Your Snack's Crunch Is Cloud-Verified -- WSJ

November 26 2018 - 3:02AM

Dow Jones News

Australian food company uses connected device to detect soggy

snacks

By Mike Cherney

This article is being republished as part of our daily

reproduction of WSJ.com articles that also appeared in the U.S.

print edition of The Wall Street Journal (November 26, 2018).

BRISBANE, Australia -- To make a snack with the perfect crunch,

one company is turning to the cloud.

Majans Pty, which makes pea- and nut-based snacks in Australia,

is teaming up with Microsoft Corp. and others to test a system that

uses a beam of light to measure moisture and salt levels, then

uploads that data in real time to the cloud. If successful, it

could allow factory managers to instantly detect an issue in

production -- possibly with just an alert on their smartphones.

Too much moisture can lead to an unsatisfying crunch, a big

problem for snack companies that have just one bite to impress

consumers. But current methods often require a technician to scoop

snacks off a conveyor belt, bring the sample into a lab and use a

special machine to get a moisture reading. At Majans, that test is

only done every one to two hours, potentially overlooking flawed

product.

"Moisture is the enemy of crunchy snacks," said Mathew

Barbagallo, the chief commercial officer at family-owned, privately

held Majans, which sells its snacks in the U.S. as well as

Australia. The crunch "triggers certain sensors in the brain to add

a level of enjoyment. The crunchier, the better."

Since batches of snacks are sometimes unfit for sale if they're

too soggy, better data from the factory floor can help reduce waste

and save money. Ensuring snacks are sufficiently crunchy can also

help food makers succeed in an industry where competition is

intensifying. Health-conscious consumers are embracing everything

from date-based protein balls to roasted fava beans, a trend that

is pushing manufacturers to look beyond potato chips and make

crunchy snacks from a wider range of foods, like kale and

seaweed.

A survey conducted earlier this year by market research firm IRI

found that 50% of U.S. consumers eat snacks that "add excitement to

their daily diet." That was a 19-point jump from a similar survey

two years prior, suggesting that many consumers are looking for

more variety in their snacks. IRI expected snacks based on beans

and chickpeas to be fast-growing categories.

Food companies that tap into shifting consumer tastes -- and use

technology to ensure a compelling crunch -- could grab a bigger

slice of the growing U.S. snack market, which research firm

IBISWorld estimates is worth nearly $43 billion in revenue this

year. The market is projected to increase 4.2% annually over the

next five years, up from 3.7% in the previous five-year period.

One day earlier this month, a conveyor belt ferried a

barbecue-flavored, tapioca-based shrimp cracker around Majans's

Australian factory. The conveyor passed under a device, called a

spectrometer, that determines moisture content by beaming light

onto the snacks and measuring what is reflected back. The

information was then displayed on a computer screen in an office

overlooking the factory floor.

"That's gold, that data," said Phil Dahlenburg, the

manufacturing manager at Majans, as he watched results from the

machine appear on the computer screen.

The spectrometer, made by a unit of German manufacturer Zeiss

Group, costs roughly $40,000, and is already used by other

companies to assess potato products and tobacco. But Microsoft says

the Majans plant is the first time it has connected a device like

this in a snack factory to the cloud -- which is being used to

bring everything from refrigerators to livestock and beer kegs

online.

Measuring moisture content "moves the game quite a fair bit"

from traditional, lab-based methods, said Angeline Achariya, chief

executive at the Monash Food Innovation Centre, a unit of a local

university in Melbourne, Australia. "Every company is looking for

technologies that can give them much more real-time data."

In general, some 3% to 5% of snacks produced in a factory might

be unfit for sale due to production issues, Mr. Dahlenburg

estimates. Depending on the severity, manufacturers might be able

to blend an irregular batch of snacks with future production runs

to recoup some losses, or use bad batches in livestock feed.

After collecting a sample for a moisture test using the

traditional machine, a technician needs to grind it up and feed it

into the device -- which can take six minutes or more to spit back

a reading.

In contrast, the cloud-connected spectrometer can offer readings

every two seconds and deliver that data to a computer nearly

instantaneously. If found to be reliable enough, Majans could

install more of the devices in a new factory being developed.

"That crunch is a promise" to customers, said Amit Raniga, a

director at Majans. "You can't compromise on that."

Write to Mike Cherney at mike.cherney@wsj.com

(END) Dow Jones Newswires

November 26, 2018 02:47 ET (07:47 GMT)

Copyright (c) 2018 Dow Jones & Company, Inc.

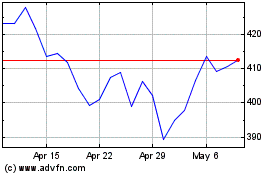

Microsoft (NASDAQ:MSFT)

Historical Stock Chart

From Mar 2024 to Apr 2024

Microsoft (NASDAQ:MSFT)

Historical Stock Chart

From Apr 2023 to Apr 2024