United States

Securities and Exchange Commission

Washington, D.C. 20549

FORM 6-K

Report of Foreign Private Issuer

Pursuant to Rule 13a-16 or 15d-16

of the

Securities Exchange Act of 1934

For the month of

October 2021

Vale S.A.

Praia de Botafogo nº 186, 18º andar,

Botafogo

22250-145 Rio de Janeiro, RJ, Brazil

(Address of principal executive office)

(Indicate by check mark whether the registrant files

or will file annual reports under cover of Form 20-F or Form 40-F.)

(Check One) Form 20-F x

Form 40-F ¨

(Indicate by check mark if the registrant is submitting the Form 6-K

in paper as permitted by Regulation S-T Rule 101(b)(1))

(Check One) Yes ¨ No x

(Indicate by check mark if the registrant is submitting the Form 6-K

in paper as permitted by Regulation S-T Rule 101(b)(7))

(Check

One) Yes ¨ No x

(Indicate by check mark whether the registrant by furnishing the information

contained in this Form is also thereby furnishing information to the Commission pursuant to Rule 12g3-2(b) under the Securities Exchange

Act of 1934.)

(Check One) Yes ¨

No x

(If “Yes” is marked, indicate below the file number assigned

to the registrant in connection with Rule 12g3-2(b). 82- __.)

www.vale.com

vale.ri@vale.com

Tel.: (5521) 3485-3900

Investor Relations Department

Ivan Fadel

André Werner

Mariana Rocha

Samir Bassil

B3: VALE3

NYSE: VALE

LATIBEX: XVALO

This press release may include

statements about Vale's current expectations about future events or results (forward -looking statements). Many of those

forward-looking statements can be identified by the use of forward -looking words such as "anticipate,"

"believe," "could," "expect," "should," "plan," "intend,"

"estimate" “will” and "potential," among others. All forward - looking statements involve various

risks and uncertainties. Vale cannot guarantee that these statements will prove correct. These risks and uncertainties include,

among others, factors related to: (a) the countries where Vale operates, especially Brazil and Canada; (b) the global economy; (c)

the capital markets; (d) the mining and metals prices and their dependence on global industrial production, which is cyclical by

nature; and (e) global competition in the markets in which Vale operates. Vale cautions you that actual results may differ

materially from the plans, objectives, expectations, estimates and intentions expressed in this presentation. Vale undertakes no

obligation to publicly update or revise any forward -looking statement, whether as a result of new information or future events or

for any other reason. To obtain further information on factors that may lead to results different from those forecast by Vale,

please consult the reports that Vale files with the U.S. Securities and Exchange Commission (SEC), the Brazilian Comissão de

Valores Mobiliários (CVM) and, in particular, the factors discussed under “Forward-Looking Statements” and

“Risk Factors” in Vale’s annual report on Form 20 -F.

Production and sales in 3Q21

Rio de Janeiro, October 19th,

2021 – The third quarter of Vale S.A. (“Vale”) was noticeable by (i) increased production of iron ore and coal,

following their respective production recovery plans and better weather conditions, (ii) the sharp drop in iron ore prices (-US$ 37/dmt

of 62%Fe index vs. 2Q21) leading to a review on production and sales of high-silica iron ore products, (iii) gradual resumption of the

North Atlantic Base Metals operations after conclusion of a new five-year collective bargaining agreement in Sudbury, and (iv) incident

at Totten mine with all 39 employees having safely returned to the surface.

Vale’s iron ore fines production1

totaled 89.4 Mt in 3Q21, 18.1% higher than in 2Q21, as a result of: (i) seasonal improvement of weather-related conditions

in Northern System, boosting Serra Norte and S11D performance; (ii) Vargem Grande production increase by dry processing while adjusting

the flowsheet of one of its wet-processing plants; (iii) Itabira’s performance improvement related to better run-of-mine (“ROM”)

availability; (iv) higher third-party purchase, although proportionally lower than the previous quarter (5.8% of total production in

3Q21 vs 6.2% in 2Q21); and (v) Fábrica’s reaching its full capacity of 6 Mtpy, after the resumption of beneficiation process

in 2Q21.

On September 9th, during 2021

Analyst and Investor Tour, Vale presented an updated view of its production capacity resumption plan and launched new portfolio solutions

for decarbonize steelmaking industry. The presentation is available here.

Vale remains committed to its capacity

resumption plan, which is also associated with eliminating restrictions and optimizing costs. In 3Q21, Maravilhas III dam

operations in Vargem Grande complex started following the issuance of a positive Stability Condition Declaration (DCE). As an

additional step on the resumption plan, Vale started to commission the long-distance conveyor belt segment close to Vargem Grande

dam in October, resuming after several tests certifying the absence of increased risk to the structure. At the end of

commissioning, an increase of 6 Mtpy is expected in the production capacity of the Vargem Grande site.

1 Including third-party purchases, run-of-mine

and feed for pelletizing plants. Vale’s product portfolio Fe content reached 62.9%, alumina 1.4% and silica 5.2%.

Vale’s pellet production totalled 8.3

Mt in 3Q21, in line with 2Q21, still restricted by pellet feed availability in Itabira and Brucutu.

Production and sales strategy is based on

market conditions, prioritizing value over volume, with focus on margin maximization. As consequence, for the fourth quarter this

year, Vale should lower its supply of high-silica low-margin products by around 4 Mt, as demand for this kind of product has been weaker.

This movement does not change our production guidance for the year, of 315-335 Mt, but should take us below the middle of the range.

If this scenario persists, we should also reduce the offer of low-margin products in 2022 by around 12-15 Mt. The purchase level of third-party

ores may also be adjusted accordingly.

