UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

Specialized Disclosure Report

Woodward,

Inc.

(Exact name of registrant as specified in its charter)

|

|

|

|

|

|

|

Delaware

|

|

0-8408

|

|

36-1984010

|

|

(State or other jurisdiction of

|

|

(Commission

|

|

(IRS Employer

|

|

incorporation or organization)

|

|

File Number)

|

|

Identification No.)

|

|

|

|

|

|

1081 Woodward Way, Fort Collins, Colorado

|

|

80524

|

|

(Address of principal executive offices)

|

|

(Zip Code)

|

A. Christopher Fawzy

(970) 482-5811

(Name and telephone number, including area code, of the person to contact in connection with this report.)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form

applies:

|

☒

|

Rule

13p-1

under the Securities Exchange Act (17 CFR

240.13p-1)

for the reporting period from January 1 to December 31, 2016.

|

Section 1 – Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

Conflict Minerals Disclosure

Woodward, Inc.

(the “Company,” “Woodward,” “we,” “us” or “our”) is filing this Form SD pursuant to Rule

13p-1

under the Securities Exchange Act of 1934 for the reporting

period from January 1, 2016 to December 31, 2016 (the “Reporting Period”).

Rule

13p-1,

through Form SD, requires the disclosure of certain information if a company manufactures or contracts to manufacture products for which certain conflict minerals (as defined below) are necessary to the functionality or production of such products.

As defined in Form SD and as used herein, “conflict minerals” means: (i)(a) columbite-tantalite (or coltan), (b) cassiterite, (c) gold and (d) wolframite, or their derivatives, which are currently limited to tantalum,

tin and tungsten; or (ii) any other mineral or its derivatives determined by the U.S. Secretary of State to be financing conflict in the Democratic Republic of the Congo or an “adjoining country” as defined in Form SD (collectively,

the “Covered Countries”). Our operations, including the operations of our consolidated subsidiaries, may at times manufacture, or contract to manufacture, products for which conflict minerals are necessary to the functionality or

production of those products. Woodward primarily serves the aerospace market and industrial market. Products we manufacture or contract to manufacture in the aerospace market include fuel pumps, metering units, actuators, air valves, specialty

valves, fuel nozzles, and thrust reverser actuation systems for turbine engines and nacelles; as well as flight deck controls (auto throttles, rudder pedal assembles, flight control assemblies), actuators, servocontrols, motors and sensors for

aircraft. Products we manufacture or contract to manufacture in the industrial market include power converters, actuators, valves, pumps, injectors, solenoids, ignition systems, governors, electronics and devices that measure, communicate and

protect low and medium voltage electrical distribution systems. Some of these products contain one or more conflict minerals, in particular:

|

|

•

|

|

All of the product families listed, except for valves, nozzles, injectors and some pumps, contain (or physically are) electronics, motors and/or sensors. These product families will contain, at a minimum, tin in the

lead/tin solder that fastens electronic components to printed circuit boards and tantalum in certain families of capacitors used in printed circuit board assemblies within those product families.

|

|

|

•

|

|

Gold is used in the plating of connectors and contacts in many of the electronics within our product families.

|

|

|

•

|

|

Finally, items in all of Woodward product families use a variety of steels, which contain tiny amounts of tungsten as part of their material recipe.

|

These determinations lead to Woodward’s requirement to conduct a reasonable country of origin inquiry (“RCOI”) in accordance with Rule

13p-1.

Woodward developed its initial good faith RCOI process in calendar year 2013 (subsequent references to whole

years refer to calendar years) and has continually improved that process. The initial RCOI process, while highly manual, was designed to conform to the Organisation for Economic

Co-operation

and

Development’s (“OECD”) framework, “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas”, Second Edition. We further refined our RCOI process during the second half

of 2014 and throughout 2015 by focusing on the elimination of duplicate supplier records and grouping multiple business groups within a common corporation. We also enhanced our RCOI process through a supplier record selection process based on spend

during a specified calendar interval and by joining the Conflict Free Sourcing Initiative (“CFSI”) in December 2015, gaining access to their extensive database of smelters or refiners (“SOR”), SOR audit records, and the mine of

origin data that CFSI has been able to acquire during their SOR audits. In July 2016, Woodward contracted with Assent to acquire the Assent Compliance Platform (“ACP”) and Assent’s support services to automate the supplier inquiry,

data collection and data validation tasks essential for RCOI. We executed our 2016 conflict minerals campaign with that platform and services. We also verified our RCOI process to conform to the “OECD Due Diligence Guidance for Responsible

Supply Chains of Minerals from Conflict-Affected and High-Risk Areas”, Third Edition (“OECD Guidelines”).

