This week at

Formnext, the world’s largest

additive manufacturing event, HP is showcasing its new commercial

Jet Fusion and Metal Jet 3D printing solutions, new post processing

capabilities, expanded Digital Manufacturing Network (DMN), new

materials and recycling program, and a variety of industrial

production applications. The show marks the first time HP is

publicly exhibiting its new

HP Jet Fusion 5420W

Solution including white applications, and the full

modular

HP Metal Jet S100 Solution including a new

John Deere production application.

“Additive manufacturing delivers on today’s most urgent market

demands including sustainable innovation, hyper-personalization,

and business resiliency,” said Didier Deltort, President of

Personalization & 3D Printing, HP Inc. “Together, with

our global network of partners and customers, we are scaling

additive manufacturing to meet these needs.”

New Metal Jet S100 Production Application

Launched in September, HP’s Metal Jet S100 Solution is enabling

industrial customers such as Domin Digital Motion, Lumenium, and

Schneider Electric, to achieve better productivity, low part cost,

and outstanding quality. John Deere, the global manufacturing

leader of agricultural and construction equipment, is using Metal

Jet technology for the production of a valve in the tractor fuel

system.

Together with GKN, John Deere is now

manufacturing Metal Jet-printed valves in its agricultural

machinery. In addition to significant productivity gains and

environmental benefits, the high-quality part is functional in

extreme weather conditions. John Deere is also leveraging HP’s

Multi Jet Fusion technology to optimize its production process,

using 3D printed prototypes to test and fine tune components and

parts such as windshield holders, reducing pre-assembly from 30

days to ten, delivery times by up to ten weeks, and overall

production costs by between 20 to 25 percent.

“Our focus on innovation and sustainability is at the core of

everything we do for our customers,” said Dr. Jochen

Müller, Manager Global Digital Engineering at John Deere.

“We are proud to be among the first in the agricultural industry to

leverage the benefits 3D printing for both prototyping and final

parts production. Leveraging industrial 3D printing platforms for

polymers and metals, we are discovering opportunities to deliver

more efficient, reliable, and sustainable equipment.”

HP Unveils New Jet Fusion 5400 Series

To enable entirely new production applications, HP is adding the

new HP Jet Fusion 5400 Series to its existing Jet

Fusion portfolio, and unveiled the first product in the series, the

HP Jet Fusion 5420W Solution. The new solution

enables consistent, high-quality production of white parts, and

provides the benefits of HP’s robust, manufacturing-ready Multi Jet

Fusion platform, including industrial-grade reliability, low cost

per part, and enhanced manufacturing predictability. Ideal for the

automotive, consumer goods, healthcare, and industrial markets,

early customers using the new solution to produce innovative white

applications include DI Labs, Prototal

Industries, and Weerg.

“HP continues to provide us with the advancements we need to

push the boundaries of additive manufacturing and produce the final

parts our customers need,” said Jan Löfving, CEO, Prototal

Industries. “Beyond the industrial grade production HP

delivers, we are seeing immediate interest in the new white

applications made possible by the latest addition to HP’s Multi Jet

Fusion family. As a proud Digital Manufacturing Partner in HP’s

DMN, we are equipped to take on bold, innovative projects and help

companies get the most value out of AM production.”

HP’s commitment to providing customers with new innovation,

technological advancements, professional services, and flexible

business models is yielding significant growth of parts production.

Since announcing its cumulative 100 million Multi Jet Fusion parts

milestone at Formnext last year, more than 70 million

additional parts have been printed in the past twelve

months.

In addition to the new white applications, HP is showcasing a

variety of production parts across industries, including

award-winning applications from General Motors and

Smith:

- Using their HP Jet Fusion fleet, GKN Forecast 3D produced

60,000 spoiler closeout seals with BASF ULTRASINT® TPU01

(thermoplastic polyurethane) for General Motors. Innovative vapor

polishing and drying processes enabled by AMT cleared a bottleneck,

halved production time, and were used to finish parts, eliminating

the need for post-print dyeing. The seals close out gaps on the

left and right sides of the rear spoiler, improving finish and fuel

efficiency, and the spoiler closeout seal recently earned top prize

in the additive manufacturing category at the 51st annual SPE

Automotive Innovation Awards.