Sales volumes of iron ore fines and pellets

totalled 75.9 Mt in 3Q21, in line with 2Q21. The approximately 13 Mt gap between production and sales in 3Q21 was an effect of (i)

Vale’s value over volume approach, by reducing the sales of high-silica iron ore products in September due to market price level;

and (ii) transiting inventories across the supply chain, which is expected to revert in 4Q21, depending on market conditions.

Iron ore price premium was US$ 6.6/t2,

US$ 1.8/t lower than in 2Q21, due to (i) lower premiums paid to low alumina ores, as BRBF and IOCJ; and (ii) lower contribution from

Pellets business as the 65/62% Fe index spread narrowed; which were partially offset by (i) higher Fe content premiums, despite the lower

benchmark index, as a result of the lower sales of high-silica iron ore products; and (ii) higher contractual pellet premiums.

Production of finished nickel was 30.2 kt

in 3Q21, 27.2% lower than 2Q21, mainly due to the labour disruption at Sudbury, which halted operations for 70 days, of which 40

days were in 3Q21, with an impact of 11kt on finished nickel production in the quarter. In addition, Onça Puma went through extended

maintenance during 3Q21, with production resuming late September.

The labor disruption at Sudbury ended on August

4th, 2021, after a new five-year collective bargaining agreement. A process to return to work safely commenced on August 9th, and critical

maintenance activities were started. During September production partially resumed, and in October all mines are planned to be back in

operation, with the exception of Totten.

Damage to the Totten mine shaft, on September

26th, has rendered the normal conveyance system inoperable, as a result production at the site was halted. Vale is assessing

the necessary measures to safely repair the mine shaft and operations are expected to resume by early 2022.

2 Iron ore premium of US$ 1.9/t and weighted average contribution

of pellets of US$ 4.6/t.

From October 4th to 7th and since October 18th,

Onça Puma mine operation was halted, following the suspension of the operating license by the Environmental and Sustainability

office of the Pará State (Secretaria de Estado de Meio Ambiente e Sustentabilidade, SEMAS).

Copper production reached 69.2 kt in 3Q21,

5.7% lower compared to 2Q21, mainly due to the labour disruption at Sudbury, which affected total copper production by 16 kt in the quarter.

This was partially offset by a more robust performance at Sossego, as plant availability increased in the quarter after scheduled maintenance

was completed in 2Q21.

In October, a fire partially affected the conveyor

belt at Salobo mine, with no injuries and no environmental damage. Copper concentration at Salobo is currently halted, but expected to

resume by the end of October.

We expect to produce 45-50 kt of nickel and

75-80 kt of copper in 4Q21, resulting in a production of approximately 165-170 kt of nickel and 295-300 kt of copper for the year of

2021. The range considers the risks associated with the scheduled resumption of operations at Totten mine and Salobo plant and the

stoppage of Onça Puma mine. In addition, the range accounts for the continued ramp up of all Sudbury operations.

Production summary

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

%

change

|

|

|

000’ metric tons

|

|

3Q21

|

|

|

2Q21

|

|

|

3Q20

|

|

|

9M21

|

|

|

9M20

|

|

|

3Q21/2Q21

|

|

|

3Q21/3Q20

|

|

|

9M21/9M20

|

|

|

Iron

ore1

|

|

|

89,421

|

|

|

|

75,685

|

|

|

|

88,676

|

|

|

|

233,137

|

|

|

|

215,877

|

|

|

|

18.1

|

%

|

|

|

0.8

|

%

|

|

|

8.0

|

%

|

|

Pellets

|

|

|

8,341

|

|

|

|

8,008

|

|

|

|

8,562

|

|

|

|

22,637

|

|

|

|

22,559

|

|

|

|

4.1

|

%

|

|

|

-2.6

|

%

|

|

|

0.3

|

%

|

|

Manganese Ore

|

|

|

108

|

|

|

|

113

|

|

|

|

109

|

|

|

|

312

|

|

|

|

621

|

|

|

|

-4.4

|

%

|

|

|

-0.9

|

%

|

|

|

-49.8

|

%

|

|

Coal

|

|

|

2,497

|

|

|

|

2,091

|

|

|

|

1,402

|

|

|

|

4,648

|

|

|

|

5,678

|

|

|

|

19.4

|

%

|

|

|

78.1

|

%

|

|

|

22.2

|

%

|

|

Nickel

|

|

|

30.2

|

|

|

|

41.5

|

|

|

|

38.6

|

|

|

|

120.2

|

|

|

|

132.9

|

|

|

|

-27.2

|

%

|

|

|

-21.8

|

%

|

|

|

-9.6

|

%

|

|

Copper

|

|

|

69.2

|

|

|

|

73.4

|

|

|

|

87.6

|

|

|

|

219.3

|

|

|

|

266.6

|

|

|

|

-5.7

|

%

|

|

|

-21.0

|

%

|

|

|

-17.7

|

%

|

|

Cobalt (metric tons)

|

|

|

452

|

|

|

|

754

|

|

|

|

622

|

|

|

|

1,919

|

|

|

|

1,849

|

|

|

|

-40.1

|

%

|

|

|

-27.3

|

%

|

|

|

3.8

|

%

|

|

Gold (000'

oz troy)

|

|

|

93

|

|

|

|

96

|

|

|

|

116

|

|

|

|

275

|

|

|

|

349

|

|

|

|

-3.1

|

%

|

|

|

-19.8

|

%

|

|

|

-21.2

|

%

|

1 Including third-party purchases,

run -of-mine and feed for pelletizing plants.

