UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE

REPORT

DEERE & COMPANY

(Exact name of the registrant as specified in its charter)

|

Delaware |

|

1-4121 |

|

36-2382580 |

|

|

|

|

|

|

|

(State of incorporation) |

|

(Commission File Number) |

|

(IRS Employer Identification No.) |

|

One John Deere Place, Moline, Illinois |

|

61265 |

|

|

|

|

|

(Address of principal executive offices) |

|

(Zip code) |

Todd E. Davies

Corporate Secretary

(309) 765-8000

(Name and telephone number, including area code, of the

person to contact in connection with this report.)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

X Rule l3p-l under the Securities Exchange Act (l7 CFR 240.l3p-l) for the reporting period from January l to December 3l, 2014.

Section 1 – Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

Deere & Company (Company) and its subsidiaries (collectively, John Deere) manufacture and distribute agriculture and turf and construction and forestry equipment and parts. For the period from January 1 to December 31, 2014 (Reporting Period), certain components and parts of John Deere’s products contained columbite-tantalite (coltan) (or its derivative tantalum), gold, wolframite (or its derivative tungsten) and/or cassiterite (or its derivative tin) (collectively, conflict minerals) necessary to the production or functionality of such equipment. The Company has conducted in good faith a reasonable country of origin inquiry that is reasonably designed to determine whether any of the conflict minerals originated in the Democratic Republic of the Congo or an adjoining country (Covered Countries) or are from recycled or scrap sources.

The Company’s Conflict Minerals Report for the Reporting Period is filed as Exhibit 1.01 hereto and can be found on its website at http://www.JohnDeere.com/secfilings.

Item 1.02 Exhibit

The Company has filed, as Exhibit 1.01 to this Specialized Disclosure Report on Form SD, a Conflict Minerals Report.

Section 2 – Exhibits

Item 2.01 Exhibits

List below the following exhibit filed as part of this report.

Exhibit 1.01 Conflict Minerals Report as required by Item 1.01 and 1.02 of this Form.

1

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of l934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

|

|

DEERE & COMPANY |

|

|

|

|

|

|

|

|

By: |

/s/ Jean H. Gilles |

|

|

|

|

Jean H. Gilles |

|

|

|

Senior Vice President, John Deere Power

Systems, Worldwide Parts Services,

Advanced Technology & Engineering, and

Global Supply Management & Logistics |

|

|

|

|

|

|

|

|

|

Dated: May 29, 2015 |

|

|

2

Exhibit 1.01

CONFLICT MINERALS REPORT

May 29, 2015

Introduction

This Conflict Minerals Report is presented to comply with Securities and Exchange Commission Rule 13p-1 under the Securities Exchange Act of 1934 (“SEC Rule”). Deere & Company (“Company”) and its subsidiaries (collectively, “John Deere”) manufacture and distribute agriculture and turf and construction and forestry equipment and parts. For the period from January 1 to December 31, 2014 (“Reporting Period”), certain components and parts of John Deere’s equipment products contained columbite-tantalite (coltan) (or its derivative tantalum), gold, wolframite (or its derivative tungsten) and/or cassiterite (or its derivative tin) (collectively, “conflict minerals”) necessary to the production or functionality of such equipment. As part of its due diligence, the Company has adopted a policy (“Conflict Minerals Policy”) providing a common set of principles for the sourcing of conflict minerals. In accordance with the SEC Rule, the Company implemented a process to determine whether any conflict minerals necessary to the production or functionality of its products originated in the Democratic Republic of the Congo or an adjoining country (“Covered Countries”) or do not come from recycled or scrap sources (the “Reasonable Country of Origin Inquiry”). Based on the Reasonable Country of Origin Inquiry, the Company believes that certain of the conflict minerals necessary to the production or functionality of its equipment manufactured in the Reporting Period may have originated in the Covered Countries and may not be from recycled or scrap sources (the “Covered Minerals”).

The Company’s due diligence procedures conform, in all material respects, with the framework in the Organisation for Economic Co-operation and Development (“OECD”) Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (“OECD Guidelines”) and the related supplements for gold and for tin, tantalum and tungsten. In accordance with the SEC Rule and the OECD Guidelines, this Conflict Minerals Report is available on the Company’s website at www.JohnDeere.com/secfilings. The Company’s Conflict Minerals Policy is available on its website at www.JohnDeere.com/corpgov.

Part I of this report describes the due diligence procedures performed by the Company on the source and chain of custody of In-Scope Components (as defined below) and the steps the Company has taken since December 31, 2014 or will take to improve its due diligence process. Part II of this report describes the Company’s products that contain In-Scope Components, the facilities used to process the Covered Minerals in those In-Scope Components if known to the Company, the country of origin of the Covered Minerals in those In-Scope Components if known to the Company and the efforts to determine the mine or location of origin with the greatest possible specificity.

