022 2024 2035 2019-

2020

2023 2021 2029

Vale Day 2020

2021 Update

Number of structures (cumulative view)

7 eliminated since 2019

23 remaining

Upstream¹ Dam²

De-characterization Program

Completion by 2035

2 completed in 2021

Forquilhas I, II

and III dams

require longer

timeframes

1 Reparation, People & Safety

¹ The same heightening method deployed at B1 dam, collapsed in Brumadinho. ² Comprises dams, dikes and waste stacks.

|

|

|

15 Click here to watch a video

|

|

|

16

Making progress with dam safety

1 Reparation, People & Safety

¹ Includes dams, dikes and drained stacks. As per the Brazilian regulation and as provided for in each Mining Dams Emergency Action Plan, considering level 3 as the critical emergency level. ² Considering the maximum number of

structures at emergency level in 2020. ³ The 31 structures encompass different heightening methods and include 11 upstream structures.

Structures at risk¹

(unit)

24 22 22

5

7 8 6

4

4 3 3

2020²

35

Jan-21 Dec-25E

33

Nov-21³

31

9 Level 3

Level 2

Level 1

Emergency level²

Level 3

Higher liquefaction risk and

back-up dams built downstream

Level 2

Anomalies identified which

require actions

Level 1

Anomalies which demand more

information, monitoring or attention

No dam at critical safety condition by 2025

|

|

|

17

Vale will comply

with the Global Industry Standard for Tailings Management

Vale

Industry

. The GISTM is

launched, based

on 15 principles

(Aug 2020)

. The 77 auditable

requirements for

adherence are made

public (May 2021)

. All tailings facilities

with “Extreme” or

“Very high” potential

consequences must

be compliant by Aug

2023

. All tailings facilities

not in a state of

safe closure must

be compliant by

Aug 2025

. 1st self-

assessment

based on the

principles

(Sep 2020)

~60% adherence¹

. Gap-assessment

based on the

conformance

protocol

(Nov 2021)

~90% adherence

(target)² ³

. External audit

. Gap treatment

2020 2021 2022 2023 2025

. In line with the

industry commitment

1 Reparation, People & Safety

¹ Based on the results of the self-assessment conducted in 2021, which had the 77 auditable requirements as main source. ² Based on the external audit results. Structures held by joint-ventures are not included. ³ Considering tailings

facilities with “Extreme” or “Very high” potential consequences.

|

|

|

18

New Pact with Society

Eduardo Bartolomeo, CEO

Luciano Siani Pires, Executive Vice President

Strategy and Business Transformation

2

|

|

|

19

. 2030 agenda revised

. Industry leader

renewable energy

. Scope 1, 2 and 3

targets

. Non-GHG targets

Environmental . Climate Change report

. ISO 14001 certification

(ongoing)

2

Leveling up ESG practices

. +300 community

relationship plans

under execution

. Formal Human

Rights Due

Diligence Process

. Increasing female

workforce

. Social ambition

Social

. Independent Board

majority, including

Chairman

. Nomination Committee

. CCO and Audit

Committee

. ESG Gaps Action Plan

. Compensation based

on ESG targets

Governance

2019 2022

New Pact with Society

|

|

|

20 Click here to watch a video

|

|

|

21

We have defined our social ambition...

. Education

. Health

. Income Generation

Resilient

communities

. Human Rights (including

Indigenous Peoples)

. Amazon

Global

causes

“To be a partner company in the development of resilient communities, engaged

in relevant issues to humanity and committed to sustainable mining”

For details of our social goals,

please visit www.vale.com/esg

. Be a good neighbor

. Create Social Value

Sustainable

mining

2 New Pact with Society

|

|

|

22

… and our 2030 Social Goals

Resilient communities

Lift 500,000 people out of extreme

poverty¹

Indigenous Peoples

Indigenous communities neighboring Vale

operations with UNDRIP2 rights plans

Sustainable Mining

Rank Top 3 in the social requirements

of the main external assessments

2 New Pact with Society

¹ People living with less than US$1.95 per day, as per the World Bank. ² United Nations Declaration on the Rights of Indigenous Peoples.

|

|

|

23

We are in line to transform the future

Reduce scope 1

and 2 emissions

by 33% by 2030¹

100% renewable

electricity

Brazil (2025),

globally (2030)

Forests

recover and

protect +500,000

ha (2030)

Net zero

scope 1 and 2

emissions by 2050

Reduce Scope 3

net emissions by

15% by 2035²

Fresh water

reduce uptake

by 10% (2030)

. Briquettes plants under construction

. ~90% renewable electricity globally

and ~240 MW3 from solar/wind

projects

. +120,000 ha of forests protected by

the end of in 20214, totaling 1.1 million

ha, ~80% in the Amazon

. 80% of water reuse in our processes

2 New Pact with Society

¹ Baseline 2017: 14.1 Mt CO2 eq. Target 2030: 9.5 Mt CO2 eq. ² Baseline 2018. ³ Sol do Cerrado Solar Power and Folha Larga Sul wind project, share of production destined to Vale or its

subsidiaries once operaitng. 4 Up to October 2021.