Sales summary

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

% change

|

|

|

000’

metric tons

|

|

3Q21

|

|

|

2Q21

|

|

|

3Q20

|

|

|

9M21

|

|

|

9M20

|

|

|

3Q21/2Q21

|

|

|

3Q21/3Q20

|

|

|

9M21/9M20

|

|

|

Iron

ore1

|

|

|

67,844

|

|

|

|

67,218

|

|

|

|

65,769

|

|

|

|

194,361

|

|

|

|

172,040

|

|

|

|

0.9

|

%

|

|

|

3.2

|

%

|

|

|

13.0

|

%

|

|

Pellets

|

|

|

8,037

|

|

|

|

7,647

|

|

|

|

8,464

|

|

|

|

21,955

|

|

|

|

22,725

|

|

|

|

5.1

|

%

|

|

|

-5.0

|

%

|

|

|

-3.4

|

%

|

|

Manganese Ore

|

|

|

111

|

|

|

|

169

|

|

|

|

428

|

|

|

|

537

|

|

|

|

917

|

|

|

|

-34.3

|

%

|

|

|

-74.1

|

%

|

|

|

-41.4

|

%

|

|

Coal

|

|

|

2,640

|

|

|

|

1,544

|

|

|

|

1,381

|

|

|

|

2,559

|

|

|

|

5,199

|

|

|

|

70.9

|

%

|

|

|

91.9

|

%

|

|

|

20.0

|

%

|

|

Nickel²

|

|

|

41.8

|

|

|

|

47.4

|

|

|

|

50.2

|

|

|

|

137.2

|

|

|

|

124.3

|

|

|

|

-11.8

|

%

|

|

|

-16.7

|

%

|

|

|

10.3

|

%

|

|

Copper

|

|

|

65.4

|

|

|

|

74.2

|

|

|

|

80.6

|

|

|

|

210.8

|

|

|

|

253.3

|

|

|

|

-11.9

|

%

|

|

|

-18.9

|

%

|

|

|

-16.8

|

%

|

1 Including

third-party purchases, run -of-mine and feed for pelletizing plants.

2 Historical

figures exclude VNC sales .

Production guidance

|

|

|

|

2021

|

|

|

Iron ore (Mt)

|

|

|

315-335

|

|

|

Nickel (kt)

|

|

|

165-170

|

|

|

Copper (kt)

|

|

|

295-300

|

|

Iron ore

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

% change

|

|

|

000’ metric tons

|

|

3Q21

|

|

|

2Q21

|

|

|

3Q20

|

|

|

9M21

|

|

|

9M20

|

|

|

3Q21/2Q21

|

|

|

3Q21/3Q20

|

|

|

9M21/9M20

|

|

|

Northern System

|

|

|

53,020

|

|

|

|

43,501

|

|

|

|

56,850

|

|

|

|

138,814

|

|

|

|

139,213

|

|

|

|

21.9

|

%

|

|

|

-6.7

|

%

|

|

|

-0.3

|

%

|

|

Serra Norte and Serra Leste

|

|

|

31,961

|

|

|

|

26,916

|

|

|

|

32,459

|

|

|

|

84,177

|

|

|

|

78,258

|

|

|

|

18.7

|

%

|

|

|

-1.5

|

%

|

|

|

7.6

|

%

|

|

S11D

|

|

|

21,059

|

|

|

|

16,585

|

|

|

|

24,391

|

|

|

|

54,637

|

|

|

|

60,955

|

|

|

|

27.0

|

%

|

|

|

-13.7

|

%

|

|

|

-10.4

|

%

|

|

Southeastern System

|

|

|

19,532

|

|

|

|

18,059

|

|

|

|

16,307

|

|

|

|

51,121

|

|

|

|

40,817

|

|

|

|

8.2

|

%

|

|

|

19.8

|

%

|

|

|

25.2

|

%

|

Itabira (Cauê, Conceição

and others)

|

|

|

7,795

|

|

|

|

7,233

|

|

|

|

6,465

|

|

|

|

20,709

|

|

|

|

17,796

|

|

|

|

7.8

|

%

|

|

|

20.6

|

%

|

|

|

16.4

|

%

|

Minas Centrais (Brucutu and others)

|

|

|

5,696

|

|

|

|

5,490

|

|

|

|

4,394

|

|

|

|

14,642

|

|

|

|

12,233

|

|

|

|

3.8

|

%

|

|

|

29.6

|

%

|

|

|

18.2

|

%

|

Mariana (Alegria, Timbopeba and

others)

|

|

|

6,041

|

|

|

|

5,337

|

|

|

|

5,448

|

|

|

|

15,770

|

|

|

|

10,788

|

|

|

|

13.2

|

%

|

|

|

10.9

|

%

|

|

|

46.2

|

%

|

|

Southern

System

|

|

|

16,138

|

|

|

|

13,441

|

|

|

|

14,930

|

|

|

|

41,287

|

|

|

|

34,054

|

|

|

|

20.1

|

%

|

|

|

8.1

|

%

|

|

|

21.2

|

%

|

|

Paraopeba (Mutuca, Fábrica

and others)

|

|

|

6,867

|

|

|

|

5,899

|

|

|

|

7,064

|

|

|

|

18,083

|

|

|

|

16,585

|

|

|

|

16.4

|

%

|

|

|

-2.8

|

%

|

|

|

9.0

|

%

|

Vargem Grande (Vargem Grande,

Pico and others)

