Silvercorp Metals Inc. ("Silvercorp" or the

“Company”) is pleased to report that a drill program targeting gold

(“Au”) mineralization is underway at the LMW, LME and TLP mines

within the Ying Mining District, Henan Province, China.

Silvercorp has previously reported limited gold

assay results in news releases dated January 4, 2011, January 10,

2011, January 26, 2012, February 13, 2012, August 20, 2012, January

31, 2013 and February 19, 2014 for the LMW, LME and TLP mines, but

as the focus was on mining silver-lead-zinc veins the

characterization of gold mineralization was poorly understood. As

such, many gold-bearing intercept results from drilling over the

years have never been released as they do not fit into any known

silver-lead-zinc veins that are mined by the Company.

Recent tunneling programs have exposed

gently-dipping quartz-ankerite-sulfide shear zones with high gold

and copper values, such as LM22 and LM26 at the LMW mine and LM4E2

at the LME mine. The photos below show the exposed LM22 structure

from the LMW mine of a massive quartz-ankerite-sulfide vein

composed of 19% Cu and 20 g/t Au over 0.3 metres (“m”) within a

silicification shear zone. This clearly shows that the

gold-mineralized, sub-horizontal, quartz-ankerite-sulfide shear

zones were cut and over-printed by the later stage sub-vertical

silver-lead-zinc veins that Silvercorp has been mining.

Figure 1 is available

at https://www.globenewswire.com/NewsRoom/AttachmentNg/12645a9b-6567-4c24-8745-00588bbe568d

Figure 2 is available

at https://www.globenewswire.com/NewsRoom/AttachmentNg/7f7ba998-65f3-46dc-adfe-a1e7e9215f6d

Initial sample results from these tunnels and

decline are listed in Table 1. LM22, from the decline at 805 m

elevation, extends 30 m long with a 0.43 m sample width and an

average grade of 13.95 g/t Au, 2.2% Cu and 26 g/t Ag. Vein LM26

also contains high copper and gold values.

Table 1: Au mineralized zones exposed by drift tunneling

at the LMW and LME mines

|

Mines |

Tunnel ID |

Target Vein |

Level (m) |

Length (m) |

Sample Width (m) |

Au (g/t) |

Ag (g/t) |

Pb (%) |

Zn (%) |

Cu (%) |

|

| LMW |

PD924-LM22-834-3SYM_Decline |

LM22 |

805 |

30.0 |

0.43 |

13.95 |

26 |

0.09 |

0.03 |

2.20 |

|

| LMW |

PD924-LM22-834-3NYM |

LM22 |

834 |

15.0 |

0.30 |

4.35 |

19 |

0.03 |

0.02 |

3.85 |

|

|

LMW |

XPDN-LM26-650-3WYM |

LM26 |

650 |

10.0 |

0.46 |

1.52 |

207 |

0.99 |

0.34 |

0.79 |

|

With the discovery of the sub-horizontal nature

of gold-related shear zones, the Company has re-examined its

database for drill intercepts with gold grades in earlier drilling

programs. Table 2 lists the assay results of the drill holes with

gold values higher than 2.0 g/t that have not been released before.

Most of these gold carrying intercepts were not mined as many

tunnels advanced horizontally and did not hit these sub-horizontal

shear zones.

The intercepts from Table 2 are relatively

narrow, which is mostly due to selective sampling techniques as

current exploration in the Ying Mining District is targeting narrow

veins. Logging of the drill core shows much wider

quartz-ankerite-epidote-k-feldspar-biotite-sulfide alteration, but

only narrow samples were taken in most occasions.

From Table 2, sub-horizontal shear zone LM22 was

intercepted by three sub-vertical drill holes ZKX0308, ZKX0310 and

ZKX0309 near 840 m elevation. ZKX0308 has a sample width of 0.28 m

grading 22.65 g/t Au and 19.8% Cu, ZKX0310 has a sample width of

0.50 m grading 75.7 g/t Au and 0.35% Cu, and ZKX0309 has a sample

width of 0.28 m grading 63.5 g/t Au and 0.32% Cu. ZKX0309 also

intercepted multiple sub-horizontal shear zones, including LM26

with a sample width of 0.61 m grading 4.7 g/t Au at 662 m

elevation, and an unknown shear zone at 403 m elevation with a

sample width of 0.91 m grading 2.55 g/t Au.