1

Part I Due Diligence Procedures

Certain components and parts of John Deere’s equipment manufactured during the Reporting Period contain conflict minerals necessary to the production or functionality of such equipment (“In-Scope Components”). The Company’s due diligence procedures are implemented and maintained throughout its supply chain. In accordance with the Company’s Conflict Minerals Policy, the SEC Rule and the OECD Guidelines, the Company has established a due diligence process with the following key components: (1) internal supply management systems and controls; (2) identification and assessment of conflict minerals risk in the supply chain; (3) strategies to address identified risks within the supply chain; and (4) independent audit procedures as required by the SEC Rule. The Company performs due diligence procedures described below on its In-Scope Components.

a. Internal Supply Management Systems and Controls

The Company’s Conflict Minerals Policy establishes the principles with regard to the responsible sourcing of conflict minerals against which the Company can assess itself and its suppliers. In order to enforce the Conflict Minerals Policy, the Company has put in place internal supply management systems and controls. The Company’s management structure consists of three levels of oversight. In accordance with the OECD Guidelines, at the top of the management structure is an executive sponsor. The executive sponsor is a member of the Company’s senior management team. The second level of management is a steering committee comprised of executive-level officers from supply management, environmental, energy and product sustainability, electronic solutions, internal audit and legal. This committee provided guidance and oversight to the third level of the management system for conflict minerals. The committee received periodic updates on the design and implementation of the due diligence procedures conducted for the Reporting Period. The third level of the management system is a team of subject matter experts (“CM Team”) from relevant functions within the Company, including supply management, environmental, quality, information technology, internal audit and legal. The CM Team was responsible for designing and implementing the Company’s due diligence procedures. In accordance with the Company’s Conflict Minerals Policy and the OECD Guidelines, the Company will maintain, and will require In-Scope Suppliers (as defined below) to maintain, conflict minerals records for five years.

b. Identification and Assessment of Conflict Mineral Risk in the Supply Chain

Due to the size and complexity of John Deere’s global supply chain as well as its considerable number of suppliers, products, parts and components, a process was developed to assess and remove parts not containing conflict minerals from the inquiry. The Reasonable Country of Origin Inquiry pertained only to suppliers with In-Scope Components (“In-Scope Suppliers”) introduced into John Deere’s supply chain during the Reporting Period. Any part, component or product that did not contain conflict minerals was excluded from further inquiry.

The risk that In-Scope Components are present in the Company’s electronics parts was considered higher than the risk that the In-Scope Components are present in the Company’s equipment or after-market parts products. As a result, the Company split the Reasonable Country of Origin Inquiry into three processes. The first process collected information on the Company’s equipment components (“Equipment Survey”). The second process collected information on the Company’s electronics components (“Electronics Survey”). For this Reporting Period, the Company added a third process to survey the In-Scope Suppliers for its after-market parts division (“All-Makes Survey” and, collectively with the Equipment Survey and

2

the Electronics Survey, the “Surveys”). In each case, the survey related only to In-Scope Suppliers of In-Scope Components during the Reporting Period.

The Equipment Survey randomly selected In-Scope Suppliers based on volume of parts provided to the Company during the Reporting Period. These suppliers were ranked based on the total volume of In-Scope Components supplied or forecasted to be supplied to the Company for the Reporting Period. The In-Scope Suppliers were then separated into groups according to volume of parts supplied to the Company: high volume, mid-volume and low volume. The In-Scope Suppliers were then randomly selected from these groups such that the survey covered 80 percent of volume from high volume suppliers, 15 percent of volume from mid-volume suppliers and 5 percent of volume from low volume suppliers. The All-Makes Survey followed a similar selection process to the Equipment Survey.

Due to the higher risk associated with electronics components, the Electronics Survey surveyed nearly all of the Company’s electronics In-Scope Suppliers. The In-Scope Suppliers were separated into groups according to volume of parts supplied to the Company: high volume, representing 99.9 percent of volume of the In-Scope Components, and low volume, representing 0.1 percent of volume of the In-Scope Components. The In-Scope Suppliers were randomly selected such that the Electronics Survey covered 100 percent of volume from high volume suppliers and 5 percent of low volume suppliers. As a result of the Surveys, the Company surveyed approximately 75 percent of all of its volume of In-Scope Components during the Reporting Period.

c. Survey of In-Scope Suppliers

The Company collected conflict minerals data from In-Scope Suppliers for each unique part supplied to the Company during the Reporting Period. Each In-Scope Supplier surveyed was required to make part-specific declarations to the Company. The Equipment Survey used the standard industry reporting template, the Conflict Minerals Reporting Template (“CMRT”), published by the Conflict-Free Sourcing Initiative (“CFSI”), to review conflict minerals risk within the supply chain and identify smelters of origin. The Company also developed proprietary software to conduct the Equipment Survey. The system enabled the Company to communicate with In-Scope Suppliers, to make an initial risk assessment and to assist In-Scope Suppliers in completing the CMRT accurately.