|

|

|

9,271

|

|

|

|

7,542

|

|

|

|

7,866

|

|

|

|

23,204

|

|

|

|

17,469

|

|

|

|

22.9

|

%

|

|

|

17.9

|

%

|

|

|

32.8

|

%

|

|

Midwestern

System

|

|

|

731

|

|

|

|

684

|

|

|

|

589

|

|

|

|

1,915

|

|

|

|

1,793

|

|

|

|

6.9

|

%

|

|

|

24.1

|

%

|

|

|

6.8

|

%

|

|

Corumbá

|

|

|

731

|

|

|

|

684

|

|

|

|

589

|

|

|

|

1,915

|

|

|

|

1,793

|

|

|

|

6.9

|

%

|

|

|

24.1

|

%

|

|

|

6.8

|

%

|

|

IRON

ORE PRODUCTION1

|

|

|

89,421

|

|

|

|

75,685

|

|

|

|

88,676

|

|

|

|

233,137

|

|

|

|

215,877

|

|

|

|

18.1

|

%

|

|

|

0.8

|

%

|

|

|

8.0

|

%

|

|

IRON

ORE SALES2

|

|

|

67,844

|

|

|

|

67,218

|

|

|

|

65,769

|

|

|

|

194,361

|

|

|

|

172,040

|

|

|

|

0.9

|

%

|

|

|

3.2

|

%

|

|

|

13.0

|

%

|

|

IRON ORE AND PELLETS SALES²

|

|

|

75,881

|

|

|

|

74,865

|

|

|

|

74,233

|

|

|

|

216,316

|

|

|

|

194,765

|

|

|

|

1.4

|

%

|

|

|

2.2

|

%

|

|

|

11.1

|

%

|

|

|

1

|

Including third-party purchases,

run -of-mine and feed for pelletizing plants.

|

|

|

2

|

Including third-party purchases

and run -of -mine.

|

Production variation (3Q21 x 2Q21)

Mt

Northern System

Northern System production

increased 21.9% vs. 2Q21, mainly as a result of better weather in the region, with lower rainfall levels 3 , guaranteeing

more stability in production. However, compared to 3Q20, production was lower mainly due to (i) licensing delays consistently impacting

Serra Norte’s ROM availability; and (ii) productivity impacts related to the processing of jaspilite materials in S11D ore body,

which was partially offset by Serra Leste production.

Vale will install the

remaining three of four jaspilite crushers in S11D during 4Q21 and 2022, which is expected improve S11D capacity throughout next year.

In addition to the four jaspilite crushers, a new crusher is required

to process large compact waste blocks, restricting S11D production capacity on around 5 Mtpy until it is installed. The start-up is expected

by 2025.

3 3Q21 = 84mm vs. 2Q21 = 279mm in Serra

Norte.

Southeastern System

Southeastern System

performance improved sequentially largely by (i) higher productivity of Itabira and Mariana complexes’ processing plants due to

the ROM quality improvement of the mines that feed these plants; and (ii) higher availability of hematite ores in Brucutu.

In September, the

Regional Superintendence of Labor (SRT) issued a term of partial suspension of the Mariana Complex interdiction, near the Xingu dam,

in order to allow the regular operation of the Vitória a Minas Railroad (EFVM) on the Fábrica Nova branch. Internal access

between the Timbopeba site and the Alegria site was also allowed. During the interdiction period, Vale implemented an unmanned train

operation covering a 16 km stretch to expedite Timbopeba site production and increased the ROM availability from Alegria mine.

Southern System

The better operational

performance (vs. 2Q21) can largely be attributed to (i) Vargem Grande production increase by dry processing while adjusting the processing

flowsheet of one of its wet-processing plants and after the scheduled maintenance at the Pico site in April; (ii) higher third-party

purchase; (iii) Fábrica site reaching its full capacity after the resumption of beneficiation plants in 2Q21; (iv) more ROM availability

in Mutuca, as expected in its mining plan.

In 3Q21,

Maravilhas III (Phase I) dam operations in Vargem Grande complex started following the issuance of a positive Stability Condition Declaration

(DCE).

In addition, Brazilian

National Mining Agency (ANM) issued a Term of Suspension in October of the interdiction of part of the Long-Distance Belt Conveyor (TCLD)

system of the Vargem Grande Complex, which had been halted since Feb/2019. Vale is commissioning the long-distance conveyor belt segment

close to Vargem Grande dam, resuming after several tests certifying the absence of increased risk to the structure. At the end of commissioning,

an increase of 6 Mtpy is expected in the production capacity of the Vargem Grande site.

Pellets

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

%

change

|

|

|

000’

metric tons

|

|

|

3Q21

|

|

|

|

2Q21

|

|

|

|

3Q20

|

|

|

|

9M21

|

|

|

|

9M20

|

|

|

|

3Q21/2Q21

|

|

|

|

3Q21/3Q20

|

|

|

|

9M21/9M20

|

|

|

Northern System

|

|

|

1,020

|

|

|

|

748

|

|

|

|

1,176

|

|

|

|

2,729

|

|

|

|

2,978

|

|

|

|

36.4

|

%

|

|

|

-13.3

|

%

|

|

|

-8.4

|

%

|

|

São

Luis

|

|

|

1,020

|

|

|

|

748

|

|

|

|

1,176

|

|

|

|

2,729

|

|

|

|

2,978

|

|

|

|

36.4

|

%

|

|

|

-13.3

|

%

|

|

|

-8.4

|

%

|

|

Southeastern System

|

|

|

4,357

|

|

|

|

3,963

|

|

|

|

4,906

|

|

|

|

11,930

|

|

|

|

13,575

|

|

|

|

9.9

|

%

|

|

|

-11.2

|

%

|

|

|

-12.1

|

%

|

|

Itabrasco

(Tubarão 3)

|

|

|

972

|

|

|

|

742

|

|

|

|

821

|

|

|

|

2,297

|

|

|

|

2,164

|

|

|

|

31.0

|

%

|

|

|

18.4

|

%

|

|

|

6.1

|

%

|

|

Hispanobras

(Tubarão 4)

