GM's Plans to Increase Truck Production Delayed by Parts Shortage

May 22 2020 - 10:17AM

Dow Jones News

By Mike Colias and Ben Foldy

A shortage of parts from Mexico is hampering General Motors

Co.'s plans to quickly ramp up production of high-profit pickup

trucks, according to a union official and other people familiar

with the matter, underscoring the auto industry's halting restart

after a two-month shutdown from the pandemic.

GM has delayed plans to roughly double output at its two main

U.S. pickup-truck factories by adding additional shifts of workers

next week, these people said. The auto maker doesn't yet have the

flow of parts it needs to accelerate production as planned, they

said.

The auto maker postponed plans to call back roughly 1,300

workers to its Fort Wayne, Ind., truck factory starting Tuesday for

a second eight-hour work shift, said Rich LeTourneau, an official

at United Auto Workers Local 2209, which represents workers at the

factory. The return date tentatively has been pushed back to June

1, he said.

"We continue to plan to ramp up production in a gradual

cadence," a GM spokesman said, declining to discuss specifics about

the schedule.

GM also delayed adding a second work shift at its Flint, Mich.,

pickup factory, which makes GM's largest, priciest pickup trucks,

some of the people said.

More than 1,000 additional employees had been scheduled to come

back Tuesday, but those plans have been delayed and workers haven't

been given a new callback date, they said.

U.S. auto makers are juggling supply-chain kinks and putting in

new safety protocols as they try to restart operations following an

unprecedented eight-week shutdown to prevent the spread of the new

coronavirus.

Write to Mike Colias at Mike.Colias@wsj.com and Ben Foldy at

Ben.Foldy@wsj.com

(END) Dow Jones Newswires

May 22, 2020 10:02 ET (14:02 GMT)

Copyright (c) 2020 Dow Jones & Company, Inc.

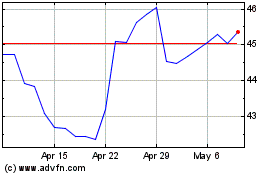

General Motors (NYSE:GM)

Historical Stock Chart

From Mar 2024 to Apr 2024

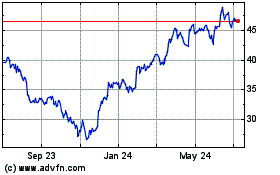

General Motors (NYSE:GM)

Historical Stock Chart

From Apr 2023 to Apr 2024