The Electronics Survey was conducted with the assistance of a third party survey protocol. The Electronics Survey also utilized the CMRT, although the third party was contracted to procure the responses. In all cases, In-Scope Suppliers were asked to complete the survey within five weeks after receipt of the request. Additionally, In-Scope Suppliers were required automatically to update their responses with a new CMRT should an In-Scope Component that is the subject of an CMRT change during the Reporting Period. In accordance with the OECD Guidelines, the Company relies on third party audits by the Conflict Free Smelter Program (“CFS”) to validate the conflict free status of mineral smelters. The Company relies on the list of third party verified CFS smelters to determine the conflict status of the smelters identified in the supplier CMRT responses.

The Equipment Survey received complete CMRTs from approximately 90 percent of the In-Scope Suppliers surveyed, representing approximately 96 percent of the volume of the In-Scope Components of those suppliers. The All-Makes Survey received complete CMRTs from approximately 83 percent of the In-Scope Suppliers surveyed, representing approximately 88 percent of the volume of the In-Scope Components of those suppliers. The Electronics Survey received complete CMRTs from approximately

3

91 percent of the In-Scope Suppliers surveyed, representing approximately 91 percent of the volume of the In-Scope Components of those suppliers. On a combined basis, the Company received complete CMRTs from approximately 90 percent of its In-Scope Suppliers surveyed, representing approximately 95 percent of the volume of the Company’s In-Scope Components of those suppliers. The supplier response rate for the Reporting Period is approximately a 13 point improvement over last year’s rate and approximately a 11 point improvement over last year in terms of volume of In-Scope Components.

The CM Team evaluated the CMRTs and assessed a risk level for each In-Scope Supplier response. The risk evaluation was based on the risks outlined in the OECD Guidelines. Based on the risk evaluation, the CM Team determined whether further due diligence was required on any In-Scope Supplier. The CM Team contacted certain In-Scope Suppliers to verify the information provided on the CMRT. The results from the Surveys were combined after completing the due diligence procedures. The supplier survey data on the Company’s In-Scope Components was consolidated at a product level to identify the conflict minerals status for the Company’s products pursuant to the SEC Rule.

d. Strategies to Address Identified Risks within the Supply Chain

In preparation for the due diligence performed for the Reporting Period, the Company improved the processes implemented last year. The Company expanded the scope of its due diligence procedures by adding the All-Makes Survey. The Company refined its data collection process to improve the response rate to the Surveys. During the Reporting Period, the Company joined the CFSI to support its effort to certify smelters as conflict-free. The Company intends to continue its due diligence efforts on its conflict minerals supply chain. The Company’s due diligence procedures will continue to develop by engaging In-Scope Suppliers to improve transparency throughout the supply chain. In accordance with the Company’s Conflict Minerals Policy, the Company will continue incorporating conflict minerals obligations into our supplier contracts. The Company’s due diligence procedures will also continue to enforce its Conflict Minerals Policy and its Supplier Code of Conduct.

Part II Product Description

a. Products Containing In-Scope Components

The Company’s equipment operations are categorized into two major business segments. The agriculture and turf segment primarily manufactures and distributes a full line of agriculture and turf equipment and related service parts — including large, medium and utility tractors; loaders; combines, corn pickers, cotton and sugarcane harvesters and related front-end equipment and sugarcane loaders; tillage, seeding and application equipment, including sprayers, nutrient management and soil preparation machinery; hay and forage equipment, including self-propelled forage harvesters and attachments, balers and mowers; turf and utility equipment, including riding lawn equipment and walk-behind mowers, golf course equipment, utility vehicles, and commercial mowing equipment, along with a broad line of associated implements; integrated agricultural management systems technology and solutions; and other outdoor power products. The construction and forestry segment primarily manufactures and distributes a broad range of machines and service parts used in construction, earthmoving, material handling and timber harvesting — including backhoe loaders; crawler dozers and loaders; four-wheel-drive loaders; excavators; motor graders; articulated dump trucks; landscape loaders; skid-steer loaders; and log skidders, feller bunchers, log loaders, log forwarders, log harvesters and related attachments.

4

As a result of the due diligence procedures described in Part I above, the Company believes that the equipment products described above contain In-Scope Components.

b. Facilities Known to Process the Covered Minerals

Attached hereto as Schedule A is a list of the facilities that, based on the due diligence process described above, are known to the Company and that the Company believes processed the Covered Minerals in the Company’s products during the Reporting Period. During the due diligence process described above, the In-Scope Suppliers identified many entities that the Company could not validate as smelters or refiners and therefore are not listed in Schedule A. A significant number of smelters that may or may not have processed the Covered Minerals in the Company’s products have not participated in the CFS and, therefore, have not yet established their conflict status.

c. Country of Origin of the Covered Minerals

As a result of the due diligence procedures described in Part I above, the Company does not have sufficient information to determine conclusively the countries of origin of all Covered Minerals. The country of origin of the smelters listed on Schedule A is set forth next to each smelter name.

d. Efforts to Determine the Mine or Location of Origin

As discussed above in Part I, the Company relies on third parties to validate the conflict status of smelter sources. The Company’s due diligence procedures are designed to identify risks within the supply chain. At present, the Company’s In-Scope Suppliers have not identified mines or location of origin.