RCOI

As noted above, some of the products Woodward manufactures contain one or more conflict minerals. Woodward does not purchase conflict minerals directly from

mines, smelters or refiners. Rather, the Company sources products containing conflict minerals from its suppliers. In accordance with the OECD Guidelines, the Company relies on its suppliers to provide information regarding the origin of conflict

minerals included in supplied products, including, where possible, the smelters or refiners of the conflict minerals.

Supplier Categorization

In connection with the preparation of the Form SD and associated Conflict Minerals Report, we create a master supplier list of direct suppliers who provide

items or services directly used in items that Woodward manufactures or contracts to manufacture. Such suppliers are classified as either direct

non-distribution

suppliers, who fabricate custom designed items

to either Woodward specification or supplier-engineered specifications, or direct distribution suppliers, who source items from multiple Original Equipment Manufacturers (“OEMs”), typically in the nature of a commercial item or items

manufactured to standard government specifications. Direct distribution

suppliers do not manufacture or contract to manufacture, nor do they influence the functionality or content of the items they obtain from OEMs and provide to their customers. Woodward relies on

the efforts and activities of professional societies such as IPC – Association Connecting Electronics Industries, which provides a leading role in the conflict minerals efforts of the electronics and electronics distribution industries, to

establish and maintain the principal mechanisms for obtaining OEM distribution component conflict minerals status from our first tier distribution suppliers.

Suppliers that contribute items or services only for Woodward’s internal operations and infrastructure, and are not incorporated into items that Woodward

manufactures or contracts to manufacture, are not included in the Company’s conflict minerals reporting.

Relevant Supplier Identification

In 2016, Woodward used a single SAP application, Business Objects (“BObj”), to filter and extract relevant supplier records from both of our

business systems. The BObj report allowed us to specifically select direct suppliers with spend during a specified time interval, in this case, November 1, 2015 through October 31, 2016. Because the Securities and Exchange Commission

(“SEC”) Final Rule requires reporting for items introduced into the stream of commerce only during the reporting calendar year, we determined a setback interval for supplier parts receipts. More specifically, a certain minimum time

interval is required from receipt of supplier parts to their use in the assembly of an end item, internal testing of that end item, and customer acceptance tests or inspections of the end item prior to its shipment. While those assembly and test

durations vary with the complexity of the end item and customer requirements, Woodward is using 2 months to reflect a typical duration and is basing this standard setback interval from its more than 140 years of business experience. Therefore,

November 1, 2015 through October 31, 2016 defines the interval for receipt of new supplier parts that can be incorporated into Woodward’s calendar year 2016 shipments. We also include suppliers of our existing inventory at the start

of the calendar year.

Woodward generated its supplier inquiry list for CY 2016 in November 2015, to completely identify the suppliers with spend during

the interval defined above, which resulted in 2,070 relevant supplier records. We improved our prior contact success rate by using the contact data 2015 supplier campaign responses for those 2016 suppliers that were also part of our 2015 campaign.

Woodward Conflict Minerals Data Requests and Supplier Responses

Woodward initiated its 2016 campaign via ACP with these 2,070 suppliers on March 10, 2017, requesting both Conflict Minerals Reporting Templates

(“CMRTs”) and updated contact data for both their Conflict Minerals point of contact (“POC”) and their overall materials compliance POC. We are using the suppliers’ CMRTs to identify if they had a parent company, their

parent company contact data if applicable, and whether their conflict minerals reporting was from a corporate or business group level. This is to further improve our inquiry approach in future reporting years.

Follow-up

inquiries were sent to current

non-respondents

via ACP on March 20 and April 3, and directly from our assigned Assent Compliance Specialist on

April 10 and April 24.

Follow-up

with suppliers submitting incomplete or incorrect CMRTs also started April 10. As of April 30, 2017, Woodward had received CMRTs from 1,273 out of 2,036 suppliers

(62.5%), of which 1,195 (58.7% of the total number of suppliers) were valid (valid indicates Excel file CMRT with no

checker-tab-indicated

errors). We reduced the total

supplier count by confirming the

out-of-scope

assertions of 34 suppliers.