LM26 was also intercepted by drill hole ZKX0306

at 625 m elevation with a sample width of 0.57 m grading 22.35 g/t

Au.

Highlights of selected drill hole interceptions

with higher Au values:

- Hole ZKX10505 has a sample width 0.51m from 397.94 m to 398.45

m, grading 25.42 g/t Au and 15 g/t Ag from LMW;

- Hole ZKL5033 has a sample width of 0.55m grading 29.5 g/t Au

from LME

- Hole ZK-Ⅲ-1124 has a sample width of 1.22 m grading 9.17 g/t

Au, 314 g/t Ag and 2.12% Pb from TLP;

- Hole ZKT05S35 has a sample width of 2.0 m grading 3.92 g/t Au,

2765 g/t Ag, 4.95% Pb and 0.88% Cu from TLP;

- Hole ZKT2901 has a sample width of 2.54 m grading 3.6 g/t Au,

266 g/t Ag, 8.55% Pb and 3.52% Cu from TLP.

Table 2: Selected drill holes with higher Au

values

|

Mine |

Hole ID |

From (m) |

To (m) |

Interval (m) |

Elevation (m) |

Au (g/t) |

Ag (g/t) |

Pb (%) |

Zn (%) |

Cu (%) |

Vein |

Year |

Ag-Pb-Zn Released |

| LMW |

ZKX10505 |

397.94 |

398.45 |

0.51 |

411 |

25.42 |

15 |

0.03 |

0.06 |

0.01 |

|

2019 |

|

| LMW |

ZKX10508 |

174.83 |

175.70 |

0.87 |

545 |

2.22 |

5 |

0.02 |

0.01 |

0.00 |

|

2019 |

|

| LMW |

ZKX10916 |

369.59 |

369.89 |

0.30 |

434 |

2.17 |

4 |

0.02 |

0.02 |

0.01 |

|

2019 |

|

| LMW |

ZKX12004 |

28.50 |

29.22 |

0.72 |

886 |

4.96 |

4 |

0.02 |

0.01 |

1.93 |

|

2019 |

|

| LMW |

ZKX117PA01 |

171.26 |

172.59 |

1.33 |

918 |

3.70 |

4 |

0.02 |

0.01 |

0.06 |

|

2017 |

|

| LMW |

ZKX02Q01 |

189.37 |

190.10 |

0.73 |

787 |

3.71 |

351 |

2.62 |

1.32 |

2.56 |

|

2016 |

Released |

| LMW |

ZKX0662 |

211.28 |

212.36 |

1.08 |

743 |

5.62 |

1 |

0.01 |

0.01 |

0.01 |

|

2016 |

|

| LMW |

ZKX104S23 |

187.44 |

188.64 |

1.20 |

796 |

2.18 |

295 |

3.35 |

0.18 |

0.07 |

|

2013 |

Released |

| LMW |

ZKX0604 |

155.71 |

155.88 |

0.17 |

864 |

4.45 |

27 |

0.05 |

0.11 |

1.97 |

|

2012 |

|

| LMW |

ZKX1124 |

32.20 |

32.46 |

0.26 |

892 |

4.27 |

8 |

0.01 |

0.01 |

0.01 |

LM22 |

2012 |

|

| LMW |

ZKX2201 |

209.23 |

210.33 |

1.10 |

805 |

4.06 |

3 |

0.01 |

0.01 |

0.01 |

|

2012 |

|

| LMW |

ZKX0001 |

306.98 |

307.28 |

0.30 |

759 |

4.54 |

3 |

0.01 |

0.01 |

0.01 |

|

2011 |

|

| LMW |

ZKX0001 |

332.55 |

333.42 |

0.87 |

745 |

4.04 |

4 |

0.01 |

0.01 |

0.32 |

|

2011 |

|

| LMW |

ZKX0003 |

542.20 |

542.40 |

0.20 |

512 |

2.89 |

34 |

0.07 |

0.02 |

1.84 |

|

2011 |

|

| LMW |

ZKX0004 |

617.55 |

618.21 |

0.66 |

399 |

8.84 |

1206 |

5.60 |

1.65 |

0.48 |

|

2011 |

|

| LMW |

ZKX0404 |

31.79 |

33.22 |

1.43 |

907 |

3.06 |

9 |

0.03 |

0.03 |

0.01 |

|

2011 |

|

| LMW |

ZKX0405 |

286.09 |

286.39 |

0.30 |

734 |

19.70 |

4 |

0.01 |

0.03 |

0.33 |

|

2011 |

|

| LMW |

ZKX0406 |

256.04 |

256.24 |

0.20 |

726 |

135.00 |

27 |

0.01 |

0.07 |

4.28 |

|

2011 |

|

| LMW |