5

Schedule A

Facilities Known to process Covered Minerals during the Reporting Period

|

Mineral |

|

Smelter Name |

|

Smelter

Country |

|

Gold (Au) |

|

Aida Chemical Industries Co. Ltd. |

|

JPN |

|

Gold (Au) |

|

Allgemeine Gold-und Silberscheideanstalt A.G. |

|

DEU |

|

Gold (Au) |

|

Almalyk Mining and Metallurgical Complex (AMMC) |

|

UZB |

|

Gold (Au) |

|

AngloGold Ashanti Córrego do Sítio Minerção |

|

BRA |

|

Gold (Au) |

|

Argor-Heraeus SA |

|

CHE |

|

Gold (Au) |

|

Asahi Pretec Corporation |

|

JPN |

|

Gold (Au) |

|

Asaka Riken Co Ltd |

|

JPN |

|

Gold (Au) |

|

Atasay Kuyumculuk Sanayi Ve Ticaret A.S. |

|

TUR |

|

Gold (Au) |

|

Aurubis AG |

|

DEU |

|

Gold (Au) |

|

Bangko Sentral ng Pilipinas (Central Bank of the Philippines) |

|

PHL |

|

Gold (Au) |

|

Bauer Walser AG |

|

DEU |

|

Gold (Au) |

|

Boliden AB |

|

SWE |

|

Gold (Au) |

|

C. Hafner GmbH + Co. KG |

|

DEU |

|

Gold (Au) |

|

Caridad |

|

MEX |

|

Gold (Au) |

|

CCR Refinery – Glencore Canada Corporation |

|

CAN |

|

Gold (Au) |

|

Cendres & Métaux SA |

|

CHE |

|

Gold (Au) |

|

Yunnan Copper Industry Co Ltd |

|

CHN |

|

Gold (Au) |

|

Chimet S.p.A. |

|

ITA |

|

Gold (Au) |

|

China National Gold Group Corporation |

|

CHN |

|

Gold (Au) |

|

Chugai Mining |

|

JPN |

|

Gold (Au) |

|

Colt Refining |

|

USA |

|

Gold (Au) |

|

Daejin Indus Co. Ltd |

|

KOR |

|

Gold (Au) |

|

DaeryongENC |

|

KOR |

|

Gold (Au) |

|

Daye Non-Ferrous Metals Mining Ltd. |

|

CHN |

1

|

Gold (Au) |

|

Do Sung Corporation |

|

KOR |

|

Gold (Au) |

|

Doduco |

|

DEU |

|

Gold (Au) |

|

Dowa |

|

JPN |

|

Gold (Au) |

|

Eco-System Recycling Co., Ltd. |

|

JPN |

|

Gold (Au) |

|

FSE Novosibirsk Refinery |

|

RUS |

|

Gold (Au) |

|

Gansu Seemine Material Hi-Tech Co Ltd |

|

CHN |

|

Gold (Au) |

|

Hangzhou Fuchunjiang Smelting Co., Ltd. |

|

CHN |

|

Gold (Au) |

|

Heimerle + Meule GmbH |

|

DEU |

|

Gold (Au) |

|

Heraeus Ltd. Hong Kong |

|

HKG |

|

Gold (Au) |

|

Heraeus Precious Metals GmbH & Co. KG |

|

DEU |

|

Gold (Au) |

|

Hunan Chenzhou Mining Industry Group |

|

CHN |

|

Gold (Au) |

|

Hwasung CJ Co. Ltd |

|

KOR |

|

Gold (Au) |

|

Inner Mongolia Qiankun Gold and Silver Refinery Share Company Limited |

|

CHN |

|

Gold (Au) |

|

Ishifuku Metal Industry Co., Ltd. |

|

JPN |

|

Gold (Au) |

|

Istanbul Gold Refinery |

|

TUR |

|

Gold (Au) |

|

Japan Mint |

|

JPN |

|

Gold (Au) |

|

Jiangxi Copper Company Limited |

|

CHN |

|

Gold (Au) |

|

Johnson Matthey Inc |

|

USA |

|

Gold (Au) |

|

Johnson Matthey Ltd |

|

CAN |

|

Gold (Au) |

|

JSC Ekaterinburg Non-Ferrous Metal Processing Plant |

|

RUS |

|

Gold (Au) |

|

JSC Uralectromed |

|

RUS |

|

Gold (Au) |

|

JX Nippon Mining & Metals Co., Ltd. |

|

JPN |

|

Gold (Au) |

|

Kazzinc Ltd |

|

KAZ |

|

Gold (Au) |

|

Kennecott Utah Copper LLC |

|

USA |

|

Gold (Au) |

|

Kojima Chemicals Co., Ltd |

|

JPN |

|

Gold (Au) |

|

Korea Metal Co. Ltd |

|

KOR |

|

Gold (Au) |

|

Kyrgyzaltyn JSC |

|

KGZ |

|

Gold (Au) |

|

L’ azurde Company For Jewelry |

|

SAU |

|