|

|

|

-

|

|

|

|

-

|

|

|

|

863

|

|

|

|

169

|

|

|

|

1,855

|

|

|

|

-

|

|

|

|

-100

|

%

|

|

|

-90.9

|

%

|

|

Nibrasco

(Tubarão 5 and 6)

|

|

|

1,069

|

|

|

|

974

|

|

|

|

1,007

|

|

|

|

2,742

|

|

|

|

3,074

|

|

|

|

9.8

|

%

|

|

|

6.2

|

%

|

|

|

-10.8

|

%

|

|

Kobrasco

(Tubarão 7)

|

|

|

826

|

|

|

|

803

|

|

|

|

849

|

|

|

|

2,236

|

|

|

|

2,200

|

|

|

|

2.9

|

%

|

|

|

-2.7

|

%

|

|

|

1.6

|

%

|

|

Tubarão 8

|

|

|

1,490

|

|

|

|

1,445

|

|

|

|

1,366

|

|

|

|

4,486

|

|

|

|

4,283

|

|

|

|

3.1

|

%

|

|

|

9.1

|

%

|

|

|

4.8

|

%

|

|

Southern System

|

|

|

803

|

|

|

|

975

|

|

|

|

-

|

|

|

|

2,434

|

|

|

|

129

|

|

|

|

-17.6

|

%

|

|

|

n.m.

|

|

|

|

1,786.8

|

%

|

|

Fábrica

|

|

|

-

|

|

|

|

-

|

|

|

|

-

|

|

|

|

-

|

|

|

|

-

|

|

|

|

-

|

|

|

|

-

|

|

|

|

-

|

|

|

Vargem

Grande

|

|

|

803

|

|

|

|

975

|

|

|

|

-

|

|

|

|

2,434

|

|

|

|

129

|

|

|

|

-17.6

|

%

|

|

|

n.m.

|

|

|

|

1,786.8

|

%

|

|

Oman

|

|

|

2,161

|

|

|

|

2,322

|

|

|

|

2,480

|

|

|

|

5,544

|

|

|

|

5,877

|

|

|

|

-6.9

|

%

|

|

|

-12.9

|

%

|

|

|

-5.7

|

%

|

|

PELLETS

PRODUCTION

|

|

|

8,341

|

|

|

|

8,008

|

|

|

|

8,562

|

|

|

|

22,637

|

|

|

|

22,559

|

|

|

|

4.1

|

%

|

|

|

-2.6

|

%

|

|

|

0.3

|

%

|

|

PELLETS

SALES

|

|

|

8,037

|

|

|

|

7,647

|

|

|

|

8,464

|

|

|

|

21,955

|

|

|

|

22,725

|

|

|

|

5.1

|

%

|

|

|

-5.0

|

%

|

|

|

-3.4

|

%

|

Production overview

Pellet

production was in line with 2Q21, still limited by the pellet feed availability from Itabira and Brucutu sites. Quarterly results variations

are mostly explained by (i) lower maintenance activities in São Luis; (ii) higher pellet feed availability from Itabira increasing

Tubarão pellet production; and (iii) lower pellet production in Vargem Grande due to less availability of pellet feed from Plant

#2, while adaptations in the wet-processing flow are being carried out.

Vale

launched a cold agglomerated product called iron ore briquettes, an agglomerated product produced from pellet feed or sinter feed ores.

The iron ore briquette is part of Vale’s strategy to reduce by 15% Scope 3 emissions by 2035. Following this strategy Vale decided

to convert Tubarão 1 & 2 pellet plants to briquetting plants, utilizing some common facilities, and optimizing investments.

Therefore, from this report onwards, the information on Tubarão 1 & 2 plants will no longer be available in this session.

Also,

a third plant is under construction in Vargem Grande Complex. Vale’s initial briquetting capacity at Tubarão 1 & 2 and

Vargem Grande will be approximately 7 Mtpy and the operations are expected to start up in 2023 with an estimated investment of US$ 185

million. More information is available here.

Manganese ore and ferroalloys

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

%

change

|

|

|

000’

metric tons

|

|

|

3Q21

|

|

|

|

2Q21

|

|

|

|

3Q20

|

|

|

|

9M21

|

|

|

|

9M20

|

|

|

|

3Q21/2Q21

|

|

|

|

3Q21/3Q20

|

|

|

|

9M21/9M20

|

|

|

MANGANESE

ORE PRODUCTION

|

|

|

108

|

|

|

|

113

|

|

|

|

109

|

|

|

|

312

|

|

|

|

621

|

|

|

|

-4.4

|

%

|

|

|

-0.9

|

%

|

|

|

-49.8

|

%

|

|

Azul

|

|

|

-

|

|

|

|

-

|

|

|

|

-

|

|

|

|

-

|

|

|

|

230

|

|

|

|

-

|

|

|

|

-

|

|

|

|

-100

|

%

|

|

Urucum

|

|

|

77

|

|

|

|

78

|

|

|

|

89

|

|

|

|

219

|

|

|

|

330

|

|

|

|

-1.5

|

%

|

|

|

-13.6

|

%

|

|

|

-33.7

|

%

|

|

Morro

da Mina

|

|

|

31

|

|

|

|

35

|

|

|

|

20

|

|

|

|

94

|

|

|

|

61

|

|

|

|

-12.9

|

%

|

|

|

57.0

|

%

|

|

|

54.9

|

%

|

|

MANGANESE

ORE SALES

|

|

|

111

|

|

|

|

169

|

|

|

|

428

|

|

|

|

537

|

|

|

|

917

|

|

|

|

-34.3

|

%

|

|

|

-74.1

|

%

|

|

|

-41.4

|

%

|

|

FERROALLOYS

PRODUCTION

|

|

|

19

|

|

|

|

19

|

|

|

|

15

|

|

|

|

54

|

|

|

|

58

|

|

|

|

0.0

|

%

|

|

|

26.7

|

%

|

|

|

-6.1

|

%

|

|

FERROALLOYS

SALES

|

|

|

16

|

|

|

|

15

|

|

|

|

15

|

|

|

|

45

|

|

|

|

52

|

|

|

|

6.7

|

%

|

|

|

6.7

|

%

|

|

|

-13.1

|

%

|

Production and sales overview

Manganese

ore production totaled 108 kt in 3Q21, 4.4% lower than in 2Q21, primarily attributable to the programmed reduction in production at Morro

da Mina, in line with its mining plan. When compared to 3Q20, production was in line.