ZKX10604 |

334.52 |

335.12 |

0.60 |

811 |

21.60 |

81 |

0.56 |

0.31 |

0.01 |

|

2011 |

|

| LMW |

ZKX10606 |

149.78 |

150.82 |

1.04 |

851 |

5.59 |

6 |

0.05 |

0.03 |

0.01 |

LM22 |

2011 |

|

| LMW |

ZKX10607 |

140.97 |

141.58 |

0.61 |

848 |

3.95 |

25 |

0.53 |

0.88 |

0.02 |

|

2011 |

|

| LMW |

ZKX0305 |

341.77 |

342.10 |

0.33 |

689 |

10.23 |

12 |

0.12 |

0.05 |

0.08 |

|

2010 |

|

| LMW |

ZKX0306 |

368.90 |

369.47 |

0.57 |

625 |

22.35 |

8 |

0.04 |

0.01 |

0.05 |

LM26 |

2010 |

|

| LMW |

ZKX0307 |

150.43 |

150.71 |

0.28 |

786 |

3.55 |

23 |

0.04 |

0.02 |

2.62 |

|

2010 |

|

| LMW |

ZKX0308 |

79.66 |

79.94 |

0.28 |

843 |

22.65 |

141 |

0.17 |

0.14 |

19.80 |

LM22 |

2010 |

|

| LMW |

ZKX0308 |

194.30 |

194.44 |

0.14 |

735 |

3.98 |

22 |

0.31 |

0.02 |

0.80 |

|

2010 |

|

| LMW |

ZKX0309 |

80.10 |

80.32 |

0.22 |

841 |

63.50 |

8 |

0.09 |

0.07 |

0.32 |

LM22 |

2010 |

|

| LMW |

ZKX0309 |

264.95 |

265.56 |

0.61 |

662 |

4.70 |

3 |

0.01 |

0.02 |

0.12 |

LM26 |

2010 |

|

| LMW |

ZKX0309 |

402.95 |

403.89 |

0.94 |

403 |

2.55 |

3 |

0.03 |

0.01 |

0.05 |

|

2010 |

|

|

LMW |

ZKX0310 |

84.37 |

84.87 |

0.50 |

834 |

75.74 |

6 |

0.02 |

0.01 |

0.35 |

LM22 |

2010 |

|

| LME |

ZKL54T1701 |

393.93 |

397.47 |

3.54 |

520 |

2.54 |

31 |

0.64 |

0.61 |

0.00 |

LM4E2 |

2019 |

|

| LME |

ZKL58T1703 |

363.71 |

364.70 |

0.99 |

547 |

4.94 |

43 |

0.50 |

0.71 |

0.01 |

LM4E2 |

2019 |

|

| LME |

ZKL6712 |

153.05 |

153.64 |

0.59 |

728 |

7.30 |

19 |

1.93 |

0.02 |

0.02 |

LM4E2 |

2019 |

|

| LME |

ZKL7605 |

672.22 |

672.83 |

0.61 |

214 |

3.99 |

5 |

0.02 |

0.02 |

0.00 |

|

2019 |

|

| LME |

ZKL5033 |

454.22 |

454.77 |

0.55 |

64 |

29.50 |

15 |

0.03 |

0.03 |

0.01 |

|

2017 |

|

| LME |

ZKL5337 |

297.77 |

298.22 |

0.45 |

239 |

3.01 |

315 |

0.58 |

0.43 |

0.04 |

|

2017 |

Released |

| LME |

ZKL5337 |

300.94 |

301.54 |

0.60 |

236 |

2.12 |

4229 |

19.76 |

0.96 |

0.15 |

|

2017 |

Released |

| LME |

ZKL53A21 |

91.96 |

92.68 |

0.72 |

522 |

2.35 |

5 |

0.16 |

0.02 |

0.02 |

|

2017 |

|

| LME |

ZKL5421 |

303.48 |

304.39 |

0.91 |

283 |

2.63 |

50 |

0.79 |

0.38 |

0.02 |

|

2017 |

|

| LME |

ZKL5421 |

358.91 |

359.18 |

0.27 |

245 |

3.51 |

5 |

0.03 |

0.07 |

0.02 |

|

2017 |

|

| LME |

ZKL5422 |

392.93 |

393.25 |

0.32 |

160 |

2.69 |

154 |

4.08 |

2.95 |

0.27 |

|

2017 |

Released |

| LME |

ZKL5422 |

424.88 |

426.14 |

1.26 |

132 |

2.72 |

182 |

9.08 |

1.79 |

0.14 |

|

2017 |

Released |

| LME |

ZKL5422 |

428.12 |

428.68 |

0.56 |

130 |

2.64 |

197 |

0.70 |

0.19 |

0.20 |

|

2017 |

|

| LME |

ZKL5423 |

497.66 |

498.30 |

0.64 |

38 |

3.77 |

194 |

1.36 |

1.46 |

0.07 |

|

2017 |

|

| LME |

ZKL55A21 |

62.38 |

