By Peter Loftus

A contract manufacturing plant that is supposed to help make

Johnson & Johnson's Covid-19 vaccine didn't keep clean,

sanitary conditions and failed to take proper steps to prevent

contamination, federal health regulators said Wednesday.

Among the problems identified during the regulators' inspection

of the plant: cross-contamination of two different vaccines in

production at the plant. Their names were redacted, but people

familiar with the matter have said they are the Covid-19 vaccines

from J&J and from AstraZeneca PLC.

The U.S. Food and Drug Administration, which inspected the plant

owned by contract manufacturer Emergent BioSolutions Inc., said it

completed the inspection on Tuesday and would work with Emergent to

address the findings from the inspection.

Production of J&J's vaccine at the Emergent plant has been

paused, and material already manufactured will undergo additional

testing before it is released for potential distribution, the FDA

said.

"We will not allow the release of any product until we feel

confident that it meets our expectations for quality," said FDA

Acting Commissioner Janet Woodcock and Peter Marks, who heads the

FDA department overseeing vaccines.

The Emergent plant recently had a contamination-related mishap

that ruined a batch of the main ingredient for J&J's Covid-19

vaccine. No doses were distributed from the failed batch, and the

FDA hasn't authorized doses using material from the Emergent plant

to be distributed.

The mishap led to J&J taking over responsibility for

producing its vaccine at the Emergent plant.

Emergent, of Gaithersburg, Md., said it is working with the FDA

and J&J to quickly resolve the issues identified.

"While we are never satisfied to see shortcomings in our

manufacturing facilities or process, they are correctable and we

will take swift action to remedy them," the company said.

J&J, of New Brunswick, N.J., said it will ensure that all of

the FDA's inspection findings are addressed promptly and

comprehensively. The company said it is trying to secure FDA

authorization for making the main ingredient at the Emergent plant

as quickly as possible.

The doses of J&J's vaccine that have been distributed in the

U.S. contain drug substance manufactured at J&J's own plant in

the Netherlands.

The FDA's inspection of the Emergent plant is unrelated to the

agency's probe of serious blood-clot conditions seen in a handful

of people after they received the J&J Covid-19 vaccine.

Vaccinations with J&J's shot have been paused in the U.S.

while health authorities investigate the blood-clotting issue.

FDA inspectors conducted their inspection at Emergent's

Baltimore plant from April 12 through April 20.

At the conclusion of the inspection, they issued a Form 483,

which is a summary of findings that a plant didn't meet quality

standards. The FDA expects drug companies to fix issues identified

in a Form 483.

Their 13-page inspection report, which is partially redacted,

outlines numerous lapses in meeting quality standards at the

plant.

The FDA cited cross-contamination of a batch of one viral

vaccine with material used for a second viral vaccine, which the

agency said Emergent failed to prevent and properly

investigate.

The names of the two vaccines involved are redacted in the

report, but people familiar with the matter have said the

cross-contamination was between materials used for the Covid-19

vaccines from J&J and from AstraZeneca and its partner the

University of Oxford.

The AstraZeneca-Oxford vaccine hasn't been authorized for use in

the U.S., while J&J's shot was cleared in late February.

Production of the AstraZeneca vaccine at the Emergent plant has

been stopped and is being moved elsewhere.

The FDA inspection report said that a worker who dispensed raw

materials for one of the vaccines entered separate areas of the

plant where the two vaccines were being made. Emergent didn't

properly investigate personnel movements around the plant as a

potential source of the contamination, the report said.

The report says Emergent didn't maintain the plant "in a clean

and sanitary condition." Waste generated during the manufacture of

the two vaccines wasn't decontaminated using qualified methods, and

the waste was transported through a warehouse in a way that created

the potential to contaminate the warehouse, the report said.

FDA inspectors also found peeling paint on the floors and walls,

paint flecks on the floor, and rough surfaces that don't allow for

adequate cleaning and sanitation.

The FDA inspectors viewed security-camera footage at the plant

and spotted several instances of workers failing to prevent

cross-contamination. In January and early February, workers threw

unsealed bags of special medical waste into a service elevator, and

when carrying the bags they came into contact with containers of

manufacturing materials, the FDA report said.

Workers also failed to adhere to proper procedures for wearing

sterile gowns and other steps meant to avoid contamination, the

report said.

Write to Peter Loftus at peter.loftus@wsj.com

(END) Dow Jones Newswires

April 21, 2021 11:26 ET (15:26 GMT)

Copyright (c) 2021 Dow Jones & Company, Inc.

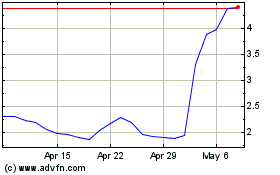

Emergent Biosolutions (NYSE:EBS)

Historical Stock Chart

From Mar 2024 to Apr 2024

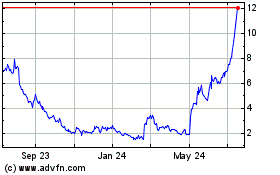

Emergent Biosolutions (NYSE:EBS)

Historical Stock Chart

From Apr 2023 to Apr 2024