Manganese

ore sales were 34.3% and 74.1% lower than in 2Q21 and 3Q20, respectively, given the suspension of operations in the Azul mine and the

end of its remaining inventory.

On

September 28th, Vale signed the agreement for the sale of its manganese ferroalloy assets in Minas Gerais to the Grupo VDL.

The conclusion of the divestment, still subject to approval by the Administrative Council for Economic Defense (CADE), will end Vale's

activities in the production of manganese ferroalloys, simplifying Vale’s portfolio.

Nickel

Finished

production by source

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

%

change

|

|

|

000’

metric tons

|

|

|

3Q21

|

|

|

|

2Q21

|

|

|

|

3Q20

|

|

|

|

9M21

|

|

|

|

9M20

|

|

|

|

3Q21/2Q21

|

|

|

|

3Q21/3Q20

|

|

|

|

9M21/9M20

|

|

|

Canada

|

|

|

12.4

|

|

|

|

20.4

|

|

|

|

18.9

|

|

|

|

58.0

|

|

|

|

67.3

|

|

|

|

-39.2

|

%

|

|

|

-34.4

|

%

|

|

|

-13.8

|

%

|

|

Sudbury

|

|

|

2.4

|

|

|

|

9.0

|

|

|

|

6.5

|

|

|

|

23.4

|

|

|

|

32.0

|

|

|

|

-73.3

|

%

|

|

|

-63.1

|

%

|

|

|

-26.9

|

%

|

|

Thompson

|

|

|

0.6

|

|

|

|

1.4

|

|

|

|

2.2

|

|

|

|

4.8

|

|

|

|

8.5

|

|

|

|

-57.1

|

%

|

|

|

-72.7

|

%

|

|

|

-43.5

|

%

|

|

Voisey's

Bay

|

|

|

9.4

|

|

|

|

10.0

|

|

|

|

10.1

|

|

|

|

29.8

|

|

|

|

26.8

|

|

|

|

-6.0

|

%

|

|

|

-6.9

|

%

|

|

|

11.2

|

%

|

|

Indonesia

|

|

|

15.1

|

|

|

|

14.5

|

|

|

|

15.3

|

|

|

|

45.0

|

|

|

|

51.4

|

|

|

|

4.1

|

%

|

|

|

-1.3

|

%

|

|

|

-12.5

|

%

|

|

Brazil

|

|

|

2.2

|

|

|

|

5.2

|

|

|

|

3.2

|

|

|

|

13.7

|

|

|

|

9.4

|

|

|

|

-57.7

|

%

|

|

|

-31.3

|

%

|

|

|

45.7

|

%

|

|

Feed

from third-parties1

|

|

|

0.6

|

|

|

|

1.3

|

|

|

|

1.3

|

|

|

|

3.5

|

|

|

|

4.8

|

|

|

|

-53.8

|

%

|

|

|

-53.8

|

%

|

|

|

-27.1

|

%

|

|

NICKEL

PRODUCTION

|

|

|

30.2

|

|

|

|

41.5

|

|

|

|

38.6

|

|

|

|

120.2

|

|

|

|

132.9

|

|

|

|

-27.2

|

%

|

|

|

-21.8

|

%

|

|

|

-9.6

|

%

|

|

NICKEL

SALES2

|

|

|

41.8

|

|

|

|

47.4

|

|

|

|

50.2

|

|

|

|

137.1

|

|

|

|

124.3

|

|

|

|

-11.8

|

%

|

|

|

-16.7

|

%

|

|

|

10.3

|

%

|

|

|

1

|

External

feed purchased from third -parties and processed into finished nickel in our Canadian operations.

|

|

|

2

|

Excludes

VNC sales volumes.

|

Production

Variation (3Q21 x 2Q21) kt

Canadian

operations

Finished

production from Sudbury and Thompson ore sources declined 73.3% and 57.1% vs, 2Q21, respectively. The production decrease was a

direct result of the labour disruption at Sudbury. Both Sudbury and Thompson source concentrate are further processed at

Sudbury’s Copper Cliff Smelter.

Finished

production from Voisey’s Bay ore source in 3Q21 was marginally lower than 2Q21, due to weather conditions caused by the Hurricane

Larry at Long Harbour.

Indonesian

operation (PTVI)

Finished

production from PTVI source reached 15.1 kt in 3Q21, 4.1% higher than 2Q21 and 5.9% lower than 3Q20.

Clydach

Nickel Refinery had a strong performance following unscheduled maintenance to one of the kilns during 2Q21. This was partially offset

by a failure of the briquetting machine at the Matsusaka Refinery, which impacted finished Tonimet Briquette production in 3Q21.

Nickel-in-matte

production at PTVI site reached 18.1 kt in 3Q21, increasing 21% compared to 2Q21, mainly due to a strong performance throughout the quarter

with no major maintenance interruptions.

