GM Seeks Tariff Relief for Ventilator Parts

April 03 2020 - 5:24PM

Dow Jones News

By Katy Stech Ferek

WASHINGTON -- General Motors Co. is asking the Trump

administration to drop import tariffs on Chinese parts that the

auto maker needs to make ventilators, saying the levies will make

it more expensive to build desperately needed machines that can

save lives.

In a letter to the U.S. Trade Representative, GM officials asked

the federal government to grant exclusions for several categories

of ventilator parts made in China. The existing tariffs on

ventilator parts "could potentially impede the ability of GM and

other U.S. manufacturers to source parts for critical care

ventilators quickly, reliably, and at as reasonable a cost as

possible," said the letter, which was dated Tuesday and made public

Thursday.

A representative for the USTR's office didn't immediately

respond to a request for comment.

Federal trade officials worked with the U.S. Department of

Health and Human Services to make sure that some crucial medicines

and medical products could be imported without the extra tariffs.

U.S. officials said last month that they also determined to not

impose tariffs on oxygen masks and ventilators themselves.

In their letter, GM officials pointed out that tariffs remain on

several categories of components used to make ventilators

domestically, including filters parts, compressor silencers,

grommets and a power cord set.

In a statement Friday, the auto maker said that most of the

ventilator components would be sourced in the U.S. and North

America, and that the "outcome of the request will have no impact

on GM's commitment to this important effort."

The federal government began collecting extra tariffs on most of

the ventilator parts in September 2018. They are being tariffed at

a rate of 25%.

U.S. trade officials began collecting extra tariffs on some

Chinese-made goods in 2018 as part of their effort to pressure the

country's manufacturing community to stop stealing U.S.

intellectual property.

The shortage of ventilators used to treat patients suffering

with the disease caused by the new coronavirus has GM and other

major manufacturers scrambling to make more for strapped

hospitals.

The auto industry, like in times of past national crisis, has

stepped up to the plate, putting to use its ability to quickly

source among thousands of parts suppliers and ramp up production

quickly. Auto makers Ford Motor Co. and Tesla Inc. are also gearing

up to boost production.

On March 20, GM officials said they partnered with Ventec, a

small maker of ventilators, to begin making machines at its idled

2.6 million-square-foot factory in Kokomo, Ind. The effort will

employ about 1,000 U.S. workers, the company said.

Executives at Ventec turned over blueprints for the machines and

collaborated with GM purchasing managers to find the more than 700

parts needed for production. Some of those parts needed to come

from China, GM officials said.

Factory workers are expected to deliver the first ventilators in

April and ramp up to a manufacturing capacity of more than 10,000

ventilators a month.

President Trump's tariffs on Chinese goods have long been

unpopular with the U.S. business community, including auto

manufacturers. Several business leaders have called for the tariffs

to be scaled back to ease the economic crisis that has accompanied

the virus's spread.

--Anthony DeBarros contributed to this article.

Write to Katy Stech Ferek at katherine.stech@wsj.com

(END) Dow Jones Newswires

April 03, 2020 17:09 ET (21:09 GMT)

Copyright (c) 2020 Dow Jones & Company, Inc.

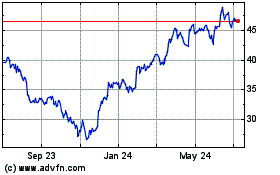

General Motors (NYSE:GM)

Historical Stock Chart

From Mar 2024 to Apr 2024

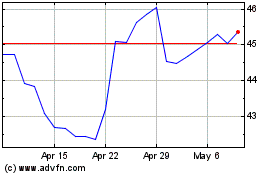

General Motors (NYSE:GM)

Historical Stock Chart

From Apr 2023 to Apr 2024