Supplier Response Assessment

The ACP and Assent’s

services team provided an extensive and comprehensive supplier CMRT assessment and validation for Woodward supplier responses using a due diligence process conforming to the

5-step

due diligence process

specified in the OECD Guidelines, and as discussed in Exhibit 1.01 to this form SD. Assent validated the SOR input provided in supplier CMRTs using an extensive database consisting of the CFSI, Responsible Jewelry Network, and London Bullion Market

Association validated SOR lists, and the results of Assent internal independent SOR validation efforts. The CMRTs that passed the assessment process were automatically combined by ACP into a Woodward company level CMRT. Those CMRTs that did not pass

were returned to the supplier with discrepancies identified and a corrective action request. Woodward, using its CFSI membership and access to the CFSI SOR audit records and country of origin data, completed its RCOI down to the mine of origin level

to the degree of accuracy and discrimination available in the CFSI database.

Based on a reasonable country of origin inquiry, Woodward has found that

some of its suppliers use smelters whose wolframite, columbite-tantalite, and cassiterite ores were acquired from mines in the Covered Countries. These ores are the sources of tungsten, tantalum and tin, respectively. All smelters so identified have

passed the CFSI conflict-free audit protocols. Therefore Woodward will further expand its due diligence process to determine the source and chain of custody of the conflict minerals specific to its procured parts and materials. As a result of our

due diligence process and findings to date, the Company has decided to file a Conflicts Minerals Report, a copy of which is filed as Exhibit 1.01 to this Form SD. Our Conflict Minerals Report is also publicly available as a document link at

http://www.woodward.com/SocialResponsibility.aspx

. The content on any web site referred to in this Form SD is not incorporated by reference into this Form SD unless expressly noted.

RCOI IMPROVEMENT ACTIONS CONTINUING OR PLANNED

Woodward has begun implementation, or intends to begin implementation in 2017 or 2018, of the following improvement actions:

|

|

•

|

|

We implemented and began using our selected product material compliance application platform to automate our RCOI efforts

|

|

|

•

|

|

We intend to continue researching the extensive use of tin as a component in a wide variety of

non-obvious

materials, to further assess if such materials are contained within

Woodward products, and using this information to facilitate and/or validate the correctness of supplier sourcing information

|

|

|

•

|

|

We will continue assessing and determining any infrastructure updates and process modifications required to support initial part level CMRT requests. Our goal is to provide each supplier a complete list of those parts

Woodward purchased from them in a specified November through

October 12-month

interval, so as to eliminate any ambiguity in the request / response process

|

|

|

•

|

|

We plan to commence part level CMRT requests to our suppliers for our 2017 reporting year

|

|

|

•

|

|

We will strive to continue to improve our supplier response rates

|

4

Item 1.02 Exhibit

The Conflict Minerals Report required by Item 1.01 is filed as Exhibit 1.01 to this Form SD.

5

Section 2 – Exhibits

Item 2.01 Exhibits

The following exhibit is filed as

part of this Form SD.

Exhibit 1.01 – Conflict Minerals Report of Woodward, Inc., for the year ended December 31, 2016.

6

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly

authorized undersigned.

|

|

|

Woodward, Inc.

|

|

(Registrant)

|

|

|

|

|

|

|

|

|

|

|

|

/s/ A. Christopher Fawzy

|

|

|

|

|

|

May 24, 2017

|

|

By:

|

|

A. Christopher Fawzy

Corporate Vice President,

General Counsel,

Corporate Secretary and Chief Compliance Officer

|

|

|

|

|

|

(Date)

|

7

EXHIBIT INDEX

|

|

|

|

|

Exhibit

No.

|

|

Description

|

|

|

|

|

1.01

|

|

Conflict Minerals Report of Woodward, Inc., for the year ended December 31, 2016.

|

8

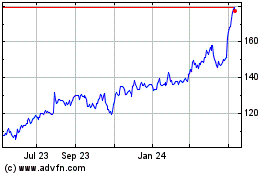

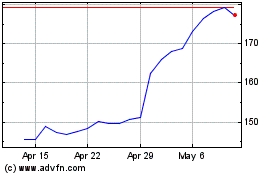

Woodward (NASDAQ:WWD)

Historical Stock Chart

From Mar 2024 to Apr 2024

Woodward (NASDAQ:WWD)

Historical Stock Chart

From Apr 2023 to Apr 2024