63.13 |

0.75 |

530 |

2.11 |

89 |

0.43 |

0.60 |

0.21 |

|

2017 |

|

| LME |

ZKL58S19 |

237.49 |

237.69 |

0.20 |

374 |

3.70 |

73 |

0.77 |

0.15 |

0.01 |

|

2017 |

|

| LMF |

ZKL7005 |

400.30 |

400.77 |

0.47 |

272 |

2.81 |

5 |

0.06 |

0.12 |

0.01 |

|

2017 |

|

| LME |

ZKL5144 |

486.69 |

487.18 |

0.49 |

518 |

2.31 |

5 |

0.03 |

0.09 |

0.01 |

|

2016 |

|

| LME |

ZKL7004 |

330.85 |

331.33 |

0.48 |

350 |

7.45 |

1821 |

2.54 |

0.34 |

0.08 |

|

2016 |

|

| LME |

ZKL5342 |

67.16 |

68.51 |

1.35 |

543 |

2.98 |

4 |

0.05 |

0.03 |

0.01 |

LM4E2 |

2015 |

|

| LME |

ZKL58S17 |

226.24 |

226.79 |

0.55 |

397 |

3.04 |

338 |

0.74 |

0.48 |

0.06 |

|

2015 |

|

| LME |

ZKL58S17 |

233.02 |

233.85 |

0.83 |

391 |

3.81 |

185 |

3.23 |

0.93 |

0.02 |

|

2015 |

|

| LME |

ZK160401 |

105.51 |

105.77 |

0.26 |

1106 |

2.33 |

1 |

0.00 |

0.00 |

0.00 |

|

2011 |

|

| LME |

ZKL5305 |

297.25 |

297.87 |

0.62 |

567 |

2.78 |

10 |

0.47 |

0.26 |

0.01 |

LM4E2 |

2010 |

|

| LME |

ZKL5305 |

328.50 |

328.66 |

0.16 |

538 |

10.56 |

3 |

0.05 |

0.01 |

0.02 |

|

2010 |

|

| LME |

ZKL5305 |

384.54 |

384.93 |

0.39 |

486 |

3.56 |

5 |

0.08 |

0.01 |

0.01 |

|

2010 |

|

| LME |

ZKL6103 |

252.51 |

253.94 |

1.43 |

597 |

3.43 |

25 |

0.13 |

0.18 |

0.01 |

LM4E2 |

2010 |

|

| LME |

ZKL6703 |

256.77 |

257.37 |

0.60 |

598 |

2.08 |

2 |

0.01 |

0.02 |

0.01 |

|

2010 |

|

| LME |

ZKL6902 |

285.56 |

286.73 |

1.17 |

566 |

2.28 |

37 |

0.19 |

0.17 |

0.02 |

|

2010 |

|

|

LME |

ZKL6903 |

276.81 |

278.10 |

1.29 |

587 |

2.46 |

13 |

0.14 |

0.10 |

0.01 |

|

2010 |

|

| TLP |

ZKG0527 |

537.22 |

537.63 |

0.41 |

195 |

2.02 |

6 |

0.27 |

0.02 |

0.01 |

|

2019 |

|

| TLP |

ZKG0934 |

336.58 |

337.70 |

1.12 |

541 |

4.41 |

9 |

0.10 |

0.14 |

0.00 |

|

2017 |

|

| TLP |

ZKTA2402 |

162.26 |

164.52 |

2.26 |

894 |

2.87 |

7 |

0.03 |

0.06 |

0.01 |

|

2016 |

|

| TLP |

ZK-Ⅲ-1124 |

281.07 |

282.29 |

1.22 |

497 |

9.17 |

314 |

2.12 |

0.33 |

0.04 |

|

2014 |

|

| TLP |

ZKX10607 |

140.97 |

141.58 |

0.61 |

848 |

3.95 |

25 |

0.53 |

0.88 |

0.02 |

|

2014 |

|

| TLP |

ZK-Ⅲ-2510 |

429.20 |

430.10 |

0.90 |

404 |

2.32 |

331 |

10.02 |

1.32 |

0.51 |

|

2013 |

Released |

| TLP |

ZKG0404 |

304.94 |

305.90 |

0.96 |

553 |

4.30 |

1761 |

9.45 |

1.56 |

0.13 |

|

2012 |

Released |

| TLP |

ZKG1401 |

75.47 |

76.19 |

0.72 |

802 |

3.48 |

71 |

0.09 |

0.05 |

0.01 |

|

2011 |

|

| TLP |

ZKT05S35 |

188.02 |

190.02 |

2.00 |

733 |

3.92 |

2765 |

4.95 |

0.80 |

0.88 |

|

2011 |

|

| TLP |

ZKT11S31 |

61.46 |

62.00 |

0.54 |

888 |

2.29 |

75 |

1.95 |

0.39 |

0.05 |

|

2011 |

|

| TLP |

ZKT13S31 |

112.87 |

113.77 |

0.90 |

867 |

4.27 |

6 |

0.02 |

0.03 |

0.01 |

|