Brazilian

operation (Onça Puma)

Production

at Onça Puma reached 2.2 kt in 3Q21, 57.7% lower than 2Q21, mainly due to an extended maintenance during the quarter, as previously

scheduled. The maintenance was successfully completed by quarter end.

Feed

from third-parties

Finished

nickel produced from third-party feed reached 0.6 kt in 3Q21, 53.8% lower than 2Q21, mainly due to the labour disruption at Sudbury,

which impacted the ability to process the material. The purchase of third-party feed is a normal process to sustain a regular finished

nickel production flow.

Sales

Nickel

sales volumes were 41.8 kt in 3Q21, 11.8% lower than 2Q21, mainly as a result of the labour disruption at Sudbury, partially offset by

inventory sales and third party sales.

Copper

Finished

production by source

|

|

|

|

|

|

|

|

|

|

|

|

|

%

change

|

|

|

000’

metric tons

|

|

|

3Q21

|

|

|

2Q21

|

|

|

3Q20

|

|

|

9M21

|

|

|

9M20

|

|

|

3Q21/2Q21

|

|

|

|

3Q21/3Q20

|

|

|

|

9M21/9M20

|

|

|

BRAZIL

|

|

|

63.4

|

|

|

55.2

|

|

|

67.6

|

|

|

168.7

|

|

|

193.0

|

|

|

14.9

|

%

|

|

|

-6.2

|

%

|

|

|

-12.6

|

%

|

|

Salobo

|

|

|

38.0

|

|

|

38.7

|

|

|

45.4

|

|

|

110.8

|

|

|

128.9

|

|

|

-1.8

|

%

|

|

|

-16.3

|

%

|

|

|

-14.0

|

%

|

|

Sossego

|

|

|

25.4

|

|

|

16.6

|

|

|

22.2

|

|

|

57.9

|

|

|

64.1

|

|

|

53.0

|

%

|

|

|

14.4

|

%

|

|

|

-9.7

|

%

|

|

CANADA

|

|

|

5.8

|

|

|

18.2

|

|

|

20.0

|

|

|

50.7

|

|

|

73.6

|

|

|

-68.1

|

%

|

|

|

-71.0

|

%

|

|

|

-31.1

|

%

|

|

Sudbury

|

|

|

1.0

|

|

|

13.0

|

|

|

13.1

|

|

|

33.4

|

|

|

58.1

|

|

|

-92.3

|

%

|

|

|

-92.4

|

%

|

|

|

-42.5

|

%

|

|

Thompson

|

|

|

-

|

|

|

0.1

|

|

|

0.2

|

|

|

0.3

|

|

|

0.7

|

|

|

-100.0

|

%

|

|

|

-100.0

|

%

|

|

|

-57.1

|

%

|

|

Voisey's

Bay

|

|

|

4.6

|

|

|

4.5

|

|

|

5.7

|

|

|

15.2

|

|

|

11.5

|

|

|

2.2

|

%

|

|

|

-19.3

|

%

|

|

|

32.2

|

%

|

|

Feed

from third-parties

|

|

|

0.3

|

|

|

0.6

|

|

|

1.0

|

|

|

2.0

|

|

|

3.3

|

|

|

-50.0

|

%

|

|

|

-70.0

|

%

|

|

|

-39.4

|

%

|

|

COPPER

PRODUCTION

|

|

|

69.2

|

|

|

73.5

|

|

|

87.6

|

|

|

219.3

|

|

|

266.6

|

|

|

-5.7

|

%

|

|

|

-21.0

|

%

|

|

|

-17.7

|

%

|

|

COPPER

SALES

|

|

|

65.4

|

|

|

74.2

|

|

|

80.6

|

|

|

210.8

|

|

|

253.3

|

|

|

-11.9

|

%

|

|

|

-18.9

|

%

|

|

|

-16.8

|

%

|

|

Copper

Sales Brazil

|

|

|

62.3

|

|

|

55.8

|

|

|

62.3

|

|

|

163.5

|

|

|

180.5

|

|

|

11.6

|

%

|

|

|

0.0

|

%

|

|

|

-9.4

|

%

|

|

Copper

Sales Canada

|

|

|

3.1

|

|

|

18.4

|

|

|

18.3

|

|

|

47.3

|

|

|

72.7

|

|

|

-83.2

|

%

|

|

|

-83.1

|

%

|

|

|

-34.9

|

%

|

Production

Variation (3Q21 x 2Q21) kt

Production

and sales overview

In

3Q21, copper production at Salobo totalled 38.0 kt, 1.8% lower than 2Q21 and 16.3 % lower than 3Q20. Total mine movement continued to

increase vs. 2Q21, achieving 11.4 Mt in September, the highest result year to date. Production decrease was a result of corrective maintenance

and low crusher availability during the quarter, which limited the ability to reach full production capacity at the site.

Copper

production at Sossego totalled 25.4 kt, 53.0% higher than 2Q21 and 14.4% higher than 3Q20. Production volumes improved compared to 2Q21

and 3Q20 as a result of increased plant availability, after scheduled maintenance was completed in 2Q21, allowing for good performance

in the quarter.

In

3Q21, copper production in Canada reached 5.8 kt, 68.1% lower than 2Q21 and 71.0% lower than 3Q20, as volumes were directly impacted

by Sudbury labour disruption.

Sales

volumes4 of copper were 65.4 kt in 3Q21, 11.9% lower than 2Q21, mainly due to the labour disruption at Sudbury. This was partially

offset by higher sales from Brazilian operations as a result of production increase.

4

Sales volumes are lower compared to production volumes due to payable copper vs. contained copper: part of the copper contained

in the concentrates is lost in the smelting and refining process, hence payable quantities of copper are approximately 3.5% lower than

contained volumes.