Our progress:

|

|

|

24

On our path to reach net zero by 2050

2

Main technological routes

Energy efficiency

and renewables

Bioenergy

Electrification

New processes

Prioritization of operational

emission reductions

Nature-based solutions

with socioenvironmental

co-benefits

High-integrity carbon markets

1

2

3

Our drivers

57%

32%

11%

Pelletizing & Metallurgy

Mining, Railway & Others

Scope 2

Scope 1 and 2 emissions

by process – BAU¹

%

New Pact with Society

¹ BAU stands for business as usual.

|

|

|

25 Click here to watch a video

|

|

|

26

Our low carbon

agenda advances

Vale Zoo and Botanical Park

Parauapebas (PA), Brazil

|

|

|

27

We have taken important steps on our Scope 3 targets

Vale’s own initiatives

(15-25% of the challenge)

. Improving our high-quality portfolio

. Developing new technologies and asset light

solutions

94%

2%

3%

1%

Shipping

Steelmaking Use of coal

Suppliers

Scope 3 emissions¹ - BAU²

%

Partnerships with clients and suppliers

(75-85% of the challenge)

. Engaged with customers accounting for ~40% of

Vale’s scope 3 emissions

. Leveraging steel industry decarbonization initiatives

. Supporting a reduction in shipping emissions³

Offsetting based on high-integrity carbon markets to

comply with the reduction targets if necessary

2 New Pact with Society

*Baseline 2018: 586 Mt CO2 eq. Target 2035: 496 Mt CO2 eq. ² BAU stands for business as usual. ³ Target to reduce intensity in 40% by 2030 and 50% absolute emissions vs. emissions

in 2008 (reference year).

|

|

|

28

We are naturally well-positioned for a low-carbon mining

Iron Ore premium portfolio

63.6

60.8 60.4 57.8

Vale Peer 2 Peer 1 Peer 3

Future

2020

Average Fe content

%Fe

Seaborne supply by Fe grade

%, 2020

28% 25% 22%

59% 83%

66% 70%

19% 17%

<60%

7%

64-60% 66-64% >66%

5%

Others

Vale

Peer 1, 2 and 3

Nickel Low-Carbon Products

Vale Class 1 Nickel among the

lowest carbon intensive products

. 1/3 less emissions for Long Harbour rounds¹

. High purity Long Harbour nickel melt rounds

. Long-term off-take agreement with EV Producers

1,000 2,000

0

220

180

1,500

20

40

140

80

200

60

0

120

160

100

500 CO2e intensity (tCO2e/t Ni eq.)

Scope 1

Scope 2

Freight & Port

Downstream Processing

Upstream Mine Emissions: E0

Cumulative Ni Production² (in kt)

Vale Class I

2 New Pact with Society

¹ Carbon footprint of Vale Long Harbour rounds compared to Nickel Institute average Class 1 nickel. Intertek Group Plc has lent independent third-party limited assurance to the carbon footprint

of nickel rounds produced at the Long Harbour refinery in Newfoundland, Canada. ² Source: Skarn Associates Limited.

|

|

|

29

Maximize flight-to-quality

in Iron Ore

Marcello Spinelli, Executive Vice President

Iron Ore

3

|

|

|

30

New way to

operate

Tailings filtration plant

Vargem Grande Complex

|

|

|

31

New projects to reduce the reliance on

tailings dams

Iron ore production by method

Mt

Dry

processing

additions

Implement

tailings

filtration plants

Dry

processing

additions

Develop dry

concentration

solutions

300 ~15%

~70%

40%

400

2015

~1%

73% 58%

2018 2020 400 Mtpy

production

level1

346

385

Dry concentration

Wet processing with tailings filtration

Wet processing

Dry processing

Dry

processing

additions

Dry tailings used

as co-products

Dry

processing

additions

Increase dry

processing

production

Northern System 240 Mtpy2

Serra Norte Usina 1 conversion3

Capanema project4

Blending strategy

Maximize flight-to-quality in Iron Ore 3

Lower tailings

dam exposure

1 Considers a time horizon after the implementation of the highlighted initiatives. The production method share over the years will depend on assets availability and production plan. 2 Northern System includes Serra Norte, Serra Leste

and S11D operations. 3 Usina 1 partially operates today by wet processing, which is expected to be converted to dry processing in 2025. 4 18 Mtpy capacity project by natural moisture with start-up expected in 2H23. Net addition

capacity of 14 Mtpy in the first years.

85%

|

|

|

32

Delivering tailings filtration plants:

more quality, fewer dams

US$ 1.2 billion

invested in 2019-21

US$ 1.3 billion

to be invested in 2022-25

Maximize flight-to-quality in Iron Ore 3

Note: Includes investments in tailings stockpiles. Physical progress as of October 30th, 2021. 2nd phase of each project is expected to start-up in the following quarter.

|

|

|

33 Click here to watch a video

|

|

|

34

Dry concentration: more quality,

no water, no dams

Dry concentration capacity

Mtpy

1.5

9.5 8.5 6.0

2.0

Vargem

Grande

Fazendão Fábrica Dry

concentration

capacity

Oman

(PF cleaner)2

Expected

approval

2023

Expected

approval

2023

Expected

approval

2022

Start-up

2023

Under construction Under evaluation

Magnetic separation: proprietary technology

Final products with up to 68% Fe1

Potentially integrated with other process routes

Modular design

Maximize flight-to-quality in Iron Ore 3

1 Final products depend on ROM quality. 2 Project to improve pellet feed (“PF”) quality to supply direct reduction pellets production.

