GM, LG to Spend $2.3 Billion on Venture to Make Electric-Car Batteries -- Update

December 05 2019 - 11:17AM

Dow Jones News

By Mike Colias

General Motors Co. and South Korea's LG Chem plan to jointly

build a large battery-cell factory in Ohio, the latest example of

auto makers plowing money into the development of electric

cars.

GM and LG said Thursday they will invest a combined $2.3 billion

in a 50-50 joint venture. The companies will co-develop and

assemble battery cells to be used in GM electric vehicles in coming

years, including a battery-powered truck that GM plans to introduce

in the fall of 2021.

Auto makers have been partnering with and investing in battery

makers as they gear up to spend around $225 billion to develop new

electric-vehicle models over the next several years, according to

consulting firm AlixPartners LP. Tightening fuel-efficiency and

emissions regulations, especially in China and Europe, are prodding

auto makers to electrify their vehicle lineups.

The GM-LG factory will be built near Lordstown, Ohio, where GM

last spring closed a large vehicle assembly plant that in recent

years had employed roughly 4,000 workers. A startup company has

acquired that facility, where it plans to make electric trucks.

GM said the new battery plant will employ more than 1,100

workers. Construction on the factory is expected to begin in

mid-2020.

The Wall Street Journal this fall reported that GM planned to

invest in a joint-venture battery plant in the Lordstown area. GM

discussed the project with United Auto Worker officials during

contract talks as a way to blunt the impact of the Lordstown

factory's closure. The company said Thursday it will be up to the

workers once in place to decide whether they want to unionize.

Car companies generally have contracted with suppliers such as

LG Chem for the lithium-ion cells that go into large battery packs

for use in electric vehicles. Auto makers have been forging closer

ties with battery makers lately, seeking to lower cost and secure

future battery supplies.

Volkswagen AG said in June it will spend $1 billion on battery

production, including a joint-venture investment with a Swedish

startup. Tesla Inc.'s massive, Gigafactory battery plant in the

Nevada desert is in partnership with Japan's Panasonic Corp.

GM Chief Executive Mary Barra said the joint venture with LG

will speed GM's electric-vehicle development and reduce costs.

"The new facility will help us scale production and dramatically

enhance EV profitability and affordability," Ms. Barra told

reporters Thursday.

The companies said the joint venture would drive down the cost

of electric-vehicle batteries to "industry-leading levels." GM said

the plant would be among the world's largest battery-cell

factories.

GM plans to introduce at least 20 electric models globally by

2023. Many of those will be for the China market, where the

government has put manufacturer quotas on sales of vehicles that

don't produce tailpipe emissions.

LG Chem supplies the cells that go into the Chevrolet Bolt, a

small electric car that GM introduced in 2016 as a potential

competitor for Tesla's Model 3. Both cars were billed as the

industry's first attempts at a relatively affordable vehicle with a

range of more than 200 miles on a single charge.

Bolt sales totaled about 13,000 through the first three quarters

of this year, compared with about 67,000 Model 3 sales, according

to the Automotive News Data Center. GM has said it would introduce

a second Chevy electric vehicle for the U.S., based on the Bolt's

mechanical layout.

Write to Mike Colias at Mike.Colias@wsj.com

(END) Dow Jones Newswires

December 05, 2019 11:02 ET (16:02 GMT)

Copyright (c) 2019 Dow Jones & Company, Inc.

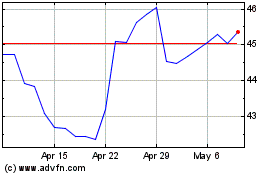

General Motors (NYSE:GM)

Historical Stock Chart

From Mar 2024 to Apr 2024

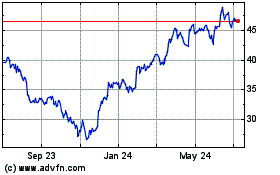

General Motors (NYSE:GM)

Historical Stock Chart

From Apr 2023 to Apr 2024