By Ben Foldy and Mike Colias

General Motors Co. is looking to build a second battery factory

in the U.S. with joint-venture partner LG Chem Ltd., the latest

move in the Detroit auto maker's efforts to expand its investment

in electric vehicles.

A GM spokesman confirmed to The Wall Street Journal that the

companies are exploring building a second battery-cell plant and

said a decision could come in the first half of this year.

GM and LG are close to completing a decision to locate the plant

in Tennessee, said people familiar with the matter. A final

selection hasn't yet been made, the people said.

Already, the two companies are building a $2.3 billion battery

plant in northeast Ohio that is expected to open next year and

eventually supply enough batteries to power hundreds of thousands

of vehicles annually. The new plant is likely to be a similar-size

investment, some of the people said.

GM, the nation's largest auto maker by sales, has set ambitious

targets for converting its global lineup to electric vehicles,

revealing its aim earlier this year to phase out gas-engine models

from its showrooms by 2035.

The rush by GM and other global car companies to sell more

plug-in models has stoked concerns among auto executives and

analysts over future battery shortages and has led some auto

manufacturers to get in the business of making their own battery

cells, often in joint ventures with big battery makers.

LG Chem is in discussions with GM to add battery production,

said Seungse Chang, the company's senior vice president of

corporate strategy at its battery-making subsidiary, in a

statement. The company also plans additional expansions of its U.S.

battery-making operations to support other auto makers, he

said.

The Biden administration has made transitioning from gas-powered

to electric vehicles a cornerstone of its domestic policy agenda,

aiming to use the technology both to fight climate change and

create new jobs to help cushion the possible loss of some in

fossil-fuel industries.

The White House last week ordered a review of the U.S. battery

supply chain, aiming to lessen dependence on countries like China,

which currently dominates the market for batteries and their

materials.

GM is investing $27 billion in electric and driverless cars

through mid-decade, among the industry's most aggressive bets.

Unlike some rivals, GM is using in-house battery technology,

branded Ultium, which company executives say will lower battery

costs by nearly 40% on new plug-in vehicles that begin to roll out

over the next year compared with those it sells today.

It is also supplying the technology to Honda Motor Co. to

develop new electric models, and GM is looking for more such deals,

GM Chief Executive Mary Barra said last week.

Ms. Barra is counting on 30 new battery-powered GM models

globally by 2025--two-thirds of which are slated for North

America--to deliver profit growth. Currently, the company sells

only one electric model in the U.S., the Chevrolet Bolt, along with

a few in China, and generates all its profit from gasoline- and

diesel-powered vehicles.

Today, most battery manufacturing occurs in Asia and Europe, and

the battery production that is in the U.S. is largely controlled by

Tesla Inc., according to research firm Benchmark Mineral

Intelligence. For example, the recently launched Ford Mustang

Mach-E relies on batteries made in Poland.

But as auto makers prepare to sell more electric cars in the

U.S., they also want to reduce the sizable costs of shipping heavy

batteries across oceans, executives say.

Some car companies, such as GM and Volkswagen AG, have moved to

vertically integrate, joining partners like LG and Northvolt AB to

invest in their own battery-cell factories and lock in supplies.

Tesla, meanwhile, operates a battery plant in Nevada with Panasonic

Corp.

Ms. Barra hinted recently that GM may expand its battery-making

capacity beyond the Ohio factory but hasn't discussed specific

plans.

"We are already seeing the benefits of having our own cell

manufacturer, " she said during a virtual investor conference last

week. "It's allowing us to go much deeper into the supply base to

secure what we need."

The company already has begun retooling its North American

factory network to build more plug-in vehicles. It is spending

roughly $6 billion to convert assembly plants in Detroit, Spring

Hill, Tenn., and Ingersoll, Ontario, to build plug-in cars.

The new U.S. battery plant would be a third for South Korean

battery maker LG Chem. The company is also embroiled in a

trade-secret dispute with rival SK Innovation Co., which it claims

stole LG's trade secrets through a targeted campaign of poaching

employees. SKI has denied the allegations.

Last month, the U.S. International Trade Commission affirmed an

earlier finding in LG's favor that SKI destroyed evidence. The

decision threatens to derail a large battery factory project SKI is

constructing in Georgia. Both companies met last month with the

Biden administration, according to people familiar with the

meetings, and LG's representatives believe the company would be

able to increase U.S. production to cover any shortfalls caused by

sanctions on SKI.

Write to Ben Foldy at Ben.Foldy@wsj.com and Mike Colias at

Mike.Colias@wsj.com

(END) Dow Jones Newswires

March 04, 2021 05:44 ET (10:44 GMT)

Copyright (c) 2021 Dow Jones & Company, Inc.

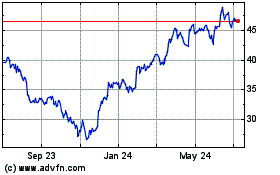

General Motors (NYSE:GM)

Historical Stock Chart

From Mar 2024 to Apr 2024

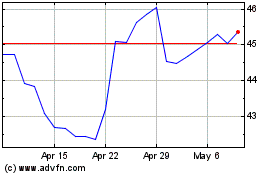

General Motors (NYSE:GM)

Historical Stock Chart

From Apr 2023 to Apr 2024