Dry magnetic concentration pilot plant

Vale’s Ferrous Technological Center

|

|

|

35

1 Tailings from current production. 2 Operations in Itabira and Vargem Grande are under analysis

for the future. 3 Sales and donations. 4 As an example, the creation of local industries and jobs

creation.

Co-products operations in place at

Brucutu and plans for Viga in 20222

Sand as a raw material for industry

(around 1.0 Mt sales3 committed to 2022)

Multiple uses under development

(e.g. bricks, green tires, quartz)

Circular economy: shared value

with communities4

Less area required to dispose

dry tailings1

Sand stockpile

Brucutu site

Maximize flight-to-quality in Iron Ore 3

Co-products: recycling dry tailings to

sustainably increase production capacity

|

|

|

36

Extended supply chain services

delivering value for clients

. >75% of sales under

CFR model with most

volumes being

transported in large

vessels

. Reduced exposure to

spot market with long-

term affreightment

contracts

. 17 ports in China and 2

distribution centers in

Malaysia and Oman

. Solutions for just in time

products and logistics

efficiency

. Pre-blending

. Partnership to develop 20

Mtpy of strategic port

capacity in Shulanghu

port (West III project)1

. Valemax vessels

unloading in more 3 ports

in China in 2021 and 2

more expected for 2H22,

totaling 9 ports

. Developing grinding

capacity to produce

GF882 in the mid term

. Capturing the growing

demand of pellet feed in

China

. Development of

beneficiation capacity in

China to concentrate

products

. Supply the Chinese

construction industry with

sand (co-product)

Freight service Blending strategy Ports’ partnerships Grinding facilities Concentration facilities

Maximize flight-to-quality in Iron Ore 3

1 The West III project consists in expanding the Shulanghu Port facilities, developing a stockyard and loading berths with additional 20 Mtpy capacity. By participating in the project, Vale will secure a total port capacity of 40Mtpy in

Shulanghu, which will help Vale to optimize its overall supply chain costs. 2 Pellet feed production using ground IOCJ.

|

|

|

37

Vale will reach 400 Mtpy capacity in the

medium term with its new way to operate…

Capacity (Mtpy)

Long

term

Vale Day

2021

Medium

term

Northern

System 240-260 203 215 205

End of

2022

Southeastern

System 110-120 70 113 93

Southern

System 70-85 65 69 69

Midwestern

System 3 3 3 3

400-450 341 400 370

Vale Day

2020

206

61

51

2

320

Main deliveries in 2022

Quality Capacity

1H22 S11D: jaspilite crushers

installation

2H22 S11D: Project +10 Mtpy

2H22 Serra Norte: Gelado project

1Q22 Brucutu/Itabira: tailings

filtration plants start-up

4Q22 Itabira: Itabiruçu dam raising

and new tailing stockpile

4Q22 Brucutu: Torto dam start-up

Maximize flight-to-quality in Iron Ore 3

|

|

|

38

… and value over volume approach will

continue defining production and sales strategy

300

2020 2021E

315-320

320-335

2022E

Iron ore production

Mt

63.6%

62.9%

63.5%

Iron ore sales Fe content (%)1

Maximize flight-to-quality in Iron Ore 3

Higher Fe content

Value over volume strategy

1 Considers sales in the seaborne market and in Brazil, including iron ore pellets

|

|

|

39

Best in class portfolio supporting

industry decarbonization

S11D mine second stockyard

S11D, Carajás (PA), Brazil

|

|

|

40

Beyond enhancing quality, we are

delivering solutions to improve Vale’s portfolio

Dry

concentration

Enabling the production of up to 68% Fe

content from low Fe ROM

Direct charge

products

Leading world’s pellets and green

briquettes production

Increasing Northern System high-quality

production to deliver IOCJ, BRBF and

GF88

High-quality

ores

Asset light

solutions

Working with partners on an asset light

platform to supply low-CO2 solutions CO2

90%

2021 Future

83%

Premium products2

>64%

2021 Future

62.9%

Fe content1

>100 Mt

2021 Future

~40 Mt

Direct charge

products3

Maximize flight-to-quality in Iron Ore 3

1 Considers sales in the seaborne market and in Brazil, including iron ore pellets. 2 Includes IOCJ, BRBF, pellets, briquettes and pellet feed. 3 Includes briquettes, pellets and lumps.

|

|

|

41

Green briquette is a breakthrough

environmentally friendly solution

Exclusive technology

18 years of in-house R&D

Technology patented1 in 47 countries

Blast furnaces: reduction of over 10% in BF-BOF route2

Direct reduction furnaces: capacity to supply the increasing demand

Less CO2 emissions

Briquettes capacity

Mtpy

6.0

Vargem Grande

>50

Other plants

0.75

Tubarão 1&2 Briquettes

capacity3

Start-up

2023 Start-up

2023

Under construction Under evaluation

Maximize flight-to-quality in Iron Ore 3

US$ 0.5-1.0 billion of potential

incremental EBITDA over sinter feed3

1 Patented or in submission process. 2 Considering the substitution of sintering process in steelmaking plants. 3 Estimates figures subject to

feasibility studies, internal approvals and market conditions. Potential EBITDA estimates updated in response to customer feedback.