Gold (Au) |

|

Lingbao Jinyuan Tonghui Refinery Co. Ltd. |

|

CHN |

2

|

Gold (Au) |

|

LS-NIKKO Copper Inc. |

|

KOR |

|

Gold (Au) |

|

Luoyang Zijin Yinhui Metal Smelt Co Ltd |

|

CHN |

|

Gold (Au) |

|

Materion |

|

USA |

|

Gold (Au) |

|

Matsuda Sangyo Co., Ltd. |

|

JPN |

|

Gold (Au) |

|

Metalor Technologies (Hong Kong) Ltd |

|

HKG |

|

Gold (Au) |

|

Metalor Technologies (Singapore) Pte. Ltd. |

|

SGP |

|

Gold (Au) |

|

Metalor Technologies SA |

|

CHE |

|

Gold (Au) |

|

Metalor USA Refining Corporation |

|

USA |

|

Gold (Au) |

|

Met-Mex Peñoles, S.A. |

|

MEX |

|

Gold (Au) |

|

Mitsubishi Materials Corporation |

|

JPN |

|

Gold (Au) |

|

Mitsui Mining and Smelting Co., Ltd. |

|

JPN |

|

Gold (Au) |

|

Moscow Special Alloys Processing Plant |

|

RUS |

|

Gold (Au) |

|

Nadir Metal Rafineri San. Ve Tic. A.Ş. |

|

TUR |

|

Gold (Au) |

|

Navoi Mining and Metallurgical Combinat |

|

UZB |

|

Gold (Au) |

|

Nihon Material Co. LTD |

|

JPN |

|

Gold (Au) |

|

Ohio Precious Metals, LLC |

|

USA |

|

Gold (Au) |

|

Ohura Precious Metal Industry Co., Ltd |

|

JPN |

|

Gold (Au) |

|

OJSC “The Gulidov Krasnoyarsk Non-Ferrous Metals Plant” (OJSC Krastvetmet) |

|

RUS |

|

Gold (Au) |

|

OJSC Kolyma Refinery |

|

RUS |

|

Gold (Au) |

|

PAMP SA |

|

CHE |

|

Gold (Au) |

|

Penglai Penggang Gold Industry Co Ltd |

|

CHN |

|

Gold (Au) |

|

Prioksky Plant of Non-Ferrous Metals |

|

RUS |

|

Gold (Au) |

|

PT Aneka Tambang (Persero) Tbk |

|

IDN |

|

Gold (Au) |

|

PX Précinox SA |

|

CHE |

|

Gold (Au) |

|

Rand Refinery (Pty) Ltd |

|

ZAF |

|

Gold (Au) |

|

Royal Canadian Mint |

|

CAN |

|

Gold (Au) |

|

Sabin Metal Corp. |

|

USA |

|

Gold (Au) |

|

SAMWON METALS Corp. |

|

KOR |

|

Gold (Au) |

|

Schone Edelmetaal |

|

NLD |

3

|

Gold (Au) |

|

SEMPSA Joyería Platería SA |

|

ESP |

|

Gold (Au) |

|

Shandong Zhaojin Gold & Silver Refinery Co. Ltd |

|

CHN |

|

Gold (Au) |

|

So Accurate Group, Inc. |

|

USA |

|

Gold (Au) |

|

SOE Shyolkovsky Factory of Secondary Precious Metals |

|

RUS |

|

Gold (Au) |

|

Solar Applied Materials Technology Corp. |

|

TWN |

|

Gold (Au) |

|

Sumitomo Metal Mining Co., Ltd. |

|

JPN |

|

Gold (Au) |

|

Tanaka Kikinzoku Kogyo K.K. |

|

JPN |

|

Gold (Au) |

|

The Great Wall Gold and Silver Refinery of China |

|

CHN |

|

Gold (Au) |

|

The Refinery of Shandong Gold Mining Co. Ltd |

|

CHN |

|

Gold (Au) |

|

Tokuriki Honten Co., Ltd |

|

JPN |

|

Gold (Au) |

|

Tongling nonferrous Metals Group Co.,Ltd |

|

CHN |

|

Gold (Au) |

|

Torecom |

|

KOR |

|

Gold (Au) |

|

Umicore Brasil Ltda |

|

BRA |

|

Gold (Au) |

|

Umicore SA Business Unit Precious Metals Refining |

|

BEL |

|

Gold (Au) |

|

United Precious Metal Refining, Inc. |

|

USA |

|

Gold (Au) |

|

Valcambi SA |

|

CHE |

|

Gold (Au) |

|

Western Australian Mint trading as The Perth Mint |

|

AUS |

|

Gold (Au) |

|

YAMAMOTO PRECIOUS METAL CO., LTD. |

|

JPN |

|

Gold (Au) |

|

Yokohama Metal Co Ltd |

|

JPN |

|

Gold (Au) |

|

Zhongyuan Gold Smelter of Zhongjin Gold Corporation |

|

CHN |

|

Gold (Au) |

|