Base Metals by-products

Finished production by source

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

% change

|

|

|

000’

metric tons

|

|

|

3Q21

|

|

|

|

2Q21

|

|

|

|

3Q20

|

|

|

|

9M21

|

|

|

|

9M20

|

|

|

|

3Q21/2Q21

|

|

|

|

3Q21/3Q20

|

|

|

|

9M21/9M20

|

|

|

COBALT

|

|

|

452

|

|

|

|

754

|

|

|

|

622

|

|

|

|

1,919

|

|

|

|

1,849

|

|

|

|

-40.1

|

%

|

|

|

-27.3

|

%

|

|

|

3.8

|

%

|

|

PLATINUM (000’ oz troy)

|

|

|

2

|

|

|

|

30

|

|

|

|

26

|

|

|

|

62

|

|

|

|

109

|

|

|

|

-93.3

|

%

|

|

|

-92.3

|

%

|

|

|

-43.1

|

%

|

|

PALLADIUM (000’ oz troy)

|

|

|

4

|

|

|

|

36

|

|

|

|

37

|

|

|

|

79

|

|

|

|

147

|

|

|

|

-88.9

|

%

|

|

|

-89.2

|

%

|

|

|

-46.3

|

%

|

|

GOLD (000’ oz troy)¹

|

|

|

93

|

|

|

|

96

|

|

|

|

116

|

|

|

|

275

|

|

|

|

349

|

|

|

|

-3.1

|

%

|

|

|

-19.8

|

%

|

|

|

-21.2

|

%

|

TOTAL BY-PRODUCTS

(000’ metric tons Cu eq.)² ³

|

|

|

23

|

|

|

|

42

|

|

|

|

43

|

|

|

|

108

|

|

|

|

202

|

|

|

|

-45.2

|

%

|

|

|

-46.5

|

%

|

|

|

-46.5

|

%

|

¹ Includes gold from Copper and Nickel

operations .

² Includes iridium, rhodium, ruthenium and silver.

³ Copper equivalent tonnes calculated using average market metal prices for each quarter. Market reference prices: for copper, cobalt, gold and silver: LME spot; for Platinum and Palladium: NYMEX spot; for other PGMs: Johnson Matthey.

Production overview

Finished production of Base Metals by-products was

largely impacted by the labour disruption at Sudbury. Both Sudbury and Thompson source concentrate are further processed at

Sudbury’s Copper Cliff Smelter, impacting the production of cobalt and PGMs.

Coal

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

% change

|

|

|

000’

metric tons

|

|

|

3Q21

|

|

|

|

2Q21

|

|

|

|

3Q20

|

|

|

|

9M21

|

|

|

|

9M20

|

|

|

|

3Q21/2Q21

|

|

|

|

3Q21/3Q20

|

|

|

|

9M21/9M20

|

|

|

COAL PRODUCTION

|

|

|

2,497

|

|

|

|

2,091

|

|

|

|

1,402

|

|

|

|

5,678

|

|

|

|

4,648

|

|

|

|

19.4

|

%

|

|

|

78.1

|

%

|

|

|

22.2

|

%

|

|

Metallurgical coal

|

|

|

1,069

|

|

|

|

980

|

|

|

|

756

|

|

|

|

2,607

|

|

|

|

2,436

|

|

|

|

9.1

|

%

|

|

|

41.4

|

%

|

|

|

7.0

|

%

|

|

Thermal coal

|

|

|

1,428

|

|

|

|

1,111

|

|

|

|

646

|

|

|

|

3,071

|

|

|

|

2,211

|

|

|

|

28.5

|

%

|

|

|

121.0

|

%

|

|

|

38.9

|

%

|

|

COAL SALES

|

|

|

2,640

|

|

|

|

1,544

|

|

|

|

1,381

|

|

|

|

5,199

|

|

|

|

4,332

|

|

|

|

71.0

|

%

|

|

|

91.2

|

%

|

|

|

20.0

|

%

|

|

Metallurgical coal

|

|

|

1,150

|

|

|

|

713

|

|

|

|

809

|

|

|

|

2,336

|

|

|

|

2,030

|

|

|

|

61.3

|

%

|

|

|

42.1

|

%

|

|

|

15.1

|

%

|

|

Thermal coal

|

|

|

1,490

|

|

|

|

831

|

|

|

|

572

|

|

|

|

2,863

|

|

|

|

2,302

|

|

|

|

79.3

|

%

|

|

|

160.5

|

%

|

|

|

24.4

|

%

|

Production Variation (3Q21 x 2Q21)

Mt

Production and sales overview

Coal production was 19.4%

higher than in 2Q21 and 78.1% higher than in 3Q20 as a result of the improved productivity of the revamped plant.

The production is ramping-up

and is expected to be concluded by the next quarter. However, due to the upcoming rainy season, the annual production rate of 15 Mtpy

may not be reached until the end of the year, although an improvement is expected for 4Q21.

Coal sales grew strongly

both on a quarter-on-quarter and year-over-year basis following the improved operational performance and stronger demand of the seaborne

market.

Signatures

Pursuant to the requirements of the Securities Exchange Act of 1934,

the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

|

Date: October 19, 2021

|

|

Head of Investor Relations

|

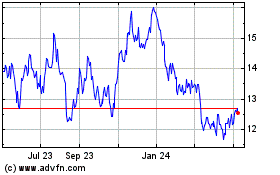

Vale (NYSE:VALE)

Historical Stock Chart

From Mar 2024 to Apr 2024

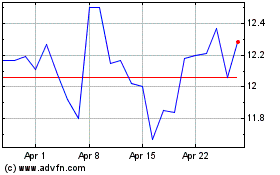

Vale (NYSE:VALE)

Historical Stock Chart

From Apr 2023 to Apr 2024