Green briquettes

|

|

|

42

There are multiple ways to decarbonize

and we are engaging with clients on this journey

Green

briquette plants

Dry

concentration

plants

Tecnored

technology Metallics

Burden mix

optimization

High-grade

products usage Biocarbon usage

Direct

reduction

technologies

Potential client solutions

North America

MoUs¹ under discussion

Brazil

MoU with Ternium Brasil

Others under discussion

Middle East

MoUs under discussion

Europe

MoUs under discussion

China

MoU with 4 clients (Baowu and

Others under discussion

Japan and Korea

MoU with 3 clients (Hyundai

Others under discussion

In 2021, Vale engaged with 20 clients representing 40% of company’s scope 3 emissions

Maximize flight-to-quality in Iron Ore 3

and POSCO among them)

Shagang, among them)

¹ MoU stands for Memorandum of Understanding.

|

|

|

43

Rebuilding Vale’s

competitiveness

Bulk vessel with rotor

sails technology

|

|

|

44

Capacity resumption is key to remove

inefficiencies and promote cost savings…

Maximize flight-to-quality in Iron Ore 3

Production costs (US$/t)

Timbopeba site

. 2022: 12% production increase in 2022 and

normalized railway operations

. Medium-term: Start-up of Capanema project in 2H23

with dry processing

27

21

15

2021 2022 Medium term

-20%

-29%

Production costs (US$/t)

Vargem Grande complex

. 2022: Resumption

conveyor belt in 4Q21,

reducing use of trucks

. Medium-term: Capacity

reaching over 50 Mtpy,

with fixed cost dilution 2022 2021 Medium

term

-5% -11%

Production costs (US$/t)

Brucutu site . 2022: Ramp-up of tailings

filtration plants (new way

to operate) and reduction

of the share of dry/high-

silica products, increasing

costs

. Medium-term: Capacity

reaching over 28 Mtpy,

with fixed cost dilution 2022 2021 Medium

term

+31% -34%

Note: Production costs includes C1 cash costs and stoppage expenses.

|

|

|

45

Dilution of

fixed costs

New way

to operate2

~17

Dilution of

fixed costs

2021E

-0.7

-1.0

Cost

efficiency1

2-3

0.5

15.5-16

2023

-1.0

-1.0

Cost

efficiency1

14-15

400 Mtpy

production

10.5-12

14-15

…reducing C1 cash cost level

Vale’s iron ore fines C1 cash cost (ex. 3rd party purchase)

US$/t

Maximize flight-to-quality in Iron Ore 3

• Inflation

• Drilling/

geotechnical

analysis

• Depletion/others

Main changes

from previous

guidance

1 Includes the removal of inefficiencies in operations and productivity gains. 2 Tailings filtration plants, dry concentration, geotechnical analysis, drilling and others.

|

|

|

46

Vale has a winning shipping strategy

Vale’s average

freight cost

2021E3

~27

~16

Spot freight

2021E2

Valemax 2G/

Guaibamax

2021E

~13

~19

Vale’s

medium term

freight cost3 4

Freight costs

US$/t

Efficient vessels

65+ Valemaxes 1G+2G / 45+ Guaibamaxes

Scrubbers installed on dedicated fleet

Lower bunker costs

Ecoshipping program

R&D portfolio including rotor sails and air lubrication

Long-term affreightment contracts

Majority of fleet under LTC1 with increase potential

Maximize flight-to-quality in Iron Ore 3

1 Long term contract. 2 C3 Route (Tubarão-Qingdao). 3 Iron ore fines freight. 4 Includes ~US$ 2.4/t reduction related to market assumptions for spot freight and bunker fuel costs.

|

|

|

47

Decarbonization and portfolio

improvements lead to higher premiums for Vale

All-in

premiums1

Market

environment

Vale’s portfolio

US$

~10/t

2018

. Chinese supply side reform

. High steel margins

. High availability of pellet

feed and pellets

. Flexibility to produce close

to 400 Mtpy

US$

~6/t

2021

. Volatile iron ore price

. High-availability of low

alumina products

. High coke prices

. Production of high-silica

products

. Low pellet feed availability

to produce pellets

US$

8-12/t

2023-26

. Healthy steel margins

. Lower availability of low

alumina products

. Higher volumes from

Northern System

. Resumption of pelletizing

capacity

. Ramp-up of briquette plants

US$

12-18/t

2029+

. Carbon pricing

. Transition to more direct

reduction demand

. Green briquettes over 50

Mtpy

. Dry concentration

improving quality

Maximize flight-to-quality in Iron Ore 3

Note: Considering different scenarios of steel production with steel margins ranging between US$25-100/t and carbon price ranging between US$0-60/t of CO2eq. 1 Vale’s iron ore weighted average premiums for the current and future

portfolio, including IOCJ, BRBF, pellets, briquettes and others, on top of 62%Fe benchmark index.

|

|

|

48

Altogether, Vale is rebuilding its

competitiveness: capacity, value and green

~3

Iron ore

price effect

2-6

~45

Freight

efficiency

2021E C1 ex-3rd

party purchase

~3

~2.5

Premium Others1 Future

premiums

(potential)

~35

400 Mtpy

production level

30-35

400 Mtpy

production level

(price adjusted)

0-6

<30

Potential

breakeven in a

decarbonized

world

Vale’s iron ore fines and pellets EBITDA break-even

US$/t

. Normalization

of spot freight

rates and

bunker prices

. Fleet

optimization

(Valemax/

Guaibamax)