Zijin Mining Group Co. Ltd |

|

CHN |

|

Gold (Au) |

|

Guangdong Jinding Gold Limited |

|

CHN |

|

Gold (Au) |

|

Umicore Precious Metals Thailand |

|

THA |

|

Gold (Au) |

|

Lingbao Gold Company Limited |

|

CHN |

|

Gold (Au) |

|

Samduck Precious Metals |

|

KOR |

|

Gold (Au) |

|

Advanced Chemical Company |

|

USA |

4

|

Tantalum (Ta) |

|

Conghua Tantalum and Niobium Smeltry |

|

CHN |

|

Tantalum (Ta) |

|

Duoluoshan |

|

CHN |

|

Tantalum (Ta) |

|

Exotech Inc. |

|

USA |

|

Tantalum (Ta) |

|

JiuJiang JinXin Nonferrous Metals Co., Ltd. |

|

CHN |

|

Tantalum (Ta) |

|

Jiujiang Tanbre Co., Ltd. |

|

CHN |

|

Tantalum (Ta) |

|

Ningxia Orient Tantalum Industry Co., Ltd. |

|

CHN |

|

Tantalum (Ta) |

|

Ulba |

|

KAZ |

|

Tantalum (Ta) |

|

Zhuzhou Cement Carbide |

|

CHN |

|

Tantalum (Ta) |

|

Changsha South Tantalum Niobium Co., Ltd. |

|

CHN |

|

Tantalum (Ta) |

|

F&X Electro-Materials Ltd. |

|

CHN |

|

Tantalum (Ta) |

|

Global Advanced Metals |

|

USA |

|

Tantalum (Ta) |

|

Guangdong Zhiyuan New Material Co., Ltd. |

|

CHN |

|

Tantalum (Ta) |

|

H.C. Starck Group |

|

DEU |

|

Tantalum (Ta) |

|

Hi-Temp |

|

USA |

|

Tantalum (Ta) |

|

Kemet Blue Powder |

|

USA |

|

Tantalum (Ta) |

|

King-Tan Tantalum Industry Ltd |

|

CHN |

|

Tantalum (Ta) |

|

LSM Brasil S.A. |

|

BRA |

|

Tantalum (Ta) |

|

Metallurgical Products India (Pvt.) Ltd. |

|

IND |

|

Tantalum (Ta) |

|

Mineração Taboca S.A. |

|

BRA |

|

Tantalum (Ta) |

|

Mitsui Mining & Smelting |

|

JPN |

|

Tantalum (Ta) |

|

Molycorp Silmet A.S. |

|

EST |

|

Tantalum (Ta) |

|

Plansee |

|

AUT |

|

Tantalum (Ta) |

|

QuantumClean |

|

USA |

|

Tantalum (Ta) |

|

RFH Tantalum Smeltry Co., Ltd |

|

CHN |

|

Tantalum (Ta) |

|

Shanghai Jiangxi Metals Co. Ltd |

|

CHN |

|

Tantalum (Ta) |

|

Solikamsk Metal Works |

|

RUS |

5

|

Tantalum (Ta) |

|

Taki Chemicals |

|

JPN |

|

Tantalum (Ta) |

|

Tantalite Resources |

|

ZAF |

|

Tantalum (Ta) |

|

Telex |

|

USA |

|

Tantalum (Ta) |

|

Yichun Jin Yang Rare Metal Co., Ltd |

|

CHN |

|

Tantalum (Ta) |

|

Hengyang King Xing Lifeng New Materials Co., Ltd. |

|

CHN |

|

Tantalum (Ta) |

|

KEMET Blue Metals |

|

MEX |

|

Tantalum (Ta) |

|

H.C. Starck Co., Ltd. |

|

THA |

|

Tantalum (Ta) |

|

H.C. Starck Inc. |

|

USA |

|

Tantalum (Ta) |

|

H.C. Starck Ltd. |

|

JPN |

|

Tantalum (Ta) |

|

H.C. Starck GmbH Goslar |

|

DEU |

|

Tantalum (Ta) |

|

H.C. Starck GmbH Laufenburg |

|

DEU |

|

Tantalum (Ta) |

|

Global Advanced Metals Boyertown |

|

USA |

|

Tantalum (Ta) |

|

Plansee SE Liezen |

|

AUT |

|

Tantalum (Ta) |

|

H.C. Starck Hermsdorf GmbH |

|

DEU |

|

Tantalum (Ta) |

|

H.C. Starck Smelting GmbH & Co.KG |

|

DEU |

|

Tantalum (Ta) |

|

Global Advanced Metals Aizu |

|

JPN |

|

Tantalum (Ta) |

|

Plansee SE Reutte |

|

AUT |

|

Tin (Sn) |

|

Malaysia Smelting Corporation (MSC) |

|

MYS |

|

Tin (Sn) |

|

Thaisarco |

|

THA |

|

Tin (Sn) |

|

China Rare Metal Materials Company |

|

CHN |

|

Tin (Sn) |

|

CNMC (Guangxi) PGMA Co. Ltd. |

|

CHN |

|

Tin (Sn) |

|

Alpha |

|

USA |

|