- Demonstrating the power of hyper-personalization, Smith I/O MAG

Imprint 3D Goggles are produced with Multi Jet Fusion technology

and offer a truly custom fit based on the individualized features

of a person’s face. Named one of Time Magazine’s Best Inventions of

2022, these first-of-their-kind goggles eliminate light leaks, air

gaps, and hot spots for world class performance on the slopes.

Ecosystem Collaboration – Materials and Post

Processing

HP continues to work closely on materials development with

partners including Arkema, BASF, Evonik, and

Lubrizol. This includes Lubrizol’s announcement of the new

ESTANE 3D M88A TPU, a flexible and highly durable material which

enables complex geometries and lattice structures.

To advance post processing, HP and AMT announced a new strategic

alliance to provide customers with seamless, fully automated post

processing support through the entire 3D printing production

workflow. Together, the companies are helping customers more

efficiently and cost effectively integrate and apply post

processing capabilities such as unpacking, cleaning, surface

finishing, coloring, sporting and quality control, for applications

produced with HP’s industrial Jet Fusion 3D printing portfolio

including HP’s new Jet Fusion 5420W Solution. Oechsler, a leading

industrial technology company and a new Digital Manufacturing

Partner in HP’s DMN, is the first to take advantage of the joint

post processing support to develop a range of applications.

“At Oechsler, we choose to work with companies who have a shared

vision of working together to deliver optimal outcomes. HP

and AMT building a comprehensive approach from printing to an

integrated post processing solution is a critical step in the

adoption of additive manufacturing at scale,” said Matthias

Weisskopf, General Manager, OECHSLER Motion.

In addition to its partnership with AMT, HP is collaborating

across the post processing ecosystem to ensure customers have

access to a broad range of alternatives from providers including

AM Flow, DyeMansion, and Rösler Group AM

Solutions. DyeMansion is offering advanced post processing

options for Multi Jet Fusion customers including surface finishing

and coloring for white parts produced with the new Jet Fusion 5420W

Solution.

HP 3D Printing Commitment to Sustainability

3D printing is increasingly being recognized as a conduit for

more sustainable manufacturing. The recent AM

Power 'Sustainability of Metal Additive

Manufacturing’ report confirmed that

metal binder jetting is one of the most sustainable production

methods compared to traditional manufacturing. As an active member

of Additive Manufacturing Green Trade Association (AMGTA), HP is

committed to accelerating sustainable manufacturing practices

internally and across its ecosystem of partners and customers.

Globally, companies of all sizes and across industries,

including HP’s network of production partners, have signaled the

importance of sustainable production practices. In response, HP is

offering its customers using polymer-based technologies a new

Virtucycle® recycling and buyback program by Arkema. The program

enables interested HP customers to sell used PA11 and PA12 powders,

and printed parts, as opposed to disposing materials via costly,

environmentally harmful practices such as landfilling or

burning.

HP Showcasing New Advancements and Applications at

Formnext

Learn more on how to propel your business with the new HP Jet

Fusion 5420W 3D Printing Solution and Metal Jet S100 Solution. See

the new solutions in action along with industrial production

applications at the HP booth at Formnext (Hall 12.1; booth

D59).

About HP

HP Inc. is a technology company that believes one thoughtful

idea has the power to change the world. Its product and service

portfolio of personal systems, printers, and 3D printing solutions

helps bring these ideas to life. Visit http://www.hp.com.

Contact:

Michele GuthrieMichele.b.guthrie@hp.com

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/33606d93-ed66-42ce-8848-460aa89c5a22

https://www.globenewswire.com/NewsRoom/AttachmentNg/f3554ede-cfc5-4b31-968e-af193002951c

https://www.globenewswire.com/NewsRoom/AttachmentNg/196c22ce-3a80-4a03-9efe-6df49efe8e61

https://www.globenewswire.com/NewsRoom/AttachmentNg/34492f9b-f087-4284-927b-19ce1c2f4044

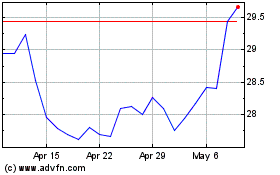

HP (NYSE:HPQ)

Historical Stock Chart

From Mar 2024 to Apr 2024

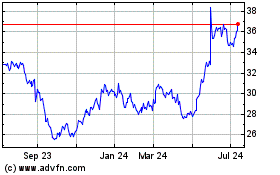

HP (NYSE:HPQ)

Historical Stock Chart

From Apr 2023 to Apr 2024