Southwest Accident Puts Focus on Widely Used Engine

April 18 2018 - 8:43AM

Dow Jones News

By Robert Wall and Doug Cameron

The engine failure that killed a passenger aboard a Southwest

Airlines Co. flight puts the spotlight on one of the industry's

most commonly used engines.

CFM International -- a joint venture between General Electric

Co. and France's Safran SA -- makes engines that have become a

mainstay of commercial aviation. The engines power most of Boeing

Co. and Airbus SE's single-aisle planes, the workhorses of the

industry.

On Tuesday, one of two CFM56-7B engines ruptured on a Boeing

737-700 operated by Southwest. The engine broke apart while

Southwest Flight 1380 was at cruising altitude, flying from New

York's LaGuardia Airport to Dallas Love Field, with 149 passengers

and crew aboard. Metal pieces struck the fuselage, though the

details of what happened inside the cabin are still unclear.

Southwest two years ago suffered a similar failure on another

CFM56 engine, forcing the plane to land but not resulting in

injuries.

A probe of that incident showed evidence of fatigue cracks in

some of the blades. In response, the Federal Aviation

Administration last year proposed enhanced inspections of certain

CFM engines. It hasn't yet made the safety fix mandatory. The

National Transportation and Safety Board said it would examine

whether there were any common factors connecting the two CFM56

incidents at Southwest.

The airline, meanwhile, said late Tuesday it was stepping up

inspections of the CFM56s used in its fleet. CFM International said

it was sending a team of experts to aid the NTSB probe.

The widespread use of the engine and its unusually dramatic

failure are likely to spur more scrutiny across fleets around the

globe. European air-safety regulators said Wednesday they were

"assessing the situation" and working with U.S. counterparts.

On average, a CFM56-powered plane takes off somewhere in the

world every two seconds. The CFM56-7B version involved in Tuesday's

incident has been in service since 1997 and is used in more than

6,700 airliners.

Engine failures are rare but aren't unheard of. Robert Sumwalt,

chairman of the NTSB, said investigators see about three to four

incidents each year.

An Airbus A380 superjumbo operated by Air France in September

suffered an engine failure on a flight from Paris to Los Angeles.

The plane diverted to Goose Bay, Canada. The accident investigation

hasn't been completed.

The engine of a Boeing 767 operated by American Airlines Group

Inc. blew up in 2016 on takeoff from Chicago O'Hare International

Airport because of unexpected component wear-and-tear. Passengers

suffered injuries during the plane's evacuation.

Engines are the often-overlooked lifeblood of the aviation

industry. Engine makers spend billions of dollars to eke out

small-percentage improvements in fuel efficiency to woo airliner

buyers.

Airlines and plane makers have endured a recent run of

operational headaches because of problems with these mini power

plants. British aircraft-engine maker Rolls-Royce Holdings PLC last

week warned that some of its engines powering Boeing 787 Dreamliner

long-haul planes would require more frequent inspections because

components were wearing out faster than expected. U.S. regulators,

as a precaution, have required airlines that use those engines to

chart courses that bring planes closer to airfields to which they

could divert.

Airlines that uses those engines have had to ground planes and

cancel flights because of an earlier round of checks on them.

Rolls-Royce, no longer affiliated with the luxury-car maker, has

said it could take until at least 2021 to fix all the engines.

Pratt & Whitney, a unit of United Technologies Corp., has

struggled with the development and production of its new geared

turbofan engine. The engine maker has halted shipments to Airbus as

it works to fix the design of components, which have been wearing

out too soon. Airlines have had to idle planes in response to

actions taken by European air-safety regulators. Pratt has said it

is working to fix the problem.

CFM also is struggling with its newest engine, the Leap used on

Boeing's new 737 Max narrow-body and some Airbus A320 models. GE

Aviation President David Joyce last month said the company was

about six weeks late on engine deliveries to Boeing and Airbus.

Write to Robert Wall at robert.wall@wsj.com and Doug Cameron at

doug.cameron@wsj.com

(END) Dow Jones Newswires

April 18, 2018 08:28 ET (12:28 GMT)

Copyright (c) 2018 Dow Jones & Company, Inc.

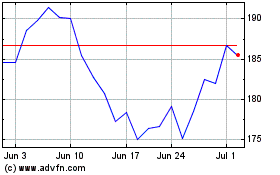

Boeing (NYSE:BA)

Historical Stock Chart

From Mar 2024 to Apr 2024

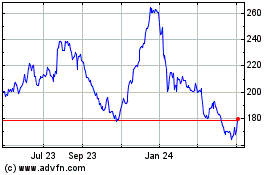

Boeing (NYSE:BA)

Historical Stock Chart

From Apr 2023 to Apr 2024