Tin (Sn) |

|

Cooper Santa |

|

BRA |

|

Tin (Sn) |

|

CV Serumpun Sebalai |

|

IDN |

|

Tin (Sn) |

|

CV United Smelting |

|

IDN |

|

Tin (Sn) |

|

EM Vinto |

|

BOL |

|

Tin (Sn) |

|

Estanho de Rondônia S.A. |

|

BRA |

|

Tin (Sn) |

|

Fenix Metals |

|

POL |

|

Tin (Sn) |

|

Gejiu Non-Ferrous Metal Processing Co. Ltd. |

|

CHN |

|

Tin (Sn) |

|

Gejiu Zi-Li |

|

CHN |

6

|

Tin (Sn) |

|

Huichang Jinshunda Tin Co. Ltd |

|

CHN |

|

Tin (Sn) |

|

Jiangxi Nanshan |

|

CHN |

|

Tin (Sn) |

|

Kai Unita Trade Limited Liability Company |

|

CHN |

|

Tin (Sn) |

|

Linwu Xianggui Smelter Co |

|

CHN |

|

Tin (Sn) |

|

China Tin Group Co., Ltd. |

|

CHN |

|

Tin (Sn) |

|

Metallo Chimique |

|

BEL |

|

Tin (Sn) |

|

Mineração Taboca S.A. |

|

BRA |

|

Tin (Sn) |

|

Minmetals Ganzhou Tin Co. Ltd. |

|

CHN |

|

Tin (Sn) |

|

Minsur |

|

PER |

|

Tin (Sn) |

|

Mitsubishi Materials Corporation |

|

JPN |

|

Tin (Sn) |

|

Novosibirsk Integrated Tin Works |

|

RUS |

|

Tin (Sn) |

|

O.M. Manufacturing (Thailand) Co., Ltd. |

|

THA |

|

Tin (Sn) |

|

OMSA |

|

BOL |

|

Tin (Sn) |

|

PT Artha Cipta Langgeng |

|

IDN |

|

Tin (Sn) |

|

PT Babel Inti Perkasa |

|

IDN |

|

Tin (Sn) |

|

PT Bangka Putra Karya |

|

IDN |

|

Tin (Sn) |

|

PT Bangka Tin Industry |

|

IDN |

|

Tin (Sn) |

|

PT Belitung Industri Sejahtera |

|

IDN |

|

Tin (Sn) |

|

PT Bukit Timah |

|

IDN |

|

Tin (Sn) |

|

PT DS Jaya Abadi |

|

IDN |

|

Tin (Sn) |

|

PT Eunindo Usaha Mandiri |

|

IDN |

|

Tin (Sn) |

|

PT Karimun Mining |

|

IDN |

|

Tin (Sn) |

|

PT Mitra Stania Prima |

|

IDN |

|

Tin (Sn) |

|

PT Prima Timah Utama |

|

IDN |

|

Tin (Sn) |

|

PT REFINED BANGKA TIN |

|

IDN |

|

Tin (Sn) |

|

PT Sariwiguna Binasentosa |

|

IDN |

|

Tin (Sn) |

|

PT Stanindo Inti Perkasa |

|

IDN |

|

Tin (Sn) |

|

PT Tambang Timah |

|

IDN |

7

|

Tin (Sn) |

|

PT Timah |

|

IDN |

|

Tin (Sn) |

|

PT Tinindo Inter Nusa |

|

IDN |

|

Tin (Sn) |

|

Rui Da Hung |

|

TWN |

|

Tin (Sn) |

|

Soft Metais, Ltda. |

|

BRA |

|

Tin (Sn) |

|

White Solder Metalurgia e Mineração Ltda. |

|

BRA |

|

Tin (Sn) |

|

Yunnan Chengfeng Non-ferrous Metals Co.,Ltd. |

|

CHN |

|

Tin (Sn) |

|

Yunnan Tin Company, Ltd. |

|

CHN |

|

Tin (Sn) |

|

Magnu’s Minerais Metais e Ligas LTDA |

|

BRA |

|

Tin (Sn) |

|

Melt Metais e Ligas S/A |

|

BRA |

|

Tin (Sn) |

|

CV Gita Pesona |

|

IDN |

|

Tin (Sn) |

|

CV JusTindo |

|

IDN |

|

Tin (Sn) |

|

CV Makmur Jaya |

|

IDN |

|

Tin (Sn) |

|

CV Nurjanah |

|

IDN |

|

Tin (Sn) |

|

Dowa |

|

JPN |

|

Tin (Sn) |

|

PT Alam Lestari Kencana |

|

IDN |

|

Tin (Sn) |

|

PT Babel Surya Alam Lestari |

|

IDN |

|

Tin (Sn) |

|

PT Bangka Kudai Tin |

|

IDN |

|

Tin (Sn) |

|

PT Bangka Timah Utama Sejahtera |

|

IDN |

|

Tin (Sn) |

|

PT BilliTin Makmur Lestari |

|

IDN |

|

Tin (Sn) |

|

PT Fang Di MulTindo |

|

IDN |

|

Tin (Sn) |

|

PT HP Metals Indonesia |

|

IDN |

|

Tin (Sn) |

|

PT Koba Tin |

|

IDN |

|

Tin (Sn) |

|

PT Panca Mega Persada |

|

IDN |

|

Tin (Sn) |

|

PT Seirama Tin investment |

|

IDN |

|

Tin (Sn) |