2011 |

|

| TLP |

ZKT0701 |

84.04 |

84.36 |

0.32 |

714 |

2.46 |

1149 |

7.15 |

2.22 |

0.15 |

|

2010 |

|

| TLP |

ZKT0701 |

98.29 |

98.55 |

0.26 |

706 |

3.46 |

77 |

2.77 |

0.45 |

0.73 |

|

2010 |

|

| TLP |

ZKT0904 |

119.08 |

119.69 |

0.61 |

643 |

3.05 |

198 |

0.36 |

0.50 |

0.03 |

|

2010 |

|

| TLP |

ZKT09S32 |

222.00 |

222.73 |

0.73 |

682 |

2.09 |

167 |

1.99 |

0.70 |

0.55 |

|

2010 |

|

| TLP |

ZKT1301 |

145.63 |

145.94 |

0.31 |

666 |

2.70 |

249 |

7.02 |

1.47 |

2.22 |

|

2010 |

|

| TLP |

ZKT13S1 |

44.90 |

45.18 |

0.28 |

738 |

3.04 |

711 |

3.00 |

0.19 |

3.52 |

|

2010 |

|

| TLP |

ZKT2105 |

291.86 |

293.52 |

1.66 |

463 |

3.05 |

22 |

0.08 |

0.09 |

0.03 |

|

2010 |

|

| TLP |

ZKT21S4 |

43.70 |

44.25 |

0.55 |

772 |

7.62 |

478 |

2.98 |

0.15 |

6.54 |

|

2010 |

|

| TLP |

ZKT31S1 |

63.73 |

64.03 |

0.30 |

762 |

4.28 |

146 |

24.24 |

0.12 |

0.16 |

|

2010 |

|

| TLP |

ZKT2901 |

180.72 |

183.26 |

2.54 |

638 |

3.60 |

266 |

8.55 |

0.63 |

3.52 |

|

2009 |

|

| TLP |

ZKT2904 |

238.00 |

239.64 |

1.64 |

525 |

3.83 |

110 |

0.60 |

0.15 |

1.58 |

|

2009 |

|

| TLP |

ZKT33S22 |

59.16 |

60.73 |

1.57 |

707 |

2.95 |

4 |

0.23 |

0.01 |

0.11 |

|

2009 |

|

|

TLP |

ZK0601 |

361.12 |

361.48 |

0.36 |

636 |

2.75 |

256 |

0.71 |

4.28 |

0.10 |

|

2008 |

|

Currently, the historical drill cores are being

re-logged and sampled for the alteration zones not previously

sampled and assayed. Meanwhile, the Company will focus its ongoing

drilling program to target gold bearing zones intercepted by the

above drill holes with a total of ten drill rigs at the LMW, TLP

and LME mines (three underground rigs and two surface rigs for LMW,

three underground rigs for TLP, and two underground rigs for LME)

with the intention of continuous sampling of all alteration zones

to test for the existence of broad gold mineralization zones.

Quality ControlDrill cores are

NQ size. Drill core samples, limited by apparent mineralization

contact or shear/alteration contact, were split into halves by saw

cutting. The half cores are stored in the Company's core shacks for

future reference and checking, and the other half core samples are

shipped in security-sealed bags to the Chengde Huakan 514 Geology

and Minerals Test and Research Institute in Chengde, Hebei

Province, China, 226 km northeast of Beijing, and the Zhengzhou

Nonferrous Exploration Institute Lab in Zhengzhou, Henan Province,

China. Both labs are ISO9000 certified analytical labs. For

analysis the sample is dried and crushed to minus 1mm and then

split to a 200-300g subsample which is further pulverized to minus

200 mesh. Two subsamples are prepared from the pulverized sample.

One is digested with aqua regia for gold analysis with atomic