. Pellet capacity

resumption

. Northern

System

production

increase

. No stoppage

expenses

. Dilution of

expenses

. Potential

lower effect

of prices on

royalties

and third-

party

purchase

Roadmap

Maximize flight-to-quality in Iron Ore 3

. Dilution of

fixed costs

. Removal of

inefficiencies

and cost

savings

. New way to

operate

. Vale’s future

portfolio

. Carbon

pricing

. Transition to

more direct

reduction

demand

1 Includes expenses, stoppage expenses related to Brumadinho, distribution costs and moisture adjustment.

|

|

|

49

Base Metals transformation

Mark Travers, Executive Vice President

Base Metals

4

Questions?

valeday2021@vale.com

|

|

|

50

2021 was a challenging year

. Broad safety reviews and strategy to drawdown maintenance backlog to

improve safety standards

. Delays in maintenance at Sossego due to COVID restrictions –

contractors’ mobilization

. Critical maintenance activities at Sossego mill and Onça Puma furnace

. 2-month labor disruption at Sudbury operations

. Delays in planned maintenance related to Sudbury stoppage

Base Metals Transformation 4

Remainder critical

maintenance to be

concluded in 2022

Continue to improve risk

management and safety through

Operational

Excellence initiatives

Sequeirinho Pit, Sossego mine

Canaã dos Carajás (PA), Brazil

|

|

|

51

For 2022, we have key milestones in the path to

performance recovery

Base Metals Transformation 4

2021 2022

295-300

330-355

2022 2021

165-170 175-190

Copper production Nickel production

. Stable production at North Atlantic mines

. Improvement in Salobo mine movement

. Planned maintenance at Sossego

. Stable production at North Atlantic Mines

. New projects ramp up (VBME and CCM1)

. Onça Puma stabilization

. PTVI furnace rebuild

In kt In kt

|

|

|

52

Strengthening our

copper portfolio

in Carajás

Former Igarapé Bahia Gold Mine, location of future Alemão

project, Parauapebas (PA), Brazil

|

|

|

53

A Tier 1 mining complex leveraged by synergies

Base Metals Transformation 4

Copper dedicated railway terminal

and railcar fleet

Copper concentrates terminal

at Itaqui port

Copper mines

Copper projects

Copper options

|

|

|

54

We are advancing Salobo 3

¹ New processing plant with a nominal processing capacity of 12 Mtpy of ore. ² Life-of-mine average. Yearly

production may vary as a result of mine plan. ³ Subject to feasibility studies, internal approvals and market

conditions

Commissioning of facilities to start in

1H22. Start up planned for 2H22

New processing plant¹ that allows to

increase copper production by 30-40 ktpy²

Further optionality with Salobo IV to

potentially add 30 ktpy of copper³

Concluded assembly of flotation cells

and energization of power substation

Goldstream tail payment > US$ 500

million

Plant construction, November 2021

Salobo 3 project, Carajás (PA), Brazil

|

|

|

55

… and taking Carajás towards growth

Alemão: approaching the next big step

towards Carajás growth

Adding on optionality to South Hub

extension Developing future growth options

Progressing on Cristalino feasibility study

Advancing on satellite deposits studies to

provide optionality e.g., Bacaba

Ongoing evaluation of South Hub

expansion – new processing plant

New underground mine in the former

Igarapé Bahia gold mine

Access to regional infrastructure

Well-advanced feasibility study.

Conclusion expected by the end of 2022.

Adding ~60 ktpy with significant gold Extending life at ~80 ktpy¹ 70-100ktpy estimated potential

Development of the North Hub to process

feed from northern deposits

Close to Salobo – synergies with some of

the existing infrastructure

60km of drilling completed YTD² ³

GROWTH

REPLACEMENT

WITH OPTIONALITY GROWTH Satellite view of North Hub area Sossego Mill Igarapé Bahia Mine – location of future Alemão project

Base Metals Transformation 4

1 Life-of-mine average. 2 Year-to-date: January-November 2021. 3 Comprising Paulo Afonso, Pojuca, Grota Funda and Gameleira.

|

|

|

56

Developing a world-class

copper discovery: Hu’u Project

Base Metals Transformation 4

Completion of the assessment of alternatives for the

pre-feasibility study¹

Onto deposit estimated to contain 17.4 Mt of copper and

32 Moz of gold in resources². Equates to an increase of

~15% in contained copper since February 2020³

Copper production estimated at 300-350 ktpy during peak

production with a predicted mine life of >45 years

Expect to conclude the pre-feasibility study in 2024

Note: Hu’u is 100% owned by PT Sumbawa Timur Mining (STM), an Indonesian private joint-venture

company owned by Eastern Star Resources Pty Ltd (80%) and PT Aneka Tambang (20%). Eastern Star

Resources Pty Ltd is 100% owned by Vale. 1 Delivered an Assessment of Alternatives for the planned

Final Pre-feasibility Study. At this time, a block cave mine with conventional mill & flotation circuit and

associated infrastructure will be further studied in the final phase of the pre-feasibility study. 2 1.1Bt

Indicated Resources @ 0.96% Cu and 0.58g/t Au containing 10 Mt Cu and 20 Moz Au and 1.0Bt

Inferred Resources @ 0.74% Cu and 0.37g/t Au containing 7.4 Mt Cu nd 12 MoztAu . 3 Mineral

Resource Estimate Statement (19 February 2020)

Core Shed

Hu’u project, Indonesia

|

|

|

57

Progressing on project development…

Pre-feasibility

FEL 2

Feasibility

FEL 3

South Hub Ext.: Cristalino

80 ktpy

South Hub Extension:

Cristalino

Alemão

+60 ktpy

2019-20 2021

North Hub

+70-100 ktpy

Alemão

Investment

Decision

2022-23

2023

South Hub Extension¹

Other satellites

Scoping

FEL 1

2024+

2026+

Hu’u

300-350 ktpy 2028+ Hu’u

REPLACEMENT GROWTH

Base Metals Transformation 4

Victor JV

20 ktpy² 2023

South Hub Expansion

+30-40 ktpy 2025+

Salobo IV

+30 ktpy 2025+

South Hub Expansion

Salobo IV

South Hub Extension¹

Other satellites

1 Satellite deposits projects vary in maturity. ² Volume presented as Vale share

|

|

|

58

… to deliver on growth with long-term potential

2023-26 2022 2027+ Hu’u North Hub Salobo IV South Hub

expansion

LT with

optionalities

330-355

390-420

450+

30-40

70-100 30

300-350* 900+

Scoping Pre-feasibility

Investing in mid-term growth Building on optionality to 900 kt and beyond

+ Upside from global exploration initiatives

in the Andean America and Eastern Europe

Base Metals Transformation 4

R Replacement project

+ Growth project

+ Salobo 3

In ktpy

* At peak production.

R South Hub (Cristalino)

+ Alemão

+ Victor (start-up: 2028+)

|

|

|

59

Transforming our

Base Metals

Business

|

|

|

60

Progressing on our Nickel agenda

Approval of Manitoba

Extension Phase 1

First ore achieved at VBME² Conclusion of VNC¹ sale

Update (pixel)

Base Metals Transformation 4

First ore achieved at

CCM 1³ South mine

¹ VNC stands for Vale New Caledonia. ² VBME stands for Voisey’s Bay mine extension. ³ CCM 1 stands for Copper Cliff Mine 1.

|

|

|

61

Well-positioned

to pivot towards North Atlantic EV

57

628

2020 2025 2030

295

Current

Future

US Megafactory capacity expected growth

GWh

1 GWh =

~0.7kt of nickel²

Signed a long-term agreement with OEM to

sell 5% of our Class I nickel to North America

Target to achieve 30-40% of Ni to North America

EV market in the mid-term (up to 5 years)

Developing black mass recycling: positive tests on

nickel and cobalt recoveries

Base Metals Transformation 4

Evaluating options to build a nickel sulphate plant

in Canada

US Megafactories

Current¹

Future

Vale Canada

Mines

Refineries

¹ Major Megafactories in 2020. Source: Benchmark Mineral Intelligence (October 2021). ² Considering current US capacity profile which is nickel-based.

|

|

|

62

Delivering on stability in Nickel

Ramping up VBME Advancing on replacement projects in

North Atlantic

Onça Puma: optimizing growth

opportunities in South Atlantic

Replacing capacity at Voisey’s Bay Replacing capacity in North Atlantic Adding capacity in South Atlantic

2nd furnace

Optionality

Additional production of 12-15ktpy in the

first 10 years

Currently performing value engineering

Onça Puma expansion

Advancing maturity assessment of pre-

feasibility study

Development of two U/G¹ mines – Reid

Brook and Eastern Deeps

Physical progress 72% in October 2021

First ore achieved in Reid Brook. Eastern

Deeps start-up expected for 2H22

Phase 1 approved

Phase 2 advanced to pre-feasibility study

Base Metals Transformation 4

Manitoba extension

CCM 3&4

Thompson operations Voisey’s bay mine Onça Puma plant

¹ U/G stands for underground.

|

|

|

63

Exploring

Canadian high-quality resources

Drilling exploration campaign planned for

the next 5 years targeting near-mine to

advanced projects (> 300Km per year)

Base Metals Transformation 4

Thompson Sudbury

Voisey’s Bay

. Advancing exploration studies on large

ultramafic-hosted Ni deposits

. Extensive regional program targeting

high-grade sediment-hosted Ni

mineralization

. Exploring near mine targets to extend

mine life at Thompson Mine

. Balanced portfolio of early-

stage targets, advanced

projects and near mine

opportunities

. Strong land position in world-

class Ni camp with synergies

to existing operations

. Extensive near mine and

regional program

. Potential to add resources and

extend mine life at Reid Brook

and Eastern Deeps

High-grade polymetallic orebodies,

especially in Sudbury basin

Canada has the largest Ni sulfide

resources in the world

|

|

|

64

Unique access to higher

quality nickel in Indonesia

One of the largest Ni resource in Indonesia¹

Currently produces 70-80 kt of Ni in matte

PTVI matte feeds into Matsusaka-Clydach flowsheet

Beyond-compliant environmental management²

Bahodopi - RKEF

70kt Ni

100% mine; 49% plant

Pomalaa - HPAL

40kt Ni

100% mine; ~20% plant

JV projects

1Q 2022 2022-23

Central Sulawesi

South Sulawesi

Southeast Sulawesi

Base Metals Transformation 4

As of Dec 2020 Reserves

Mt %Ni Mt Ni

Resources³

Mt %Ni Mt Ni

Saprolite 104 1.73 ~1.8 222 1.85 ~4

Limonite - - - 131 1.33 ~1.7 ¹ According to data available at S&P. ² Awarded a Green PROPER, an award from the Government to business entities that

comply and even beyond compliance in terms of environmental management. ³ Saprolite resources including inferred

resources of 116 Mt @1.9% Ni.

