Coronavirus Outbreak Could Affect Production at 2 GM Plants, Union Officials Say -- Update

February 14 2020 - 1:25PM

Dow Jones News

By Ben Foldy and Mike Colias

Union officials at two major General Motors Co. factories in the

U.S. are warning of parts shortages related to the coronavirus

outbreak in China, a sign that fallout for the auto industry's

global supply chain could soon touch U.S. shores..

A GM factory in Flint, Mich., which makes heavy-duty versions of

GM's Chevrolet Silverado and GMC Sierra pickup trucks, faces

shortages of at least two parts sourced from China, said Chad

Fabbro, a financial secretary at the United Auto Workers' local

representing workers at the plant.

In Arlington, Texas, GM's assembly plant is confronting the

possibility of running out of certain parts from China, said Terry

Valenzuela, president of UAW's local chapter. The situation remains

fluid, he added.

That factory makes large sport-utility vehicles that are

mechanically similar to pickup trucks, including the Cadillac

Escalade and Chevrolet Suburban.

GM said it doesn't anticipate an impact on truck production as

of now.

"We continue to monitor our supply chain and are in close

communications with our Tier One suppliers to mitigate any risk to

production in North America," the company said in a statement.

The outbreak of the novel disease, which health authorities have

named Covid-19, led China's government to impose extended shutdowns

of manufacturing plants throughout the country after the

traditional Lunar New Year holiday, in hopes of slowing its

spread.

Although many companies said they planned to restart plants this

week, analysts have stressed the impact of supply-chain

disruptions, and worker quarantines make it difficult to anticipate

when production will return to normal.

The outbreak has halted assembly lines at several car plants in

China. Forecasters at LMC Automotive expect the outbreak to depress

Chinese auto production by around 1.2 million cars this quarter.

Last year, GM produced nearly 640,000 cars -- nearly 40% of its

Chinese production -- in Hubei province, where the outbreak

originated and where most of the infections have been diagnosed,

the firm said.

The shutdowns have also affected factories making auto parts and

components. Shortages of China-made parts have already started

rippling through the global automotive supply chain, leading

Hyundai Motor Co. and France's Renault SA to temporarily idle some

assembly lines in South Korea.

The Flint factory is one of GM's largest in the U.S., employing

about 5,000 workers. It would likely run out of decals and vents

first, both of which can be installed after a near-finished truck

rolls off the assembly line, Mr. Fabbro said.

Longer delays could impact more critical components, he said.

"This is going to be a day-by-day monitoring thing," he said. "If

it goes six weeks, then we all have bigger problems."

GM has arranged for parts to be flown by chartered jet from

China when they are available, Mr. Fabbro said. A GM spokesman

declined to comment.

GM derives the majority of its global profit from sales of large

pickup-trucks and SUVs built in North America. The pickups are

built at the Flint factory, along with a plant in Fort Wayne, Ind.,

and another in Silao, Mexico. The Arlington plant makes all of GM's

large SUVs.

GM has been scrambling already to replenish truck stocks after a

40-day strike last fall that shut down production across its U.S.

factories.

Car companies have fortified their global supply chains in the

years since a tsunami in Japan in 2011 knocked out supplies of

certain components and led to cuts in vehicle production across the

globe.

Write to Ben Foldy at Ben.Foldy@wsj.com and Mike Colias at

Mike.Colias@wsj.com

(END) Dow Jones Newswires

February 14, 2020 13:10 ET (18:10 GMT)

Copyright (c) 2020 Dow Jones & Company, Inc.

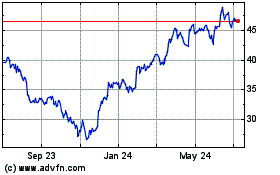

General Motors (NYSE:GM)

Historical Stock Chart

From Mar 2024 to Apr 2024

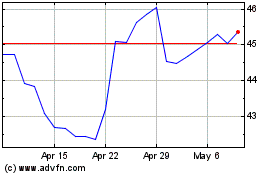

General Motors (NYSE:GM)

Historical Stock Chart

From Apr 2023 to Apr 2024