By William Boston

BERLIN -- Volkswagen AG will restart car plants across Europe

next week, offering a pandemic-era blueprint for other global

manufacturers that will alter workers' daily lives and, at least

temporarily, relegate productivity to the back seat.

The world's biggest car maker by sales is issuing new manuals to

its global workforce, detailing a list of 100 workplace changes

designed to minimize the risk of coronavirus infections. Workers

will be asked to take their temperatures from home each morning,

change into their factory-floor uniforms before arriving and bring

their own lunch. Carpooling is out.

The changes are so extensive that unions say staff will need

extra time to familiarize themselves with the new practices. "We

have never developed, built or sold cars in these conditions,"

Bernd Osterloh, head of Volkswagen's works council, said in a

statement.

Volkswagen and other global car makers have orchestrated rolling

closures of many of their plants around the world -- first shutting

factories in China, then Europe and North America. The closures

were intended to curb the spread of the virus at the workplace, but

also to deal with collapsing global demand, dealership closures and

the need to virus-proof assembly lines.

Car makers have mostly restarted plants in China, the early

epicenter of the outbreak. New-car sales there plunged when swaths

of the country were quarantined in January and February. But after

factories began to reopen in early March, car production and sales

have started to climb again. It is too early to say how soon, or

whether, demand will fully recover.

Now, manufacturers in Europe are restarting plants, too, and

hoping for a similar boost. The German auto industry, home to one

in 10 manufacturing jobs in Europe, is at the heart of the

continent's efforts to relaunch its economy. By the end of March,

1.1 million of Europe's 2.6 million auto manufacturing workers had

been furloughed, according to the European Automobile

Manufacturers' Association.

Some European car makers have already begun to resume

production. France's Renault SA restarted a plant in Portugal.

Magna Steyr AG, a contract manufacturer, has resumed production of

Mercedes-Benz G-Class sport-utility vehicles. Next week, Daimler

AG's Mercedes will restart production of powertrains at plants in

Berlin, Hamburg and Untertürkheim.

Employees of Volvo Cars, owned by China's Zhejiang Geely Holding

Group, are also returning next week to a vastly different workplace

at the company's plant in Torslanda, Sweden.

"When people arrive on Monday there will be checkpoints at the

entrance where we can check temperature and also blood oxygen

levels," Volvo Chief Executive Hakan Samuelsson said.

Volvo plans to begin working three shifts at its Torslanda plant

starting Monday, but probably only three to four days a week to

achieve about 60% capacity as demand slowly ramps up, Mr.

Samuelsson said.

Volkswagen, meanwhile, is deploying some of the measures it

applied in China, where the new coronavirus emerged. It is also

adding new ones. Many will require workers to reorganize their

daily lives.

The changes begin before workers leave home. To eliminate

crowded changing rooms inside the plant, employees will have to put

on their shop clothes at home before coming to work. Cafeterias

will be closed, so workers will have to bring their own lunches,

which they can eat at their workstation while practicing social

distancing.

In China, returning workers are screened for fever as they

entered the plant. In Europe, workers are being asked to take their

own temperature and go through a checklist of Covid-19 symptoms

before leaving the house each day. Employees are expected to report

any symptoms. The company is also asking workers to refrain from

coming to work in carpools.

Volkswagen will institute buffer periods between changing shifts

to allow one group of workers to leave before the next shift comes

in, to minimize interactions. Workers will enter in a single file,

keeping a distance of 6 feet between each other.

Inside the factory, routes have been remapped to add space

between workers. Wherever the required 6-foot separation cannot be

guaranteed, employees will have to wear face masks. Workers will

also no longer pass material or tools by hand. They will need to

set things down so others can pick them up at a safe distance.

Andreas Tostmann, Volkswagen's global production chief, said

production ramp-up will be gradual. "If necessary, we will produce

less rather than take any risks," he said in an email exchange. "We

won't have the entire workforce back in the early days, but rather

successively increase capacity."

Volkswagen plants would begin operating at about 30% capacity,

gradually building up over weeks, Mr. Tostmann said. He cited the

restart in China, which began slowly in February and March.

Volkswagen's factories in China are now working three shifts and

operate at 60% to 70% of precrisis capacity.

The first European Volkswagen plant to resume operation will be

its factory in Bratislava, Slovakia, which on Monday will switch

the assembly lines back on. The plant builds cars for the company's

Volkswagen, Audi, Porsche, Skoda and SEAT brands.

Then, on Thursday, Volkswagen's electric-vehicle plant in

Zwickau, in eastern Germany, is set to go back online and begin

filling orders for the first 37,000 ID.3 all-electric cars. The

company's main plant in Wolfsburg is set to resume operation on

April 27.

Volkswagen plants in Latin America, Russia and Chattanooga,

Tenn., are expected to follow and will also adopt the new antivirus

regime.

Write to William Boston at william.boston@wsj.com

(END) Dow Jones Newswires

April 17, 2020 12:34 ET (16:34 GMT)

Copyright (c) 2020 Dow Jones & Company, Inc.

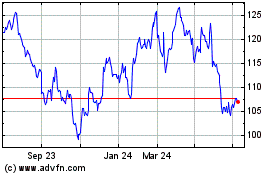

Volkswagen (TG:VOW3)

Historical Stock Chart

From Mar 2024 to Apr 2024

Volkswagen (TG:VOW3)

Historical Stock Chart

From Apr 2023 to Apr 2024