Final Investment Decision:

|

|

|

65

Building a stable business

Pre-feasibility

FEL 2

Feasibility

FEL 3

OP 2nd furnace

+12-15kt

Investment

Decision

2022

CCM 3&4

Scoping

FEL 1

2023+

Manitoba

Extension Ph 2

2024+

CCM 3&4

2019-20 2021

REPLACEMENT GROWTH

Base Metals Transformation 4

2024+ 2022-23

175-190

200+ *Peak at ~220kt

as Onça Puma

2nd furnace starts

Nickel production

In ktpy

Manitoba

Extension Ph 2

|

|

|

66

Transforming our Base Metals business

Base Metals Transformation 4

Unique access

to higher

quality nickel

in Indonesia

Well-positioned to

pivot towards

North Atlantic EV

A Tier 1 mining

complex with growth

optionality

|

|

|

67

Discipline in capital

allocation

Gustavo Pimenta, Executive Vice President & CFO

5

|

|

|

68

. Benchmark in safety

. Best-in-class reliable operator

. Talent-driven organization

. Leader in low-carbon mining

. Reference in creating and

sharing value

Re-rating

De-risking

Reshaping

Sound cash flow generation

Discipline in capital allocation

Reshaping

Discipline in capital allocation 5

We are focused on delivering

superior value to our shareholders

. Focus on core business

. Elimination of cash drains

. Accretive growth opportunities

. Cost efficiency

. Brumadinho

. Dam safety

. Robust ESG practices

. Production resumption

|

|

|

69

Reparation Agreement1

US$ billion

The Reparation Agreement brought certainty on Vale’s

disbursements

1 Amounts stated include inflation and do not include discount to present value, considering average BRL/USD exchange rates in 2019 of 3.95, in 2020 of 5.2 and of 5.4 for 2021 onwards. It does not include

individual indemnification nor incurred expenses. ² It considers the release of judicial deposits.

Discipline in capital allocation | De-risking 5

1.7

2.3

0.4 0.4

1.4 0.3 0.4

0.3 0.5

1.9

0.5

Previously

disbursed

0.2

2021 2022E 2023E

0.6

0.4

0.2

2024E

0.2

2025E

0.2

2026-

2029E

Total

2022-

2029E

2.4

0.7 0.8 0.7

3.4

Performance obligations

Payment obligations²

55% of total

agreement to be

concluded by 2021

2/3 of payment

obligations

|

|

|

70

2022, a year of important deliveries

for the Renova Foundation

Discipline in capital allocation | De-risking 5

Acceleration of individual

indemnifications following Federal

Court decisions

Final revision of 42 programs under

the existing agreement framework

Peak spending and delivery

on resettlements

Resettlement under construction

Bento Rodrigues (MG), Brazil

|

|

|

71

CSA

Fertilizer

assets in

Brazil

Potash

projects in

Canada

Coal assets

in Australia

Zhuhai

YPM

Mosaic

Moatize

CSI

Manganese

ferro-alloy

in Minas

Gerais,

Brazil

CSP

Henan

Longyu

Energy

Resources

VNC

Biopalma

Fertilizer

assets in

Peru

Potássio

Rio

Colorado

2015 2021 2018 2020

MRN

What is next?

Simplifying the portfolio to deliver on the reshaping…

Discipline in capital allocation | Reshaping 5

Deals since Vale Day 2020

Advanced stage of negotiations

Other non-core assets

|

|

|

72

… leading to a significant decrease of our cash drains

Discipline in capital allocation | Reshaping 5

1 VNC result in 2021 does not consider the US$ 555 million paid for the divestment. ³ Including Samarco’s working capital needs. ³ Including Biopalma and CSP needs

US$ million

Moatize

VNC1

1,480

1,140 320

300 70

2020 2021E

-

-

2022 onwards

Total

Main measures

. VNC was sold to Trafigura consortium in 1Q21

. Achieved break-even in 3Q21

. Sale process is advanced

Others3 300 40 - . Biopalma was sold in Nov/20

. CSP being positively impacted by market environment

2019

790

370

220

1,900 450 -

Samarco2 160 20 - . Operations resumption in Dec/20 100

|

|

|

73

Focusing on cost efficiency with an

US$ 1 billion reduction program…

Discipline in capital allocation | Reshaping 5

Note: Compared to 2021 figures. Considering current operations and excluding effects of exchange rates variation.

. A leaner and more efficient

organization

. Removal of inefficiencies, better

planning process (VPS) and

incorporation of digital solutions

Organizational

redesign

Productivity

gains

Levers

. Specification and scope review,

demand management

Sourcing and

third-party

services

~US$ 750 million of fixed cost savings

~US$ 250 million of sustaining investments

efficiency

From 12 to 24 months:

~US$ 500 million of inflation costs avoidance

Next 12 months:

|

|

|

74

… freeing up resources for growth opportunities

Discipline in capital allocation | Reshaping 5

Gelado12

+10 Mtpy

Serra Leste

expansion6

Serra Sul

+20 Mtpy

Northern

System8

260 Mtpy

Salobo III

+30-40 ktpy

CCM PH

3&41

Onça Puma

2nd furnace

+12-15 ktpy

North Hub6

+70-100 ktpy

Hu’u10

+300-350 ktpy Cristalino1

Bahodopi7

+70 ktpy

Pomalaa7

+40 ktpy

S11C6

2022 > 2026 2023 - 2026

South Hub

expansion6

30-40 ktpy

S11D

+10 Mtpy

Briquettes4

+7 Mtpy

Manitoba

Phase 2¹

Salobo IV6

+30 ktpy

Briquettes9

40+ Mtpy

Dry concentr.