absorption spectroscopy (AAS), and the other is digested with

two-acids for analysis of silver, lead, zinc and copper with

AAS.Channel samples are collected along sample lines perpendicular

to the mineralized vein structure in exploration tunnels. Spacing

between sampling lines is typically 5m along strike. Both the

mineralized vein and the altered wall rocks are cut with continuous

chisel chipping. Sample length ranges from 0.2m to more than 1m,

depending on the width of the mineralized vein and the

mineralization type. Channel samples are prepared and assayed with

AAS at Silvercorp’s mine laboratory (Ying Lab) located at the mill

complex in Luoning County, Henan Province, China. The Ying lab is

officially accredited by the Quality and Technology Monitoring

Bureau of Henan Province and is qualified to provide analytical

services. The channel samples are dried, crushed and pulverized. A

200g sample of minus 160 mesh is prepared for assay. A duplicate

sample of minus 1mm is made and kept in the laboratory archives.

Gold is analysed by fire assay with AAS finish, and silver, lead,

zinc and copper are assayed by two-acid digestion with AAS finish.A

routine quality assurance/quality control (QA/QC) procedure is

adopted to monitor the analytical quality at each lab. Certified

reference materials (CRMs), pulp duplicates and blanks are inserted

into each lab batch of samples. QA/QC data at the lab are attached

to the assay certificates for each batch of samples.The Company

maintains its own comprehensive QA/QC program to ensure best

practices in sample preparation and analysis of the exploration

samples. Project geologists regularly insert CRM, field duplicates

and blanks to each batch of 30 core samples to monitor the sample

preparation and analysis procedures at the labs. The analytical

quality of the labs is further evaluated with external checks by

sending about 3-5% of the pulp samples to higher level labs to

check for lab bias.Data from both the Company's and the labs' QA/QC

programs are reviewed on a timely basis by project

geologists.Guoliang Ma, P. Geo., Manager of Exploration and

Resource of the Company, is the Qualified Person for Silvercorp

under NI 43-101 and has reviewed and given consent to the technical

information contained in this news release.

About Silvercorp

Silvercorp is a profitable Canadian mining

company producing silver, lead and zinc metals in concentrates from

mines in China. The Company’s goal is to continuously create

healthy returns to shareholders through efficient management,

organic growth and the acquisition of profitable projects.

Silvercorp balances profitability, social and environmental

relationships, employees’ wellbeing, and sustainable development.

For more information, please visit our website at

www.silvercorp.ca.

For further information

Lon ShaverVice PresidentSilvercorp Metals

Inc.