|

PT Sumber Jaya Indah |

|

IDN |

8

|

Tin (Sn) |

|

PT Supra Sukses Trinusa |

|

IDN |

|

Tin (Sn) |

|

PT Pelat Timah Nusantara Tbk |

|

IDN |

|

Tin (Sn) |

|

PT Tommy Utama |

|

IDN |

|

Tin (Sn) |

|

PT Yinchendo Mining Industry |

|

IDN |

|

Tin (Sn) |

|

PT ATD Makmur Mandiri Jaya |

|

IDN |

|

Tin (Sn) |

|

O.M. Manufacturing Philippines, Inc. |

|

PHL |

|

Tungsten (W) |

|

Vietnam Youngsun Tungsten Industry Co., Ltd |

|

VNM |

|

Tungsten (W) |

|

Xiamen Tungsten (H.C.) Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

A.L.M.T. Corp. |

|

JPN |

|

Tungsten (W) |

|

ATI Tungsten Materials |

|

USA |

|

Tungsten (W) |

|

Guangdong Xianglu Tungsten Industry Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Chongyi Zhangyuan Tungsten Co Ltd |

|

CHN |

|

Tungsten (W) |

|

Dayu Weiliang Tungsten Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Fujian Jinxin Tungsten Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Global Tungsten & Powders Corp. |

|

USA |

|

Tungsten (W) |

|

HC Starck GmbH |

|

DEU |

|

Tungsten (W) |

|

Hunan Chenzhou Mining Group Co |

|

CHN |

|

Tungsten (W) |

|

Hunan Chun-Chang Nonferrous Smelting & Concentrating Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Japan New Metals Co Ltd |

|

JPN |

|

Tungsten (W) |

|

Ganzhou Non-ferrous Metals Smelting Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Ganzhou Huaxing Tungsten Products Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Kennametal Fallon |

|

USA |

|

Tungsten (W) |

|

Tejing (Vietnam) Tungsten Co., Ltd. |

|

VNM |

|

Tungsten (W) |

|

Wolfram Bergbau und Hütten AG |

|

AUT |

|

Tungsten (W) |

|

Wolfram Company CJSC |

|

RUS |

|

Tungsten (W) |

|

Xiamen Tungsten Co., Ltd |

|

CHN |

|

Tungsten (W) |

|

Xinhai Rendan Shaoguan Tungsten Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Zhuzhou Cemented Carbide Group Co Ltd |

|

CHN |

|

Tungsten (W) |

|

Jiangxi Minmetals Gao’an Non-ferrous Metals Co., Ltd. |

|

CHN |

9

|

Tungsten (W) |

|

Ganzhou Jiangwu Ferrotungsten Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Jiangxi Yaosheng Tungsten Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Jiangxi Xinsheng Tungsten Industry Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Jiangxi Tonggu Non-ferrous Metallurgical & Chemical Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Malipo Haiyu Tungsten Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Jiangxi Gan Bei Tungsten Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Jiangxi Richsea New Materials Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

Ganzhou Seadragon W & Mo Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

H.C. Starck GmbH |

|

DEU |

|

Tungsten (W) |

|

Chenzhou Diamond Tungsten Products Co., Ltd. |

|

CHN |

|

Tungsten (W) |

|

H.C. Starck Smelting GmbH & Co.KG |

|

DEU |

|

Tungsten (W) |

|

Nui Phao H.C. Starck Tungsten Chemicals Manufacturing LLC |

|

VNM |

10

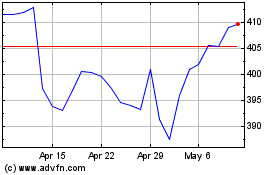

Deere (NYSE:DE)

Historical Stock Chart

From Mar 2024 to Apr 2024

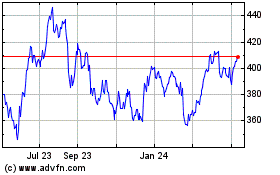

Deere (NYSE:DE)

Historical Stock Chart

From Apr 2023 to Apr 2024