plant5

+9.5 Mtpy

Northern

System N31

Capanema3

+18 Mtpy

Alemão

+60 ktpy

Victor111

+20 ktpy

Northern

System

N1/N21

1 Replacement project. 2 Project starts with 5 Mtpy capacity as requires Usina 1 conversion to achieve full capacity of 10 Mtpy. 3 Net addition capacity of 14 Mtpy in the first years. 4 Includes Vargem Grande (0.75

Mtpy) and Tubarão 1&2 (6 Mtpy) briquette plant projects. 5 Dry concentration plant. Includes Vargem Grande (1.5 Mtpy approved), Fazendão (6 Mtpy) and Fábrica (2 Mtpy). In addition, a project in Oman to improve

pellet feed quality (8.5 Mtpy) to supply direct reduction pellets production is under evaluation. 6 Project’s capacity under evaluation. Estimated figures subject to feasibility studies, internal approvals and market

conditions. 7 Participation through joint ventures. Volumes shown as 100% basis. 8 Logistics project to increase Northern System capacity to 260 Mtpy (+20 Mtpy). 9 Different projects to produce iron ore briquettes.

Estimates figures subject to feasibility studies, internal approvals and market conditions. 10 Volumes shown as 100% basis. Hu’u Project is 100% owned by PT Sumbawa Timur Mining (STM), an Indonesian private

joint venture company owned by Eastern Star Resources Pty Ltd (80%) and PT Aneka Tambang (20%). Eastern Star Resources Pty Ltd is 100% owned by Vale. 11 JV partnership under discussion. Volume

presented as Vale share.

Iron Ore

Copper

Nickel

Approved

Apolo1

+14 Mtpy

|

|

|

75

A disciplined capital allocation focused on shareholder

return…

Discipline in capital allocation | Re-rating 5

36%

Through the cycle

Return surplus cash

Attractive investment

1 Including liability management, financial guarantees, acquisitions and sale of assets. Including dividends and interest on capital.

Minimum

dividend policy

Extraordinary

dividends

Share buyback

program

1.9 2.4

7.6

1.4

5.9

4.8

1.0

2020

0.9

2018 2019 Up until 3Q21

8.9 8.1

9.2

20.1

Others1

Share buyback

Ordinary dividends

Extraordinary dividends

90%

36%

- 50%

Free cash flow returned to shareholder (%)

Free cash flow returned to shareholder

US$ billion

|

|

|

76

… which should remain our focus as we resume capacity

and manage cash use

EBITDA 2023 - Sensitive analysis

(US$ billion)

5

Cash Flow Drivers

Iron ore price (US$/t)

mid-point based on analysts’ forecast

~17.0 ~17.5

350 360

~20.0 ~20.5

~23.5 ~24.0 100

90

80

Iron ore sales volumes (Mt)

340

~16.5

~19.5

~23.0

Discipline in capital allocation | Re-rating

Note: Volumes and price ranges for sensitivity purpose only and do not constitute any guidance by Vale. Average BRL/USD exchange rate in 2023 of 5.00, average copper price (LME) of US$ 10,000/t and average

nickel price (LME) of US$ 17,500/t.

Transitory expenditures

Controlled sustaining capex

Accretive growth opportunities

CAPEX

US$ 5.8 bn (2022)

US$ 5.0-6.0bn (avg. next years)

Capacity resumption to drive

volume growth EBITDA

Increased knowledge with

diluted annual payments

Dam

de-characterization

Substantial progress on

reparation process Brumadinho

Indemnifications accelerating

and skewed towards short term Renova

|

|

|

77

Important catalysts to unlock value

in the next 12-18 months

Discipline in capital allocation 5

Note: Capacity additions and cost savings compared to 2021E figures. Considering current operations and excluding effects of exchange rates variation.

. Iron Ore: 30+ Mt

Volume mainly from

Itabira and Brucutu

. Copper: +30-40 kt

Salobo III

Capacity increase Cost reduction

. Next 12 months:

~US$ 500 million of

inflation avoidance

. 12 – 24 months:

~US$ 1 billion of costs/

investments efficiencies

. Progress on reparation

liabilities

. 6 dams to be

de-characterized

. 11 ESG gaps to be

concluded

De-risking

|

|

|

78

Questions &

Answers

|

|

|

79

|

Signatures

Pursuant to the requirements of the Securities Exchange Act of 1934,

the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

|

|

Vale S.A.

(Registrant)

|

|

|

|

|

|

By:

|

/s/ Ivan Fadel

|

|

Date: November 29, 2021

|

|

Head of Investor Relations

|

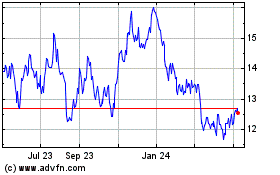

Vale (NYSE:VALE)

Historical Stock Chart

From Mar 2024 to Apr 2024

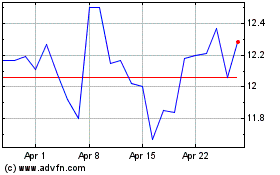

Vale (NYSE:VALE)

Historical Stock Chart

From Apr 2023 to Apr 2024