Phone: (604) 669-9397Toll Free: 1(888)

224-1881Email: investor@silvercorp.ca Website:

www.silvercorp.ca

CAUTIONARY DISCLAIMER - FORWARD LOOKING

STATEMENTS

Certain of the statements and information in

this press release constitute “forward-looking statements” within

the meaning of the United States Private Securities Litigation

Reform Act of 1995 and “forward-looking information” within the

meaning of applicable Canadian provincial securities laws. Any

statements or information that express or involve discussions with

respect to predictions, expectations, beliefs, plans, projections,

objectives, assumptions or future events or performance (often, but

not always, using words or phrases such as “expects”, “is

expected”, “anticipates”, “believes”, “plans”, “projects”,

“estimates”, “assumes”, “intends”, “strategies”, “targets”,

“goals”, “forecasts”, “objectives”, “budgets”, “schedules”,

“potential” or variations thereof or stating that certain actions,

events or results “may”, “could”, “would”, “might” or “will” be

taken, occur or be achieved, or the negative of any of these terms

and similar expressions) are not statements of historical fact and

may be forward-looking statements or information. Forward-looking

statements or information relate to, among other things: the price

of silver and other metals; the accuracy of mineral resource and

mineral reserve estimates at the Company’s material properties; the

sufficiency of the Company’s capital to finance the Company’s

operations; estimates of the Company’s revenues and capital

expenditures; estimated production from the Company’s mines in the

Ying Mining District; timing of receipt of permits and regulatory

approvals; availability of funds from production to finance the

Company’s operations; and access to and availability of funding for

future construction, use of proceeds from any financing and

development of the Company’s properties.

Forward-looking statements or information are

subject to a variety of known and unknown risks, uncertainties and

other factors that could cause actual events or results to differ

from those reflected in the forward-looking statements or

information, including, without limitation, risks relating to:

social and economic impacts of COVID-19; fluctuating commodity

prices; calculation of resources, reserves and mineralization and

precious and base metal recovery; interpretations and assumptions

of mineral resource and mineral reserve estimates; exploration and

development programs; feasibility and engineering reports; permits

and licenses; title to properties; property interests; joint

venture partners; acquisition of commercially mineable mineral

rights; financing; recent market events and conditions; economic

factors affecting the Company; timing, estimated amount, capital

and operating expenditures and economic returns of future

production; integration of future acquisitions into the Company’s

existing operations; competition; operations and political

conditions; regulatory environment in China and Canada;

environmental risks; foreign exchange rate fluctuations; insurance;

risks and hazards of mining operations; key personnel; conflicts of

interest; dependence on management; internal control over financial

reporting as per the requirements of the Sarbanes-Oxley Act; and

bringing actions and enforcing judgments under U.S. securities

laws.

This list is not exhaustive of the factors that

may affect any of the Company’s forward-looking statements or

information. Forward-looking statements or information are

statements about the future and are inherently uncertain, and

actual achievements of the Company or other future events or

conditions may differ materially from those reflected in the

forward-looking statements or information due to a variety of

risks, uncertainties and other factors, including, without

limitation, those referred to in the Company’s most recent Annual

Information Form under the heading “Risk Factors”. Although the

Company has attempted to identify important factors that could

cause actual results to differ materially, there may be other

factors that cause results not to be as anticipated, estimated,

described or intended. Accordingly, readers should not place undue

reliance on forward-looking statements or

information.

The Company’s forward-looking statements and

information are based on the assumptions, beliefs, expectations and

opinions of management as of the date of this press release, and

other than as required by applicable securities laws, the Company

does not assume any obligation to update forward-looking statements

and information if circumstances or management’s assumptions,

beliefs, expectations or opinions should change, or changes in any

other events affecting such statements or information. For the

reasons set forth above, investors should not place undue reliance

on forward-looking statements and information.

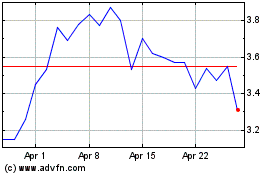

Silvercorp Metals (AMEX:SVM)

Historical Stock Chart

From Mar 2024 to Apr 2024

Silvercorp Metals (AMEX:SVM)

Historical Stock Chart

From Apr 2023 to Apr 2024